How to determine the gallon size of the air compressor you need

When it comes to choosing an air compressor, one important factor to consider is the gallon size. The gallon size of an air compressor refers to the tank capacity, which determines how long it can run before it needs to be refilled. Determining the right gallon size for your needs is crucial for ensuring efficient and effective operation.

When deciding on the gallon size of an air compressor, you should assess the specific tasks you will be using it for. Different applications require different amounts of air supply, so it’s essential to match the tank capacity to your specific needs. For example, if you plan to use the air compressor for light tasks such as inflating tires or powering small tools, a smaller gallon size may be sufficient. However, if you intend to use it for heavy-duty tasks like sandblasting or powering large tools, a larger gallon size will be necessary to provide enough air supply.

Additionally, you should consider factors such as the length of time you will be using the air compressor, the frequency of use, and the amount of air flow required for your applications. These factors will help you determine the gallon size that can handle your workload without straining the compressor or causing frequent refills. It’s important to choose a tank capacity that provides a balance between runtime and efficiency, ensuring that the air compressor can meet your needs without unnecessary downtime.

Understanding air compressors

An air compressor is a mechanical device that converts power, typically from an electric motor, gasoline engine, or diesel engine, into potential energy stored in pressurized air. This stored compressed air can then be used for a variety of applications, including powering pneumatic tools, inflating tires, or supplying air to HVAC systems, among other uses.

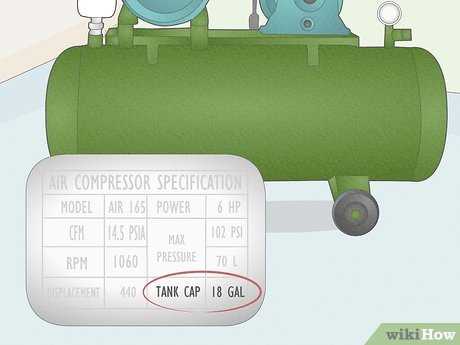

When choosing an air compressor, it is important to understand its specifications and capabilities to ensure it meets your specific needs. One important factor to consider is the gallon size of the air compressor, which relates to its air storage capacity. However, it is worth noting that the gallon size does not refer to the physical size of the compressor, but rather to the amount of air the tank can hold.

How does the gallon size affect the performance of an air compressor?

The gallon size of an air compressor plays a crucial role in determining its performance. A larger gallon size means that the compressor can store more compressed air, which results in longer run times before the motor needs to kick in and refill the tank. This is particularly important for applications that require a continuous and steady supply of compressed air, as it allows the compressor to run less frequently and reduces the risk of overheating.

Additionally, a larger gallon size can also help mitigate pressure drops, which occur when multiple pneumatic tools are used simultaneously or when a tool requires a large volume of air. The larger storage capacity ensures a more consistent and steady supply of compressed air, which can improve the performance and efficiency of the tools being used.

How to calculate the gallon size you need?

Calculating the gallon size needed for your air compressor mainly depends on the specific applications and tools you plan to use. Generally, it is recommended to choose an air compressor with a gallon size that is large enough to suit your highest-demand tool or application.

One way to estimate the gallon size requirement is to consider the average air consumption of your tools. Some tools may have this information listed in their specifications or manuals. If it is not available, you can estimate the required air volume by looking at the tool’s airflow (CFM) and duty cycle.

It is also important to consider future expansion or additional tools that may be added to your setup. In such cases, it is generally better to opt for a larger gallon size to ensure your air compressor can handle the increased demand.

Importance of choosing the right size

Choosing the right size of an air compressor is crucial for ensuring that your tools and equipment receive the proper amount of air pressure to operate efficiently. The size of the air compressor is measured in gallons and directly affects its capacity to deliver compressed air.

Matching the air compressor size to your specific needs is important for several reasons. Firstly, an air compressor that is too small for the job will struggle to provide sufficient air pressure, resulting in decreased performance and potentially damaging the tools or equipment. On the other hand, an air compressor that is too large for the task may lead to unnecessary energy consumption and increased costs.

By choosing the right size of air compressor, you can optimize your overall productivity and efficiency. The right size will provide consistent air pressure, allowing your tools to work at their optimal level. This is especially important for tasks that demand a specific air pressure, such as painting or operating pneumatic tools.

Additionally, choosing the appropriate size of air compressor can help extend its lifespan and preserve its performance. When an air compressor is properly matched to the intended workload, it will experience less strain and operate more smoothly, reducing the risk of mechanical failures and costly repairs.

Lastly, by selecting the right size of air compressor, you can also achieve cost savings in the long run. A properly-sized air compressor will consume less energy compared to an oversized one, resulting in lower electricity bills. Furthermore, it will require less maintenance and replacement parts, reducing the overall operating costs.

In conclusion, choosing the right size of an air compressor is essential for maximizing productivity, protecting your equipment, and optimizing costs. By understanding your specific needs and matching them to the appropriate compressor size, you can ensure efficient operation and achieve better overall results.

Factors to consider

When determining the gallon size of an air compressor that you need, there are several important factors to consider:

- Air consumption rate: The first factor to consider is the air consumption rate of the tools and equipment that you plan to use with the air compressor. Different tools have different air consumption rates, so it’s important to know the specific requirements of the tools you will be using. This information is usually provided by the manufacturer.

- Operating pressure: The operating pressure is another important factor to consider. Different tools and equipment require different operating pressures. It’s important to choose an air compressor that can provide the required operating pressure for your specific needs. This information is also usually provided by the manufacturer.

- Duty cycle: The duty cycle refers to the amount of time the compressor can run within a given time period. If you plan to use the air compressor for extended periods of time, you will need a compressor with a higher duty cycle to ensure it can handle the continuous operation.

- Tank size: The gallon size of the air compressor tank is also an important factor to consider. A larger tank size allows for more compressed air storage, which can be beneficial for tools and equipment that require short bursts of air or have intermittent usage. However, if the tools you are using have a high air consumption rate, you may need a larger tank size to ensure a continuous supply of air.

By considering these factors and evaluating your specific needs, you can determine the gallon size of the air compressor that will best suit your requirements.

Calculating your air needs

When determining the gallon size of the air compressor you need, it is essential to calculate your air needs accurately. This will ensure that you select a compressor that can handle the demands of your specific tasks or projects. Estimating your air needs involves considering factors like the tools you will be using, the air volume required by those tools, and the duration of their operation.

1. Identify your tools: Make a list of all the pneumatic tools and equipment you will be using with the air compressor. This could include tools like impact wrenches, nail guns, paint sprayers, and sanders.

2. Determine the required air volume: Each pneumatic tool will have a specified air volume requirement, expressed in either cubic feet per minute (CFM) or liters per minute (L/min). Consult the tool’s user manual or specifications to find this information.

3. Calculate total air volume: Add up the individual air volume requirements of all the tools you identified in step 1. This will give you the total air volume needed to operate all the tools simultaneously.

4. Consider the duty cycle: Reflect on the duration of time the tools will be in use. If you will be operating the tools for extended periods, you may need a larger air compressor with a higher gallon size to ensure it can provide a continuous air supply.

5. Factor in any special requirements: Some applications, such as sandblasting or spray painting, may have specific air supply requirements. Take into account any special considerations when determining the gallon size of the air compressor.

By carefully calculating your air needs, you can choose an air compressor with an appropriate gallon size that will meet your specific requirements and ensure efficient operation of your pneumatic tools.

Choosing the appropriate tank size

When selecting an air compressor, one important consideration is the tank size. The tank size determines how much air the compressor can hold and how long it can run before needing to refill. Choosing the appropriate tank size depends on your specific needs and the type of projects you will be using the air compressor for.

1. Consider the type of work:

Before deciding on a tank size, it’s important to consider the type of work you will be doing with the air compressor. If you will be using the compressor for light tasks such as inflating tires or operating small air tools, a smaller tank size may be sufficient. However, if you will be using the compressor for heavy-duty tasks such as powering air tools or spraying paint, a larger tank size may be necessary to provide a continuous supply of air.

2. Evaluate the required air pressure:

Another factor to consider when choosing a tank size is the required air pressure for your specific tasks. Some applications may require a higher air pressure, which can necessitate a larger tank size to ensure a continuous supply of air at the desired pressure. It’s important to determine the minimum and maximum air pressure needed for your projects and select a tank size that can accommodate those requirements.

3. Consider the frequency of use:

The frequency of use is another crucial consideration when choosing an appropriate tank size. If you will be using the air compressor frequently or for extended periods, a larger tank size is recommended. A larger tank can provide a longer run time before the compressor needs to refill, allowing you to complete tasks without interruption. On the other hand, if you will only be using the compressor occasionally or for short durations, a smaller tank size may be sufficient to meet your needs.

4. Evaluate available space:

Lastly, it’s important to consider the available space where the compressor will be located. Larger tank sizes typically require more space for storage. Ensure you have enough room to accommodate the chosen tank size without compromising workspace or creating inconvenience.

By considering these factors and evaluating your specific needs, you can choose the appropriate tank size for your air compressor, ensuring optimal performance and efficiency for your projects.

Benefits of selecting the correct gallon size

Choosing the right gallon size for your air compressor can have several benefits. Here are a few key advantages:

Increased productivity

Having an air compressor with the correct gallon size allows for improved productivity. With a larger gallon size, the compressor can hold more compressed air, reducing the need for the motor to constantly run and refill the tank. This means you can work for longer periods without having to wait for the compressor to catch up, increasing efficiency and productivity.

Enhanced performance

Using the correct gallon size for your air compressor ensures that it can provide the necessary air pressure and flow rate for your tools and equipment. When the compressor has a sufficient gallon size, it can deliver a consistent and steady flow of compressed air, allowing your tools to operate at their optimal performance levels. This leads to better results and overall improved performance.

Extended tool lifespan

By selecting the correct gallon size, you can prevent overworking the air compressor and putting excessive strain on the motor. When the compressor is not constantly cycling on and off, it reduces the wear and tear on its components, resulting in a longer lifespan for both the compressor and your tools. This can save you money on repairs or replacements in the long run.

Flexibility in applications

If you have a variable range of applications that require different air pressure levels, choosing an air compressor with the appropriate gallon size can offer you more versatility. A larger gallon size can handle a wider range of tools and equipment, allowing you to switch between tasks without the need for additional compressors or adjustments to your setup. This flexibility can save you time and effort in your work.

Overall, selecting the correct gallon size for your air compressor is crucial for maximizing productivity, improving performance, extending the lifespan of your equipment and providing flexibility in your applications. Take the time to assess your specific needs and choose an air compressor with the appropriate gallon size to enjoy these benefits.

FAQ:

What factors should I consider when determining the gallon size of the air compressor I need?

When determining the gallon size of the air compressor you need, there are several factors you should consider. First, you need to determine the specific air tools or equipment that you will be using with the compressor. Different tools have different air requirements, so you will need to make sure the compressor can meet those requirements. Additionally, you should consider the frequency and duration of use. If you will be using the compressor for long periods of time or for heavy-duty applications, you may need a larger gallon size to ensure it can handle the workload. Finally, you should consider any future expansion or growth. If you anticipate needing more air in the future, it may be wise to invest in a larger gallon size now.

How can I determine the air requirements of the tools I will be using?

To determine the air requirements of the tools you will be using, you will need to consult the manufacturer’s specifications for each tool. The specifications should provide information on the minimum air pressure and air volume required for proper operation. Additionally, you can check the tool’s user manual or do a quick internet search to find the necessary information. Once you have gathered the air requirements for all your tools, you can add up the total air volume needed to determine the gallon size of the air compressor you need.

What happens if I choose an air compressor with a gallon size that is too small?

If you choose an air compressor with a gallon size that is too small, you may run into several issues. First, the compressor may not be able to supply enough air volume to meet the demands of your tools or equipment. This can result in reduced performance and potential damage to the tools. Additionally, a small compressor may run continuously or cycle on and off frequently, putting extra strain on the motor and potentially causing it to overheat or wear out more quickly. Overall, choosing a gallon size that is too small can lead to inefficient operation and decreased tool lifespan.

What are the advantages of choosing a larger gallon size for an air compressor?

Choosing a larger gallon size for an air compressor can offer several advantages. First, a larger compressor typically has a higher maximum pressure and flow rate, allowing it to power a wider range of tools and equipment. This can be especially beneficial if you plan on expanding your tool collection or taking on more demanding projects in the future. Additionally, a larger compressor often has a larger air storage tank, which means it can run longer without cycling on and off. This can help maintain a more consistent air pressure and reduce wear on the motor. Overall, choosing a larger gallon size can provide greater versatility and better performance.

Do I need a specific gallon size for different types of air tools?

Yes, different types of air tools may have specific gallon size requirements. For example, smaller tools like brad nailers or airbrushes may only require a small gallon size, such as 1 or 2 gallons. On the other hand, larger tools like impact wrenches or sandblasters may require a larger gallon size, such as 20 or 30 gallons. It is important to check the manufacturer’s specifications for each tool to determine the appropriate gallon size. If you have a variety of tools with different gallon size requirements, you may need to invest in a compressor with a larger gallon size to accommodate all your tools.

Can I use a larger air compressor with smaller air tools?

Yes, you can use a larger air compressor with smaller air tools. In fact, using a larger compressor can provide some benefits. Since the larger compressor has a higher maximum pressure and flow rate, it can deliver air more efficiently to the smaller tools, allowing them to operate at optimal performance. Additionally, a larger compressor with a larger air storage tank will cycle on and off less frequently when powering smaller tools, which can help prolong the compressor’s lifespan. However, it is important to make sure the larger compressor meets the minimum air requirements of the smallest tool you will be using.

Video:

![Ankier Potato Growing Bags,3 pack 7 Gallon Vegetable Grow Bags Planter Container with Hook & Loop Window and Strap Handles - Non-woven Garden Plant Bags for Various Vegetables and Flower [Black]](https://m.media-amazon.com/images/I/51IYh8h2HCL._SL160_.jpg)