How to Calculate CFM for Air Compressor: A Complete Guide

When it comes to determining the efficiency and performance of an air compressor, one crucial factor to consider is the CFM, or Cubic Feet per Minute. CFM is a measurement that indicates how much air the compressor can deliver at a given pressure. Whether you’re a DIY enthusiast or a professional, understanding how to calculate CFM for an air compressor is essential for selecting the right tool for your needs.

To calculate CFM, you need to consider a few key variables. The first is the tank size, which determines how much air can be stored. The second factor is the pressure rating, which is usually listed in PSI (Pound per Square Inch). Lastly, the compressor’s horsepower or motor rating plays a significant role in the CFM calculation. By using these variables, you’ll be able to determine how much air the compressor can deliver in a minute.

Calculating CFM for an air compressor can be done using a simple formula. It involves multiplying the tank size by the pressure rating and dividing the result by the compressor’s horsepower. However, it’s important to note that this formula provides an estimate and certain factors, such as air leakage, can affect the actual CFM. Additionally, it’s crucial to consider the application for which you’ll be using the compressor, as different tools and equipment require various CFM levels to operate optimally.

By understanding how to calculate CFM for an air compressor, you’ll be able to make an informed decision when selecting a compressor for your needs. Whether you’re using it for small DIY projects or heavy-duty industrial work, knowing the CFM rating will ensure that you have enough air power to get the job done efficiently. So, before investing in an air compressor, take the time to calculate CFM and choose the right tool for the task at hand.

Understanding CFM (Cubic Feet per Minute)

CFM stands for Cubic Feet per Minute and is a unit of measurement that represents the volume of air that a compressor can deliver or produce in a minute. It is an important metric to consider when choosing an air compressor, as it determines the performance and capabilities of the compressor.

When it comes to air compressors, the CFM rating refers to the airflow capacity of the compressor. It indicates how much air the compressor can provide to power tools or other devices that require compressed air. In simpler terms, the CFM rating tells you how quickly the compressor can fill up a specific volume of space with compressed air.

Calculating CFM involves considering several factors such as the compressor’s horsepower, tank size, pressure, and efficiency. These factors affect the compressor’s ability to deliver a certain volume of air at a specific pressure. As a general rule, a larger compressor with a higher horsepower rating and tank size will have a higher CFM rating.

It’s worth noting that the CFM requirements for different tools and applications can vary. For example, a pneumatic tool may require a certain CFM rating to operate optimally. Failing to provide the necessary CFM may result in reduced performance or even damage to the tool. Therefore, it’s essential to match the CFM rating of the compressor to the requirements of the tools or devices you plan to use.

What is CFM and Why is it Important?

CFM stands for Cubic Feet per Minute, a unit of measurement used to quantify the volume of air flow in a ventilation system or a compressor. It represents the amount of air that can be delivered or consumed by a machine within a minute.

CFM is an important metric to consider when working with air compressors because it determines the capability and efficiency of the machine. The CFM rating of a compressor indicates how much air it can supply to pneumatic tools or other equipment at a given pressure. This information is crucial in order to select the right compressor for a specific task.

When calculating the CFM requirements for an application, several factors need to be taken into account. The specific tools or equipment being used, the required pressure level, and the frequency of usage are all important considerations. Having the correct CFM rating ensures that the compressor will be able to meet the demands of the job efficiently and effectively.

It’s important to note that not all compressors are created equal, and their CFM ratings can vary significantly. Some compressors may have a higher CFM rating but not deliver enough pressure, while others might have sufficient pressure but a lower CFM rating. It’s crucial to find the right balance between CFM and pressure to ensure optimal performance.

In summary, CFM is a key metric in the world of air compressors. It determines the flow rate of air and is crucial in selecting the right compressor for a given application. By understanding the importance of CFM and properly calculating the requirements, you can ensure that your air compressor will deliver the necessary air volume and pressure to get the job done efficiently and effectively.

Factors to Consider When Calculating CFM

When calculating CFM (cubic feet per minute) for an air compressor, there are several important factors to take into consideration. These factors include:

1. Compressor Discharge Pressure

One key factor to consider is the compressor discharge pressure. The CFM output of an air compressor is typically measured at a specific pressure level, commonly 90 PSI (pounds per square inch). It is important to know the desired discharge pressure in order to accurately calculate the required CFM.

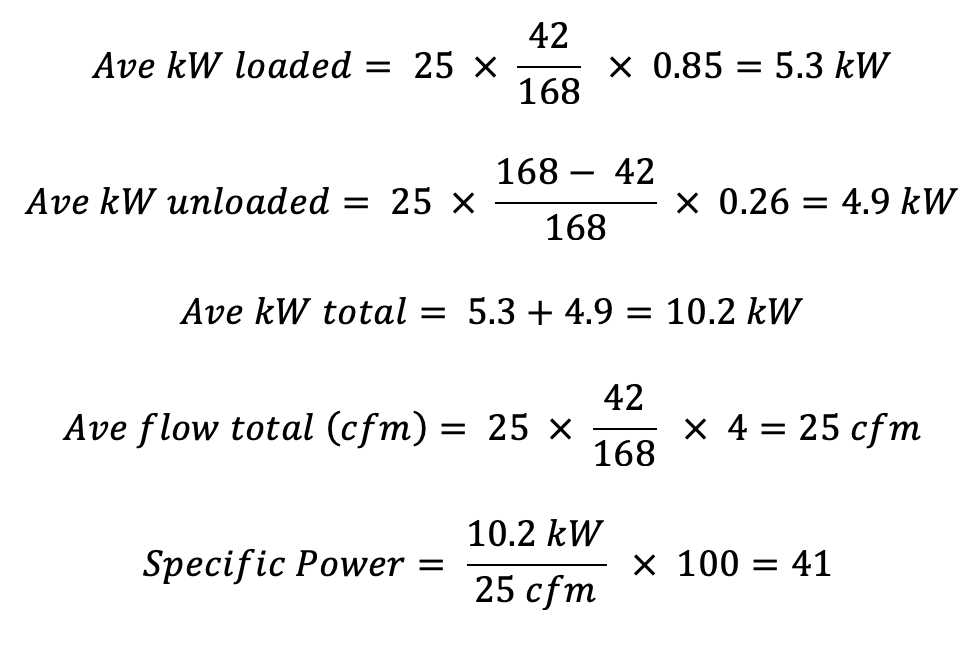

2. Operating Time

The amount of time the air compressor will be operating is another factor to consider. If the compressor will be running continuously, the CFM calculation should be based on continuous usage. However, if the compressor will only be used intermittently or for short durations, the CFM calculation may need to take into account peak usage periods.

3. Tools and Equipment

The type of tools and equipment that will be powered by the air compressor is another important consideration. Different tools and equipment have different CFM requirements. It is essential to determine the CFM requirements of the specific tools and equipment that will be used with the air compressor in order to calculate the required CFM.

4. Air System Losses

Air system losses, such as leaks and pressure drops, can significantly impact the required CFM. It is important to account for these losses when calculating the CFM for an air compressor. By addressing and minimizing air system losses, you can ensure that the compressor is providing the necessary CFM for optimal performance.

5. Ambient Conditions

Ambient conditions, such as temperature and humidity, can also affect the performance of an air compressor and its CFM output. It is important to consider the ambient conditions in the calculation to ensure that the compressor is capable of meeting the required CFM under the specific operating conditions.

6. Safety Factor

Lastly, it is recommended to include a safety factor when calculating CFM. A safety factor accounts for any unforeseen circumstances or variations in usage. By including a safety factor, you can ensure that the air compressor can handle potential fluctuations in CFM requirements without being overworked or strained.

By considering these factors and accurately calculating the required CFM, you can ensure that your air compressor is properly sized for your specific needs and will provide optimal performance.

Determining the Air Requirements of Your Tools

When calculating the CFM (cubic feet per minute) for your air compressor, it is important to accurately determine the air requirements of your tools. This will ensure that your compressor can supply enough air to power them effectively.

Step 1: Identify the tools you plan to use. Make a list of all the tools that you will be using with your air compressor. This could include tools such as air drills, impact wrenches, spray guns, sanders, or any other pneumatic tool.

Step 2: Determine the CFM requirements of each tool. Research or consult the user manual of each tool to find out its CFM requirements. CFM is a measure of the volume of air that the tool requires to operate effectively. This information is typically provided by the manufacturer.

Step 3: Calculate the total CFM requirement. Once you have determined the CFM requirements of each tool, add them up to find the total CFM requirement. This will give you an idea of the minimum CFM capacity that your air compressor should have to power all your tools simultaneously.

Step 4: Consider additional factors. In addition to the CFM requirements of your individual tools, there are other factors to consider when determining the air requirements. These include factors such as the duty cycle of the compressor, the length and diameter of the air hose, and any additional accessories or attachments used with the tools.

Step 5: Choose an air compressor with sufficient CFM capacity. Once you have determined the total CFM requirement, choose an air compressor that can supply the necessary amount of air. It is always recommended to choose a compressor with a slightly higher CFM rating than the total requirement to account for any fluctuations in air demand.

In conclusion, accurately determining the air requirements of your tools is crucial when calculating the CFM for your air compressor. By following these steps and considering all the necessary factors, you can ensure that your compressor can handle the air demand of your tools effectively.

How to Measure CFM of Your Air Compressor

When it comes to determining the CFM (cubic feet per minute) of your air compressor, there are a few steps you can take to get an accurate measurement. CFM is a crucial metric as it determines the amount of air your compressor can deliver to power air tools and equipment effectively.

Step 1: Identify the Intake Method

The first step is to identify whether your compressor uses a single-stage or two-stage intake method. This information can usually be found in the manufacturer’s specifications or documentation. A single-stage intake draws in air once per rotation, while a two-stage intake draws in air twice per rotation. Knowing the intake method will help you determine the compressor’s volumetric efficiency, which is necessary for calculating CFM.

Step 2: Voltage and Motor Horsepower

Next, you need to know the voltage and motor horsepower of your air compressor. This information is typically displayed on the manufacturer’s label or documentation. The motor horsepower directly affects the compressor’s ability to produce CFM. A higher horsepower motor can typically deliver a higher CFM. Additionally, make sure you have access to the appropriate voltage supply for your compressor.

Step 3: Measure Tank Size

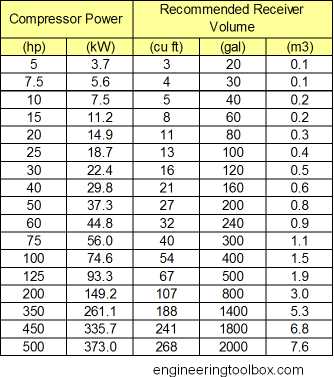

Measure the size of your compressor’s tank in gallons. The tank size is important as it affects the air storage capacity and the duration the compressor can run before needing to refill. Additionally, some calculations require this measurement to determine the CFM accurately.

Step 4: Utilize Manufacturer’s CFM Specifications

Finally, check the manufacturer’s specifications for the CFM rating of your air compressor. The CFM rating provided by the manufacturer is typically based on standardized testing conditions. However, keep in mind that the CFM rating may vary under different operating conditions, such as changes in temperature, pressure, or humidity.

Remember, accurately measuring the CFM of your air compressor is essential for understanding its capabilities and ensuring you have the appropriate amount of airflow for your tools and equipment. Following these steps will help you determine the CFM rating of your air compressor and ensure efficient performance.

Calculating CFM for Multiple Tools

Calculating the CFM (cubic feet per minute) for multiple tools is essential to ensure that your air compressor can handle the demands of your workload. Each tool you plan to use will require a certain amount of CFM to operate effectively. By calculating the total CFM needed for all your tools, you can determine the size and capacity of the air compressor you will need.

1. Identify the CFM requirements

Start by identifying the CFM requirements for each individual tool you plan to use. This information can typically be found in the tool’s user manual or specifications. Make note of the CFM rating for each tool.

2. Determine the simultaneous tool usage

If you plan to use multiple tools at the same time, you need to consider their simultaneous usage. Add up the CFM requirements of the tools that will be used simultaneously. For example, if one tool requires 4 CFM and another requires 5 CFM, the total simultaneous CFM would be 9.

3. Calculate the total CFM needed

Once you have identified the CFM requirements for each tool and determined the simultaneous tool usage, you can calculate the total CFM needed. Add up the CFM requirements of all the tools you plan to use, including any additional CFM needed for simultaneous usage.

4. Choose an air compressor with sufficient CFM capacity

Based on the total CFM needed, you can now choose an air compressor with sufficient capacity. Look for an air compressor that can deliver the total CFM required by your tools. It’s also recommended to choose a compressor with a slightly higher CFM capacity to account for any potential changes or additions to your tool collection.

5. Consider other factors

In addition to CFM, there are other factors to consider when choosing an air compressor for multiple tools. These factors include the tank size, horsepower, and duty cycle. Make sure to research and select an air compressor that meets all your specific requirements, not just the CFM capacity.

By calculating CFM requirements for multiple tools, you can ensure that your air compressor is capable of providing the necessary air supply to operate all your tools effectively and efficiently.

Considering Pressure Drop in CFM Calculation

When calculating CFM for an air compressor, it is important to take into account the pressure drop that occurs in the system. Pressure drop refers to the decrease in pressure that occurs as the air flows through hoses, pipes, fittings, and other components of the compressed air system.

This pressure drop can have a significant impact on the actual CFM delivered by the air compressor. If the pressure drop is not accounted for, the actual CFM delivered may be lower than expected, leading to inefficient operation and potential equipment damage.

To calculate the CFM considering pressure drop, you need to determine the total pressure drop in the system. This can be done by measuring or estimating the pressure drop across each component and adding them together. It is important to use accurate data and consider factors like the length and diameter of the pipes, flow velocity, and fittings used.

Once the total pressure drop is known, you can subtract it from the initial pressure to determine the effective pressure available for the air compressor. This effective pressure can then be used to calculate the CFM using the appropriate formulas or tables for the specific air compressor model.

It is worth noting that pressure drop can vary depending on factors such as the type and condition of the components, the air temperature and humidity, and the desired flow rate. Therefore, it is recommended to regularly monitor and adjust the system to minimize pressure drop and optimize CFM delivery.

Choosing the Right Air Compressor for Your Needs

Determine Your Air Requirements

In order to choose the right air compressor for your needs, it is important to determine your specific air requirements. Consider what tasks you will be using the air compressor for and how much air flow you will need. This will help you determine the necessary cubic feet per minute (CFM) rating of the air compressor.

Consider the Pressure Requirements

Another important factor to consider when choosing an air compressor is the pressure requirements. Different tools and applications require different levels of pressure. Make sure to choose an air compressor with a pressure rating that matches the highest pressure requirement of the tools you will be using.

Think About Portability

If you will be using your air compressor in different locations or need to move it around frequently, portability is a key consideration. Look for a portable air compressor that is lightweight and easy to transport. Consider factors such as size, weight, and the presence of handles or wheels.

Check the Power Source

Air compressors can be powered by different sources, such as electricity or gasoline. Consider the availability and convenience of the power source when choosing an air compressor. If you have access to electricity, an electric air compressor can be a suitable choice. However, if you will be working in remote areas or without access to electricity, a gas-powered air compressor may be more appropriate.

Compare and Research

Before making a final decision, it is important to compare and research different air compressor models. Consider factors such as brand reputation, customer reviews, warranty, and price. Read product specifications and technical details to ensure that the air compressor meets your specific needs and requirements.

By following these guidelines and considering your specific needs, you can choose the right air compressor that will effectively meet your air flow and pressure requirements.

FAQ:

What is CFM and why is it important for an air compressor?

CFM stands for cubic feet per minute, and it is a measure of the volume of air that an air compressor can deliver. It is an important factor to consider when choosing an air compressor because it determines its ability to power air tools and equipment.

How do you calculate CFM for an air compressor?

To calculate CFM for an air compressor, you need to determine the amount of air flow required by your air tools or equipment. This can be done by referring to the manufacturer’s specifications. Once you know the required CFM, you can choose an air compressor that can deliver that amount of air flow.

What are the factors that affect CFM for an air compressor?

There are several factors that can affect the CFM for an air compressor. These include the size of the air tank, the horsepower of the motor, the pressure at which the compressor operates, and the efficiency of the compressor itself.

Can I use a higher CFM air compressor for my air tools?

Yes, you can use a higher CFM air compressor for your air tools. However, it is important to note that using an air compressor with a significantly higher CFM than what your tools require may result in wasted energy and increased operating costs.

How can I increase the CFM of my air compressor?

There are a few ways to increase the CFM of your air compressor. One way is to use a larger air tank, as this allows for more stored compressed air. Another option is to upgrade the motor to one with a higher horsepower rating. Additionally, you can adjust the pressure at which the compressor operates to increase the CFM.

Is it better to have a higher CFM or a higher PSI for an air compressor?

It depends on the application. If you are using air tools that require a high volume of air, such as sanders or spray guns, a higher CFM is more important. On the other hand, if you are using tools that require a high pressure, such as air nailers or impact wrenches, a higher PSI is more crucial.

Video: