How to Determine the Correct Size for an Air Compressor

When it comes to purchasing an air compressor, one of the most important factors to consider is the size. Choosing the correct size for your specific needs is crucial for ensuring the compressor performs optimally and meets your requirements. The size of an air compressor is determined by several factors, including the volume of air it can produce, the pressure it can maintain, and the amount of power it requires.

One of the first considerations when determining the correct size for an air compressor is the volume of air it can produce. The volume of air, usually measured in liters or cubic feet per minute (CFM), determines how much air the compressor can deliver to power tools or other equipment. Different tools and equipment require different volumes of air, so it’s important to choose a compressor that can deliver the necessary CFM for your intended use.

Another factor to consider is the pressure the air compressor can maintain. Pressure is measured in pounds per square inch (PSI) and determines the force with which the air is delivered. Some tools and equipment require higher pressure to operate effectively, so it’s important to choose a compressor that can generate and maintain the necessary PSI for your specific applications.

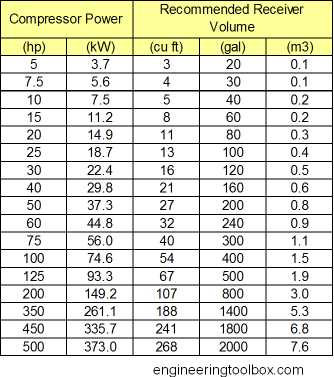

Lastly, it’s important to consider the power requirements of the air compressor. The power, usually measured in horsepower (HP), determines the ability of the compressor’s motor to drive the pump and generate air. Different applications may require different levels of power, so it’s essential to choose a compressor that can provide the necessary HP to meet your specific needs.

Overall, determining the correct size for an air compressor requires taking into account the volume of air it can produce, the pressure it can maintain, and the power it requires. By carefully considering these factors and matching them to your specific needs, you can ensure that you select the right size compressor for optimal performance and productivity.

Importance of Choosing the Correct Size for an Air Compressor

Efficiency and Effectiveness

Choosing the correct size for an air compressor is crucial for ensuring its efficiency and effectiveness. An improperly sized air compressor may not be able to generate enough air pressure or volume to meet the demands of your specific application. This can result in inefficiencies and reduced productivity.

Energy Consumption

Using an air compressor that is too large for your needs can result in unnecessary energy consumption. A larger air compressor will require more power to operate, leading to higher energy bills and increased costs over time. On the other hand, using an air compressor that is too small may result in overworking the motor, leading to higher energy consumption due to inefficient operation.

Longevity and Durability

Choosing the correct size for an air compressor is also important for ensuring its longevity and durability. Using an air compressor that is too small for your demands may cause it to run continuously, leading to excessive wear and tear on the motor and other components. On the other hand, using an air compressor that is too large may result in infrequent use, allowing moisture to accumulate and causing corrosion and damage to the internal parts.

Safety

Using the correct size of air compressor is essential for maintaining a safe working environment. An air compressor that is too small may struggle to meet the air demands of your tools or equipment, resulting in slow or incomplete tasks. This could increase the risk of accidents or injuries as workers may attempt to compensate for the lack of pressure by using alternative methods. Conversely, using an air compressor that is too large may generate excessive pressure, which can be dangerous and cause damage to tools or equipment, making it crucial to choose the correct size for safe and efficient operations.

Proper Tool Functionality

Each air tool has specific pressure and airflow requirements. Choosing an air compressor that meets these requirements is necessary for proper tool functionality. Using an air compressor with insufficient airflow can lead to reduced tool performance and ineffective operation. Similarly, using an air compressor with excessive pressure can cause damage to the tools and compromise their functional abilities. Taking into account the required airflow and pressure of your tools and selecting the correct size air compressor will ensure optimal tool performance and longevity.

Cost Savings

Choosing the correct size for an air compressor can also lead to cost savings in the long run. By selecting an air compressor that matches your specific needs, you can avoid overpaying for an unnecessarily large unit and reduce energy consumption. Additionally, a properly sized air compressor is less prone to breakdowns and other mechanical issues, resulting in lower maintenance and repair costs.

Overall, selecting the correct size for an air compressor is vital for ensuring efficiency, energy savings, longevity, safety, proper tool functionality, and cost savings. Carefully assessing your specific air pressure and volume requirements, as well as the needs of your tools or equipment, will help determine the appropriate size of air compressor for your application.

Factors to Consider when Determining the Correct Size for an Air Compressor

Type of Applications

The type of applications you plan to use the air compressor for is an important factor to consider when determining the correct size. Different applications require different amounts of compressed air. For example, if you are planning to use the air compressor for small DIY projects or inflating tires, a smaller size compressor may be sufficient. However, if you are using it for heavy-duty tasks such as powering pneumatic tools or operating machinery, you will likely need a larger size compressor.

Air Pressure Requirements

The required air pressure for your applications is another crucial factor to consider. Air compressors are rated in terms of pounds per square inch (psi), which represents the air pressure they can produce. Check the pressure requirements of your tools or equipment to ensure that the air compressor you choose can provide a sufficient amount of pressure. Keep in mind that different tools and equipment may have different pressure needs, so it’s important to take that into account when determining the correct size for your air compressor.

Cubic Feet per Minute (CFM)

The cubic feet per minute (CFM) is a measurement of the airflow capacity of an air compressor. It represents the volume of air the compressor can deliver per minute. To determine the correct size for your air compressor, you need to match the CFM rating of the compressor with the CFM requirements of your applications. It’s important to consider not only the average CFM consumption but also any peak demands that may occur. Make sure the compressor has a CFM rating that can meet your needs without overworking the unit.

Tank Size

The tank size of an air compressor plays a role in its performance and capability. A larger tank size allows for more storage of the compressed air, which can be beneficial for applications with intermittent usage, such as spray painting or operating air tools. It provides a reserve of compressed air that can handle peak demands. However, if you have continuous high-demand applications, you may need to look for a compressor with a high CFM rating, regardless of the tank size.

Power Source

When determining the correct size for an air compressor, consider the power source available. Air compressors can be powered by electricity or gasoline. If you have access to electricity, an electric-powered compressor can be a suitable option. However, if you need to use the compressor in remote locations or areas without power, a gasoline-powered compressor may be required. Be sure to choose a size that suits the available power source to ensure proper function and performance.

In conclusion, when determining the correct size for an air compressor, consider factors such as the type of applications, air pressure requirements, CFM rating, tank size, and power source. Taking these factors into account will help ensure that you choose an air compressor that is suitable for your specific needs.

Understanding CFM and PSI Ratings

When determining the correct size for an air compressor, it is important to understand the CFM and PSI ratings, as they are crucial factors in its performance. CFM stands for cubic feet per minute, which measures the volume of air that the compressor can deliver. PSI stands for pounds per square inch, which measures the pressure of the air being delivered.

CFM Rating: The CFM rating indicates the ability of the air compressor to deliver a specific volume of air. It is important to consider the CFM requirements of the tools or equipment that will be connected to the compressor. Each tool will have its own CFM requirement, which must be matched or exceeded by the compressor’s CFM rating. If the CFM rating is too low, the tools may not receive enough air pressure, resulting in decreased performance.

PSI Rating: The PSI rating is equally important as it determines the pressure at which the air is delivered. Different tools and applications require different levels of air pressure to operate effectively. It is crucial to ensure that the compressor’s PSI rating matches or exceeds the maximum pressure required by the tools or equipment that will be used. If the PSI rating is too low, the tools may not be able to function properly.

It is also important to consider the duty cycle of an air compressor, which refers to the amount of time it can run continuously without overheating or wearing out. Some compressors have a higher duty cycle, allowing them to run for longer periods, while others may only be suitable for short bursts of usage.

Calculating Your Required CFM

To determine the correct size for an air compressor, you need to calculate the required CFM (cubic feet per minute) for your specific application. CFM is a measure of the volume of air that a compressor can deliver in a minute. Knowing the required CFM will help you select an air compressor with enough capacity to meet your needs.

Step 1: Identify the tools or equipment you will be using

Start by making a list of all the tools or equipment that you plan to connect to your air compressor. Include any pneumatic tools, such as nail guns, impact wrenches, or spray guns, as well as any air-powered machinery.

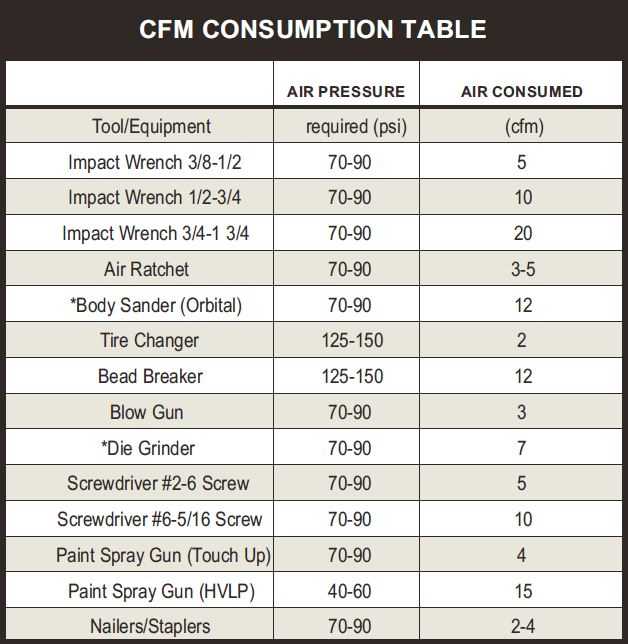

Step 2: Determine the CFM requirements for each tool or equipment

Next, research the CFM requirements for each tool or equipment on your list. This information can usually be found in the manufacturer’s specifications or user manuals. Note down the CFM requirements for each item.

Step 3: Calculate the total CFM

Add up the CFM requirements for all the tools and equipment on your list to determine the total CFM required. This will give you an idea of the minimum CFM capacity that your air compressor should have.

Step 4: Consider future growth and usage

It’s important to consider any future growth or additional tools that you may need to use with your air compressor. If you anticipate adding more tools or equipment, it is recommended to choose an air compressor with a slightly higher CFM capacity to accommodate these future needs.

Step 5: Compare CFM ratings of air compressors

Once you have determined the total CFM required, you can start comparing different air compressors. Look for models that have a CFM rating that meets or exceeds your total requirement. Keep in mind that it is better to have a slightly higher CFM rating than your requirement to ensure optimal performance.

By following these steps and calculating your required CFM, you can confidently choose the correct size for an air compressor that will meet your application needs.

Matching Your Air Compressor’s CFM and PSI Ratings to Your Tools and Equipment

When it comes to choosing the correct size air compressor for your tools and equipment, it is important to consider both the CFM (cubic feet per minute) rating and the PSI (pounds per square inch) rating. These two measurements are crucial in determining whether your air compressor has the power and capacity to handle the tools and equipment you will be using.

The CFM rating refers to the amount of air flow that the compressor can produce. Different tools and equipment require different CFM ratings to operate effectively. For example, a small pneumatic nail gun may only require 2-3 CFM, while a larger impact wrench may need 7-8 CFM. It is important to check the CFM requirements of your tools and equipment and choose an air compressor with a CFM rating that meets or exceeds those needs.

The PSI rating, on the other hand, refers to the pressure at which the air is delivered from the compressor. Again, different tools and equipment have different PSI requirements. For instance, a paint sprayer may require a PSI rating of 30-60, while a sandblaster may need 90-100 PSI. It is essential to match the PSI rating of your air compressor to the PSI requirements of your tools and equipment to ensure proper operation.

In addition to considering the CFM and PSI ratings, it is also important to take into account the duty cycle of your air compressor. The duty cycle refers to the amount of time the compressor can operate continuously before it needs to rest. A higher duty cycle is ideal for tools and equipment that require prolonged use, while a lower duty cycle may be sufficient for tools that are used intermittently.

To determine the correct size for your air compressor, it is recommended to make a list of all the tools and equipment you will be using and their corresponding CFM and PSI requirements. Once you have this information, you can compare it to the CFM and PSI ratings of different air compressors to find the one that best suits your needs. Remember to also consider the duty cycle and any additional features or accessories that may be necessary for your specific applications. Taking the time to properly match your air compressor’s CFM and PSI ratings to your tools and equipment will ensure efficient and effective operation, saving you time and money in the long run.

Selecting the Right Tank Size

When it comes to choosing an air compressor, one important factor to consider is the tank size. The tank size determines the amount of compressed air that can be stored and used at any given time.

Tank size depends on the intended usage:

- For small-scale applications, such as inflating tires or operating small tools, a tank size of 1 to 6 gallons may be sufficient. These tanks provide a limited amount of stored air but can still handle low-demand tasks effectively.

- For medium-scale applications, such as running a paint sprayer or operating multiple small tools simultaneously, a tank size of 6 to 20 gallons is recommended. These tanks provide a larger capacity of stored air, allowing for longer continuous usage before the compressor needs to cycle on again.

- For large-scale applications, such as automotive work or operating high-demand tools, a tank size of 20 gallons or more is necessary. These tanks provide a significant amount of compressed air, allowing for extended periods of continuous usage without the need for frequent cycling of the compressor.

It’s also important to consider the compressor’s airflow requirements:

Depending on the tools or equipment that will be connected to the compressor, it’s important to ensure that the airflow requirements are met. A larger tank size can help meet increased airflow demands by providing a buffer of stored air. This allows the compressor to deliver a consistent flow of air, even when the demand spikes temporarily.

However, it’s important not to oversize the tank:

An oversized tank may result in longer compressor runtime and more frequent cycling, which can lead to increased wear and tear on the compressor components. It’s important to strike a balance between tank size and usage requirements to ensure optimal performance and longevity of the compressor.

Overall, when selecting the right tank size for an air compressor, it’s crucial to consider the intended usage, airflow requirements, and strike a balance to achieve the best performance and efficiency.

Other Considerations for Choosing the Correct Size for an Air Compressor

1. Required Air Pressure

One important factor to consider when determining the correct size for an air compressor is the required air pressure for your specific applications. Different tools and equipment have different pressure requirements, so you need to make sure that the air compressor can provide enough pressure to meet your needs. Check the specifications of your tools or consult the manufacturer’s recommendations to determine the required air pressure.

2. Air Volume Requirements

In addition to air pressure, you also need to consider the air volume requirements of your tools or equipment. The air volume, usually measured in cubic feet per minute (CFM), determines how quickly the compressor can deliver a continuous supply of compressed air. If your tools require a high air volume, you will need a larger compressor with a higher CFM rating to ensure smooth and efficient operation.

3. Duty Cycle

The duty cycle of an air compressor refers to the amount of time it can operate without overheating. If you anticipate using your air compressor for extended periods of time or in a professional setting, it is important to choose a compressor with a high duty cycle. Compressors with a lower duty cycle may overheat and require more frequent breaks, which can affect productivity and efficiency.

4. Tank Size

The size of the air tank also plays a role in determining the correct size for an air compressor. A larger tank allows the compressor to store more compressed air, which can be beneficial for applications that require a continuous supply of air or for tools that have intermittent usage. However, it is important to strike a balance and not choose a tank that is excessively large for your needs, as it can increase the overall size and weight of the compressor.

5. Power Source

Lastly, you should consider the power source available to you when choosing the correct size for an air compressor. Air compressors can be powered by electricity or gas, and the availability of these power sources may influence your decision. Electric compressors are generally more convenient for indoor use, while gas-powered compressors offer greater portability and are better suited for outdoor applications or remote locations.

Overall, when determining the correct size for an air compressor, it is important to consider factors such as required air pressure, air volume requirements, duty cycle, tank size, and power source. By taking these factors into account, you can select an air compressor that will meet your specific needs and provide optimal performance.

FAQ:

What factors should I consider when determining the correct size for an air compressor?

When determining the correct size for an air compressor, you should consider factors such as the type of tools you will be using, the required CFM (cubic feet per minute) of the tools, the air pressure required by the tools, and the duty cycle of the compressor.

How do I determine the required CFM for my tools?

To determine the required CFM for your tools, you can check the specifications provided by the tool manufacturers. The required CFM can vary depending on the type and size of the tool. It is important to choose an air compressor that can supply the necessary CFM for your tools to operate efficiently.

What is the duty cycle of an air compressor?

The duty cycle of an air compressor refers to the percentage of time the compressor can run in a given time frame without overheating. For example, a compressor with a 50% duty cycle can run for half of the time without overheating. It is important to consider the duty cycle if you plan to use the compressor for extended periods of time.

Can I use a smaller air compressor for my tools?

Using a smaller air compressor for your tools may cause the compressor to run continuously or struggle to supply enough air. This can lead to decreased performance and potentially damage the compressor. It is recommended to choose an air compressor that can supply the necessary CFM for your tools to operate efficiently.

What happens if I use an air compressor with a higher CFM rating?

If you use an air compressor with a higher CFM rating than required by your tools, it is generally not a problem. The tools will only draw the amount of air they need, and the compressor will supply it. However, running a larger compressor than necessary may lead to higher energy consumption and can be less cost-effective.

Is it better to have a higher psi or CFM rating on an air compressor?

Both psi (pounds per square inch) and CFM (cubic feet per minute) are equally important when choosing an air compressor. The psi rating determines the maximum pressure the compressor can deliver, while the CFM rating determines the volume of air the compressor can supply. It is important to choose an air compressor that meets the minimum psi requirement of your tools and provides the necessary CFM.

Video: