Common Causes of Air Compressor Fuse Blowouts

An air compressor is a crucial piece of equipment in various industrial and commercial settings. It is used to compress and store air, which can then be used to perform a wide range of tasks, such as operating power tools, inflating tires, and providing pressurized air for various systems. However, like any electrical equipment, air compressors can experience issues, such as fuse blowouts. Understanding the common causes of these blowouts is essential in preventing and addressing potential problems.

One of the primary causes of air compressor fuse blowouts is overloading the system. Air compressors have a specified amperage rating, and if the equipment being connected to the compressor draws more current than the rating, it can lead to overheating and ultimately blow the fuse. This can happen when multiple devices are connected to the compressor simultaneously or when a device with a higher power consumption is used without considering the compressor’s limitations.

Another common cause of fuse blowouts is a short circuit. This occurs when there is a direct path for electrical current to flow between the positive and negative sides of the circuit, bypassing the compressor’s intended pathway. Short circuits can be caused by damaged wiring, loose connections, or faulty electrical components. When a short circuit occurs, the excessive current flow can overload the fuse and cause it to blow.

Improper maintenance and neglect can also contribute to fuse blowouts in air compressors. Lack of regular cleaning and inspection can lead to the accumulation of dirt, debris, and moisture, which can create electrical conductivity issues and increase the risk of short circuits. Additionally, worn-out or damaged components, such as capacitors or electrical switches, can also contribute to fuse blowouts if not promptly replaced or repaired.

In conclusion, understanding the common causes of air compressor fuse blowouts is crucial in maintaining the equipment’s performance and preventing potential damage or safety hazards. Overloading the system, short circuits, and improper maintenance are all factors that can contribute to these issues. By addressing these causes and implementing proper maintenance practices, the risk of fuse blowouts can be significantly reduced, ensuring the smooth operation of air compressors and the equipment they power.

Electrical Overload

Electrical overload is one of the common causes of air compressor fuse blowouts. When the electrical circuit is overloaded, it means that the electrical demand exceeds the capacity of the circuit. This can occur due to various reasons such as excessive use of electrical devices, running multiple appliances simultaneously, or using a faulty electrical system.

An electrical overload can occur in the air compressor when there is a sudden surge in power demand. This can happen when the compressor motor tries to start up, especially if it is an older model or if it hasn’t been properly maintained. The power surge can cause the fuse to blow out as a safety measure to protect the electrical system from damage.

Another cause of electrical overload in an air compressor can be a short circuit. A short circuit occurs when there is a direct connection between the hot wire and the neutral wire or the ground wire. This can happen due to faulty wiring, damaged insulation, or loose connections. A short circuit can cause a sudden and excessive flow of electricity, leading to an overload and subsequent fuse blowout.

To prevent electrical overload in an air compressor, it is important to ensure that the electrical system is properly sized and can handle the power requirements of the compressor. Regular maintenance and inspection of the electrical system, including wiring, connections, and insulation, can help identify and address any potential issues before they lead to an overload. Additionally, it is important to avoid running multiple high-power appliances or equipment on the same circuit to prevent overloading.

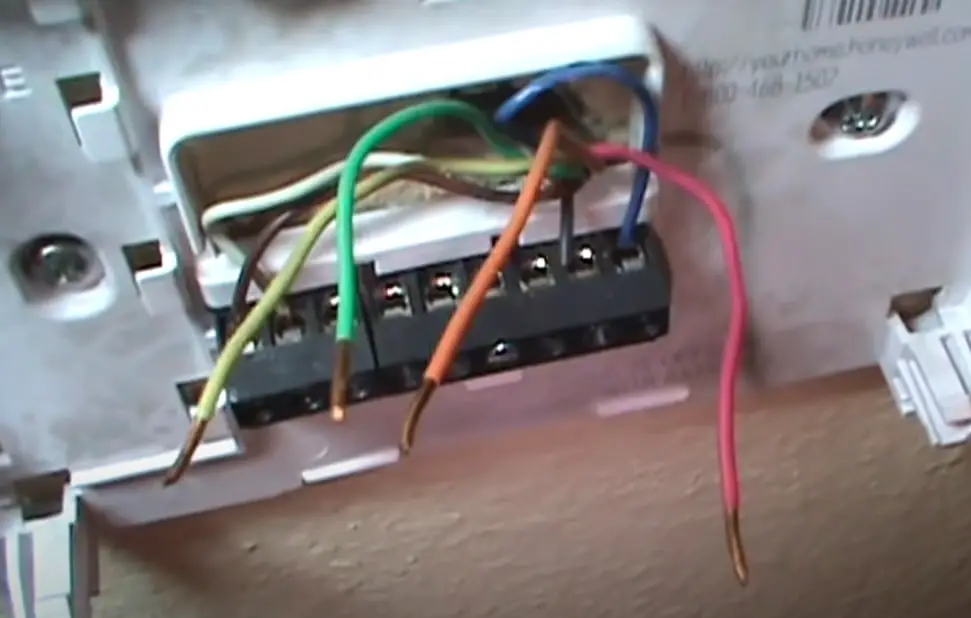

Faulty Wiring

Faulty wiring is one of the common causes of air compressor fuse blowouts. Electrical wiring plays a crucial role in ensuring the safe operation of an air compressor. If there are any issues with the wiring, it can lead to excessive heat buildup, short circuits, or even electrical fires.

One common wiring issue is loose or damaged connections. When the connections are loose, it can cause intermittent power interruptions, which can result in fuse blowouts. Additionally, damaged wiring, such as frayed or exposed wires, can increase the risk of short circuits and electrical malfunctions.

Another wiring problem that can cause fuse blowouts is incorrect wiring installation. If the wiring is not properly installed, it may result in improper grounding or the wrong voltage being supplied to the air compressor. This can overload the system and cause the fuse to blow.

To prevent faulty wiring from causing fuse blowouts, it is important to regularly inspect the wiring for any signs of damage or wear. Any loose connections should be tightened, and damaged wiring should be repaired or replaced. It is also crucial to ensure that the wiring is installed correctly, following the manufacturer’s instructions and guidelines.

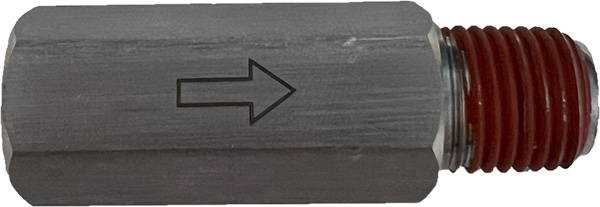

Defective Pressure Switch

A defective pressure switch is one of the common causes of air compressor fuse blowouts. The pressure switch is responsible for regulating the pressure inside the compressor tank and turning the compressor on and off when necessary. If the pressure switch becomes defective, it may fail to accurately detect the pressure levels and can cause the compressor to run at an excessively high pressure.

This can lead to an overload on the compressor motor, resulting in the blowing of the fuse. Additionally, a defective pressure switch may also cause the compressor motor to run continuously, without automatically shutting off when the desired pressure is reached. This constant running of the compressor motor can cause overheating and ultimately lead to a blown fuse.

One way to identify if the pressure switch is defective is to check for any signs of physical damage or wear. If there are any visible cracks or broken components, it is likely that the pressure switch is faulty. Another way to test the pressure switch is to use a multimeter to measure the continuity of the switch contacts. If there is no continuity when the switch is activated, it indicates a defective switch.

If a defective pressure switch is identified as the cause of the fuse blowout, it is recommended to replace the switch with a new one that is compatible with the air compressor model. It is important to ensure that the replacement switch is of high quality and is properly installed to prevent any future issues. Regular maintenance and periodic inspection of the pressure switch can also help to prevent further fuse blowouts and maintain the efficient operation of the air compressor.

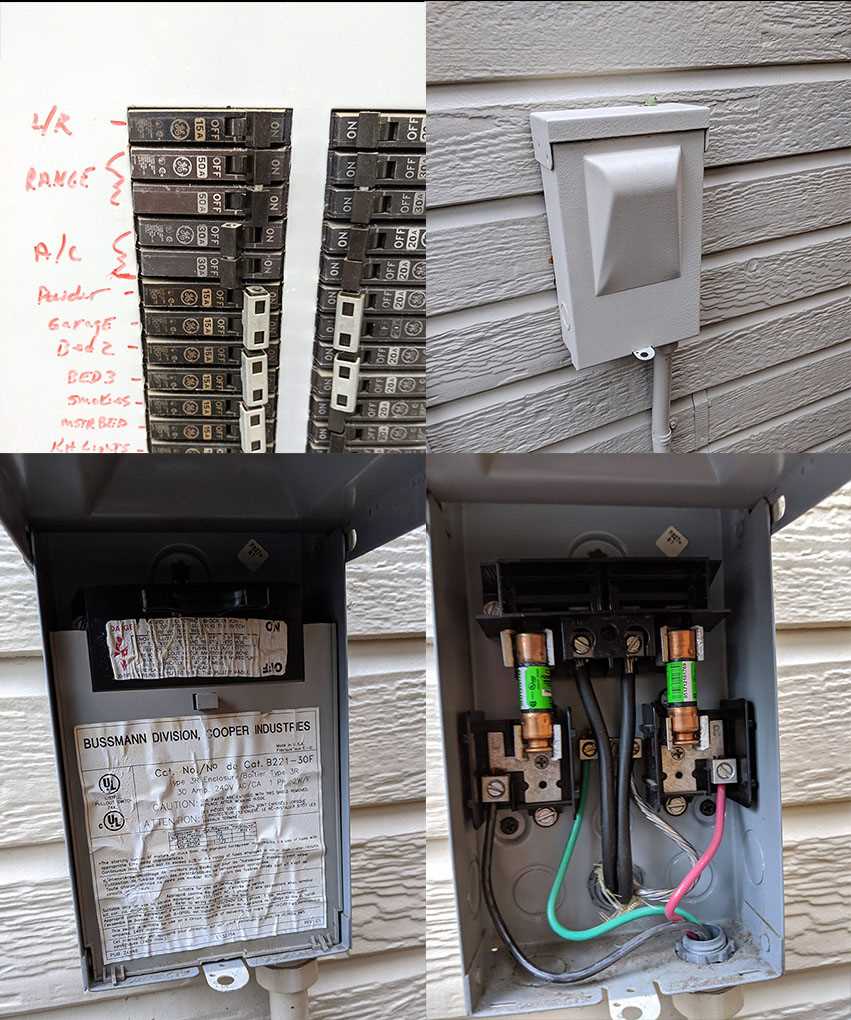

Insufficient Grounding

Insufficient grounding is a common cause of air compressor fuse blowouts. Proper grounding is important for electrical equipment, including air compressors, as it helps to prevent electrical shocks and ensure the safe operation of the equipment.

When an air compressor is not properly grounded, it can cause a buildup of static electricity, which may result in a fuse blowing out. This can occur when the compressor is not properly connected to a grounding source or when the grounding connection is damaged or loose.

One way to ensure sufficient grounding is to check the grounding connection of the air compressor. This involves inspecting the grounding wire for any damage, ensuring that it is securely connected to the compressor, and verifying that the grounding source, such as an electrical outlet or grounding rod, is functioning properly.

If the grounding connection is damaged or loose, it should be repaired or replaced. Additionally, if there are multiple electrical devices connected to the same outlet, it is important to ensure that the outlet can handle the electrical load and that each device is properly grounded.

In some cases, it may be necessary to consult a qualified electrician to ensure that the air compressor is properly grounded and to address any underlying electrical issues. Proper grounding not only helps to prevent fuse blowouts but also promotes the safe and efficient operation of the air compressor.

Overheating

One common cause of air compressor fuse blowouts is overheating. When the compressor runs for extended periods of time or is placed in a hot environment, it can lead to overheating. This can be caused by a lack of proper ventilation or a malfunctioning cooling system.

Overheating can result in excessive heat buildup within the compressor, which can cause the fuse to blow. This can be dangerous as it can potentially damage the compressor and other components. It can also pose a fire hazard if not addressed promptly.

To prevent overheating, it is important to ensure that the compressor is placed in a well-ventilated area and that any cooling systems, such as fans or heat sinks, are functioning properly. Regular maintenance and inspections can help identify any issues that may contribute to overheating and allow for timely repairs.

If an air compressor is frequently experiencing fuse blowouts due to overheating, it may be necessary to increase ventilation, upgrade the cooling system, or consider relocating the compressor to a cooler area. Consulting with a professional technician can help determine the best course of action to address the overheating issue and prevent further fuse blowouts.

In summary, overheating is a common cause of air compressor fuse blowouts. Proper ventilation, functioning cooling systems, and regular maintenance are essential to prevent overheating and ensure the safe and efficient operation of the compressor.

Incorrect Voltage

One common cause of air compressor fuse blowouts is incorrect voltage. Air compressors are designed to operate at specific voltage levels, and using the wrong voltage can put a strain on the electrical components. This can lead to overheating and ultimately, fuse blowouts.

Under Voltage: If an air compressor is operated at a lower voltage than it is designed for, it may not have enough power to function properly. This can cause the motor to work harder, leading to increased heat and potential fuse blowout.

Over Voltage: Similarly, if an air compressor is operated at a higher voltage than it is designed for, it can put excessive stress on the electrical components. This can cause them to fail prematurely and increase the likelihood of fuse blowouts.

To prevent incorrect voltage from causing fuse blowouts, it is important to ensure that the air compressor is connected to a power source with the correct voltage. The voltage requirements should be clearly stated in the compressor’s manual or on the device itself. If there is any doubt about the voltage, it is advisable to consult an electrician or the manufacturer.

In addition, it is important to regularly inspect the power cord and plug for any signs of damage or wear. A damaged cord or plug can affect the flow of electricity and increase the risk of voltage issues. If any damage is detected, the cord should be replaced immediately.

Overall, using the correct voltage is essential for the safe and efficient operation of an air compressor. By paying attention to voltage requirements and maintaining the power cord and plug, the risk of fuse blowouts can be minimized.

Moisture or Water Damage

Moisture or water damage is a common cause of air compressor fuse blowouts. Water can enter the compressor system through various sources, such as condensation, leaks, or improper drainage. When water enters the compressor, it can cause corrosion and damage to electrical components, leading to a short circuit and blowing of the fuse.

One possible source of water damage is condensation that forms inside the compressor tank. As the air inside the tank cools down, moisture can accumulate and mix with the air. If the tank is not properly drained, this moisture can enter the compressed air system, causing damage to the electrical components.

Leaks in the air compressor system can also allow water to enter. If there are any cracks or holes in the air pipes, fittings, or valves, water can seep in and damage the electrical connections and components. Regular inspections and maintenance can help identify and fix any leaks before they cause significant damage.

Improper drainage is another common cause of water damage in air compressors. If the condensate drains are not properly installed or maintained, water can accumulate and cause damage to the compressor system. Regularly checking and cleaning the drains can help prevent water from entering the system and causing fuse blowouts.

To prevent moisture or water damage, it is important to keep the air compressor and its components dry. This can be achieved by properly draining the tank, fixing any leaks, and ensuring the condensate drains are working effectively. Regular maintenance and inspections can help identify and address any potential water damage issues before they cause fuse blowouts.

Excessive Power Surges

An excessive power surge is one of the common causes of air compressor fuse blowouts. Power surges occur when there is a sudden increase in the flow of electricity, which can overload the electrical components of the compressor. This surge of power can cause the fuse to blow, preventing further damage to the compressor.

Possible Causes:

- Lightning strikes: Lightning strikes can send massive power surges through electrical systems, causing fuses to blow.

- Power outages: When the power is restored after an outage, there can be a sudden surge in electricity that can overload the compressor’s electrical components.

- Faulty electrical wiring: If the wiring in the electrical system is old or damaged, it can cause power surges that can lead to fuse blowouts.

- Faulty power supply: In some cases, the power supply itself may be delivering inconsistent or unstable power, leading to power surges.

Preventing Excessive Power Surges:

- Install surge protectors: Plugging the air compressor into a surge protector can help to prevent excessive power surges.

- Update electrical wiring: Regularly inspect and update the electrical wiring to ensure it is in good condition and can handle the electrical load.

- Use a voltage stabilizer: Using a voltage stabilizer can help to regulate the power supply and prevent power surges.

- Unplug during storms: During storms or when lightning is likely, it is advisable to unplug the air compressor to protect it from power surges caused by lightning strikes.

By taking steps to prevent excessive power surges, you can minimize the risk of fuse blowouts in your air compressor and ensure its longevity and proper functioning.

FAQ:

What are some common causes of air compressor fuse blowouts?

There are several common causes of air compressor fuse blowouts. One of the most common causes is a short circuit caused by a damaged or frayed wire in the compressor’s electrical system. Another common cause is an overload of the compressor’s motor, which can be caused by excessive usage or a malfunctioning motor. A third common cause is a faulty pressure switch, which can cause the compressor to run continuously and put strain on the electrical system. Finally, a blown fuse can also be caused by an electrical surge or power spike.

How can I prevent air compressor fuse blowouts?

There are several steps you can take to prevent air compressor fuse blowouts. First, you should regularly inspect the electrical system of your compressor for any damaged or frayed wires and repair or replace them as necessary. It is also important to ensure that the electrical system is properly grounded. Second, you should avoid overloading the compressor’s motor by monitoring usage and avoiding prolonged continuous operation. Third, it is important to regularly inspect and maintain the pressure switch to ensure it is functioning properly. Finally, you may consider installing surge protectors or voltage regulators to protect against electrical surges and power spikes.

How do I troubleshoot a blown fuse in my air compressor?

If you have a blown fuse in your air compressor, there are several steps you can take to troubleshoot the issue. First, you should visually inspect the electrical system for any visible damage, such as frayed wires or loose connections. If you identify any damage, you should repair or replace the affected components. Second, you should check the pressure switch to ensure it is functioning properly. You can do this by testing the continuity of the switch using a multimeter. If the switch is not functioning correctly, it may need to be replaced. Finally, if you are unable to identify and fix the issue, it is recommended to consult a professional for further assistance.

Can a blown fuse in an air compressor be fixed?

In many cases, a blown fuse in an air compressor can be fixed by simply replacing the fuse. However, it is important to identify and address the underlying cause of the blown fuse to prevent future issues. If the fuse continues to blow after it has been replaced, it is likely that there is a larger electrical issue with the compressor that will need to be repaired by a professional. It is not recommended to continue using the compressor with a blown fuse as it can cause further damage to the electrical system.

Video: