How to Connect Two Air Compressor Tanks at Home

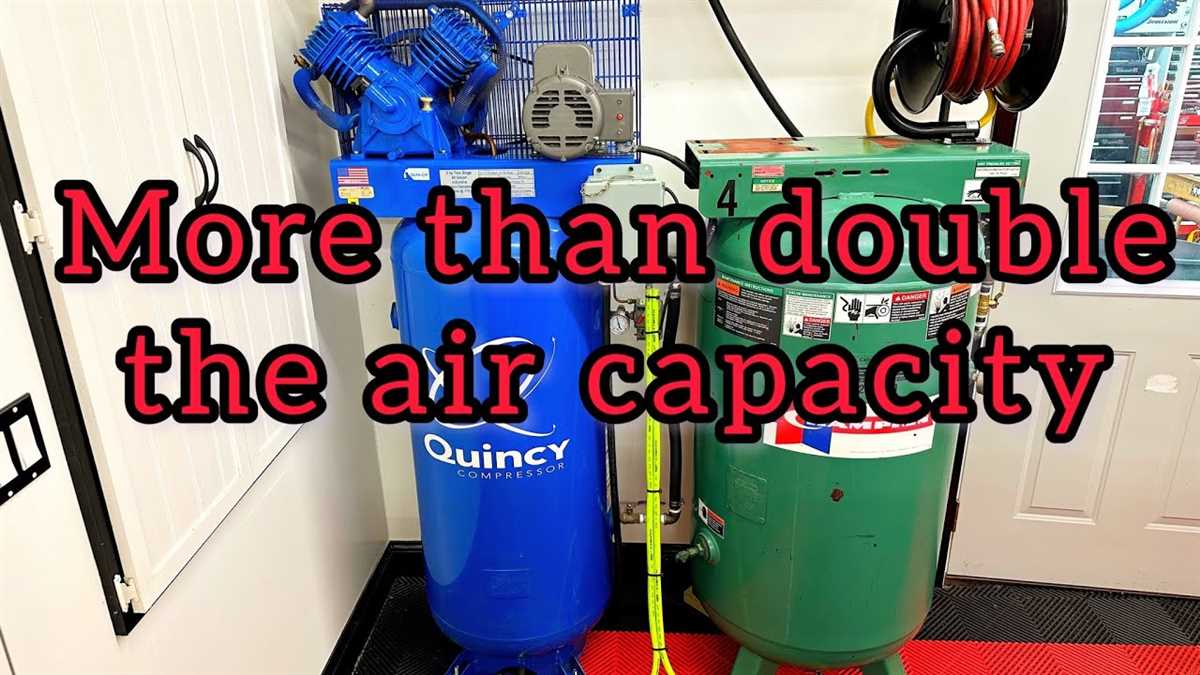

Connecting two air compressor tanks at home can provide you with a larger supply of compressed air, giving you the ability to tackle bigger projects and work for longer periods without interruptions. It can also help to increase the efficiency and performance of your air compressor setup. In this article, we will guide you through the process of connecting two air compressor tanks at home, ensuring a secure and reliable connection.

Before you start, it’s important to gather all the necessary tools and materials. You will need a set of pipe wrenches, Teflon tape, a pressure relief valve, a tee fitting, and a short piece of pipe. It’s also essential to carefully read and follow the manufacturer’s instructions for your specific air compressor model. Safety should always be a priority, so make sure to wear protective eyewear and gloves.

To connect the two air compressor tanks, you will need to carefully remove the existing fittings on both tanks. Using a pipe wrench, loosen the fittings and disconnect them from the tanks. Clean the threads of the tanks and the fittings to ensure a proper seal. Apply Teflon tape to the threads to prevent any air leaks.

Next, install the tee fitting to connect the two tanks together. Apply Teflon tape to the threads of the tee fitting and screw it into one of the tanks. Tighten it securely with a pipe wrench. Attach the pressure relief valve to the top of the tee fitting. This valve is crucial for safety, as it will release excess pressure from the system to prevent any damage or accidents.

Finally, connect the other end of the tee fitting to the second tank using a short piece of pipe. Apply Teflon tape to the threads and tighten securely with a pipe wrench. Once all the connections are properly tightened, turn on the air compressor and test for any air leaks. Adjust the pressure relief valve to the desired setting and check that both tanks are filling and pressurizing evenly.

By following these steps, you can successfully connect two air compressor tanks at home. Remember to always prioritize safety and consult the manufacturer’s instructions for your specific air compressor model. With a larger supply of compressed air, you’ll be able to take on bigger projects with ease and enjoy the increased efficiency and performance of your air compressor setup.

Preparing to Connect Two Air Compressor Tanks

Before connecting two air compressor tanks, it is important to gather all the necessary tools and materials. Here are the steps to prepare for the connection:

1. Turn off the power

Ensure that the power to the air compressor is turned off. This will prevent any accidents or injury while working on the tanks.

2. Gather the tools

Collect all the tools and materials needed for the connection, such as pipe wrenches, Teflon tape, pipe fittings, and a pressure gauge. These tools will be essential in connecting the tanks securely.

3. Drain the tanks

Before connecting the tanks, it is important to drain any air and water from the tanks. This can be done by opening the drain valve on each tank and allowing the air and water to escape completely.

4. Clean the tanks

Inspect the tanks for any debris or obstructions. Clean the tanks thoroughly to ensure a clean and secure connection. This will help prevent any leaks or issues during operation.

5. Measure and mark the connection point

Measure and mark the location where the tanks will be connected. This will ensure an accurate and secure connection. Use a measuring tape and marker to mark the spot.

Following these preparatory steps will help ensure a smooth and successful connection between two air compressor tanks at home.

Choosing the Right Tanks

When connecting two air compressor tanks at home, it is important to choose the right tanks that meet your needs and requirements. There are several factors to consider when selecting the tanks:

1. Size and Capacity

The size and capacity of the tanks will determine the amount of compressed air that can be stored. Consider the amount of air required for your specific applications and choose tanks with sufficient capacity to meet your needs. It is important to ensure that both tanks have similar sizes and capacities to ensure proper operation.

2. Material and Durability

It is crucial to choose tanks made from durable materials that can withstand the pressure and demands of compressed air. Common materials used for air compressor tanks include steel and aluminum. Steel tanks are more durable and can handle higher pressures, while aluminum tanks are lighter and more corrosion-resistant.

3. Pressure Rating

The pressure rating of the tanks needs to be considered to ensure they can handle the pressure produced by the air compressors. Check the maximum pressure rating of the tanks and make sure it is suitable for the compressors you will be using. It is recommended to have tanks with pressure ratings that exceed the maximum pressure output of your compressors for safety reasons.

4. Connection Options

Consider the connection options available on the tanks and ensure they are compatible with the connectors on your air compressors. The tanks should have suitable inlet and outlet ports that can be easily connected to the compressor system. It is important to have a secure and leak-free connection to maintain proper air pressure.

5. Safety Features

Look for tanks that have safety features such as pressure relief valves and pressure gauges. These features help to regulate and monitor the pressure inside the tanks, ensuring safe operation. Pressure relief valves automatically release excess pressure in case of emergencies, while pressure gauges provide visual feedback of the pressure level.

By carefully considering these factors, you can choose the right air compressor tanks that will effectively meet your needs and ensure safe and efficient operation when connecting them at home.

Gathering the Necessary Tools

Before you begin connecting two air compressor tanks at home, it is important to gather all the necessary tools and equipment. Having the right tools on hand will ensure a smooth and efficient installation process. Here are some essential tools you will need:

- A wrench or adjustable wrench for loosening and tightening nuts and bolts.

- Pipe cutter or hacksaw for cutting the pipes to the desired length.

- Flaring tool for creating a smooth and secure connection between the pipes.

- Teflon tape or pipe sealant for ensuring a tight and leak-free seal.

- Measuring tape or ruler to accurately measure the length of the pipes.

- Pipe fittings, such as couplings, elbows, and tees, for connecting the pipes together.

- Pipe clamps or brackets for securing the pipes to the wall or other support structures.

It is important to use high-quality and durable tools to ensure the installation is safe and long-lasting. Investing in good tools will save you time, effort, and money in the long run. Additionally, it is important to wear appropriate safety gear, such as goggles and gloves, to protect yourself during the installation process.

Assembling the Necessary Adapters and Fittings

When connecting two air compressor tanks at home, it is important to have the necessary adapters and fittings to ensure a secure and efficient connection. Here are the steps to assemble the necessary components:

- Identify the type and size of adapters: Measure the diameter of the air outlets on both tanks and determine the appropriate adapters. These adapters will allow you to connect the tanks together.

- Obtain the adapters: Purchase the needed adapters from a local hardware store or online. Make sure to choose adapters that are made of durable materials, such as brass or stainless steel, to withstand the pressure of the air compressor.

- Prepare the tanks: Before installing the adapters, clean the air outlets on both tanks to remove any dirt or debris. This will help ensure a proper seal and prevent leaks.

- Apply thread sealant: Apply a small amount of thread sealant to the threaded ends of the adapters. This will create a tight seal and prevent air from escaping.

- Connect the adapters: Screw the adapters into the air outlets of both tanks, making sure to tighten them securely. Use a wrench or pliers to ensure a tight connection.

- Test for leaks: After connecting the tanks, turn on the air compressor and check for any leaks around the connection points. If there are any leaks, tighten the adapters further or add more thread sealant as needed.

By assembling the necessary adapters and fittings, you can easily connect two air compressor tanks at home and increase your compressed air storage capacity. Just be sure to follow the instructions carefully, and always prioritize safety when working with pressurized air.

Selecting the Proper Adapters

When connecting two air compressor tanks at home, it is essential to select the proper adapters. Adapters are used to join different types or sizes of connections together, ensuring a secure and leak-free connection.

First, it is important to identify the type of connection on each air compressor tank. The most common types of connections include NPT (National Pipe Taper), BSP (British Standard Pipe), and quick-release fittings. Each type requires a specific adapter to connect two tanks together.

Once the type of connection is determined, the next step is to measure the size of the connections. Adapters come in various sizes, such as 1/4 inch, 3/8 inch, or 1/2 inch. It is crucial to measure the diameter of the connections on both tanks to ensure compatibility.

After identifying the type and size of the connections, it is time to select the appropriate adapters. Adapters can be found at hardware stores, home improvement centers, or online retailers. It is recommended to consult with a professional or read product descriptions to ensure the adapters meet the required specifications.

When selecting adapters, it is advisable to choose high-quality materials, such as brass or stainless steel, to ensure durability and longevity. It is also important to consider the pressure rating of the adapters to ensure they can handle the desired airflow between the two air compressor tanks.

In summary, selecting the proper adapters is crucial when connecting two air compressor tanks at home. By identifying the type and size of the connections, and choosing high-quality and compatible adapters, a secure and leak-free connection can be achieved, allowing for efficient and effective operation of the air compressor tanks.

Connecting the Fittings

To connect the fittings between two air compressor tanks, you will need a couple of key components:

- Compression fittings: These fittings are used to connect the pipes or hoses together. Ensure that you have the correct size fittings for your air compressor tanks.

- Teflon tape: Teflon tape is used to create a tight seal between the fittings. Wrap the teflon tape around the threads of the fittings before connecting them.

Here are the steps to connect the fittings:

- Prepare the tanks: Before connecting the fittings, make sure that both air compressor tanks are clean and free from debris. This will ensure a proper connection.

- Apply teflon tape: Take a roll of teflon tape and wrap it around the threads of the fittings in a clockwise direction. Make sure to cover the threads completely to create a tight seal.

- Screw in the fittings: Once the teflon tape is applied, screw in the fittings into the designated ports on each tank. Use a wrench to tighten the fittings securely.

- Check for leaks: After connecting the fittings, it’s important to check for any leaks. Apply a soap and water solution to the connections and look for any bubbles. If bubbles appear, tighten the fittings further or reapply teflon tape if necessary.

By following these steps, you will be able to connect the fittings between two air compressor tanks securely and efficiently. It’s important to ensure that all connections are properly sealed to prevent any air leaks.

Installing the Tanks and Connecting the Air Lines

When installing two air compressor tanks at home, it is important to properly position and secure the tanks before connecting the air lines. Begin by selecting a suitable location for the tanks, ensuring they are placed on a stable surface and have enough space around them for proper ventilation. It is recommended to install the tanks in a well-ventilated area to prevent overheating and ensure optimal performance.

Next, position the tanks at the desired location and secure them in place using mounting brackets or straps. This will help prevent any movement or vibration during operation. Ensure that the tanks are positioned in a way that allows easy access to the air connections.

Once the tanks are securely in place, it’s time to connect the air lines. Start by attaching a shut-off valve to each tank’s outlet port. These valves will allow you to control the flow of air between the tanks. It is important to use shut-off valves that are compatible with the air pressure and size of your compressor system.

After attaching the shut-off valves, connect the air lines to each tank. Use high-quality air hoses and fittings to ensure a secure and leak-free connection. It is recommended to use threaded fittings or quick-connect couplers for easy installation and maintenance.

If connecting the tanks in series, where one tank feeds into the other, connect the air line from the first tank’s outlet port to the second tank’s inlet port. This will allow air to flow from one tank to the other, increasing the overall storage capacity of the system. Make sure to tighten all connections using wrenches or pliers to prevent air leaks.

If connecting the tanks in parallel, where both tanks work independently, connect the air lines from each tank’s outlet port to a manifold or distribution block. This will distribute the compressed air evenly between the tanks and allow them to operate individually. Again, ensure all connections are tightened properly to avoid air leaks.

Once all the air lines are securely connected, turn on the air compressor and check for any leaks. If any leaks are detected, tighten the connections or replace faulty parts as necessary. Regularly inspect and maintain the air lines and tanks to ensure safe and efficient operation.

In conclusion, installing and connecting two air compressor tanks at home requires proper positioning, securing the tanks, and connecting the air lines using shut-off valves, high-quality hoses, fittings, and proper tightening. Following these steps will help create a reliable and efficient compressed air system for various home applications.

Determining the Ideal Location for the Tanks

Before connecting two air compressor tanks at home, it is crucial to determine the ideal location for the tanks. Factors such as accessibility, ventilation, and noise level should be taken into consideration.

1. Accessibility: Choose a location for the tanks that is easily accessible for maintenance and repairs. It should be easy to reach the tanks and perform any necessary tasks such as draining water or replacing filters. This will ensure that the tanks can be properly maintained and serviced.

2. Ventilation: Proper ventilation is important for the safe and efficient operation of the air compressor tanks. Choose a location that allows for adequate airflow to prevent overheating and condensation build-up. Avoid placing the tanks in enclosed spaces or near flammable materials, as this can pose a safety risk.

3. Noise Level: Air compressor tanks can produce significant noise during operation. Consider locating the tanks in an area where the noise will not be disruptive, especially if they will be installed in a residential setting. This could include placing the tanks in a separate room or using soundproofing materials to reduce noise levels.

4. Stability: Ensure that the chosen location provides a stable and secure base for the tanks. The tanks should be placed on a level surface that can support their weight and prevent any shifting or movement during operation. This will help to prevent accidents or damage to the tanks and surrounding area.

By carefully considering these factors and selecting the ideal location for the air compressor tanks, you can ensure their safe and efficient operation in your home. Remember to consult the manufacturer’s guidelines and local regulations to ensure compliance with any specific requirements.

Mounting the Tanks Properly

When connecting two air compressor tanks at home, it is important to mount them properly to ensure safety and efficiency. Here are some steps to follow:

1. Choose a Suitable Location:

Select a suitable location in your home where you plan to mount the air compressor tanks. Make sure it is an area that is well-ventilated and away from any flammable materials. Also, consider the weight of the tanks and ensure that the mounting surface can support them securely.

2. Secure the Tanks:

Use sturdy brackets or mounting plates to secure the tanks to the chosen location. Ensure that the brackets are securely anchored to the wall or floor to prevent any movement or vibrations during operation. It is advisable to use heavy-duty hardware to ensure the tanks are firmly mounted.

3. Connect the Tanks:

Once the tanks are securely mounted, you can proceed with connecting them together. Use appropriate fittings and pipes to connect the tanks in the desired configuration. Make sure to tighten all connections properly to avoid any air leaks.

4. Install Safety Measures:

It is important to install safety measures when connecting two air compressor tanks. This may include pressure relief valves, pressure gauges, and check valves to regulate and monitor the pressure inside the tanks. These safety measures help prevent overpressurization and ensure safe operation.

5. Test and Inspect:

After mounting the tanks and connecting them, it is crucial to test and inspect the setup. Check for any signs of air leaks, loose connections, or abnormal pressure readings. Conduct a pressure test to ensure that the tanks are functioning properly and can hold the desired pressure without any issues.

By following these steps and taking the necessary precautions, you can successfully mount two air compressor tanks at home and create a reliable and efficient compressed air system.

Connecting the Air Lines

In order to connect two air compressor tanks at home, you will need to properly connect the air lines between the two tanks. This step is crucial for ensuring that the compressed air can flow efficiently between the tanks.

1. Determine the type and size of air lines: First, you need to determine the type and size of air lines you will be using to connect the tanks. The size of the air lines will depend on the capacity of your air compressor and the intended use of the tanks. It is recommended to use high-quality steel or aluminum pipes for better durability and performance.

2. Cut and prepare the air lines: Once you have determined the size of the air lines, use a pipe cutter to cut the necessary lengths. Make sure to clean the cut ends and remove any burrs or sharp edges to ensure a secure and leak-free connection.

3. Install fittings and connectors: Next, install fittings and connectors on the ends of the air lines to enable easy connection to the tanks. Depending on the type of air lines you are using, you may need to use compression fittings, push-to-connect fittings, or threaded connectors. Follow the manufacturer’s instructions for proper installation.

4. Connect the air lines: With the fittings and connectors in place, connect one end of the air line to the air outlet of the first tank. Use a pipe wrench or adjustable wrench to secure the connection tightly. Then, connect the other end of the air line to the air inlet of the second tank in the same manner. Double-check that both connections are secure and leak-free.

5. Test and adjust: Once the air lines are connected, it is important to test the system for any leaks. Apply a mixture of soap and water to all connections and check for any bubbles. If you see bubbles forming, tighten the connections as needed. Test the compressed air flow between the tanks to ensure proper functioning of the system.

6. Optional: add a pressure regulator: If desired, you can add a pressure regulator to adjust and control the air pressure between the two tanks. This can be useful for different applications and to ensure that both tanks operate at the desired pressure levels.

By following these steps, you can successfully connect two air compressor tanks at home and create an efficient and reliable compressed air system.

FAQ:

What is an air compressor tank?

An air compressor tank is a storage tank that holds compressed air. It is an essential component of an air compressor system, as it allows for the accumulation and storage of compressed air for later use.

Can I connect two air compressor tanks at home?

Yes, it is possible to connect two air compressor tanks at home. This can be done by using a Y-connector to merge the air lines from both tanks into a single line. However, it is important to ensure that the combined capacity of the tanks does not exceed the maximum working pressure of the compressor system.

What tools do I need to connect two air compressor tanks?

To connect two air compressor tanks, you will need a Y-connector or a T-connector, depending on the configuration you prefer. You will also need appropriate fittings, such as couplings or connectors, to attach the air lines to the tanks. Additionally, you may need plumbing tape or thread sealant to ensure a proper seal.

What are the benefits of connecting two air compressor tanks?

Connecting two air compressor tanks can provide several benefits. Firstly, it increases the overall storage capacity, allowing for a larger volume of compressed air to be stored. This can be especially useful for applications that require a continuous and high volume of compressed air. Additionally, it can help to balance the load on the compressor system and reduce the frequency of cycling, which can prolong the lifespan of the compressor.

Are there any limitations or considerations when connecting two air compressor tanks?

Yes, there are several limitations and considerations to keep in mind when connecting two air compressor tanks. Firstly, the combined capacity of the tanks should not exceed the maximum working pressure of the compressor system. Additionally, the air lines connecting the tanks should be appropriately sized to ensure proper airflow. It is also important to ensure that the tanks are properly drained and maintained to prevent corrosion and other issues.

Can I connect more than two air compressor tanks?

Yes, it is possible to connect more than two air compressor tanks. The process is similar to connecting two tanks, but additional fittings and connectors may be required to accommodate the additional tanks. However, it is important to carefully consider the capacity of the compressor system and ensure that it can handle the increased load.

Are there any alternative methods for increasing the storage capacity of an air compressor system?

Yes, there are alternative methods for increasing the storage capacity of an air compressor system. One common method is to use a larger single tank instead of connecting multiple tanks. Another option is to use auxiliary air storage tanks, which can be connected to the main tank to provide additional storage capacity. Additionally, using a pressure regulator or a demand control system can help optimize the usage of compressed air and reduce the need for additional storage.

Video: