How to Increase Air Pressure from Your Compressor: Tips and Tricks

Increasing air pressure from your compressor can be a useful skill to have, especially if you often work with pneumatic tools or machinery. By increasing the air pressure, you can improve the performance and efficiency of these tools, allowing you to complete your tasks faster and more effectively. In this article, we will share some tips and tricks on how to increase air pressure from your compressor.

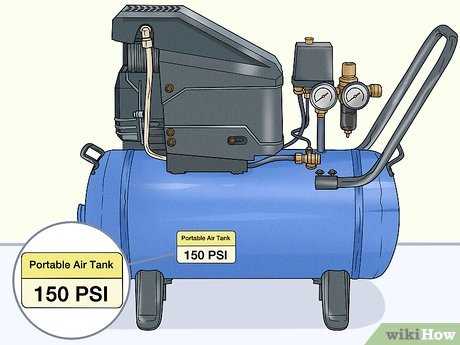

1. Check the compressor’s settings: The first step in increasing air pressure is to ensure that your compressor is set to the desired pressure. Most compressors come with an adjustable pressure switch or regulator that allows you to control the output pressure. Consult the user manual of your compressor to locate the pressure settings and adjust them accordingly.

2. Inspect and clean the air filter: A clogged or dirty air filter can restrict airflow and reduce the overall pressure output of your compressor. Regularly inspect the air filter and clean or replace it as needed. A clean air filter will help maintain proper air pressure and improve the efficiency of your compressor.

3. Check for air leaks: Air leaks can significantly impact the air pressure output of your compressor. Inspect all the connections, hoses, and fittings for any signs of leaks. Use a soapy water solution to identify leaks – if you notice any bubbles forming, it indicates a leak. Repair or replace any damaged or worn-out parts to prevent air leaks and maintain optimal air pressure.

4. Upgrade your compressor: If you find that your current compressor is not providing the desired air pressure, it may be time to consider upgrading to a more powerful model. Look for a compressor with a higher horsepower rating or a larger tank capacity. This will ensure that you have sufficient air pressure for your specific needs and projects.

5. Use a pressure booster: In some cases, using a pressure booster can help increase the air pressure output of your compressor. A pressure booster is a device that can be installed between your compressor and tools to amplify the compressed air pressure. It can be a cost-effective solution for increasing air pressure without investing in a new compressor.

Remember, it is essential to follow proper safety guidelines when working with compressed air. Always wear appropriate safety gear and operate your compressor according to the manufacturer’s instructions. Additionally, be mindful of the maximum pressure capacity of your tools and equipment to avoid any damage or accidents.

By implementing these tips and tricks, you can effectively increase the air pressure from your compressor, allowing you to accomplish your tasks more efficiently. Remember to regularly maintain and inspect your compressor to ensure optimal performance and extend its lifespan. With the right techniques and equipment, you can maximize the air pressure output and improve the overall productivity of your work.

Importance of Air Pressure in Compressors

The air pressure in compressors plays a crucial role in ensuring the efficiency and effectiveness of various applications. By maintaining the correct air pressure, you can optimize the performance of your compressor and achieve desired results in tasks such as pneumatic tools operation, sandblasting, and painting.

Improved Tool Performance: Adequate air pressure allows pneumatic tools to function at their optimal level, providing better performance and increasing productivity. Whether you are using a nail gun, an impact wrench, or any other pneumatic tool, having the right air pressure ensures smooth and consistent operation, resulting in better outcomes.

Efficient Sandblasting: Sandblasting is a common application that requires high air pressure. By maintaining the correct pressure in your compressor, you can effectively remove rust, paint, and other contaminants from surfaces. This not only improves the overall finish but also saves time and effort in the sandblasting process.

Quality Painting: Air pressure is crucial in achieving a professional and smooth finish in painting projects. Different painting techniques require specific air pressure levels, and by adjusting the compressor pressure accordingly, you can ensure an even coat, prevent paint splattering, and minimize overspray.

Extended Tool Lifespan: Operating tools with insufficient air pressure can result in excessive wear and tear, leading to frequent breakdowns and shorter lifespans. By maintaining the air pressure within the recommended range, you can prolong the lifespan of your tools and reduce the need for repairs or replacements.

Energy Efficiency: Operating a compressor at the correct air pressure helps optimize energy usage. When the pressure is too low, the compressor has to work harder to meet the demand, resulting in higher energy consumption. On the other hand, maintaining the optimal pressure allows the compressor to operate more efficiently, saving energy and reducing operating costs.

A properly maintained and adjusted air pressure in compressors not only enhances performance but also ensures safety. It is important to regularly monitor and adjust the air pressure based on the specific application requirements to achieve the desired outcomes and maximize the overall efficiency of the compressor.

Understanding Air Pressure and Its Role in Compressors

The Basics of Air Pressure

Air pressure refers to the force exerted by air molecules against a surface. It is measured in units such as pounds per square inch (psi) or bars. Air pressure is influenced by several factors, including temperature, altitude, and the volume of air present. Understanding air pressure is crucial in the context of compressors, as they rely on creating high-pressure air to perform various tasks.

The Role of Air Pressure in Compressors

Compressors are machines designed to increase the air pressure by reducing its volume. They are commonly used in industries that require pressurized air for activities such as powering tools, inflating tires, or supplying air to pneumatic systems. Compressors work by pulling in air and compressing it using a piston, impeller, or rotary screw. By increasing the air pressure, compressors enable the stored air to be used for a wide range of applications.

Importance of Proper Air Pressure

Having the correct air pressure is crucial for the efficient operation of compressors. If the pressure is too low, the compressor may struggle to perform its intended tasks, resulting in reduced productivity and potentially damaging the equipment. On the other hand, if the pressure is too high, it can put unnecessary strain on the compressor and other connected systems, leading to premature wear and tear. Regular monitoring and adjustment of air pressure ensure optimal performance and extend the lifespan of the compressor.

Factors Affecting Air Pressure in Compressors

Several factors can impact the air pressure produced by compressors. These include the size and design of the compressor, the power source used, and the efficiency of the compressor’s components. Additionally, factors like air leaks, clogged filters, and improper maintenance can affect the pressure output. Regular inspections, maintenance, and addressing any issues promptly are essential to ensure that the compressor operates at the desired air pressure levels.

Conclusion

Understanding air pressure and its role in compressors is vital for achieving optimal performance and efficiency. By comprehending the basics of air pressure, recognizing its importance, and considering the factors that affect it, users can ensure that their compressors operate at the desired pressure levels, leading to successful completion of various tasks and prolonged equipment lifespan.

Common Problems with Low Air Pressure

The air pressure produced by a compressor is crucial for many applications, such as powering pneumatic tools and inflating tires. However, low air pressure can lead to various issues that can hinder productivity and effectiveness. Here are some common problems that can arise from low air pressure:

1. Insufficient power output:

Low air pressure directly affects the power output of pneumatic tools. When the pressure is inadequate, tools may not perform at their optimum level, resulting in slower work progress and less efficient operation. This can significantly impact productivity, causing delays and increasing overall project timelines.

2. Incomplete inflation:

Low air pressure can lead to incomplete inflation of objects, such as tires or sports balls. Inadequate pressure may not provide enough air volume to fully inflate the objects, resulting in underinflated or flat tires and poorly inflated balls. This can affect vehicle performance and handling, as well as impact the functionality and playability of sports equipment.

3. Inconsistent airflow:

When air pressure is low, the airflow from pneumatic tools or other devices may become inconsistent. This can cause interruptions in operations, as tools may not function as intended or deliver a steady stream of airflow. Inconsistent airflow can affect the quality of work, especially in tasks that require precise and continuous air pressure.

4. Increased energy consumption:

Low air pressure can lead to increased energy consumption by the compressor. When the pressure is insufficient, the compressor has to work harder and longer to achieve the desired air pressure level. This results in higher energy consumption, leading to increased operating costs and reduced energy efficiency.

5. Reduced tool lifespan:

Pneumatic tools used with low air pressure may experience increased wear and tear. Inadequate pressure can cause tools to overwork, leading to increased stress on their components and decreased lifespan. This can result in frequent repairs or replacement of tools, adding to maintenance costs and reducing overall efficiency.

It is important to regularly monitor and maintain the air pressure from your compressor to avoid these common problems. Adequate air pressure ensures the optimal performance and longevity of tools and equipment, leading to more successful and efficient operations.

Tips for Increasing Air Pressure

1. Clean and Maintain Your Compressor Regularly

Regular cleaning and maintenance of your air compressor is essential for optimal performance and increased air pressure. Make sure to clean the intake vents, filters, and valves regularly to prevent any blockages or accumulation of debris. Clean air compressor parts allow for better airflow, which results in increased air pressure.

2. Check for Leaks

Inspect your air compressor regularly for any leaks. Leaks can significantly reduce air pressure and affect the performance of your compressor. To check for leaks, you can use soapy water on the connections and observe for any bubbles. If you identify any leaks, repair or replace the faulty parts immediately to prevent further loss of air pressure.

3. Upgrade Your Air Tools

Using high-quality air tools can help increase air pressure and efficiency. Low-quality or worn-out tools can cause air pressure to drop due to increased resistance or leakage. Invest in good quality air tools that are designed to handle higher air pressure, ensuring that your compressor can deliver the desired output.

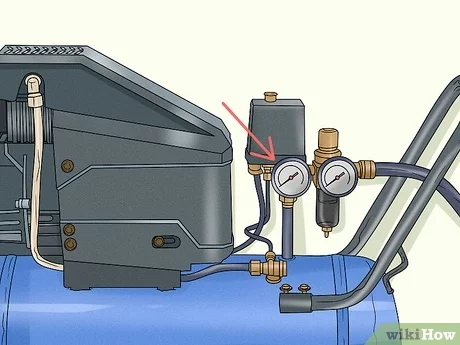

4. Adjust the Pressure Regulator

The pressure regulator on your air compressor allows you to control and adjust the air pressure. Make sure to set it to the desired pressure according to your application requirements. Adjusting the pressure regulator to a higher setting can increase the air pressure output, but be cautious not to exceed the maximum capacity of your compressor.

5. Enhance Airflow

Improving the airflow around your air compressor can help increase air pressure. Ensure that the intake vents and exhaust are clear of any obstructions, and there is sufficient ventilation in the compressor room. Better airflow prevents overheating and allows the compressor to operate more efficiently, resulting in increased air pressure.

6. Upgrade Your Compressor

If you consistently require higher air pressure, consider upgrading your compressor to a more powerful model. A larger or more advanced compressor can deliver higher air pressure and meet your specific needs. Consult with an expert or professional to determine the right compressor size and specifications for your requirements.

Overall, by following these tips, you can enhance the air pressure output of your compressor, ensuring that it meets your application needs effectively. Regular maintenance, checking for leaks, upgrading tools, adjusting pressure, enhancing airflow, and considering an upgrade can all contribute to increased air pressure performance.

Regular Maintenance to Ensure Optimum Air Pressure

1. Clean Air Filters

Air filters are an essential component of an air compressor as they prevent dust, debris, and other contaminants from entering the system. Over time, these filters can become clogged, reducing the airflow and compromising the air pressure. It is important to regularly clean or replace air filters to ensure optimum air pressure.

2. Check and Tighten Connections

Regularly inspect all connections in the air compressor system, including hoses, fittings, and valves. Loose connections can cause air leaks, resulting in a drop in air pressure. Use a wrench or tightening tool to secure any loose connections and prevent air leakage.

3. Monitor and Adjust Pressure Regulator

The pressure regulator controls the amount of air pressure that is delivered from the compressor to the tools or equipment. It is important to monitor the pressure regulator regularly and make any necessary adjustments to maintain the desired air pressure. Use a pressure gauge to accurately measure and adjust the pressure as needed.

4. Drain Moisture from Tanks

Air compressors often collect moisture in their tanks due to condensation. This moisture can affect the air pressure and cause corrosion in the system. Regularly drain any accumulated moisture from the tanks to prevent these issues and ensure optimum air pressure.

5. Inspect and Replace Worn Parts

Worn or damaged parts can negatively impact the performance of an air compressor, including the air pressure. Regularly inspect the system for any signs of wear or damage, such as cracked hoses or worn-out seals. Replace these parts promptly to maintain optimal air pressure.

By following these regular maintenance practices, you can ensure that your air compressor operates at its full potential and delivers the desired air pressure for various applications.

Choosing the Right Compressor for High Air Pressure

When looking to increase air pressure from your compressor, it is essential to select the right type of compressor that is capable of generating high air pressure. The two main types of compressors that are suitable for high pressure applications are reciprocating compressors and rotary screw compressors.

Reciprocating compressors, also known as piston compressors, are suitable for applications that require intermittent high air pressure. They operate by using a piston and cylinder arrangement to compress air. These compressors are capable of providing high-pressure air but are generally slower and noisier compared to rotary screw compressors.

Rotary screw compressors, on the other hand, are better suited for applications that require a continuous supply of high-pressure air. They use two rotors that compress the air, providing a more efficient and steady airflow. Rotary screw compressors are known for their reliability, low noise levels, and high energy efficiency.

When selecting a compressor for high air pressure, it is important to consider the maximum pressure rating of the compressor. This rating signifies the maximum pressure that the compressor can generate and sustain. It is crucial to choose a compressor that has a maximum pressure rating higher than the desired air pressure for your specific application. This will ensure that the compressor is not operating at its maximum capacity, which can lead to excessive wear and reduced longevity.

Additionally, it is important to consider the air supply requirement of your application. Different applications have varying air demands, and it is crucial to choose a compressor that can meet these requirements consistently. Factors such as air flow rate, duty cycle, and compressed air quality should be considered when selecting a compressor for high air pressure.

In summary, choosing the right compressor for high air pressure involves considering the type of compressor, the maximum pressure rating, and the air supply requirement of your specific application. By selecting the appropriate compressor, you can ensure that your air pressure needs are met effectively and efficiently.

Safety Precautions when Dealing with High Air Pressure

1. Wear Protective Gear

When working with high air pressure, it is crucial to wear appropriate protective gear to ensure your safety. This includes safety glasses or goggles to protect your eyes from any potential flying debris or compressed air. Additionally, wearing a dust mask or respirator can help protect your respiratory system from any airborne particles that may be present.

2. Check Equipment Regularly

Prior to using any equipment that deals with high air pressure, it is essential to conduct regular inspections to check for any signs of damage or wear. Inspect the hoses, fittings, and valves for leaks or cracks, as well as the pressure gauge to ensure it is functioning properly. By doing so, you can identify and address any issues before they escalate and pose a safety risk.

3. Follow Proper Operating Procedures

It is important to familiarize yourself with the proper operating procedures for your specific compressor and equipment. Always follow the manufacturer’s instructions and guidelines to ensure safe and effective operation. Do not exceed the recommended pressure limits and avoid using equipment for purposes it is not intended for. This will help prevent accidents and maintain the integrity of the equipment.

4. Securely Fasten Connections

Ensure that all connections between the compressor, hoses, and equipment are securely fastened. Loose connections can result in air leaks or sudden bursts of pressure, which can be dangerous. Use appropriate clamps or fittings and tighten them properly to prevent any potential hazards.

5. Release Pressure before Making Adjustments

Before making any adjustments or repairs to the compressor or any associated equipment, always release the air pressure completely. This can be done by turning off the compressor and allowing the pressure to dissipate naturally. Trying to adjust or repair equipment under high pressure can lead to serious injuries.

6. Store and Handle Compressed Air Cylinders Safely

If you are using compressed air cylinders, it is important to store and handle them with care. Transport the cylinders in an upright position in a well-ventilated area, away from any heat sources or flammable materials. Ensure that cylinders are properly secured to prevent them from falling or tipping over. When not in use, store them in a designated area that is away from traffic and where they will not be exposed to extreme temperatures or direct sunlight.

By following these safety precautions when dealing with high air pressure, you can minimize the risks associated with handling compressed air and ensure a safe working environment.

Benefits of Increased Air Pressure in Compressors

1. Improved Efficiency

Increasing the air pressure in compressors can lead to improved efficiency in various industrial applications. When the air pressure is increased, more air can be compressed and stored in a given space, allowing for a higher volume of work to be done with the same amount of compressed air. This increased efficiency can result in higher productivity and reduced operating costs.

2. Enhanced Performance

Higher air pressure in compressors can also lead to enhanced performance in pneumatic tools and equipment. With increased pressure, tools such as air drills, impact wrenches, and spray guns can deliver more power and perform at their best. This can improve the overall effectiveness and speed of various tasks, making them easier and more efficient to complete.

3. Increased Air Flow

One of the main advantages of increased air pressure in compressors is the ability to achieve higher air flow rates. This is particularly important in applications where a high volume of air is required, such as in industrial processes or large-scale operations. By increasing the air pressure, compressors can deliver a greater amount of air, making it possible to meet the demands of even the most demanding operations.

4. Better Control

By increasing the air pressure in compressors, operators can have better control over the output and performance of pneumatic systems. The higher pressure provides more precise control over the speed, force, and timing of air-powered tools, allowing for more accurate and controlled operations. This can be especially crucial in applications that require precision, such as in assembly lines or manufacturing processes.

5. Extended Equipment Lifespan

When used within recommended limits, increased air pressure in compressors can actually help extend the lifespan of pneumatic equipment. Higher pressure can prevent the accumulation of moisture in the system, reducing the risk of corrosion and damage to the equipment. Additionally, proper pressure levels can reduce strain on the tools and components, minimizing wear and tear and prolonging their overall lifespan.

Overall, increasing the air pressure in compressors can bring numerous benefits, including improved efficiency, enhanced performance, increased air flow, better control, and extended equipment lifespan. These advantages make it worth considering adjustments to air pressure settings for various applications to maximize the potential of your compressor.

FAQ:

Video: