DIY Vacuum Pump: How to Make It Using an Air Compressor

Are you in need of a vacuum pump but don’t want to spend a fortune on buying one? Look no further, because we have the perfect solution for you! In this article, we will show you how to make your very own vacuum pump using an air compressor. With just a few simple steps and some readily available materials, you can create a powerful and effective vacuum pump that will meet all your needs.

The first step in making your DIY vacuum pump is to gather all the necessary materials. You will need an air compressor, a vacuum chamber, a vacuum gauge, and some tubing. The air compressor will serve as the main component, providing the necessary suction force. The vacuum chamber will house the material or object you want to extract air from. The vacuum gauge will help you monitor the pressure inside the chamber, while the tubing will connect all the components together.

Once you have gathered all the materials, the next step is to assemble your DIY vacuum pump. Start by attaching the tubing to the air compressor and the vacuum chamber. Make sure the connections are secure and airtight to avoid any leaks. Then, connect the vacuum gauge to the chamber, allowing you to monitor the pressure. Test the connections by turning on the air compressor and checking if the gauge registers any changes in pressure.

Now that your DIY vacuum pump is assembled, it’s time to put it to the test. Place the material or object you want to extract air from inside the vacuum chamber. Close the chamber tightly to create a sealed environment. Turn on the air compressor and let it run for a few minutes. As the air compressor creates suction, it will slowly remove the air from the chamber, creating a vacuum. Monitor the pressure gauge to ensure it reaches the desired level.

In conclusion, making your own vacuum pump using an air compressor is a cost-effective and practical solution. With just a few simple steps, you can create a powerful vacuum pump that will meet all your needs. Whether you need it for scientific experiments, woodworking projects, or any other application, this DIY vacuum pump will not disappoint. So why wait? Start gathering your materials and enjoy the benefits of a homemade vacuum pump!

What is a DIY Vacuum Pump?

A DIY vacuum pump is a device that is created by an individual using accessible materials and an air compressor to create a vacuum. This innovative solution is an alternative to purchasing a commercial vacuum pump, which can be expensive.

With a DIY vacuum pump, users can remove air or other gases from a sealed container or space, creating a lower pressure environment. This can be useful in a variety of applications, such as science experiments, woodworking, and even automotive repairs.

A DIY vacuum pump typically consists of an air compressor, a container or chamber, and various valves and fittings to control the flow of air. By connecting the air compressor to the container, the user can create a vacuum by removing the air from within the chamber.

There are several benefits to creating a DIY vacuum pump:

- Cost-effective: By using readily available materials and tools, individuals can save money by creating their own vacuum pump instead of purchasing one.

- Customizable: A DIY vacuum pump allows users to customize the design and specifications according to their specific needs and requirements.

- Education: Building a vacuum pump from scratch is a great educational opportunity to learn about the principles of vacuum technology and mechanical systems.

While a DIY vacuum pump may not have the same level of performance or durability as a commercial pump, it can still be a practical and cost-effective solution for many applications.

Understanding the Basics of a Homemade Vacuum Pump

A vacuum pump is a device used to create a partial vacuum by removing air or other gases from a sealed space. It is often used in various industries and applications, such as scientific research, manufacturing, and automotive maintenance. While there are commercially available vacuum pumps, it is also possible to build one at home using an air compressor.

How does a homemade vacuum pump work?

To understand the basics of a homemade vacuum pump, it is essential to know how an air compressor functions. An air compressor works by compressing air and then releasing it with force. In the case of a homemade vacuum pump, the air compressor is used to create a vacuum by sucking air out of a sealed container.

Components required for a homemade vacuum pump:

- Air Compressor: The air compressor is the main component of a homemade vacuum pump. It should have sufficient power to create a vacuum by effectively removing air from the system.

- Vacuum Chamber: The vacuum chamber is the container where the air is sucked out to create a vacuum. It should be airtight and made of a non-porous material such as glass or metal.

- Check Valve: The check valve is a one-way valve that allows air to flow in only one direction. It prevents the backflow of air into the vacuum chamber once it has been removed.

- Tubing and Connectors: Tubing and connectors are used to connect the air compressor to the vacuum chamber and the check valve. They should be airtight to avoid any leaks.

Assembly and operation:

To assemble a homemade vacuum pump, start by connecting the tubing to the air compressor and the check valve. Then, connect the other end of the tubing to the vacuum chamber. Make sure all connections are tight and secure to prevent any air leaks.

Once the homemade vacuum pump is assembled, turn on the air compressor and allow it to start sucking air out of the vacuum chamber. As the air is removed, a partial vacuum is created, lowering the pressure inside the chamber. This can be measured using a vacuum gauge.

Applications of a homemade vacuum pump:

A homemade vacuum pump can be utilized in various DIY projects and applications. It can be used for degassing liquids, creating a vacuum for scientific experiments, or even as a component in a homemade vacuum-forming machine. However, it is important to use caution and ensure proper safety measures when working with a homemade vacuum pump.

In conclusion, understanding the basics of a homemade vacuum pump is essential for anyone looking to build one using an air compressor. By knowing how it works and the required components, one can assemble and operate a homemade vacuum pump for various applications.

Why Make a DIY Vacuum Pump?

There are several reasons why you might want to make your own DIY vacuum pump using an air compressor. One of the main reasons is cost-saving. Buying a ready-made vacuum pump can be quite expensive, especially if it is for occasional use or for a specific project. Making your own vacuum pump allows you to save money by using materials that you may already have on hand or that are easily accessible and affordable.

Another reason to make a DIY vacuum pump is customization. By building your own vacuum pump, you have the flexibility to customize it to your specific needs and requirements. You can choose the size, power, and capacity of the pump based on your intended applications. This level of customization can be especially useful if you have unique or specialized projects that require a specific vacuum level or flow rate.

Additionally, making a DIY vacuum pump can be a fun and educational project. It allows you to learn about the principles of vacuum technology and how different components work together to create suction. It can also give you a sense of accomplishment and satisfaction when you successfully build and test your own vacuum pump.

Furthermore, having a DIY vacuum pump can be a useful tool to have in your workshop. It can be used for a variety of applications such as degassing liquids, vacuum forming, vacuum packing, or even as a central vacuum system for your workshop. Having a vacuum pump on hand can open up new possibilities for your projects and make certain processes more efficient and effective.

In summary, making a DIY vacuum pump offers cost-saving benefits, customization options, educational opportunities, and practical uses in various applications. Whether you are a hobbyist, a DIY enthusiast, or a professional, building your own vacuum pump can be a rewarding and worthwhile endeavor.

Step-by-Step Guide: Making a Vacuum Pump Using an Air Compressor

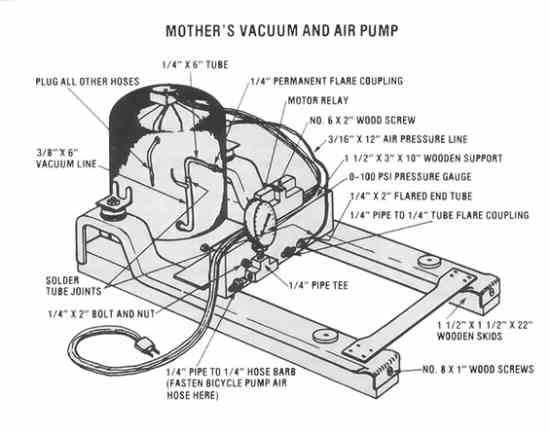

1. Gather the Necessary Materials:

Before you begin, make sure you have all the materials required to make your DIY vacuum pump using an air compressor. You will need an air compressor, a pressure regulator, a pressure gauge, a check valve, a vacuum pump oil, and some piping fittings.

2. Assemble the Air Compressor:

Start by setting up the air compressor. Connect the pressure regulator to the air compressor outlet and then attach the pressure gauge to the regulator. This will allow you to control and monitor the air pressure during the vacuum pump operation.

3. Install the Check Valve:

Next, install the check valve on the compressor outlet. The check valve prevents the backflow of air from the pump into the compressor. This is crucial for maintaining the vacuum pressure during operation.

4. Connect the Piping Fittings:

Now, connect the piping fittings to the check valve. Use a combination of straight and elbow fittings to create a proper airflow path. Ensure that the fittings are tightly secured to prevent any air leaks.

5. Add the Vacuum Pump Oil:

Before starting the vacuum pump, add the vacuum pump oil to its designated oil reservoir. Consult the manufacturer’s instructions to determine the appropriate amount of oil required. The oil will lubricate the pump and help maintain its effectiveness.

6. Start the Vacuum Pump:

Once everything is set up, turn on the air compressor and adjust the pressure regulator to the desired level. The vacuum pump will start creating a vacuum by drawing air out of the system. Monitor the pressure gauge to ensure it is within the desired range.

7. Test the Vacuum Pump:

To test the efficiency of your DIY vacuum pump, you can use a vacuum gauge or a vacuum chamber. Place the gauge or the chamber in the system and observe the pressure readings. A properly functioning vacuum pump should be able to achieve and maintain the desired vacuum level.

8. Maintain and Monitor:

Regularly check the vacuum pump oil levels and replace it when necessary. Monitor the pressure gauge during operation to ensure the vacuum pump is functioning effectively. Address any air leaks or issues with the pump promptly to maintain optimal performance.

9. Safety Precautions:

When working with an air compressor and vacuum pump, always wear appropriate safety gear such as goggles and gloves. Follow the manufacturer’s instructions and safety guidelines to avoid accidents or injuries.

With this step-by-step guide, you can successfully create a vacuum pump using an air compressor. Remember to prioritize safety and regularly maintain your pump to ensure its longevity and efficiency.

Choosing the Right Air Compressor for Your DIY Vacuum Pump

When building a DIY vacuum pump using an air compressor, it is important to choose the right air compressor for your project. The air compressor you select will determine the effectiveness and efficiency of your vacuum pump, so it is crucial to make an informed decision.

First, consider the CFM (cubic feet per minute) rating of the air compressor. The CFM rating indicates the volume of air the compressor can deliver per minute. For a vacuum pump, you will need an air compressor with a higher CFM rating to generate sufficient suction power. Look for an air compressor with a CFM rating that matches the requirements of your DIY vacuum pump.

Next, pay attention to the PSI (pounds per square inch) rating of the air compressor. The PSI rating determines the pressure at which the air is delivered. While the PSI rating may not be as critical as the CFM rating for a vacuum pump, it is still important to select an air compressor with a suitable PSI rating. A higher PSI rating can provide more consistent pressure, which can help improve the performance of your vacuum pump.

Noise level is another factor to consider when choosing an air compressor. Since your DIY vacuum pump may be used indoors, it is essential to select an air compressor with a noise level that is acceptable for your environment. Look for air compressors that have low noise ratings or come with noise-reducing features to ensure a quieter operation.

Additionally, consider the size and portability of the air compressor. Depending on your workspace and mobility needs, you may want to choose a compact and lightweight air compressor that is easy to move around. Look for air compressors with built-in handles or wheels for added convenience.

Finally, keep your budget in mind when selecting an air compressor. Determine how much you are willing to spend and compare the prices of different models. While it is important to choose a quality air compressor, there may be options available that meet your requirements without breaking the bank.

In conclusion, selecting the right air compressor is crucial for building an effective DIY vacuum pump. Consider factors such as CFM and PSI ratings, noise level, size, portability, and budget to make an informed decision. By choosing the right air compressor, you can ensure the success of your DIY vacuum pump project.

Tips and Tricks for Making the Perfect DIY Vacuum Pump

When creating your own DIY vacuum pump using an air compressor, there are several tips and tricks that can help you achieve the perfect results. These tips will ensure that your vacuum pump functions efficiently and effectively.

1. Choose the right air compressor:

Selecting the appropriate air compressor for your DIY vacuum pump is crucial. Look for a compressor with a high CFM (cubic feet per minute) rating to ensure that it can provide sufficient airflow for creating a strong vacuum. Additionally, consider the tank size and motor power to ensure optimal performance.

2. Use a reliable vacuum chamber:

Invest in a high-quality vacuum chamber to ensure the success of your DIY vacuum pump. A reliable vacuum chamber will ensure a tight seal and prevent air leaks, allowing you to achieve the desired level of vacuum pressure. It should be made of durable materials such as stainless steel or acrylic to withstand the pressure.

3. Use proper sealing materials:

To create an airtight seal, it is important to use the right sealing materials. Silicone gaskets or O-rings are commonly used for sealing vacuum systems. These materials are flexible and can withstand the negative pressure created by the vacuum pump without deforming or leaking.

4. Regularly check for air leaks:

Air leaks can significantly reduce the efficiency of your DIY vacuum pump. Regularly inspect all connections, seals, and fittings for any signs of leakage. Apply a soapy water solution to these areas and look for bubbles, which indicate air leaks. Repair or replace any faulty components to ensure optimal performance.

5. Monitor the vacuum pressure:

It is important to carefully monitor the vacuum pressure during operation to ensure that it stays within the desired range. Use a vacuum gauge or a digital pressure monitor to track the pressure levels. Adjust the airflow or sealing as needed to maintain the desired vacuum pressure.

By following these tips and tricks, you can create a DIY vacuum pump using an air compressor that will provide reliable and efficient vacuum pressure for your various projects and applications.

Applications and Benefits of a Homemade Vacuum Pump

A homemade vacuum pump, made using an air compressor, offers a range of applications and benefits. Whether you are a DIY enthusiast or a professional in need of a budget-friendly option, a homemade vacuum pump can be a useful tool in various fields. Let’s explore some of the applications and benefits of this DIY device.

1. Vacuum sealing food

One of the primary applications of a homemade vacuum pump is in the kitchen. By using a vacuum sealer, you can extend the shelf life of food items by removing air and creating an airtight seal. This can help prevent spoilage, reduce food waste, and save you money in the long run.

2. Scientific experiments

A homemade vacuum pump can also be utilized for scientific experiments and research. By creating a vacuum environment, scientists can study various phenomena such as gas behavior, chemical reactions, and even simulate space conditions. This DIY solution provides an affordable option for conducting experiments without the need for expensive laboratory equipment.

3. Electronics and electrical work

When working with electronics or electrical systems, a homemade vacuum pump can be a valuable tool. It can help remove trapped air from components or systems, ensuring proper functioning and preventing damage. This is particularly useful when working with delicate devices like computer chips or circuit boards.

4. Automotive maintenance

Automotive enthusiasts can also benefit from a homemade vacuum pump. It can be used for tasks such as bleeding brakes, testing for vacuum leaks, or removing trapped air from power steering systems. Having a DIY vacuum pump on hand can save you time and money by allowing you to perform these maintenance tasks yourself.

5. General household tasks

Aside from specific applications, a homemade vacuum pump can also be helpful in everyday household tasks. For example, it can aid in unclogging drains by creating suction, or be used as a makeshift vacuum cleaner for small areas or tight spaces. Its versatility makes it a useful addition to any DIY toolkit.

In conclusion, a homemade vacuum pump made with an air compressor has numerous applications and benefits. From extending the shelf life of food to conducting scientific experiments or performing automotive maintenance, this DIY device offers a cost-effective solution for various tasks. Its versatility and affordability make it a worthwhile addition to your toolbox.

Safety Measures to Consider When Using a DIY Vacuum Pump

1. Wear Proper Protective Equipment

When operating a DIY vacuum pump, it is crucial to wear the appropriate protective equipment to ensure your safety. This may include safety glasses or goggles to protect your eyes from any potential debris or splashing liquids. Additionally, wearing gloves can protect your hands from any sharp objects or chemicals that may be involved in the process.

2. Work in a Well-Ventilated Area

It is important to carry out the operation of a DIY vacuum pump in a well-ventilated area. This will help to ensure that any potentially harmful fumes or gases that are generated during the process can disperse safely. If working indoors, make sure windows or doors are open or use a ventilation system to remove any hazardous substances from the air.

3. Follow Proper Electrical Safety Guidelines

When using a DIY vacuum pump that is powered by electricity, it is essential to follow electrical safety guidelines. Ensure that the power source is properly grounded and that all electrical connections are secure. Avoid using extension cords or adapters unless they are specifically designed for the equipment being used.

4. Handle Chemicals Safely

If the DIY vacuum pump involves the use of chemicals, it is important to handle them safely. Read and follow all instructions and warnings provided by the chemical manufacturer. Wear appropriate protective clothing and gloves when handling chemicals, and make sure to store them properly in a well-ventilated area away from any potential ignition sources.

5. Regularly Inspect and Maintain the Equipment

To ensure the safe operation of a DIY vacuum pump, it is important to regularly inspect and maintain the equipment. This includes checking for any signs of damage or wear and tear, and promptly repairing or replacing any faulty components. Regularly clean and lubricate the equipment as instructed in the user manual to keep it functioning properly.

By following these safety measures, you can reduce the risk of accidents and injuries when using a DIY vacuum pump. Remember to always prioritize safety and take necessary precautions to protect yourself and others throughout the process.

FAQ:

What is a vacuum pump?

A vacuum pump is a device used to create a partial vacuum in a sealed container by removing air or gas molecules from it.

Can I make a vacuum pump using an air compressor?

Yes, you can make a vacuum pump using an air compressor. It involves modifying the air compressor to create suction and removing the moisture trap and lubricator.

What tools and materials do I need to make a DIY vacuum pump?

To make a DIY vacuum pump, you will need an air compressor, a pressure regulator, a vacuum gauge, PVC pipe and fittings, a ball valve, and epoxy or Teflon tape for sealing.

What are the benefits of making a DIY vacuum pump?

Making a DIY vacuum pump is a cost-effective solution compared to buying a commercial vacuum pump. It allows you to use readily available materials and customize the pump according to your specific needs.

How does a DIY vacuum pump work?

A DIY vacuum pump works by creating suction through the modified air compressor. The air compressor draws air out of the sealed container, creating a vacuum. The vacuum gauge helps in monitoring the level of vacuum achieved.

Video: