How to Increase PSI on Your Air Compressor

Having a high PSI (pound per square inch) on your air compressor is essential for certain tasks that require a greater amount of pressure. Whether you are using it for painting, auto repair, or even home improvement projects, being able to increase the PSI of your air compressor can make a significant difference in the quality and effectiveness of your work.

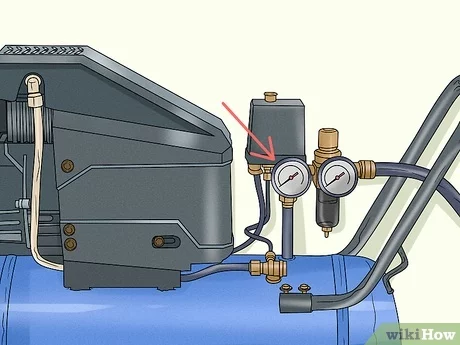

One effective way to increase the PSI on your air compressor is by adjusting the pressure regulator. The pressure regulator is a device that controls the airflow and pressure coming into your compressor. By turning the regulator clockwise, you can increase the pressure and thus increase the PSI. It is important to note, however, that you should follow the manufacturer’s guidelines and not exceed the maximum recommended PSI for your particular compressor.

Another way to increase the PSI on your air compressor is by using a smaller or shorter air hose. The length and diameter of the hose can affect the pressure and ultimately the PSI. Using a shorter and narrower hose can help increase the pressure and ensure a higher PSI. Additionally, check for any leaks or obstructions in the hose that may be causing a drop in pressure.

Lastly, it is important to regularly clean and maintain your air compressor. Over time, dust and debris can build up in the compressor’s components, causing a decrease in its efficiency and maximum PSI. By regularly cleaning and inspecting the compressor, you can ensure that it is running at its optimal performance and maintain a higher PSI.

Understanding PSI and Its Importance

What is PSI?

PSI stands for pounds per square inch, and it is a unit of pressure commonly used to measure the force exerted in an air compressor. It indicates the amount of pressure the compressor can generate when pushing air through its system. Understanding PSI is crucial for ensuring optimal performance and safety when using an air compressor.

The Importance of PSI

Having a clear understanding of PSI and its significance is essential for various reasons:

- Efficiency: PSI directly affects the efficiency of an air compressor. Operating an air compressor at the correct PSI level ensures that it delivers the necessary airflow to power pneumatic tools or perform other tasks effectively.

- Safety: Using an air compressor at the recommended PSI ensures safe operation. Exceeding the manufacturer’s recommended PSI can lead to equipment failure, damage, or even accidents. On the other hand, insufficient PSI may result in reduced performance or the inability to complete tasks effectively.

- Versatility: Different applications require different PSI levels. Understanding the PSI requirements for specific tasks allows for the versatility and adaptability of the air compressor. This knowledge enables users to adjust and optimize the PSI settings based on their needs.

- Longevity: Operating an air compressor within the recommended PSI range helps prolong its lifespan. Consistently using an air compressor at improper PSI levels can cause excessive wear and tear on the compressor’s components, leading to premature failure and the need for costly repairs or replacements.

Overall, understanding PSI and its importance ensures the efficient and safe operation of an air compressor, extends its lifespan, and allows for versatility in various applications.

Factors Affecting PSI in an Air Compressor

Air compressors are essential tools in many industries, and the psi (pounds per square inch) rating of an air compressor determines its power and performance. There are several factors that can affect the psi output of an air compressor. Understanding these factors can help you optimize the performance of your air compressor and increase its psi output.

1. Compressor Size and Design

The size and design of an air compressor play a significant role in its psi output. Generally, larger compressors have the ability to generate higher psi due to their larger tanks and more powerful motors. Additionally, the design of the compressor’s pump, valves, and pistons can also impact its psi output. Compressors with efficient and well-designed components tend to have higher psi ratings.

2. Motor Power

The power of the motor driving the air compressor has a direct impact on its psi output. The motor should be adequately sized to provide enough power to generate the desired psi level. Insufficient motor power can result in lower psi output, while a more powerful motor can increase the psi rating of the compressor.

3. Air Inlet Restrictions

The presence of air inlet restrictions can limit the amount of air intake into the compressor, thereby affecting its psi output. Some common restrictions include clogged filters, dirty intake valves, or small diameter inlet pipes. Regular maintenance and cleaning of these components can help prevent airflow restrictions and maintain the desired psi level.

4. Ambient Temperature

The ambient temperature can also impact the psi output of an air compressor. Higher temperatures can cause the air inside the compressor to expand, resulting in an increase in psi. Conversely, lower temperatures can cause the air to contract, reducing the psi output. It is important to consider the ambient temperature and make necessary adjustments to maintain the desired psi level.

5. Air Leaks

Air leaks in the compressor’s system can lead to a drop in psi output. These leaks can occur in various components such as hoses, fittings, valves, or the tank itself. Regular inspection and repair of any leaks can help maintain the desired psi level and optimize the performance of the air compressor.

By considering these factors affecting the psi in an air compressor and taking appropriate measures, you can increase the psi output and ensure optimal performance of your air compressor.

Choosing the Right Air Compressor for Higher PSI

When it comes to increasing the PSI on your air compressor, one of the first things you need to consider is the type of air compressor you have. Not all air compressors are designed to handle higher PSI settings, so it’s important to choose the right one for your needs.

1. Determine Your PSI Requirements

The first step in choosing the right air compressor for higher PSI is to determine your specific PSI requirements. Consider the tools or equipment you will be using with the air compressor and check their recommended PSI levels. This will give you an idea of the maximum PSI you will need.

2. Consider the CFM Rating

Another factor to consider is the CFM (cubic feet per minute) rating of the air compressor. CFM is a measure of how much air the compressor can deliver in a minute. If you need higher PSI, you will generally need a higher CFM rating to ensure sufficient air flow.

3. Check the Horsepower

The horsepower of the air compressor is also important as it affects the overall performance. Higher horsepower generally means the compressor can handle higher PSI and deliver more air. Take into account the horsepower needed for the tools or equipment you will be using.

4. Look at the Tank Size

The tank size of the air compressor can also impact the PSI settings. A larger tank size can help maintain a consistent PSI level by providing a reserve of compressed air. This can be particularly useful if you will be using tools that require a continuous airflow at a higher PSI.

5. Consider the Duty Cycle

The duty cycle refers to the amount of time an air compressor can run before it needs to rest and cool down. Higher PSI settings may require longer run times, so it’s important to choose an air compressor with a duty cycle that matches your needs. Be sure to check the duty cycle of the compressor before making a purchase.

By considering these factors and choosing the right air compressor for higher PSI, you can ensure that your air tools and equipment operate at their optimal levels. Remember to always follow the manufacturer’s recommendations and guidelines for safe and efficient use of your air compressor.

Regular Maintenance to Increase PSI

Air compressors are essential tools for various applications, including inflating tires, powering pneumatic tools, and operating machinery. To ensure optimal performance and increase the PSI (pounds per square inch) output of your air compressor, regular maintenance is crucial. By following these maintenance steps, you can enhance the efficiency and reliability of your compressor.

Clean the Air Filter

The air filter is responsible for removing dust, debris, and contaminants from the air before it enters the compressor. Over time, the filter can become clogged, reducing the airflow and putting strain on the compressor. To increase the PSI, regularly clean or replace the air filter according to the manufacturer’s instructions.

Inspect the Intake Valve

The intake valve controls the flow of air into the compressor. If the valve is damaged or worn out, it can result in a decrease in PSI output. Inspect the valve regularly for any signs of wear or damage, such as cracks or leaks. Replace the valve if necessary to maintain optimal PSI levels.

Check for Air Leaks

Air leaks are a common cause of decreased PSI in air compressors. Inspect all fittings, hoses, and connections for any signs of leaks. Use a soapy water solution to detect leaks – if bubbles form, there is a leak. Tighten loose fittings or replace damaged components to prevent air leakage and maintain higher PSI levels.

Oil and Lubrication

Proper lubrication is essential for the smooth operation of an air compressor. Follow the manufacturer’s guidelines for oil changes and lubrication. Regularly check the oil level and quality and replace it as needed. Proper lubrication reduces friction and improves the efficiency of the compressor, thus increasing the PSI output.

Regular Maintenance Schedule

To ensure the longevity and optimal performance of your air compressor, it is important to establish a regular maintenance schedule. This schedule should include tasks such as cleaning the filter, inspecting valves and fittings, checking for leaks, and maintaining proper lubrication. By adhering to a maintenance routine, you can maximize the PSI output and avoid costly repairs.

Remember, increasing the PSI output of your air compressor requires regular maintenance and attention to detail. By following these maintenance steps, you can enhance performance and prolong the lifespan of your compressor, ensuring that it operates at its full potential when you need it most.

Upgrading Your Air Compressor for Greater PSI

If you are looking to increase the PSI (pounds per square inch) of your air compressor, there are several upgrades and modifications you can make to achieve higher pressure levels. By improving the performance of your air compressor, you can take on more demanding tasks and achieve better results.

1. Install a larger air tank: One way to increase the PSI of your air compressor is to install a larger air tank. A larger tank can hold more compressed air, allowing for a higher pressure output. This upgrade is relatively simple and can significantly increase the PSI of your compressor.

2. Upgrade the compressor pump: Another option is to upgrade the compressor pump itself. A more powerful pump can deliver higher levels of air pressure, resulting in a greater PSI. Look for a pump that is specifically designed for higher pressures, and consider consulting with a professional to ensure compatibility with your existing setup.

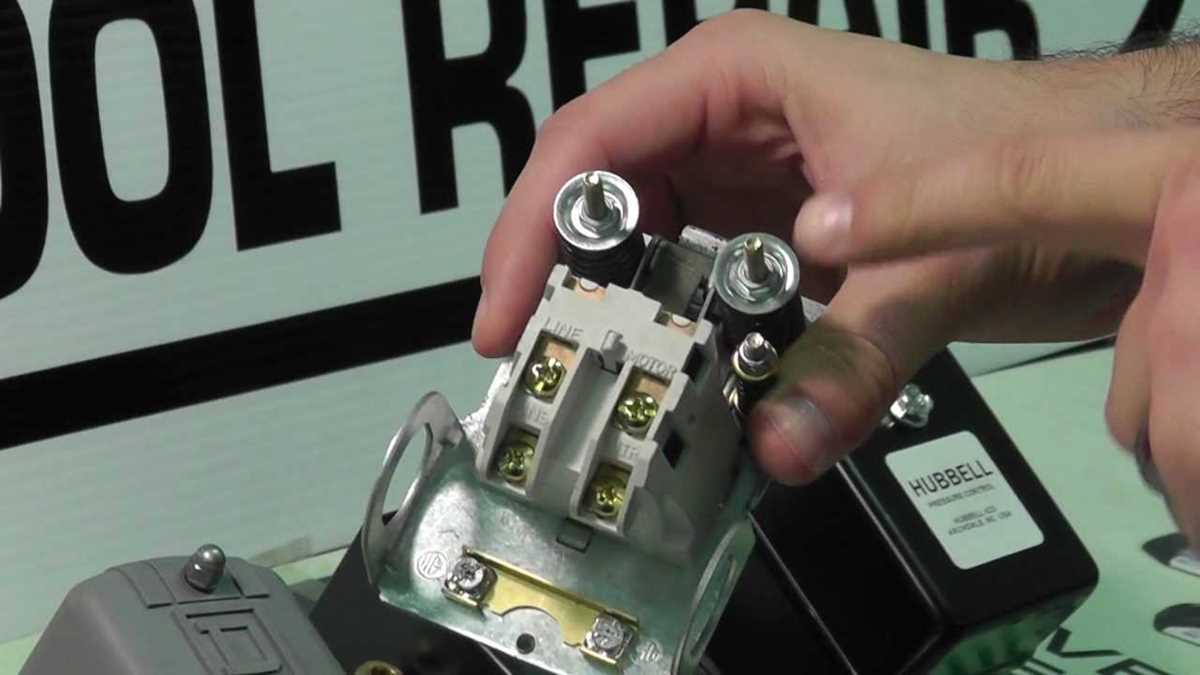

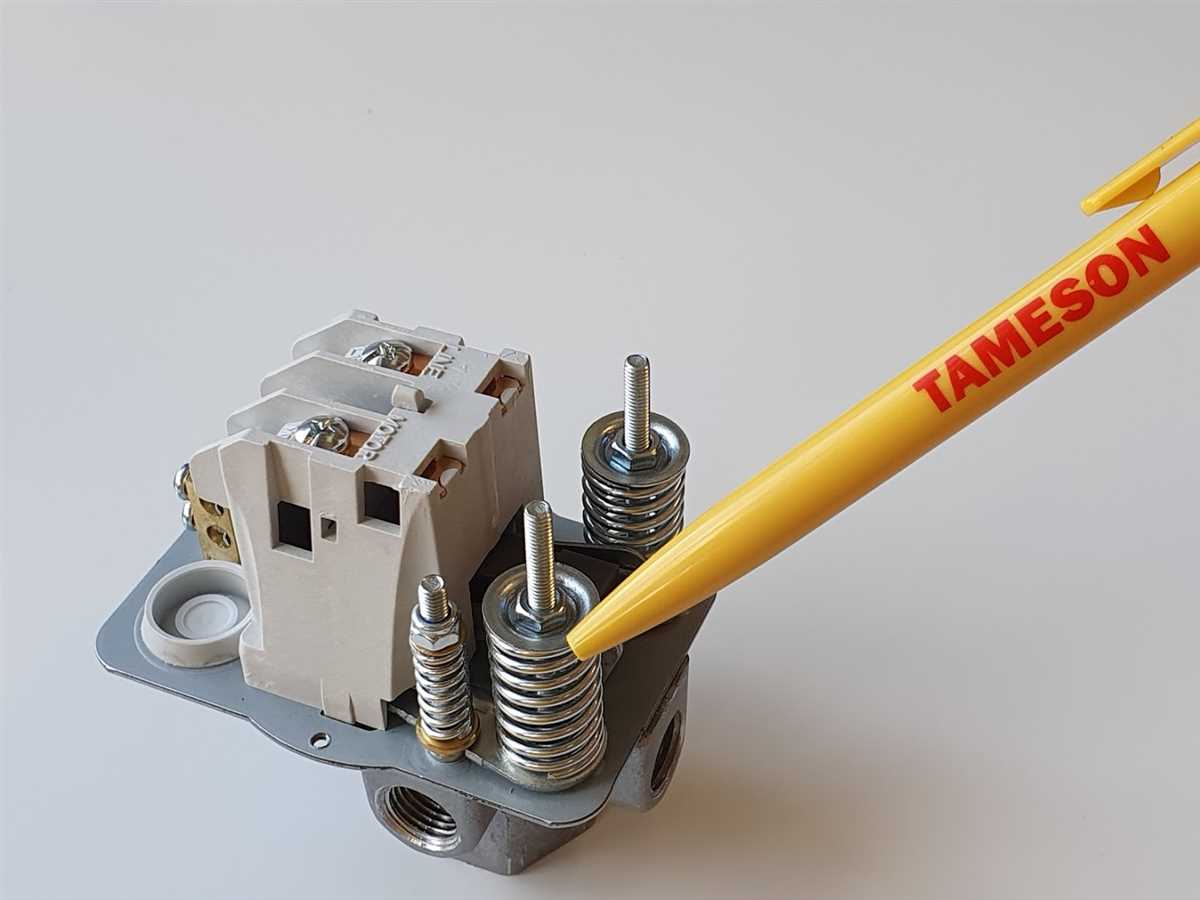

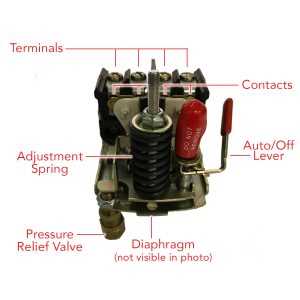

3. Replace the pressure switch: The pressure switch is responsible for regulating the pressure level in the air compressor. Upgrading to a higher-rated pressure switch can allow you to achieve greater PSI. Make sure to choose a switch that can handle the increased pressure without compromising safety.

4. Upgrade the compressor motor: If you’re looking for a more significant boost in PSI, upgrading the compressor motor might be necessary. A more powerful motor can drive the compressor pump at higher speeds, resulting in greater air pressure output. This upgrade should be done by a professional to ensure proper installation and compatibility.

5. Regular maintenance: Finally, it’s important to regularly maintain your air compressor to optimize its performance and ensure it operates at its maximum potential. This includes cleaning the air filters, checking for leaks, and lubricating moving parts. Regular maintenance can help improve efficiency and potentially increase the PSI of your air compressor.

By upgrading various components of your air compressor and performing regular maintenance, you can achieve a higher PSI and take on more demanding tasks with confidence. However, it’s essential to consult with professionals and ensure compatibility and safety when making any modifications or upgrades to your air compressor.

Adjusting the Pressure Regulator for Higher PSI

The pressure regulator on your air compressor is a key component in controlling the amount of pressure that is delivered to your tools or equipment. By adjusting the pressure regulator, you can increase the PSI (pounds per square inch) output of your air compressor.

1. Locate the pressure regulator: The pressure regulator is usually located near the air outlet or on the control panel of your air compressor. It is a small, round or square-shaped device with a dial or knob that allows you to adjust the pressure.

2. Check the current PSI setting: Before making any adjustments, it is important to know the current PSI setting of your air compressor. This information can usually be found on the pressure regulator or in the user manual. Take note of the current PSI setting so you can compare it to the desired PSI.

3. Increase the PSI: To increase the PSI, turn the knob or dial on the pressure regulator clockwise. This will close the valve, allowing less air to pass through and increasing the pressure. Make small adjustments and monitor the PSI using a pressure gauge until you reach the desired PSI.

4. Test the pressure: After adjusting the pressure regulator, it is important to test the PSI output of your air compressor. Connect a pressure gauge to the air outlet and turn on the compressor. Allow the compressor to build up pressure and observe the pressure gauge. If the PSI is at the desired level, the adjustment was successful. If not, make further adjustments as needed.

5. Safety precautions: When adjusting the pressure regulator, always wear safety glasses and gloves to protect yourself from any potential air leaks or blowouts. Follow the manufacturer’s instructions and recommendations for your specific air compressor model.

Using Additional Tools to Boost PSI

Increasing the PSI on your air compressor can be achieved by using a variety of additional tools and techniques. These tools can help you optimize your compressor’s performance and achieve higher pressure levels.

Air Compressor Pressure Switch

One tool that can help boost PSI is an air compressor pressure switch. This switch allows you to control and adjust the pressure output of your air compressor. By setting the switch to a higher pressure level, you can increase the PSI of your compressor.

Air Compressor Tank Upgrade

Another way to boost PSI is by upgrading your air compressor tank. A larger tank will allow for more air storage, which can result in higher pressure output. Consider upgrading to a larger tank if you find that your current tank is limiting the maximum PSI you can achieve.

Air Compressor Regulator

An air compressor regulator is another useful tool for boosting PSI. This device allows you to control the airflow and pressure output of your compressor. By adjusting the regulator to a higher pressure setting, you can increase the PSI of your air compressor.

Air Compressor Intercooler

An intercooler is a tool commonly used in high-performance air compressors to boost PSI. It helps cool down the compressed air before it enters the tank, which improves efficiency and allows for higher pressure levels. Consider adding an intercooler to your air compressor setup to increase its PSI.

Proper Maintenance and Cleaning

Finally, regular maintenance and cleaning of your air compressor can also contribute to increased PSI. Ensure that all components are properly lubricated and free from debris or obstructions. This will help your compressor operate at its maximum efficiency and achieve higher pressure levels.

By utilizing these additional tools and techniques, you can effectively boost the PSI on your air compressor and optimize its performance for a variety of applications.

Safety Measures to Keep in Mind when Increasing PSI

When increasing the PSI on your air compressor, it is important to prioritize safety to prevent accidents and damage to the equipment. Here are some key safety measures to keep in mind:

1. Read the manual

Before attempting to increase the PSI on your air compressor, thoroughly read the manufacturer’s manual. The manual will provide specific instructions and safety guidelines relevant to your equipment. Familiarize yourself with any warnings or precautions outlined to avoid any potential hazards.

2. Wear protective gear

When working with an air compressor, it is crucial to wear appropriate personal protective equipment (PPE) to protect yourself from potential injuries. This includes safety glasses or goggles to shield your eyes from flying debris, earplugs or earmuffs to protect your hearing from the noise, and gloves to prevent cuts or burns.

3. Check for leaks

Prior to increasing the PSI, inspect your air compressor for any signs of leaks. Leaks can cause a decrease in performance and pose a safety risk. Check all connections, hoses, and fittings for any air or fluid leakage. Repair or replace any faulty components before proceeding.

4. Monitor the pressure gauge

When increasing the PSI, closely monitor the pressure gauge on your air compressor. Pay attention to the recommended PSI range for your specific equipment and ensure that you do not exceed the maximum limit. Excessive pressure can cause damage to the compressor and increase the risk of accidents.

5. Use a pressure relief valve

Install a pressure relief valve in your air compressor system to prevent overpressure. This valve will automatically release excess pressure when it reaches a certain threshold, ensuring the safety of the system. Regularly test and maintain the pressure relief valve to ensure its proper functioning.

6. Follow proper shutdown procedures

After increasing the PSI and completing your work, it is essential to follow proper shutdown procedures to ensure safety. Turn off the compressor, release any remaining pressure, and disconnect it from the power source before performing any maintenance or making adjustments to the equipment.

By following these safety measures, you can increase the PSI on your air compressor effectively and safely, minimizing the risk of accidents or damage to the equipment. Remember to always prioritize safety and use caution when working with compressed air.

FAQ:

Why do I need to increase the PSI on my air compressor?

Increasing the PSI on your air compressor can provide several benefits. It allows you to operate certain tools or equipment that require higher pressure levels, such as pneumatic nail guns or spray guns. It can also improve the efficiency and effectiveness of your air compressor, as higher pressure levels can enable faster and more powerful air delivery.

What is PSI?

PSI stands for pounds per square inch, and it is a unit of pressure measurement commonly used in the United States. It represents the force exerted by one pound of mass on a one-square-inch area. In the context of an air compressor, PSI refers to the pressure at which the compressed air is delivered.

How can I increase the PSI on my air compressor?

To increase the PSI on your air compressor, you can adjust the pressure regulator or pressure switch, if your compressor has one. These devices control the pressure output of your compressor. By turning the adjustment knob clockwise, you can increase the pressure setting. However, it’s important to be cautious and not exceed the maximum PSI rating of your compressor, as it can result in damage or safety hazards.

What are the safety precautions when increasing the PSI on an air compressor?

When increasing the PSI on your air compressor, there are several safety precautions to keep in mind. First, always refer to the manufacturer’s instructions and guidelines. Make sure to wear appropriate safety gear, such as safety goggles and gloves, to protect yourself from potential accidents. Additionally, periodically inspect your compressor for any signs of damage or wear, and never exceed the maximum PSI rating recommended by the manufacturer.

Can I increase the PSI on any type of air compressor?

The ability to increase the PSI on an air compressor depends on the specific model and design. Some air compressors have adjustable pressure regulators or switches that allow you to increase the pressure output. However, not all compressors have this feature, especially smaller portable models. It’s important to consult the user manual or contact the manufacturer to determine if your compressor can be adjusted.

Is increasing the PSI on an air compressor difficult?

Increasing the PSI on an air compressor can be a relatively simple process, as long as you have the necessary tools and follow the proper steps. If your compressor has an adjustable pressure regulator or switch, it usually involves turning a knob or adjusting a setting. However, it’s important to exercise caution and not exceed the maximum PSI rating recommended by the manufacturer, as it can lead to damage or safety hazards.

Video: