How Does an Air Compressor Regulator Work?

An air compressor regulator is an important component of any air compressor system. It regulates the pressure of the compressed air coming out of the compressor to ensure it is at the desired level for use in various applications.

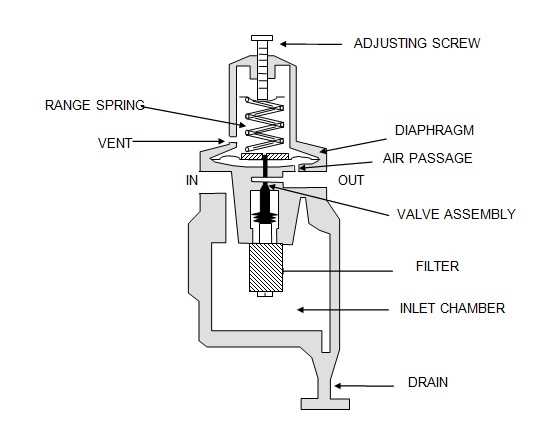

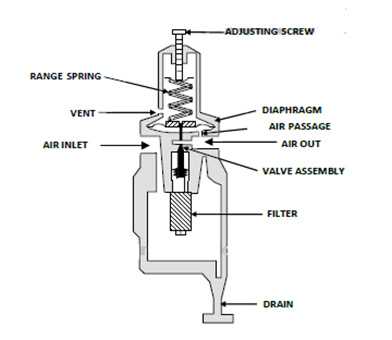

The regulator works by controlling the airflow and pressure through a system of valves and diaphragms. When the compressed air enters the regulator, it passes through a series of chambers and channels. These chambers and channels are designed to divert and control the flow of air, allowing the regulator to adjust the pressure to the desired level.

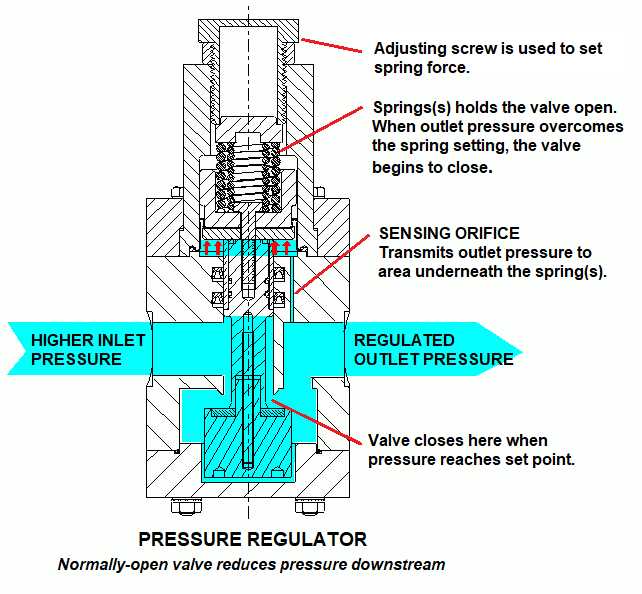

The primary component of an air compressor regulator is the diaphragm. The diaphragm acts as a flexible barrier between the incoming high-pressure air and the outgoing low-pressure air. As the high-pressure air enters the regulator, it pushes against the diaphragm, causing it to move and adjust the position of the valve. This valve then controls the amount of air that is allowed to pass through, restricting or increasing the flow to maintain the desired pressure.

What is an Air Compressor Regulator?

An air compressor regulator is a device that controls and regulates the amount of air pressure coming out of an air compressor. It is an important component in any compressed air system as it allows users to adjust and maintain the desired air pressure for different applications.

Function

The main function of an air compressor regulator is to control the air pressure output from the compressor. It acts as a valve that opens and closes to regulate the flow of air. When the set pressure is reached, the regulator closes to prevent the air pressure from exceeding the desired level.

Components

An air compressor regulator typically consists of several components including a pressure gauge, an adjusting knob, and a diaphragm. The pressure gauge displays the current air pressure, while the adjusting knob allows users to set the desired pressure level. The diaphragm is responsible for regulating the air flow by opening and closing the valve.

Adjusting the Pressure

To adjust the air pressure, users can turn the adjusting knob clockwise or counterclockwise. Turning it clockwise increases the pressure, while turning it counterclockwise decreases the pressure. This allows users to customize the air pressure based on the specific requirements of their application.

Applications

An air compressor regulator is commonly used in various industries and applications where compressed air is needed. It is used in automotive garages, construction sites, manufacturing plants, and many other settings. Different tools and equipment require different air pressure levels, and the regulator ensures that the right pressure is delivered.

Understanding the Role of an Air Compressor Regulator

Introduction

An air compressor regulator is a vital component of an air compressor system. It plays a crucial role in regulating the pressure of the compressed air, ensuring that it is at the desired level for efficient operation of the various pneumatic tools and equipment.

Pressure Control

The main function of an air compressor regulator is to control and maintain the pressure of the compressed air being delivered to the tools or equipment. This is important because different tools and applications require different levels of air pressure to function optimally.

Air compressor regulators are typically equipped with a pressure adjustment knob or dial that allows users to manually set the desired pressure level. This helps to prevent overpressurizing the tools or equipment, which can lead to damage or inefficient operation.

Pressure Relief

In addition to pressure control, air compressor regulators also provide a safety feature known as pressure relief or a pressure release valve. This valve automatically releases excess pressure from the system if it exceeds a certain limit, preventing damage or accidents due to over-pressurization.

The pressure relief valve is usually set at a level slightly higher than the maximum operating pressure of the system. If the pressure exceeds this limit, the valve opens and allows the excess air to escape, bringing the pressure back down to a safe level.

Monitoring and Maintenance

Air compressor regulators often come equipped with pressure gauges that allow users to monitor the pressure levels in real-time. This enables users to make adjustments as needed to ensure consistent and optimal performance of the tools and equipment.

Regular maintenance is also important for air compressor regulators to ensure their proper functioning. This may involve cleaning, lubrication, and periodic calibration to ensure accurate pressure control.

Conclusion

The air compressor regulator plays a critical role in maintaining the desired pressure levels for efficient operation of pneumatic tools and equipment. It allows users to control and adjust the pressure, providing a safe and optimal working environment. Understanding how an air compressor regulator works and properly maintaining it is essential for maximizing the performance and lifespan of the air compressor system.

Components of an Air Compressor Regulator

An air compressor regulator is a vital component in controlling air pressure and ensuring the proper functioning of various pneumatic tools and equipment. It consists of several key components that work together to accurately regulate the air pressure output.

1. Pressure Gauge

The pressure gauge is used to measure and display the air pressure inside the compressor tank. It provides a visual indication of the current pressure level, allowing the user to monitor and adjust it as needed.

2. Adjustment Knob

The adjustment knob is used to control the air pressure output from the compressor. By turning the knob clockwise or counterclockwise, the user can increase or decrease the pressure to the desired level. The knob is typically marked with numerical values to indicate the pressure setting.

3. Diaphragm

The diaphragm is a flexible membrane that moves in response to changes in air pressure. It is located inside the regulator and helps to regulate the airflow. When the pressure exceeds the set limit, the diaphragm pushes against a spring, causing the air to be released and reducing the pressure.

4. Spring

The spring inside the regulator provides the necessary force to push against the diaphragm. It helps to maintain a consistent pressure by compressing or expanding according to the air pressure changes. The tension of the spring can be adjusted to control the overall pressure range.

5. Inlet and Outlet Ports

The inlet and outlet ports are the connections through which air flows into and out of the regulator. The inlet port is where the compressed air enters from the compressor, while the outlet port is where the regulated air is supplied to the pneumatic tools or equipment. The ports are typically threaded to allow for easy connection and disconnection.

Overall, these components work together in an air compressor regulator to provide accurate and consistent air pressure control. By adjusting the pressure setting and monitoring the pressure gauge, users can ensure the optimal performance and safety of their pneumatic systems.

How Does the Air Compressor Regulator Work?

An air compressor regulator is an essential component that helps control the pressure of the air being released from the compressor. It plays a crucial role in maintaining consistent airflow and preventing damage to the tools and equipment being used.

The Basics: The air compressor regulator is typically located near the outlet of the compressor. It consists of a pressure gauge, an adjustment knob, and a valve. The pressure gauge measures the pressure of the air, which is displayed on the gauge dial. The adjustment knob allows the user to control the pressure by increasing or decreasing the setting. The valve, also known as the regulator valve, is responsible for regulating the pressure based on the setting chosen by the user.

Working Principle:

The air compressor regulator works on a simple principle of controlling the flow of air by adjusting the size of the valve opening. When the user turns the adjustment knob clockwise, the valve opening decreases, resulting in a higher pressure. Conversely, turning the knob counterclockwise increases the valve opening, allowing more air to escape and reducing the pressure. This mechanism allows the user to fine-tune the pressure according to the requirements of the tools or equipment being used.

Benefits:

The air compressor regulator offers several benefits. First and foremost, it enables users to operate their tools and equipment at a consistent and safe pressure level. This not only enhances the performance of the tools but also prolongs their lifespan. Additionally, the regulator helps prevent pressure surges or spikes that can occur when starting or stopping the compressor. It also ensures that different tools or equipment connected to the compressor receive the appropriate pressure required for optimal operation.

Usage Tips:

When using an air compressor regulator, it is important to follow a few guidelines. Firstly, always start the compressor with the regulator set at the lowest pressure and gradually increase it as needed. This allows for a smooth startup and prevents sudden pressure surges. Secondly, periodically check the pressure gauge to ensure that the set pressure is maintained. If there are any fluctuations, adjust the regulator accordingly. Lastly, when finished using the compressor, it is advisable to release the air pressure completely before shutting it down to prevent any damage or wear on the regulator and other components.

In conclusion, the air compressor regulator is a crucial component that helps control and maintain the desired pressure for efficient operation of tools and equipment. It works by adjusting the valve opening, enabling users to fine-tune the pressure according to their specific needs. By following the recommended usage tips, users can ensure the longevity and optimal performance of their air compressor and attached devices.

Controlling Air Pressure with an Air Compressor Regulator

Regulating Air Pressure

An air compressor regulator is a device that controls the pressure of the air coming out of the compressor. It allows you to adjust the pressure to the desired level, ensuring that it is not too high or too low for your specific application.

Working Principle

The air compressor regulator works by utilizing a diaphragm and a spring mechanism. As the air flows through the regulator, it presses against the diaphragm, creating a force. This force is balanced by the tension in the spring, which is adjustable.

By turning the adjustment knob, you can change the tension in the spring, thereby changing the amount of force required to balance the diaphragm. This in turn affects the pressure of the air coming out of the regulator.

Pressure Gauge

Most air compressor regulators come with a pressure gauge that shows the current pressure setting. This allows you to easily monitor and adjust the pressure as needed.

The pressure gauge is typically located on the top of the regulator and displays the pressure in pounds per square inch (PSI) or other units of measurement. You can use this gauge to ensure that the pressure is within the desired range for your specific application.

Applications

The use of an air compressor regulator is essential in many applications where precise air pressure is required. It is commonly used in industries such as automotive, manufacturing, and construction.

Some examples of applications that require precise air pressure include pneumatic tools, painting, airbrushing, and inflating tires. By using an air compressor regulator, you can ensure that the air pressure is controlled and consistent, resulting in better performance and efficiency.

Conclusion

An air compressor regulator plays a crucial role in controlling air pressure in various applications. It allows you to adjust the pressure to meet your specific requirements, ensuring optimal performance and safety.

By understanding how an air compressor regulator works and utilizing it correctly, you can achieve accurate and reliable air pressure control for your specific needs.

Benefits of Using an Air Compressor Regulator

1. Pressure Control:

An air compressor regulator allows you to control the pressure of the air that is being released from the compressor. This is particularly useful when different tools and equipment require different levels of air pressure for optimal performance. By adjusting the regulator, you can ensure that the air pressure is set at the appropriate level for the task at hand, preventing damage to your tools and equipment.

2. Efficiency:

Using an air compressor regulator can greatly improve the efficiency of your air compressor system. By regulating the pressure, you can prevent air leaks and wasted energy, ensuring that the compressed air is being used effectively. This can result in lower energy costs and a longer lifespan for your compressor.

3. Consistent Output:

An air compressor regulator helps to maintain a consistent air pressure output, which is crucial for the proper functioning of many tools and equipment. Without a regulator, the air pressure may fluctuate, leading to inconsistent results and potential damage to the tools. With a regulator in place, you can ensure a stable air pressure output, resulting in consistent and reliable performance.

4. Safety:

Using an air compressor regulator can also improve safety in the workplace. By controlling the pressure, you can prevent the air pressure from exceeding the recommended limits, which can be dangerous and potentially cause accidents. Additionally, a regulator can help to prevent sudden bursts of high pressure, reducing the risk of equipment failure or injury.

5. Extended Tool Lifespan:

By adjusting the air pressure to the optimal level for each tool, an air compressor regulator can help prolong the lifespan of your tools. Too high or too low air pressure can cause premature wear and tear or damage to the tools. With a regulator, you can ensure that the air pressure is always set to the manufacturer’s recommended level, helping to preserve the tools and prevent costly replacements.

In conclusion, using an air compressor regulator offers a range of benefits, including pressure control, improved efficiency, consistent output, increased safety, and extended tool lifespan. Investing in a regulator can help optimize the performance of your air compressor system and ensure that your tools and equipment are operating at their best.

Tips for Choosing the Right Air Compressor Regulator

When selecting an air compressor regulator, there are several factors to consider to ensure you choose the right one for your needs. Here are some tips to help guide you in making an informed decision:

Determine the Required Flow Rate

First, you need to determine the required flow rate for your specific application. The flow rate is measured in cubic feet per minute (CFM) and it represents the amount of air that the regulator needs to handle. Be sure to check the flow rate requirements of your tools or equipment to select a regulator that can handle the necessary airflow.

Consider the Operating Pressure Range

Next, you should consider the operating pressure range of the air compressor regulator. The operating pressure range is typically measured in pounds per square inch (PSI) and it represents the range of pressures that the regulator is designed to handle. Make sure the regulator can handle the maximum pressure output of your air compressor without any issues.

Look for Pressure Adjustment Features

Another important consideration is the presence of pressure adjustment features. A good air compressor regulator should offer the ability to adjust the output pressure to match the requirements of your tools or equipment. Look for regulators that have clear and easy-to-use pressure adjustment knobs or buttons.

Consider the Type of Regulator

There are different types of air compressor regulators available, including diaphragm regulators, piston regulators, and modular regulators. Each type has its own advantages and disadvantages, so consider the specific needs of your application to choose the most suitable type of regulator.

Check for Durability and Quality

Finally, check for the durability and quality of the air compressor regulator. It is important to invest in a regulator that is made of high-quality materials and has a solid construction. Look for regulators that are known for their reliability and longevity to ensure you get the most value for your money.

By considering these tips, you can choose the right air compressor regulator that will meet your specific needs and provide you with reliable performance for years to come.

Maintaining and Troubleshooting an Air Compressor Regulator

Regular Cleaning

To ensure optimal performance, it is important to regularly clean the air compressor regulator. Over time, dust, dirt, and other debris can accumulate inside the regulator, which can affect its functionality. To clean the regulator, first, make sure to disconnect it from the air compressor. Then, use a soft brush or cloth to remove any visible dirt or debris. Next, use compressed air or a vacuum cleaner to clean out any remaining particles. Finally, reconnect the regulator and test its performance to ensure it is functioning properly.

Inspecting for Leaks

One common issue with air compressor regulators is leaks. Leaks can occur at various points, such as the connections between the regulator and the air compressor or between the regulator and the air tools. To check for leaks, you can perform a simple test. Start by turning off the air compressor and closing the shut-off valve on the regulator. Then, apply a soapy water solution to the connections and observe for any bubbles. If you see bubbles forming, this indicates a leak and the connection should be tightened or replaced.

Adjusting the Pressure

The air compressor regulator allows you to adjust the pressure of the compressed air that is delivered to your tools. If you are experiencing issues with the air pressure, it may be necessary to adjust the regulator settings. Start by identifying the desired pressure level for your specific application. Use a pressure gauge to measure the current pressure and then turn the adjusting screw on the regulator to increase or decrease the pressure as needed. It is important to make adjustments slowly and carefully, testing the pressure with each adjustment, until the desired pressure level is achieved.

Replacing Worn Parts

If your air compressor regulator is not functioning properly despite regular maintenance and adjustments, it may be necessary to replace worn parts. Over time, certain components of the regulator, such as the diaphragm or springs, can wear out and become less effective. Before replacing any parts, it is recommended to consult the manufacturer’s instructions or seek professional assistance to ensure the correct replacement parts are used and the regulator is properly reassembled.

Seeking Professional Help

If you are experiencing persistent issues with your air compressor regulator or are unsure how to properly maintain or troubleshoot it, it is always best to seek professional help. Air compressor regulators can be complex devices, and attempting to repair or modify them without proper knowledge or experience can be dangerous. A professional technician can diagnose any issues, perform necessary repairs or replacements, and ensure that your air compressor regulator is working safely and efficiently.

FAQ:

What is an air compressor regulator and what does it do?

An air compressor regulator is a device that controls and regulates the air pressure that is delivered by the compressor. It ensures that the pressure remains within a specific range, as required for the intended application.

How does an air compressor regulator work?

An air compressor regulator works by using a diaphragm and a spring to control the flow of compressed air. When the pressure exceeds the desired level, the diaphragm is pushed against the spring, closing off the air flow and reducing the pressure. When the pressure drops below the desired level, the diaphragm moves away from the spring, allowing more air to flow through and increasing the pressure.

Can an air compressor regulator be adjusted?

Yes, an air compressor regulator can be adjusted. Most regulators have a knob or dial that allows the user to set the desired pressure range. This allows for flexibility in different applications and ensures that the pressure is always within the required limits.

Why is it important to have an air compressor regulator?

Having an air compressor regulator is important because it helps to maintain a consistent and controlled air pressure. This is crucial for many applications, such as powering pneumatic tools, operating machinery, or providing a steady air supply for various processes. Without a regulator, the pressure could fluctuate too much, leading to inefficient or even dangerous operation.

How can I tell if my air compressor regulator is not working properly?

If you suspect that your air compressor regulator is not working properly, there are a few signs to look out for. These include inconsistent pressure, excessive or insufficient pressure, or leaking air. If you notice any of these issues, it may be necessary to have your regulator inspected or replaced.

Can an air compressor regulator be used for other gases or fluids?

No, an air compressor regulator is specifically designed for controlling the pressure of compressed air. Using it for other gases or fluids could result in inaccurate pressure regulation and potential damage to the regulator. It is important to use the appropriate regulator for the specific type of gas or fluid being used.

Are there different types of air compressor regulators?

Yes, there are different types of air compressor regulators available on the market. Some common types include relieving regulators, non-relieving regulators, proportional regulators, and filter regulators. Each type has its own specific features and applications, so it is important to choose the right one for your needs.

Video: