How long does it take for an air compressor to fill?

An air compressor is a device that converts power (using an electric motor, diesel or gasoline engine, etc.) into potential energy stored in pressurized air. It works by pulling in air from the surroundings and compressing it to a higher pressure. Air compressors are used in various industries and applications, such as powering pneumatic tools, inflating tires, and operating machinery.

The time it takes for an air compressor to fill depends on several factors, including the size and capacity of the compressor, the initial pressure in the tank, and the desired final pressure. A larger compressor with a higher capacity will generally fill the tank faster than a smaller one. Similarly, if the initial pressure in the tank is lower, it will take longer to fill it to the desired final pressure.

Another factor that affects the filling time is the power source of the air compressor. Electric air compressors tend to fill the tank faster compared to gasoline or diesel-powered compressors. This is because electric compressors can provide a continuous and consistent power supply, while the power output of gasoline or diesel engines may fluctuate.

It’s also important to note that the type of compressor affects the filling time. Reciprocating compressors, which use pistons, usually take longer to fill the tank compared to rotary screw or centrifugal compressors. However, reciprocating compressors are typically more cost-effective and can generate higher pressures, making them suitable for certain applications.

Understanding air compressor fill time

An air compressor is a device that converts power, usually from an electric motor or a gasoline engine, into potential energy stored in pressurized air. Understanding the fill time of an air compressor is crucial for determining its efficiency and performance.

Factors affecting fill time

The fill time of an air compressor can be influenced by several factors:

- Tank size: The size of the air tank plays a significant role in determining the fill time. A larger tank can store more compressed air, resulting in a longer fill time.

- Motor power: The power of the motor or engine driving the air compressor affects the fill time. A more powerful motor can compress the air faster, reducing the overall fill time.

- Pressure requirements: The desired pressure level influences the fill time. Higher pressure requirements will take longer to reach, increasing the fill time.

- Compressor type: Different types of air compressors, such as reciprocating, rotary screw, or centrifugal, have varying fill times due to their design and operating principles.

Calculating fill time

Fill time can be calculated by using the formula: Fill time = (Tank volume ÷ Compressor flow rate) × 60. The tank volume is measured in gallons or liters, while the compressor flow rate is measured in cubic feet per minute (CFM) or liters per minute (LPM).

| Tank volume | Compressor flow rate | Fill time |

|---|---|---|

| 20 gallons | 5 CFM | 8 minutes |

Using this formula, you can estimate the fill time for different air compressor setups and make informed decisions about their usage and efficiency.

Factors affecting the fill time of an air compressor

Several factors can affect the fill time of an air compressor. Understanding these factors can help you optimize the performance and efficiency of your air compressor system.

Air tank size and volume

The size and volume of the air tank can have a significant impact on the fill time of an air compressor. A larger tank can hold more compressed air, allowing the compressor to run for longer periods before needing to refill. This can result in a shorter fill time as the compressor does not need to cycle as frequently.

Compressor size and horsepower

The size and horsepower rating of the compressor also play a crucial role in determining the fill time. A larger compressor with higher horsepower can generate more compressed air per minute, filling the tank faster. It is important to properly match the compressor size to the desired air volume and pressure requirements to ensure optimal fill time.

Air pressure and desired volume

The desired air pressure and volume also impact the fill time. Higher pressure or larger volumes will require more time to fill the tank. It is essential to consider the specific application and air demand when determining the desired pressure and volume to achieve the optimal fill time.

Compressor efficiency and maintenance

The efficiency and maintenance of the compressor can affect the fill time. Regular maintenance, such as cleaning or replacing filters, can improve the airflow and efficiency of the compressor, resulting in shorter fill times. Ensuring that the compressor is properly lubricated and in good working condition can also help optimize fill time.

Pressure regulator and control system

The pressure regulator and control system can influence the fill time by managing the compressor’s start and stop cycles. A well-calibrated pressure regulator and control system will accurately monitor and control the air pressure in the tank, allowing for efficient operation and faster fill times.

Overall, by considering these factors and ensuring proper maintenance and calibration, you can optimize the fill time of your air compressor system, providing more efficient and reliable compressed air for your applications.

Choosing the right air compressor for your needs

Determining air volume and pressure requirements

When selecting an air compressor, it is important to consider your specific air volume and pressure requirements. These requirements will depend on the type of tools or equipment you plan to power with the compressor. For example, if you are planning to use air tools that require a high volume of air, such as a sandblaster or impact wrench, you will need a compressor with a higher CFM (cubic feet per minute) rating. On the other hand, if you only plan to use the compressor for light-duty tasks, a lower CFM rating may be sufficient.

Understanding tank size and duty cycle

The tank size of an air compressor determines how much compressed air it can store. A larger tank size can be beneficial if you require a consistent air supply for longer periods of time or if you have tools that require a continuous flow of air. Additionally, it is important to consider the duty cycle of the compressor, which refers to the amount of time it can operate continuously before needing a rest. If you plan to use the compressor for extended periods, look for a model with a higher duty cycle.

Considering portability and noise level

If you need to move the compressor around frequently or if you have limited space in your working area, consider the portability of the compressor. Look for a model with handles or wheels for easier transport. Additionally, noise level can be a crucial factor, especially if you will be using the compressor in a residential or noise-sensitive area. Check the manufacturer’s specifications for the noise level rating of the compressor to ensure it meets your requirements.

Comparing different types of compressors

There are several types of air compressors available, each with its own advantages and disadvantages. The most common types include reciprocating compressors, rotary screw compressors, and centrifugal compressors. Reciprocating compressors are generally more affordable and suitable for intermittent use, while rotary screw compressors are known for their continuous duty and higher air output. Centrifugal compressors are used for large-scale industrial applications. Determine the type of compressor that aligns with your specific needs and budget.

In conclusion, choosing the right air compressor involves considering your air volume and pressure requirements, understanding tank size and duty cycle, evaluating portability and noise level, and comparing different types of compressors. By taking these factors into account, you can select a compressor that will meet your needs and provide reliable and efficient air power.

Calculating the fill time of an air compressor

Understanding the factors

To calculate the fill time of an air compressor, there are several factors that need to be considered. Firstly, the tank capacity of the compressor plays a crucial role in determining the fill time. The larger the tank, the longer it will take to fill. Additionally, the compressor’s motor horsepower also affects the fill time. A higher horsepower means the compressor can fill the tank faster. The compressor’s CFM (cubic feet per minute) rating is another important factor to consider. A higher CFM rating indicates a faster fill time.

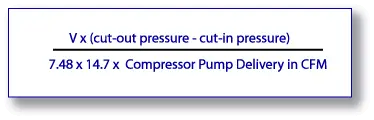

Calculating the fill time

To calculate the fill time, you need to know the tank capacity of the compressor, the motor horsepower, and the CFM rating. Firstly, determine the tank capacity in gallons. Next, find the compressor’s motor horsepower. Then, check the CFM rating of the compressor. Divide the tank capacity by the CFM rating to determine how many minutes it will take to fill the tank to its maximum capacity.

For example, let’s say you have a compressor with a tank capacity of 20 gallons, a motor horsepower of 2, and a CFM rating of 5. To calculate the fill time, divide 20 by 5, which equals 4 minutes. Therefore, it would take approximately 4 minutes for the air compressor to fill its tank to its maximum capacity.

Considerations

It’s important to note that the calculated fill time is an estimate and may vary depending on other factors such as the condition of the compressor, the air pressure settings, and any leaks in the system. It’s always a good idea to consult the manufacturer’s specifications for the compressor to get a more accurate fill time estimate.

Additionally, keep in mind that the fill time may also be affected by the desired air pressure in the tank. If the compressor is set to fill the tank to a higher pressure, it may take longer to reach that pressure compared to a lower pressure setting.

In conclusion, calculating the fill time of an air compressor requires considering factors such as tank capacity, motor horsepower, and CFM rating. By using these values, you can estimate the time it will take for the compressor to fill its tank to its maximum capacity. Remember to consider other factors and consult the manufacturer’s specifications for a more accurate estimate.

Ways to optimize the fill time of an air compressor

1. Increase the airflow: One of the most effective ways to optimize the fill time of an air compressor is to increase the airflow. This can be done by increasing the size of the air intake or installing a more powerful fan. By improving the airflow, the compressor can draw in and compress more air, resulting in a faster fill time.

2. Maintain proper pressure: Another important factor in optimizing fill time is to ensure that the air compressor is operating at its optimal pressure. Regularly check and adjust the pressure settings to ensure that the compressor is not over-pressurizing or under-pressurizing. Proper pressure will ensure efficient filling of the tank, reducing the overall fill time.

3. Minimize air leaks: Air leaks can significantly impact the fill time of an air compressor. Check all connections and fittings regularly for leaks and repair or replace any damaged components. By minimizing air leaks, the compressor can maintain a consistent airflow, resulting in faster filling of the tank.

4. Upgrade to a larger tank: If you have a high demand for compressed air, consider upgrading to a larger tank. A larger tank can store more compressed air, reducing the frequency of fill-ups and decreasing the overall fill time. This is especially useful for applications that require continuous or high-volume use of compressed air.

5. Optimize compressor placement: Proper compressor placement can also contribute to optimizing fill time. Ensure that the compressor is placed in a well-ventilated area, away from heat sources or other equipment that could obstruct airflow. This will allow the compressor to operate at its optimal efficiency, resulting in faster fill times.

6. Regular maintenance: Regular maintenance of the air compressor is essential to ensure optimal performance and minimize fill time. This includes cleaning or replacing air filters, checking and lubricating moving parts, and inspecting the overall condition of the compressor. By keeping the compressor in good working condition, it can operate more efficiently and reduce fill time.

7. Consider a two-stage compressor: For applications that require higher pressure levels, consider upgrading to a two-stage compressor. Two-stage compressors are designed to compress air in two stages, resulting in a higher pressure output. This can significantly reduce the fill time, making it a suitable option for demanding applications.

8. Optimize compressor settings: Adjusting the compressor settings can also help optimize fill time. Fine-tuning parameters such as pressure cut-off and cut-in levels can ensure that the compressor operates within the optimal range, minimizing fill time. Consult the manufacturer’s guidelines or seek professional advice for proper compressor settings.

9. Use proper compressor accessories: Using the right accessories can also contribute to optimizing fill time. Consider using larger diameter hoses and fittings, as well as high-flow connectors and nozzles. These accessories can help improve airflow and reduce any restrictions that could slow down the fill time.

10. Opt for a compressor with faster fill rate: Finally, if optimizing fill time is a top priority, consider investing in a compressor specifically designed for fast fill rates. These compressors are equipped with features such as larger air intakes and higher horsepower motors, allowing for faster compression and filling of the tank.

By implementing these strategies, you can optimize the fill time of your air compressor, improving productivity and efficiency in your compressed air applications.

Common mistakes that can increase fill time

Increasing the fill time of an air compressor can be frustrating, especially when time is of the essence. However, there are several common mistakes that can inadvertently cause the fill time to increase. By avoiding these mistakes, you can ensure a quicker and more efficient fill process.

Inadequate maintenance

Poor maintenance of an air compressor can lead to decreased efficiency and longer fill times. For example, neglecting to regularly clean or replace filters can result in clogged airflow, causing the compressor to work harder and take longer to fill. Similarly, worn-out or improperly calibrated valves and fittings can cause air leaks, reducing the overall fill rate.

Incorrect compressor sizing

Using a compressor that is either too small or too large for the intended application can significantly increase the fill time. An undersized compressor will struggle to supply enough air to fill the desired volume quickly, while an oversized compressor may cycle on and off frequently, wasting energy and extending the time needed to reach the desired pressure.

Inefficient compressed air distribution

Problems in the distribution system can also impact the fill time of an air compressor. For instance, using undersized or clogged air hoses and fittings can restrict airflow, leading to slower fill rates. Additionally, improperly designed or installed distribution pipelines can create pressure drops and turbulence that hinder the flow of air, resulting in longer fill times.

Inadequate compressor placement

The location and placement of the air compressor can affect its fill time. Placing the compressor in a poorly ventilated area or near sources of heat can cause it to overheat more quickly, leading to longer cooling-off periods and overall longer fill times. It is important to ensure that the compressor is properly placed in a well-ventilated area to optimize its performance.

By avoiding these common mistakes, you can minimize the fill time of an air compressor and improve its overall efficiency. Regular maintenance, proper sizing, efficient distribution, and suitable placement are all crucial factors in achieving faster fill times and optimal performance.

Maximizing efficiency during the fill process

1. Optimize air compressor capacity

When choosing an air compressor, it is important to consider its capacity and match it to your specific needs. A larger capacity compressor can fill the desired volume of air more quickly, thus reducing the overall fill time. However, it is important to note that using a compressor with excessive capacity may result in unnecessary energy consumption.

2. Maintain proper compressor maintenance

Regular maintenance and inspections of the air compressor can help ensure its optimal performance during the fill process. It is essential to check and replace any worn-out parts, clean filters, and perform regular oil changes. Neglecting maintenance can lead to decreased efficiency, longer fill times, and potential breakdowns.

3. Optimize air pressure settings

Adjusting the air pressure settings to match the specific requirements of the application can improve efficiency during the fill process. Lowering the air pressure to the minimum necessary level can reduce the time needed to fill the desired volume without compromising the performance of the equipment or the final product.

4. Use efficient air distribution systems

The use of properly sized and efficient air distribution systems can help minimize pressure drops during the fill process. This ensures that the compressed air reaches its intended destination without any unnecessary loss of pressure. Regularly inspecting and maintaining the air distribution system can further optimize its efficiency.

5. Consider storage solutions

In situations where continuous air supply is required, having a storage solution, such as an air receiver tank, can help maximize efficiency during the fill process. The compressor can fill the tank during periods of low demand, and the stored air can be used during peak demand, reducing the overall fill time and strain on the compressor.

By implementing these strategies, it is possible to maximize efficiency during the fill process, reduce fill times, and optimize the overall performance of the air compressor system.

Signs that your air compressor may be taking too long to fill

1. Decreased airflow

If you notice a significant decrease in the airflow from your air compressor, it could be a sign that it is taking too long to fill. This could be due to various factors such as worn-out components, leaks, or inadequate pressure regulation. It is important to address this issue promptly to prevent further damage to the compressor and ensure efficient operation.

2. Extended compressor runtime

If your air compressor is running for longer periods of time than usual to fill up, it may indicate that it is taking too long to reach its maximum pressure. This can be due to issues such as worn-out valves, dirty filters, or insufficient lubrication. Regular maintenance and periodic inspection can help identify and resolve these problems to optimize the compressor’s performance.

3. Unusual noise or vibrations

If your air compressor is producing unusual noises or vibrations during operation, it could be a sign that it is struggling to fill up. These symptoms can indicate problems such as worn-out pistons, damaged bearings, or loose components. Ignoring these signs can lead to further damage and potentially expensive repairs. It is recommended to have a professional inspect and diagnose the issue to ensure safe and efficient operation of the air compressor.

4. Inconsistent pressure levels

When your air compressor takes too long to fill, it may result in inconsistent pressure levels. This can cause fluctuations in the performance of air tools and machinery that rely on a consistent air supply. It is important to monitor the pressure levels and address any inconsistencies promptly to maintain optimal performance and prevent potential damage to equipment.

5. Excessive heat buildup

If your air compressor is taking too long to fill, it can lead to excessive heat buildup within the system. This can be caused by factors such as dirty air filters, inadequate ventilation, or improper lubrication. Excessive heat can negatively impact the compressor’s performance and potentially lead to component failure. Regular maintenance and addressing any issues promptly can help prevent overheating and ensure efficient operation of the air compressor.

Troubleshooting common issues with air compressor fill time

If you are experiencing issues with the fill time of your air compressor, there are several common problems that you can troubleshoot to identify the cause.

1. Check for air leaks

One of the most common reasons for a slow fill time is air leaks in the system. An air leak can cause the compressor to run continuously without filling the tank to its desired pressure. To check for air leaks, listen for any hissing sounds or feel for any air escaping. You can use a soapy water solution to spray around connections and hoses to identify the location of the leak. Once the leak is identified, it can be repaired or replaced to improve the fill time.

2. Inspect the intake filter

A clogged or dirty intake filter can restrict the airflow into the compressor, resulting in a longer fill time. Inspect the intake filter and clean or replace it if necessary. A clean filter ensures proper airflow and can significantly improve the fill time of your compressor.

3. Check the compressor oil

If your air compressor uses oil, the level and condition of the oil can affect its performance. Check the oil level and ensure it is within the recommended range. If the oil is dirty or contaminated, it should be drained and replaced with fresh oil. Proper lubrication is crucial for the efficient operation of the compressor and can help reduce fill time.

4. Evaluate the pressure regulator

The pressure regulator controls the amount of pressure delivered by the compressor. If it is not properly set, it can result in a slower fill time. Check the pressure regulator and adjust it to the desired pressure level. Additionally, ensure that the pressure gauge on the compressor is accurate and calibrated correctly.

5. Consider the compressor capacity

The size and capacity of the air compressor can also affect the fill time. If the compressor is undersized for the intended application, it may take longer to reach the desired pressure. Evaluate the requirements of your specific application and consider upgrading to a larger capacity compressor if necessary.

Conclusion

Troubleshooting the fill time of your air compressor involves identifying and addressing common issues such as air leaks, clogged filters, inadequate lubrication, pressure regulation, and compressor capacity. By following these troubleshooting steps, you can improve the fill time and ensure efficient operation of your air compressor.

FAQ:

How long does it typically take for an air compressor to fill?

The time it takes for an air compressor to fill depends on a few factors, including the size and capacity of the compressor, as well as the pressure required. In general, smaller compressors with lower capacities will take less time to fill compared to larger compressors with higher capacities. Additionally, if you are filling the compressor to a higher pressure, it may take longer. On average, it can take anywhere from a few minutes to several hours to fill an air compressor.

What can affect the time it takes for an air compressor to fill?

Several factors can affect the time it takes for an air compressor to fill. The size and capacity of the compressor play a significant role, with larger compressors generally taking longer to fill. The pressure required also affects the time, as filling the compressor to a higher pressure will take longer. Additionally, the condition of the compressor and its components, such as the valve or tubing, can impact the filling time.

Does the size of the air tank affect the filling time of an air compressor?

Yes, the size of the air tank can affect the filling time of an air compressor. Smaller air tanks will generally fill up faster compared to larger ones, as there is less volume to fill. However, it’s important to note that the size of the air tank is not the only factor that determines the filling time. The capacity of the compressor and the pressure required also play significant roles.

Can the power supply affect how long it takes for an air compressor to fill?

Yes, the power supply can have an impact on the filling time of an air compressor. If the power supply is insufficient or if there are voltage fluctuations, it can affect the efficiency of the compressor motor. This, in turn, can affect the time it takes to fill the compressor. It’s important to ensure that the air compressor is connected to a stable and adequate power supply to optimize its performance.

Is there a way to speed up the filling process of an air compressor?

There are a few ways to potentially speed up the filling process of an air compressor. One option is to use a compressor with a higher capacity, as it can pump more air into the tank in a given time period. Another option is to increase the pressure of the compressor, although this may also increase the risk of overloading the compressor. It’s important to note that these methods should be used within the manufacturer’s recommended guidelines to avoid any damage to the compressor or its components.

Are there any risks associated with filling an air compressor too quickly?

Filling an air compressor too quickly can pose risks to the compressor and its components. Rapid filling can generate excess heat, which may damage the compressor’s motor or other internal parts. It can also put excessive pressure on the tank, leading to leaks or even tank failure. It’s important to follow the manufacturer’s guidelines and recommendations for filling the air compressor and to avoid overloading or overheating the compressor.

Video: