How to Check Your Air Conditioner Compressor

If you’re experiencing issues with your air conditioner, one potential culprit could be a malfunctioning compressor. The compressor is an essential component of your air conditioning system, responsible for pressurizing and circulating the refrigerant that cools the air. Without a properly functioning compressor, your air conditioner may not cool effectively or may fail to turn on at all.

Fortunately, checking your air conditioner compressor is a relatively straightforward process that can be done using a few simple steps. By inspecting the compressor and performing basic troubleshooting techniques, you can determine if the compressor is the source of the problem and take appropriate action to address it.

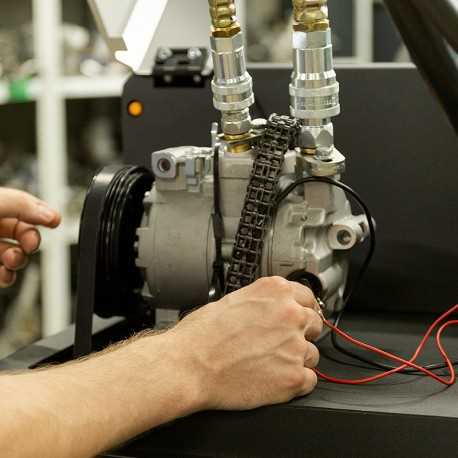

First, visually inspect the compressor to look for any signs of damage or leaks. Pay attention to any oil stains or refrigerant leaks that may indicate a problem. Next, listen for any unusual noises coming from the compressor when the air conditioner is running. Strange or loud sounds such as rattling, screeching, or banging could indicate a mechanical issue with the compressor.

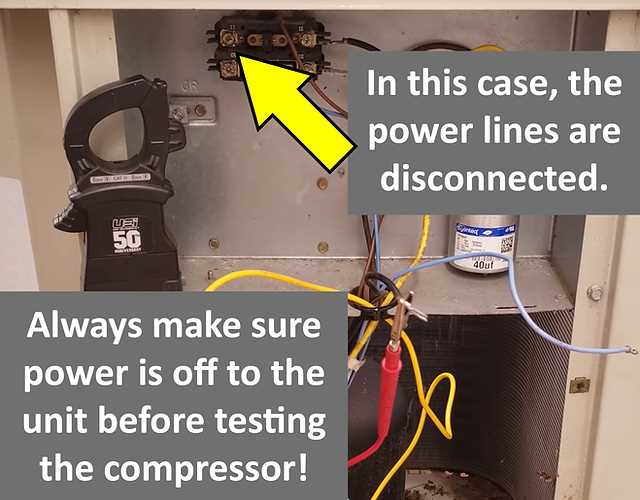

Additionally, check the electrical connections and wiring leading to the compressor. Ensure that all connections are secure and that there are no visible signs of damage or fraying. Faulty or loose electrical connections can cause the compressor to malfunction or fail to start.

If you suspect a problem with your air conditioner compressor and are unsure of how to proceed, it’s always best to consult a professional HVAC technician. They have the knowledge and experience to accurately diagnose and repair compressor issues, ensuring that your air conditioning system operates efficiently and effectively.

Why Checking Your Air Conditioner Compressor is Important

The air conditioner compressor is a vital component of your HVAC system, responsible for pumping refrigerant through the system and transferring heat from inside your home to the outside. Without a properly functioning compressor, your air conditioner will not be able to cool your home effectively. That is why it is crucial to regularly check your air conditioner compressor.

Regularly checking your air conditioner compressor helps identify any potential issues early on, preventing major breakdowns and costly repairs. By inspecting the compressor, you can detect signs of wear and tear, such as worn-out belts, loose connections, or damaged components. Addressing these issues promptly can prolong the life of your compressor and ensure optimal performance.

Checking your air conditioner compressor also allows you to monitor its efficiency. A compressor that is struggling to perform due to clogged filters, low refrigerant levels, or other problems can consume more energy, leading to higher energy bills. By inspecting and maintaining the compressor, you can ensure that it is operating at peak efficiency, saving you money on utility costs.

Furthermore, a malfunctioning air conditioner compressor can have a negative impact on indoor air quality. If the compressor is not working correctly, it may not be able to remove humidity effectively, leading to dampness and mold growth. Regularly checking and maintaining your compressor can help prevent these issues and ensure that your home’s air quality remains healthy and comfortable.

In conclusion, checking your air conditioner compressor is essential for the proper functioning and efficiency of your HVAC system. It helps identify potential issues, ensures optimal performance, and promotes good indoor air quality. Regular maintenance and inspections can save you money on repairs and utility bills in the long run, making it a worthwhile investment of your time and effort.

Signs of a Problematic Air Conditioner Compressor

If your air conditioner is not cooling your home properly, it could be a sign of a problematic compressor. The compressor is an essential component of your AC system that is responsible for pressurizing and refrigerating the refrigerant, which allows the air to cool. When the compressor is not functioning properly, it can result in various issues that affect the overall performance of your air conditioner.

1. Strange Noises: One of the common signs of a problematic compressor is unusual noises coming from the AC unit. If you hear grinding, rattling, or banging noises, it could indicate that the compressor is failing or has internal damage.

2. Warm Air: If your air conditioner is blowing warm air instead of cold air, it could be a symptom of a faulty compressor. This can occur when the compressor is not able to effectively compress the refrigerant and remove heat from the air.

3. Frequent Cycling: When the compressor is not functioning properly, your air conditioner may start to cycle on and off more frequently. This can lead to increased energy consumption and reduced cooling efficiency.

4. High Electric Bills: A problematic air conditioner compressor can also contribute to higher energy bills. When the compressor is not operating efficiently, it requires more energy to cool the air, resulting in increased electricity usage and higher bills.

5. Ice Buildup: If you notice ice buildup on your air conditioner’s refrigerant lines or evaporator coils, it could be a sign of a compressor issue. A faulty compressor can cause refrigerant to accumulate and freeze, leading to reduced airflow and poor cooling performance.

6. Leaking Refrigerant: A compressor problem can also result in refrigerant leaks. If you notice any signs of refrigerant leaking, such as oily spots or hissing sounds, it’s important to have the compressor inspected and repaired as soon as possible.

7. Tripped Circuit Breaker: A failing compressor can put a strain on the electrical system of your air conditioner, causing the circuit breaker to trip. If you experience frequent circuit breaker trips, it may be due to a compressor issue.

If you observe any of these signs, it’s essential to have a professional HVAC technician inspect your air conditioner and diagnose the problem. They can determine if the issue lies with the compressor and provide the necessary repairs or replacement to ensure your AC system works efficiently again.

Tools Required for Checking Your Air Conditioner Compressor

When it comes to checking your air conditioner compressor, there are a few tools that you will need to have on hand. These tools will help you accurately diagnose any issues with your compressor and ensure that it is running at its optimal level. Here are some of the essential tools that you should have:

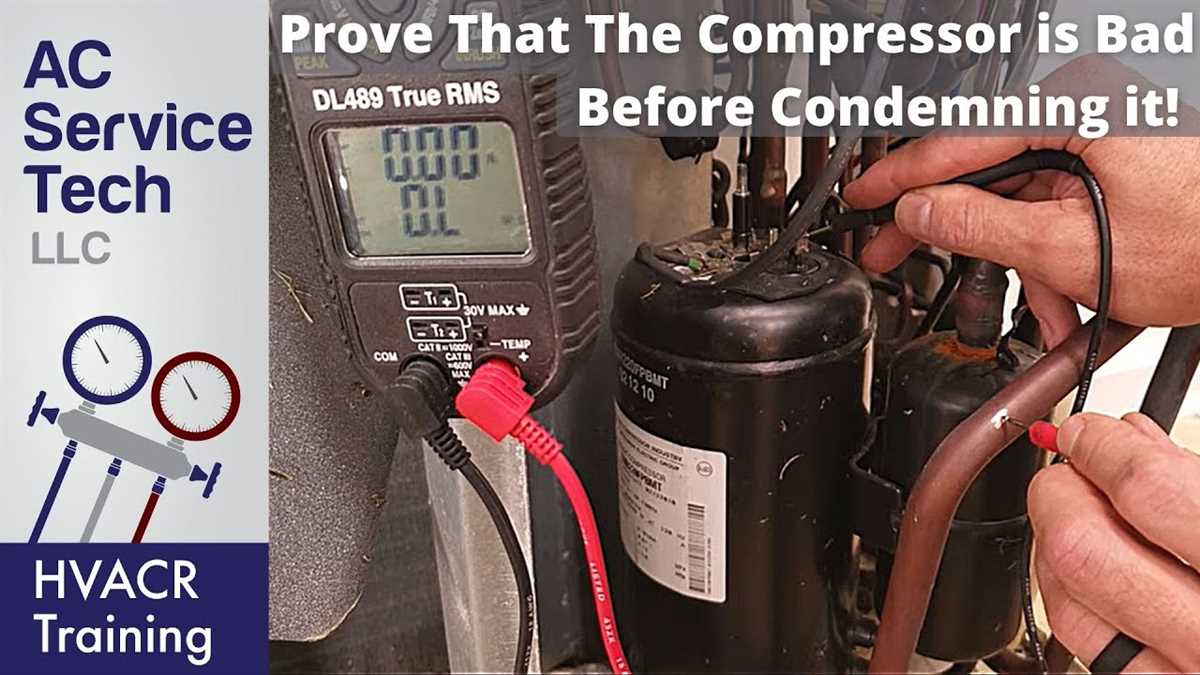

1. Multimeter:

A multimeter is a must-have tool for checking the electrical components of your air conditioner compressor. This device allows you to measure voltage, resistance, and continuity, which are crucial in identifying any electrical issues that may be affecting the compressor’s performance.

2. Pressure Gauge Set:

A pressure gauge set is used to measure the refrigerant pressure in your air conditioner compressor system. This tool provides valuable information about the refrigerant levels in the system and can help identify any leaks or other issues that may be impacting the compressor’s efficiency.

3. Thermometer:

A thermometer is essential for monitoring the temperature of the air conditioner compressor. This tool allows you to check if the compressor is running at the proper temperature, as an overheated compressor can indicate a problem with the cooling system or the compressor itself.

4. Insulation Resistance Tester:

An insulation resistance tester is used to measure the insulation resistance of the motor windings in the air conditioner compressor. This tool helps identify any insulation breakdown or leakage that may be affecting the compressor’s performance and efficiency.

By having these tools on hand, you can effectively check and diagnose any problems with your air conditioner compressor, ensuring that it is working efficiently and effectively to cool your space.

Common Issues Found in Air Conditioner Compressors

1. Refrigerant Leaks

One of the most common issues found in air conditioner compressors is refrigerant leaks. The compressor is responsible for pressurizing and pumping the refrigerant through the system, so any leaks can result in a loss of cooling capacity. Leaks can occur due to faulty valves, worn-out seals, or damaged tubing. It is important to detect and fix refrigerant leaks promptly to ensure efficient operation and prevent further damage to the compressor.

2. Electrical Problems

Electrical issues can also affect the performance of an air conditioner compressor. Common problems include faulty wiring, blown fuses, or a malfunctioning capacitor. These issues can prevent the compressor from receiving the necessary power or cause it to overheat. Regular inspection and maintenance of the electrical components can help identify and resolve any potential issues before they lead to compressor failure.

3. Compressor Motor Failure

The motor in an air conditioner compressor plays a crucial role in powering the compressor. Over time, the motor can wear out or fail due to various reasons, such as overheating, lack of lubrication, or electrical problems. When the motor fails, the compressor may make unusual noises, fail to start, or trip the circuit breaker. In such cases, it is necessary to replace the motor to restore the cooling function of the air conditioner.

4. Dirty Coils

Accumulated dirt and debris on the coils can restrict airflow and cause the compressor to work harder than necessary. This can lead to increased energy consumption, reduced cooling efficiency, and even compressor failure. Regular cleaning of the coils is essential to maintain optimal performance and prevent unnecessary strain on the compressor.

5. Insufficient Lubrication

Lubrication is vital for the proper functioning of the compressor’s moving parts. Insufficient lubrication can result in increased friction, overheating, and premature wear and tear. Regular lubrication of the compressor’s bearings and other moving components can help prevent these issues and prolong the lifespan of the compressor.

Overall, regular maintenance and prompt resolution of any issues that arise are essential for keeping an air conditioner compressor in optimal condition. By addressing common issues like refrigerant leaks, electrical problems, motor failure, dirty coils, and insufficient lubrication, homeowners can ensure their air conditioner operates effectively and efficiently, providing them with cool and comfortable indoor air.

Tips and Tricks to Maintain Your Air Conditioner Compressor

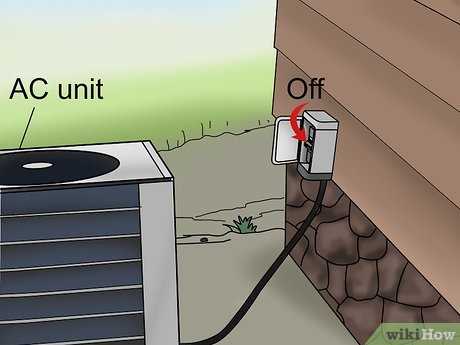

Regularly Clean and Inspect the Outdoor Unit

One of the most important maintenance tasks for your air conditioner compressor is cleaning and inspecting the outdoor unit. Over time, the unit can accumulate dirt, leaves, and other debris, which can obstruct the airflow and reduce its efficiency. To maintain your compressor, make sure to regularly clean the unit using a soft brush or a vacuum cleaner. Additionally, inspect the unit for any visible damage or signs of wear and tear.

Check and Replace the Air Filters

The air filters in your air conditioner help to trap dirt and dust from entering the system. However, over time, the filters can become clogged, reducing the airflow and putting strain on the compressor. To maintain your compressor, check the air filters on a regular basis and clean or replace them as needed. This will not only improve the efficiency of your air conditioner but also prolong the lifespan of the compressor.

Maintain Proper Refrigerant Levels

Refrigerant is a crucial component of your air conditioner compressor, as it helps in the cooling process. If the refrigerant levels are too low or too high, it can put strain on the compressor and lead to performance issues. To maintain your compressor, it is important to periodically check the refrigerant levels and top them up or adjust them as necessary. It is recommended to hire a professional HVAC technician to handle refrigerant-related tasks.

Trim Vegetation Around the Outdoor Unit

Another tip to maintain your air conditioner compressor is to trim any vegetation or plants around the outdoor unit. When vegetation grows too close to the unit, it can obstruct the airflow and reduce the efficiency of the compressor. Regularly trim the plants and ensure that there is at least two feet of clearance around the unit. This will help your compressor to function optimally and prevent any potential damage.

Schedule Regular Maintenance by a Professional

To ensure the proper functioning of your air conditioner compressor, it is advisable to schedule regular maintenance by a professional HVAC technician. They will perform thorough inspections, clean the components, check for any leaks or issues, and make necessary repairs or adjustments. Regular maintenance will not only maintain the efficiency of your compressor but also prevent any major breakdowns or costly repairs in the future.

When to Call a Professional for Air Conditioner Compressor Issues

If you are experiencing issues with your air conditioner compressor, it is important to know when it is time to call a professional for help. While some minor problems can be easily fixed by homeowners, there are certain situations where it is best to leave the job to a trained technician.

Strange Noises

If you notice any strange or loud noises coming from your air conditioner compressor, it is a sign that something is not right. Grinding, squealing, or banging noises could indicate a problem with the compressor motor or the fan blades. These are complex components that require the expertise of a professional to diagnose and repair.

Leaking Refrigerant

If you notice any signs of refrigerant leaking from your air conditioner compressor, it is important to call a professional right away. Refrigerant leaks can not only affect the performance of your air conditioner, but they can also be harmful to your health. A trained technician will be able to identify the source of the leak and safely repair it.

Inconsistent Cooling

If your air conditioner compressor is not consistently cooling your home, it could be a sign of a larger problem. Inconsistent cooling can be caused by issues with the compressor, such as a faulty motor or a clogged refrigerant line. These are complex issues that should be handled by a professional to ensure proper repair and prevent further damage.

Electrical Problems

If you experience any electrical problems with your air conditioner compressor, such as tripped breakers or blown fuses, it is best to leave the repairs to a professional. Working with electricity can be dangerous and requires specialized knowledge. A trained technician will be able to safely diagnose and fix any electrical issues.

In conclusion, when it comes to air conditioner compressor issues, it is always best to err on the side of caution and call a professional. They have the expertise and tools necessary to diagnose and repair complex problems, ensuring the longevity and efficiency of your air conditioner.

FAQ:

What is an air conditioner compressor?

An air conditioner compressor is a vital component of an AC system that is responsible for compressing refrigerant gas and pumping it through the condenser and evaporator coils.

How can I check if my air conditioner compressor is working?

To check if your air conditioner compressor is working, you can start by turning on the AC and listening for any unusual sounds coming from the outdoor unit. You can also check the airflow and the temperature of the air coming out of the vents. If you notice any issues or inconsistencies, it may indicate a problem with the compressor.

Can I visually inspect the air conditioner compressor?

Yes, you can visually inspect the air conditioner compressor by looking for any signs of damage, such as oil leaks, rust, or loose connections. It’s also important to check if the compressor is running and if the fan is turning properly.

How often should I check my air conditioner compressor?

It is recommended to check your air conditioner compressor at least once a year, preferably before the start of the summer season when you will be relying on your AC the most. Regular maintenance and inspection can help prevent major problems and ensure the proper functioning of the compressor.

What should I do if my air conditioner compressor is not working?

If your air conditioner compressor is not working, the first step is to check if the system is receiving power and that the settings are correct. If everything seems fine, you may need to call a professional HVAC technician to diagnose and repair the issue. It’s important not to attempt any repairs yourself, as it can be dangerous and may void the warranty.

How much does it cost to repair an air conditioner compressor?

The cost of repairing an air conditioner compressor can vary depending on the extent of the damage and the specific model of your AC unit. On average, the cost of repairing an AC compressor can range from $500 to $2000. However, it’s important to consult with a professional technician who can provide an accurate estimate based on your specific situation.

Can I prevent compressor issues?

While some compressor issues may be unavoidable, there are steps you can take to minimize the risk and prolong the lifespan of your air conditioner compressor. Regular maintenance and inspection, changing air filters regularly, keeping the outdoor unit clean and free of debris, and ensuring proper airflow can all help prevent compressor issues.

Video: