Choosing the Right Weight Oil for Your Air Compressor

When it comes to maintaining your air compressor, choosing the right weight oil is crucial. The oil plays a vital role in the performance and longevity of your compressor, as it lubricates the internal parts and helps to dissipate heat. However, with so many options available on the market, it can be overwhelming to determine which weight oil is best suited for your specific compressor. In this article, we will discuss the importance of selecting the correct oil weight and explore the factors that should be considered when making your decision.

One of the first considerations when choosing the right weight oil for your air compressor is the manufacturer’s recommendations. Each compressor model is designed to operate optimally with a specific type of oil, and deviating from these guidelines can result in subpar performance and potential damage. It is essential to consult the user manual or the manufacturer’s website to identify the recommended oil weight for your compressor.

Another factor to consider is the ambient temperature in which your compressor will be operating. Oil viscosity, or thickness, is measured using numbers such as 10W, 30W, or 40W, with the “W” standing for winter. The first number indicates the oil’s viscosity at cold temperatures, while the second number represents its viscosity at operating temperatures. In colder climates, a lower viscosity oil may be required to ensure proper lubrication at startup, while in hot climates, a higher viscosity oil may be necessary to prevent thinning and inadequate lubrication.

In addition to the manufacturer’s recommendations and ambient temperature, it is also crucial to consider the compressor’s workload and duty cycle. Air compressors that are used more frequently or in applications that require higher pressure will generate more heat, placing greater demands on the oil. In these cases, it may be beneficial to select an oil with a higher viscosity to provide better protection against thermal breakdown. Conversely, compressors with lighter workloads may be adequately protected with a lower viscosity oil.

In conclusion, selecting the right weight oil for your air compressor is a critical decision that can impact its overall performance and lifespan. By following the manufacturer’s recommendations, considering the ambient temperature, and evaluating the compressor’s workload, you can make an informed choice that will ensure optimal lubrication and heat dissipation. Regularly monitoring the oil’s condition and replacing it at recommended intervals will further contribute to the compressor’s longevity and efficiency.

Importance of Choosing the Right Weight Oil

Choosing the right weight oil for your air compressor is crucial for its optimal performance and longevity. The weight, or viscosity, of the oil refers to its thickness and ability to flow. Using the wrong weight oil can lead to various issues, including reduced lubrication, increased wear and tear, and decreased efficiency.

Lubrication: The main function of oil in an air compressor is to lubricate the moving parts, such as the pistons, valves, and bearings. Using oil with the wrong viscosity can result in insufficient lubrication, causing increased friction and heat generation. This can lead to premature wear of the components and eventually result in costly repairs or replacements.

Wear and Tear: When the oil is too thin or too thick, it does not provide adequate protection to the internal components of the air compressor. Thin oil may not form a proper oil film, while thick oil may not flow smoothly. Both scenarios can lead to accelerated wear and tear on the parts, reducing the overall lifespan of the compressor.

Efficiency: The right weight oil ensures that the air compressor operates at its optimum efficiency. Oil that is too thick can impede the movement of the pistons and valves, causing them to work harder, which results in increased energy consumption. On the other hand, oil that is too thin may not create enough resistance to maintain steady pressure in the system. This can lead to reduced performance and increased energy costs.

Manufacturer’s Recommendations: To avoid any potential issues, it is important to follow the manufacturer’s recommendations for the oil weight. The manufacturer will specify the appropriate oil weight based on the design, operating conditions, and requirements of the air compressor. Using the recommended oil weight ensures that the compressor operates as intended, maximizing its lifespan and efficiency.

Regular Maintenance: Along with choosing the right weight oil, it is crucial to perform regular oil changes and maintenance on your air compressor. This helps to remove any contaminants or debris that may have accumulated in the oil, ensuring smooth operation and prolonging the life of the compressor.

In conclusion, choosing the right weight oil for your air compressor plays a vital role in its performance, reliability, and longevity. It ensures proper lubrication, minimizes wear and tear, improves efficiency, and allows the compressor to operate at its optimal level. By following the manufacturer’s recommendations and performing regular maintenance, you can ensure that your air compressor functions effectively for years to come.

Understanding Air Compressor Lubrication

Proper lubrication is essential for maintaining and extending the life of an air compressor. Compressors rely on lubrication to reduce friction and minimize wear and tear on internal components. Understanding air compressor lubrication is crucial for selecting the right oil and ensuring optimal performance.

The Role of Oil in Air Compressors

Oil plays a critical role in air compressors by providing lubrication to moving parts, sealing internal clearances, and dissipating heat. As the compressor operates, oil is circulated throughout the system, lubricating the piston, bearings, and other crucial components. This lubrication helps reduce friction, prevent overheating, and ensure smooth operation.

Types of Compressor Oils

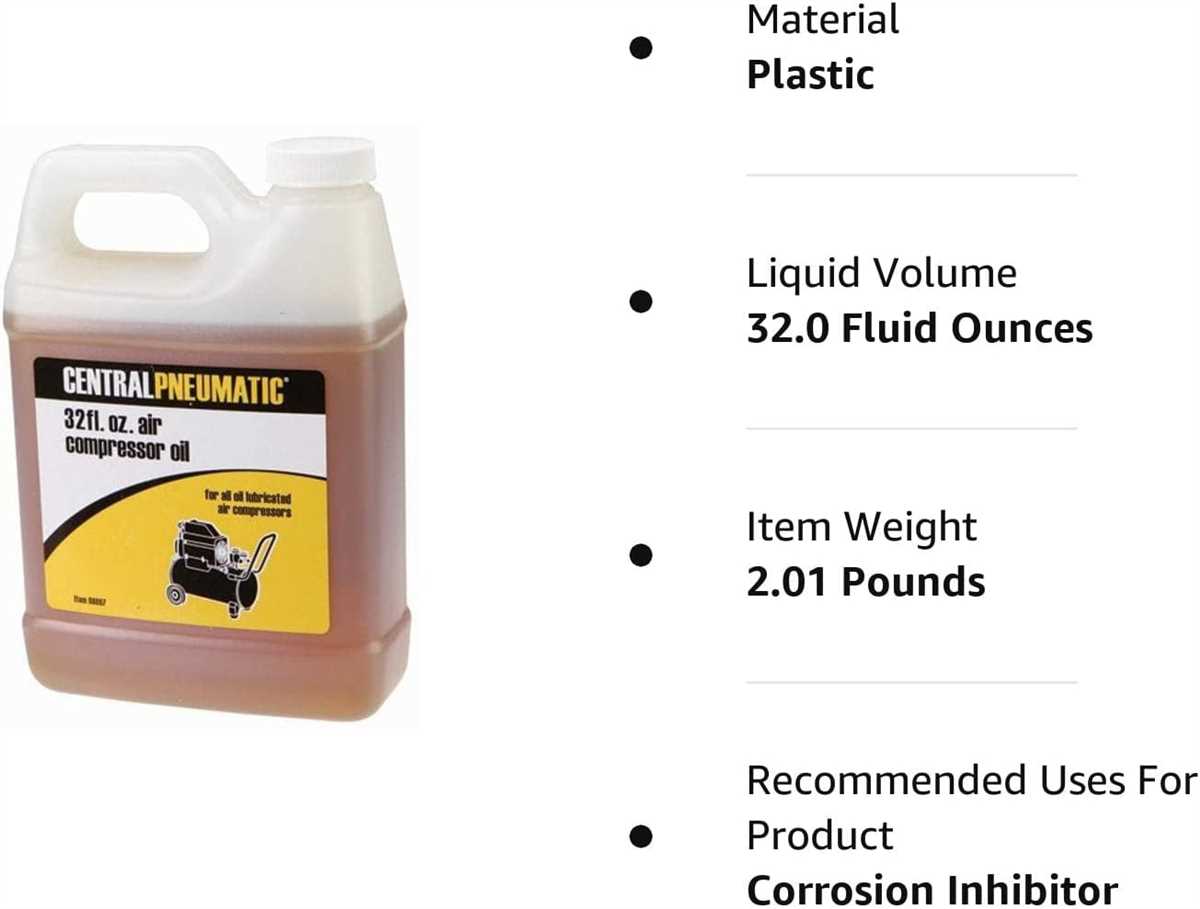

There are different types of oils available for air compressors, including mineral oil, synthetic oil, and semi-synthetic oil. Mineral oil, made from refined petroleum, is the most commonly used type of compressor oil. Synthetic oil, on the other hand, is made from chemically engineered compounds and offers superior performance in terms of lubrication, stability, and resistance to temperature extremes. Semi-synthetic oils combine the benefits of both mineral and synthetic oils.

Choosing the Right Oil Weight

Oil weight refers to the viscosity of the oil. When selecting an oil weight for an air compressor, it is crucial to consider the manufacturer’s recommendations and the operating conditions. An oil with a higher viscosity (thicker) will provide better lubrication in high-temperature environments, while an oil with a lower viscosity (thinner) is more suitable for low-temperature conditions.

Regular Oil Changes

Regular oil changes are essential for maintaining optimal performance and preventing buildup of contaminants. Over time, oil can break down, lose its lubricating properties, and become contaminated with dirt, debris, and moisture. Regular oil changes ensure the compressor is consistently supplied with clean and fresh lubricant.

It is important to follow the manufacturer’s recommendations for oil change intervals. Some compressors may require more frequent oil changes, especially in heavy-duty applications or harsh operating conditions.

Conclusion

Understanding air compressor lubrication is crucial for selecting the right oil and ensuring the longevity and efficiency of the compressor. A well-lubricated compressor will minimize friction, reduce wear and tear on internal components, and help prevent overheating. Regular oil changes and adhering to manufacturer recommendations are essential for maintaining optimal performance.

Factors to Consider When Choosing Oil Weight

Choosing the right oil weight for your air compressor is crucial for maintaining optimal performance and prolonging the lifespan of your equipment. There are several factors you should consider before making a decision:

1. Operating Temperature:

The operating temperature of your air compressor is an important factor to consider when selecting oil weight. If you frequently operate the compressor in high temperatures, you may need a heavier oil weight. On the other hand, if you typically use the compressor in lower temperatures, a lighter oil weight may be more suitable.

2. Compressor Type:

The type of air compressor you have will also influence the oil weight you choose. Different compressor types, such as reciprocating compressors or rotary screw compressors, have different lubrication requirements. Consult the manufacturer’s recommendations to determine the appropriate oil weight for your specific compressor type.

3. Load and Usage:

The load and usage of your air compressor can also impact the oil weight selection. If you frequently operate the compressor at full load or under heavy usage, a heavier oil weight may be needed to provide sufficient lubrication and protection. Conversely, if your compressor operates under lighter load or intermittent usage, a lighter oil weight may be sufficient.

4. Oil Viscosity:

Consider the viscosity of the oil when choosing the weight. Viscosity refers to the thickness or flow characteristics of the oil. The optimal viscosity will depend on the compressor’s design, operating conditions, and temperature range. Consult the manufacturer’s recommendations or consult with a knowledgeable technician to determine the appropriate viscosity for your air compressor.

Keep in mind that using the wrong oil weight can lead to decreased performance, increased wear, and potential damage to your air compressor. It is always best to consult the manufacturer’s recommendations or seek professional advice to ensure you are selecting the correct oil weight for your specific compressor needs.

Recommended Oil Weights for Different Air Compressor Types

Choosing the appropriate oil weight is crucial for maintaining the optimal performance and longevity of your air compressor. Different types of air compressors require different oil weights to ensure smooth operation.

Reciprocating Air Compressors

Reciprocating air compressors, also known as piston compressors, are commonly used in automotive and industrial applications. These compressors rely on a piston and cylinder arrangement to compress air. For reciprocating air compressors, it is recommended to use a heavier weight oil, typically an ISO 100 or ISO 150 grade. The heavier oil helps provide better lubrication and prevent excessive wear in the high-pressure cylinder and piston rings.

Rotary Screw Air Compressors

Rotary screw air compressors are commonly used in large industrial applications. These compressors utilize two interlocking helical screws to compress air. For rotary screw air compressors, it is recommended to use a lighter weight oil, typically an ISO 46 or ISO 68 grade. The lighter oil helps reduce friction and improve the efficiency of the screw elements.

Centrifugal Air Compressors

Centrifugal air compressors are typically used in large-scale industrial applications that require a continuous supply of high-volume compressed air. These compressors use centrifugal force to accelerate and compress air. For centrifugal air compressors, it is recommended to use a synthetic oil with a low viscosity, typically an ISO 32 or ISO 46 grade. The low viscosity oil helps reduce friction and heat generation in the compressor’s rotating components.

It is important to refer to the manufacturer’s recommendations and specifications for your specific air compressor model when selecting the appropriate oil weight. Using the incorrect oil weight can lead to premature wear, decreased efficiency, and potential equipment failure.

Impact of Using the Wrong Oil Weight

Using the wrong weight of oil in your air compressor can have serious consequences for its performance and longevity. The oil in an air compressor serves as a lubricant, helping to reduce friction and wear on the moving parts. When the wrong weight of oil is used, it can lead to inadequate lubrication or excessive heat, which can cause damage to the compressor.

Inadequate lubrication: Using an oil with a weight that is too light can result in inadequate lubrication. The oil may not provide sufficient protection to the moving parts, leading to increased friction and wear. This can cause the compressor to run less efficiently and eventually lead to damage or failure of the components.

Excessive heat: Using an oil with a weight that is too heavy can result in excessive heat buildup. The thicker oil may not be able to circulate properly, leading to increased friction and heat generation. This can put added stress on the compressor and increase the risk of overheating, which can cause the oil to break down and lose its lubricating properties.

Reduced energy efficiency: Using the wrong weight of oil can also negatively impact the energy efficiency of the air compressor. If the oil is not able to properly lubricate the moving parts, the compressor may have to work harder and consume more energy to achieve the same level of performance. This can lead to increased energy costs and reduce the overall efficiency of the compressor.

Decreased lifespan: When the wrong weight of oil is used in an air compressor, the increased friction and heat can shorten its lifespan. The components may wear out more quickly, leading to more frequent repairs or the need for replacement parts. This can be costly and time-consuming, and it may result in a shorter overall lifespan for the compressor.

It is important to consult the manufacturer’s recommendations: To avoid these potential issues, it is important to consult the manufacturer’s recommendations for the correct weight of oil to use in your air compressor. They will typically provide guidelines based on the specific model and operating conditions. Following these recommendations will help ensure proper lubrication, maintain optimal performance, and extend the lifespan of your air compressor.

Tips for Selecting the Right Oil for Your Air Compressor

If you want your air compressor to run smoothly and efficiently, it’s important to choose the right oil. Here are some tips to help you select the most suitable oil for your air compressor:

Consider the viscosity

Viscosity refers to the thickness or resistance to flow of the oil. It is typically measured in centistokes (cSt). Different air compressors require different viscosities of oil. Be sure to check the manufacturer’s recommendations for the correct viscosity range for your specific compressor model. Using oil with the wrong viscosity can lead to poor lubrication and increased wear and tear on the compressor.

Look for oil with anti-wear properties

Air compressors operate under high pressures and temperatures, which can cause wear and tear on the internal components. To protect your compressor from excessive wear, choose an oil that has anti-wear properties. Look for oils that are labeled as “anti-wear” or “extreme pressure.”

Consider the oil’s oxidation stability

Oxidation stability refers to the oil’s resistance to breaking down or becoming contaminated over time. Air compressors generate heat during operation, which can accelerate oil oxidation. It’s important to choose an oil with good oxidation stability to ensure optimal performance and longevity of your compressor. Look for oils that are specifically formulated for air compressors and have a good track record of stability.

Other factors to consider:

- Check if the oil has good water separation properties. This is important as air compressors can produce condensate, which can mix with the oil.

- Consider the oil’s compatibility with seals and gaskets used in your compressor. Using the wrong oil can cause seal degradation or leakage.

- Consult the compressor’s manual or contact the manufacturer for specific oil recommendations.

Remember, choosing the right oil for your air compressor is crucial for its smooth operation and longevity. By considering factors like viscosity, anti-wear properties, oxidation stability, and other compatibility factors, you can ensure that your compressor performs optimally and lasts for a long time.

Common Oil Weight Misconceptions

When it comes to choosing the right weight oil for your air compressor, there are several common misconceptions that can lead to confusion and potential damage to your equipment.

1. Thicker oil is always better

One of the most common misconceptions is that thicker oil is always better for air compressors. While it is true that a higher viscosity oil can provide better lubrication, using oil that is too thick can actually hinder the compressor’s performance. The air compressor’s manual will provide specific recommendations for the ideal oil weight range, and it’s important to follow these guidelines to ensure optimal performance.

2. Any oil can be used for any compressor

Another misconception is that any type of oil can be used for any air compressor. However, different compressors have different requirements when it comes to oil weight and additives. Some compressors may require oil with specific additives to prevent deposits and maintain cleanliness, while others may require oil with a different viscosity rating. It’s important to consult the compressor’s manual or contact the manufacturer to determine the correct oil weight and type for your specific compressor.

3. Changing oil weight is not necessary

Many people assume that once they have chosen an oil weight for their air compressor, they can stick with it indefinitely. However, oil weight requirements can change depending on factors such as ambient temperature, compressor size, and usage frequency. It’s important to regularly check the manufacturer’s recommendations and adjust the oil weight accordingly to ensure optimal performance and longevity of your air compressor.

4. It’s okay to mix different oil weights

Sometimes, users may think that it’s acceptable to mix different oil weights if they don’t have the correct oil on hand. However, mixing different oil weights can alter the viscosity and performance of the oil, potentially leading to inadequate lubrication. It’s always best to use the recommended oil weight and avoid mixing different oils.

By understanding and avoiding these common misconceptions, you can ensure that you are using the correct oil weight for your air compressor, maximizing its performance and lifespan.

Maintenance and Oil Change Recommendations

Regular Maintenance

Regular maintenance is essential to keep your air compressor in good working condition. It is recommended to inspect and clean the air filter regularly to remove any dust or debris that can clog the system. A clogged air filter can affect the performance and efficiency of the compressor, so it is important to clean or replace it as needed.

Additionally, it is important to check the oil level regularly. Low oil levels can cause damage to the compressor, so it is important to keep it adequately lubricated. Check the compressor’s manual for specific instructions on how to check the oil level and ensure it is at the recommended level.

Oil Change Recommendations

Regular oil changes are a crucial part of air compressor maintenance. Over time, oil can become contaminated with dirt, moisture, and other debris, which can reduce its effectiveness as a lubricant. The frequency of oil changes depends on the type of compressor and its usage, so it is important to refer to the manufacturer’s recommendations.

When performing an oil change, it is important to drain the old oil completely and replace it with the recommended weight of oil. Using the right oil weight is important as it ensures proper lubrication of the compressor’s moving parts. Refer to the manufacturer’s specifications or consult a professional for guidance on which oil weight to use.

Additional Tips

In addition to regular maintenance and oil changes, there are a few other tips to keep in mind for optimal air compressor performance. It is important to keep the compressor in a clean and well-ventilated area to prevent dust and debris from entering the system. Regularly inspect the hoses and connections for any leaks or damage and replace them if necessary.

Furthermore, it is important to follow the manufacturer’s guidelines for operating the air compressor. Avoid overloading the compressor, as this can put excessive strain on the motor and other components. It is also important to let the compressor cool down after extended use to prevent overheating and potential damage.

FAQ:

What is the purpose of using oil in an air compressor?

The oil in an air compressor helps to lubricate the moving parts and reduce friction, which in turn helps to extend the lifespan of the compressor.

How often should I change the oil in my air compressor?

The frequency of changing the oil in an air compressor depends on the type of compressor and the usage. It is recommended to check the manual of your specific compressor for the manufacturer’s recommendations on oil change intervals.

What happens if I use the wrong weight oil in my air compressor?

Using the wrong weight oil in an air compressor can lead to poor lubrication and higher friction. This can result in increased wear and tear on the compressor’s components and potentially reduce its overall lifespan.

How do I determine the right weight oil for my air compressor?

The right weight oil for an air compressor is determined by the manufacturer’s recommendations. This information can usually be found in the compressor’s manual or by contacting the manufacturer directly. It is important to choose the correct weight oil to ensure proper lubrication and performance of the compressor.

Video: