Connecting an Air Compressor to a Hose Reel: Step-by-Step Guide

When it comes to using an air compressor, one of the essential components is a hose reel. A hose reel allows you to easily access and use your air compressor while keeping the hose neatly organized and tangle-free. In this step-by-step guide, we will walk you through the process of connecting an air compressor to a hose reel, ensuring you have a smooth and efficient setup.

The first step in connecting an air compressor to a hose reel is selecting the right hose for your needs. It is important to choose a hose that is compatible with both your air compressor and hose reel. Look for a hose that has the right length and diameter, as well as the appropriate pressure rating to handle the air compressor’s output.

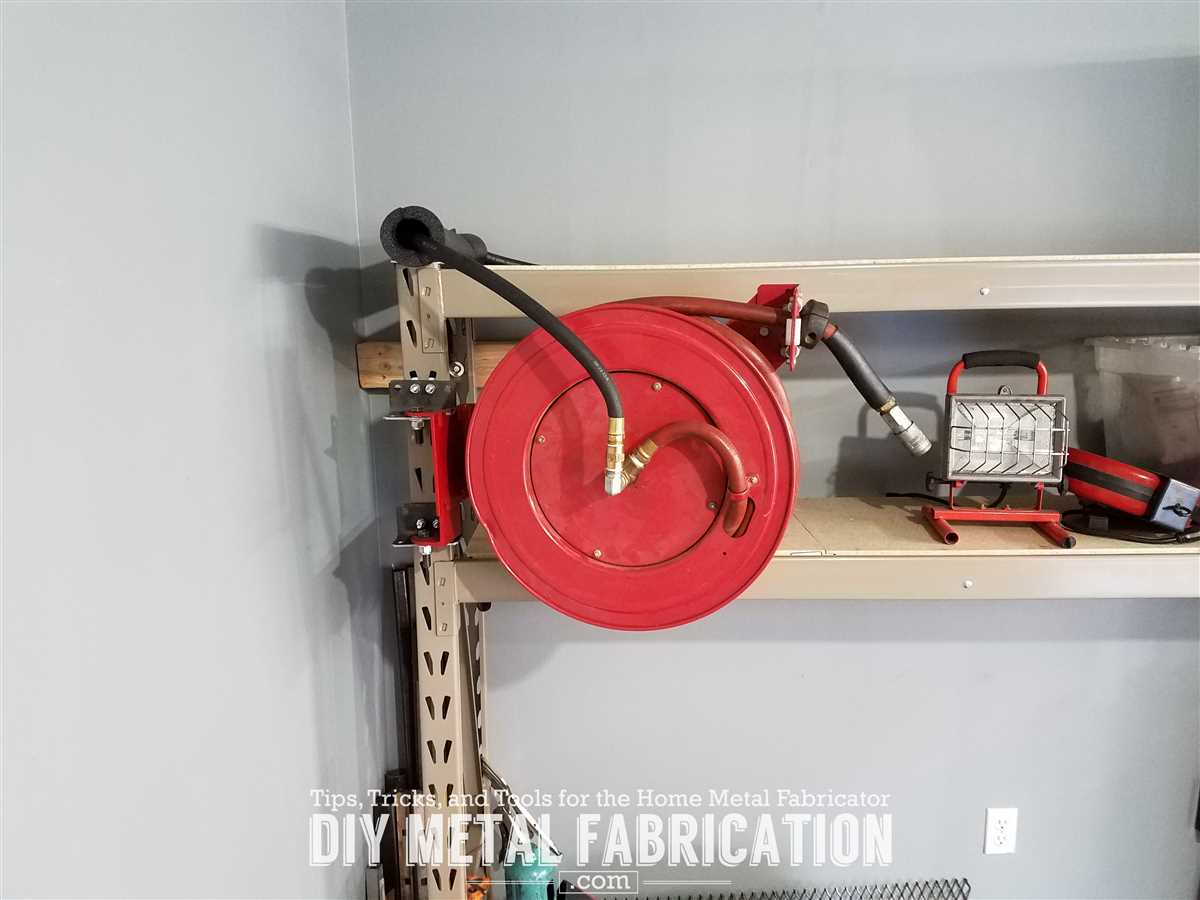

Once you have selected the right hose, the next step is to attach the hose reel to a stable surface. This can be done using screws or other suitable mounting hardware. Make sure the hose reel is positioned in a convenient location, allowing easy access to the air compressor.

Now it’s time to connect the hose to the air compressor and the hose reel. Start by attaching one end of the hose to the air compressor’s outlet port. Use a wrench to securely tighten the connections, ensuring there are no air leaks. Then, run the hose along the designated path, making sure it does not interfere with any obstructions. Finally, connect the other end of the hose to the inlet port on the hose reel, again using a wrench to tighten the connection.

With the hose properly connected, you can now turn on the air compressor and test the system. Check for any air leaks and adjust the hose reel tension if necessary. Once everything is in order, you can start using your air compressor with the convenience and organization provided by the hose reel.

In conclusion, connecting an air compressor to a hose reel is a straightforward process that can greatly enhance the usability and efficiency of your air compressor. By following this step-by-step guide, you can ensure a proper and secure connection, allowing you to easily access and use your air compressor whenever needed.

Choosing the Right Hose Reel

When it comes to connecting an air compressor to a hose reel, choosing the right hose reel is essential. There are several factors to consider when making this decision.

Type of Hose Reel

There are different types of hose reels available on the market, including manual, automatic, and spring-driven reels. Manual hose reels require manual winding and unwinding of the hose, while automatic and spring-driven reels offer more convenience with their ability to retract the hose automatically.

An automatic hose reel is a good option for those who want ease of use and don’t want to spend time manually winding the hose. Spring-driven hose reels are another popular choice as they provide a balance between convenience and affordability.

Hose Length and Diameter

The length and diameter of the hose should also be taken into consideration when choosing a hose reel. The length of the hose should be compatible with the distance between the air compressor and the desired location, allowing for easy maneuverability.

The diameter of the hose is important for determining the airflow capacity. A larger diameter hose will allow for higher volumes of air to flow, which can be beneficial for applications requiring more air pressure. However, it’s important to ensure that the hose diameter is compatible with the air compressor’s specifications.

Material and Construction

The material and construction of the hose reel are important factors to consider in terms of durability and longevity. Hose reels can be made from various materials, including plastic, steel, and aluminum.

Plastic hose reels are affordable and lightweight, but may not be as durable as those made from metal. Steel hose reels offer excellent durability but can be heavier and more expensive. Aluminum hose reels are a popular choice for their lightweight construction and resistance to corrosion.

Considering the intended use and environment where the hose reel will be installed can help determine the most suitable material and construction for your needs.

Gathering the Necessary Tools

Before connecting an air compressor to a hose reel, it is important to gather all the necessary tools to ensure a smooth installation process. Having the right tools at hand will help to complete the task efficiently and effectively.

Here is a list of tools that you will need:

- An air compressor – This is the main component that will provide the necessary air pressure for your tools or equipment.

- A hose reel – Choose a high-quality hose reel that is suitable for your specific needs. Consider factors such as reel size, hose length, and durability.

- A wrench or pliers – These tools will be used to tighten and secure the connections between the air compressor, hose reel, and other components.

- Teflon tape – This tape will help to create a watertight seal, preventing any air leaks at the connections.

- Hose clamps – These clamps will ensure a secure connection between the air compressor and the hose reel, preventing any air leaks or loosening of the connections.

- Allen wrench – In some cases, an Allen wrench may be needed to assemble or adjust certain parts of the hose reel.

- Screwdriver – A screwdriver may be required to tighten screws or other fasteners on the hose reel or compressor.

By gathering these tools before starting the installation process, you will save time and avoid any interruptions or delays. It is always best to be prepared before beginning any task to ensure a successful outcome.

Prepping the Air Compressor

Before connecting the air compressor to a hose reel, it is important to properly prep the compressor to ensure optimal performance and longevity. Here are the steps to prepping the air compressor:

1. Check the oil level:

Start by checking the oil level in the air compressor. Ensure that there is enough oil and that it is at the correct level as indicated by the manufacturer’s instructions. If the oil level is low, add the recommended type and amount of oil.

2. Inspect the air filter:

Inspect the air filter on the compressor and clean or replace it if necessary. A dirty filter will restrict airflow and reduce the efficiency of the compressor. Regularly cleaning or replacing the air filter is essential for optimal performance.

3. Drain the moisture:

Air compressors tend to accumulate moisture, which can affect the performance and lifespan of the machine. Drain any accumulated moisture from the compressor’s tank by opening the drain valve located at the bottom of the tank. This will help prevent rust and ensure that the air compressor delivers clean, dry air.

4. Check for leaks:

Inspect the air compressor for any signs of leaks. Check the connections, valves, and hoses for any air or oil leaks. If any leaks are detected, tighten the connections or replace any faulty parts to prevent air loss and ensure the compressor works efficiently.

5. Test the pressure switch:

Make sure the pressure switch on the air compressor is working correctly. Start the compressor and let it build pressure until it automatically shuts itself off. If the pressure switch is functioning properly, it should automatically turn off the compressor when the desired pressure is reached.

By following these steps to prep the air compressor before connecting it to a hose reel, you can ensure that your compressor operates effectively and efficiently. This will help extend the life of your compressor and improve the performance of your air tools.

Attaching the Hose Reel to the Wall

Attaching the hose reel to the wall is an important step in connecting an air compressor to a hose reel. Follow these steps to securely mount the hose reel:

1. Choose the ideal location

Before attaching the hose reel to the wall, determine the best location for it. Consider factors such as the proximity to the air compressor, accessibility for using the hose, and the availability of a strong wall surface.

2. Mark the mounting holes

Once you have selected the location, hold the hose reel against the wall and use a pencil or marker to mark the positions of the mounting holes. Ensure that the reel is level and centered on the wall before marking the holes.

3. Drill pilot holes

Using an appropriate drill bit, drill pilot holes at the marked positions. Make sure the drill bit size matches the size of the screws or bolts that came with the hose reel.

4. Attach the mounting bracket

Next, align the mounting bracket of the hose reel with the pilot holes and secure it to the wall using the provided screws or bolts. Ensure that the bracket is tightly attached and stable, as it will bear the weight of the reel.

5. Hang the hose reel

Once the mounting bracket is securely attached, hang the hose reel onto the bracket. Make sure it is properly seated and stable before proceeding.

6. Connect the air compressor

After you have successfully attached the hose reel to the wall, connect the air compressor to the reel using the appropriate fittings. Make sure all connections are tight and secure to prevent any air leaks or accidents.

Following these steps will ensure that your hose reel is properly attached to the wall, providing a secure and convenient storage solution for your air compressor hose.

Connecting the Hose Reel to the Air Compressor

Step 1: Gather the necessary equipment

Before connecting the hose reel to the air compressor, make sure you have all the necessary equipment. This may include a wrench, Teflon tape, and the specified fittings for your air compressor and hose reel. It’s important to have the right equipment to ensure a secure and leak-free connection.

Step 2: Prepare the air compressor

Start by preparing the air compressor. Make sure it is turned off and unplugged before proceeding. Examine the air outlet port on the compressor and check for any dirt or debris. Clean it if necessary using a clean cloth or compressed air.

Step 3: Apply Teflon tape

Next, apply Teflon tape to the male threads of the air outlet port on the compressor. This tape helps create a tight seal and prevents air leaks. Wrap the tape around the threads in a clockwise direction, making sure to cover them completely.

Step 4: Attach the fitting

Once the Teflon tape is applied, screw the fitting for the hose reel onto the air outlet port of the compressor. Use a wrench to tighten it securely, but be careful not to overtighten and damage the threads. Make sure the fitting is aligned properly to prevent any kinks or bends in the hose.

Step 5: Connect the hose reel

Now it’s time to connect the hose reel to the fitting on the air compressor. Attach one end of the air hose to the fitting on the reel, making sure to tighten it securely. If your hose reel has a swivel fitting, make sure it is properly aligned and tightened. The other end of the hose can be connected to your desired air tool or accessory. Ensure all connections are tight and secure before using the air compressor.

By following these steps, you can successfully connect your hose reel to the air compressor, allowing for easy and convenient access to compressed air when you need it. Remember to regularly inspect and maintain your connections to ensure optimal performance and safety.

Testing the Connection

After connecting your air compressor to a hose reel, it is important to test the connection to ensure that it is working properly. Testing the connection will help you identify any potential issues or leaks that may need to be addressed before using the air compressor.

Start by turning on your air compressor and allowing it to build up pressure. Once the pressure gauge on the air compressor indicates that it has reached the desired pressure level, you can proceed to test the connection.

Begin by listening for any unusual noises or sounds coming from the connection. If you hear any hissing or leaking sounds, it may indicate a problem with the connection or a leak in the hose. In this case, you will need to tighten the connections or repair any leaks before using the air compressor.

Next, visually inspect the connection and hose reel for any signs of air leakage or damage. Look for any visible cracks, holes, or loose fittings that may need to be addressed. It is important to fix any damage or issues before using the air compressor to ensure safe and efficient operation.

You can also perform a bubble test to check for any small leaks that may not be immediately visible. Mix a solution of water and dish soap, and then apply it to the connections using a brush or sponge. If you see any bubbles forming, it indicates a leak that needs to be repaired.

Finally, test the functionality of the hose reel by pulling out the hose and retracting it back. Ensure that the reel mechanism is working smoothly and that the hose is retracting without any issues. If you encounter any difficulties or problems, it may indicate a malfunction in the hose reel that needs to be addressed.

By conducting these tests, you can ensure that the connection between your air compressor and hose reel is secure and functioning properly. This will help you avoid any potential problems or accidents and ensure that your air compressor operates efficiently for all your needs.

Maintaining the Air Compressor and Hose Reel

Regular Cleaning

To ensure the longevity and smooth operation of your air compressor and hose reel, regular cleaning is essential. Dust and dirt can accumulate on the surfaces of these equipment, which can hinder their performance. Use a soft cloth or a brush to gently wipe away any debris from the exterior of the air compressor and hose reel. For hard-to-reach areas, you can use a small vacuum cleaner or compressed air to remove the dirt.

Checking for Leaks

Leaks can cause a decrease in air pressure and efficiency of your air compressor and hose reel. Periodically inspect the connections and valves for any signs of leakage. This can be done by applying soapy water to the fittings and observing for any bubbles. If you notice any leaks, tighten the connections or replace faulty parts immediately to prevent further damage.

Inspecting the Hose Reel

The hose reel is an important component for storing and protecting the air hose. Regularly inspect the hose reel for any signs of wear and tear. Check for any cracks or damage that may compromise the integrity of the hose. If you notice any issues, consider replacing the hose reel or repairing the damaged parts to ensure safe and efficient operation.

Draining Moisture

Moisture can accumulate inside the air compressor and hose reel, which can lead to corrosion and decreased performance. It is important to drain the moisture regularly to prevent these issues. Most air compressors are equipped with a drain valve, usually located at the bottom of the tank. Open the valve and let the moisture drain out completely. Additionally, consider installing a moisture trap or filter to further prevent moisture buildup.

Storing Properly

Proper storage is crucial for maintaining the air compressor and hose reel in good condition. When not in use, store the equipment in a clean and dry environment. Avoid exposing them to extreme temperatures or direct sunlight, as this can cause damage. Additionally, make sure the air hose is properly coiled and secured to the hose reel to prevent tangling and kinks.

By following these maintenance steps, you can ensure the proper functioning and longevity of your air compressor and hose reel.

Troubleshooting Common Issues

1. Low Air Pressure

If you are experiencing low air pressure when using your hose reel, there are a few potential causes to consider. First, check the air compressor’s pressure gauge to ensure it is set at the desired level. If the pressure is too low, adjust it accordingly. Additionally, check for any obstructions in the air hose or connections that may be causing a decrease in air flow. Finally, inspect the hose reel itself for any damage or leaks that could be affecting air pressure.

2. Air Leaks

Air leaks can be a common issue when connecting an air compressor to a hose reel. These leaks can occur at the connections between the hose reel, air compressor, and air hose. To troubleshoot this issue, start by tightening all connections using a wrench. If the leak persists, consider replacing any damaged fittings or hoses. It may also be helpful to apply a sealant or Teflon tape to the threads of the connections to ensure a tight seal.

3. Hose Reel Jamming

If your hose reel is jamming or not retracting properly, there are a few steps you can take to troubleshoot the issue. First, check for any kinks or tangles in the air hose that may be causing the jam. Straighten out any obstructions and ensure that the hose is properly aligned with the reel. Lubricating the reel with a silicone-based lubricant can also help to alleviate any friction or resistance that may be causing the jam. If the issue persists, consult the manufacturer’s instructions or reach out to customer support for further assistance.

4. Overheating

Overheating can be a common issue when using an air compressor and hose reel for extended periods of time. This can be caused by a variety of factors, including excessive use, inadequate ventilation, or a malfunctioning compressor motor. To troubleshoot this issue, allow the compressor to cool down and inspect it for any visible signs of damage or overheating. Ensure that the compressor is located in a well-ventilated area and that the motor is clean and free from debris. If the problem persists, it may be necessary to consult a professional or contact the manufacturer for further assistance.

5. Inadequate Air Flow

If you are experiencing inadequate air flow when using your hose reel, there are a few possible causes to consider. First, check the air filter on your air compressor to ensure it is clean and not clogged with debris. A dirty air filter can restrict the flow of air and decrease overall performance. Additionally, inspect the air hose and connections for any blockages or obstructions. Clearing any debris or replacing damaged hoses can help to improve air flow. If the issue persists, it may be necessary to consult a professional for further troubleshooting.

6. Uneven Hose Reel Retraction

If your hose reel is retracting unevenly or not retracting at all, there are a few steps you can take to troubleshoot the issue. First, check for any obstructions or tangles in the hose that may be causing resistance. Straighten out any kinks or tangles and ensure that the hose is properly aligned with the reel. Lubricating the reel with a silicone-based lubricant can also help to ensure smooth retraction. If the problem persists, consult the manufacturer’s instructions or contact customer support for further assistance.

FAQ:

What tools do I need to connect an air compressor to a hose reel?

To connect an air compressor to a hose reel, you will need the following tools: an adjustable wrench, Teflon tape, and a hose clamp. These tools will help you secure the connections and prevent any air leaks.

How do I choose the right hose reel for my air compressor?

Choosing the right hose reel for your air compressor depends on a few factors. First, you need to consider the length and diameter of the hose you will be using. The hose reel should be able to accommodate the size of your hose. Additionally, you should also consider the maximum pressure and airflow of your air compressor to ensure that the hose reel can handle the output. Lastly, you should also consider the mounting options and durability of the hose reel.

Can I connect multiple hose reels to my air compressor?

Yes, you can connect multiple hose reels to your air compressor. However, you will need to make sure that your air compressor has enough airflow and pressure to support multiple reels. You may also need to use a T-fitting or manifold to split the air output from the compressor to multiple hoses.

Can I use any type of hose with an air compressor and hose reel?

No, it is important to use a hose that is suitable for air compressor use. Air hoses are specifically designed to handle the high pressure and airflow of air compressors. Using a hose that is not designed for air compressor use can result in leaks or bursts, which can be dangerous.

Do I need to use Teflon tape when connecting the hose to the air compressor?

Yes, it is recommended to use Teflon tape when connecting the hose to the air compressor. Teflon tape helps create a seal between the threads of the hose and the air compressor, preventing any air leaks. It is a simple and inexpensive solution to ensure a tight and secure connection.

What should I do if I notice any air leaks after connecting the hose to the air compressor?

If you notice any air leaks after connecting the hose to the air compressor, you should first check if all connections are tight and secure. Use an adjustable wrench to tighten any loose connections. If the leak persists, you may need to replace the hose or the fittings. It is important to address any air leaks as they can affect the performance and efficiency of your air compressor.

How often should I check the connections between the air compressor and the hose reel?

It is recommended to regularly check the connections between the air compressor and the hose reel for any signs of wear or leaks. Ideally, you should inspect the connections every time you use the air compressor. This will help ensure that the connections are secure and prevent any potential issues during operation.

Video: