Choosing the Right Size Air Hose for Your Pancake Compressor

When it comes to using a pancake compressor, one of the most important factors to consider is the size of the air hose you will be using. The air hose is the vital link between the compressor and the pneumatic tools you will be using, so choosing the right size is crucial for optimal performance.

The size of the air hose is typically measured in terms of its inner diameter, expressed in inches. The most common sizes for pancake compressors are 1/4-inch, 3/8-inch, and 1/2-inch. Each size has its own advantages and disadvantages, depending on the type of work you will be doing and the length of the hose required.

If you will be using your pancake compressor for light-duty tasks, such as inflating tires or powering small tools, a 1/4-inch air hose would be sufficient. This size is compact and lightweight, making it easy to maneuver and store. However, it may not provide enough airflow for heavy-duty tools or tasks that require a longer hose.

On the other hand, if you will be using your pancake compressor for more demanding tasks, such as running air-powered impact wrenches or spray guns, a larger diameter air hose, such as 3/8-inch or 1/2-inch, would be more suitable. These sizes provide increased airflow, allowing for better performance and efficiency.

It is also important to consider the length of the air hose you will need. Longer hoses can result in pressure drops and decreased performance, so it is important to choose the appropriate length for your specific needs. If you need a longer hose, opting for a larger diameter can help compensate for the potential pressure drop.

Ultimately, choosing the right size air hose for your pancake compressor requires careful consideration of your specific requirements and the type of work you will be doing. By selecting the optimal size, you can ensure that your pneumatic tools perform at their best and that you have a smooth and efficient working experience.

Factors to Consider When Choosing an Air Hose for Your Pancake Compressor

When selecting an air hose for your pancake compressor, there are several factors that you need to consider to ensure optimal performance and efficiency. These factors include:

1. Hose Length:

The length of the hose you choose will depend on the specific needs of your projects. If you’ll be working in a small area, a shorter hose length may be sufficient. However, if you need to work in larger or more spread-out areas, a longer hose will allow you to move around without having to constantly move your compressor.

2. Hose Diameter:

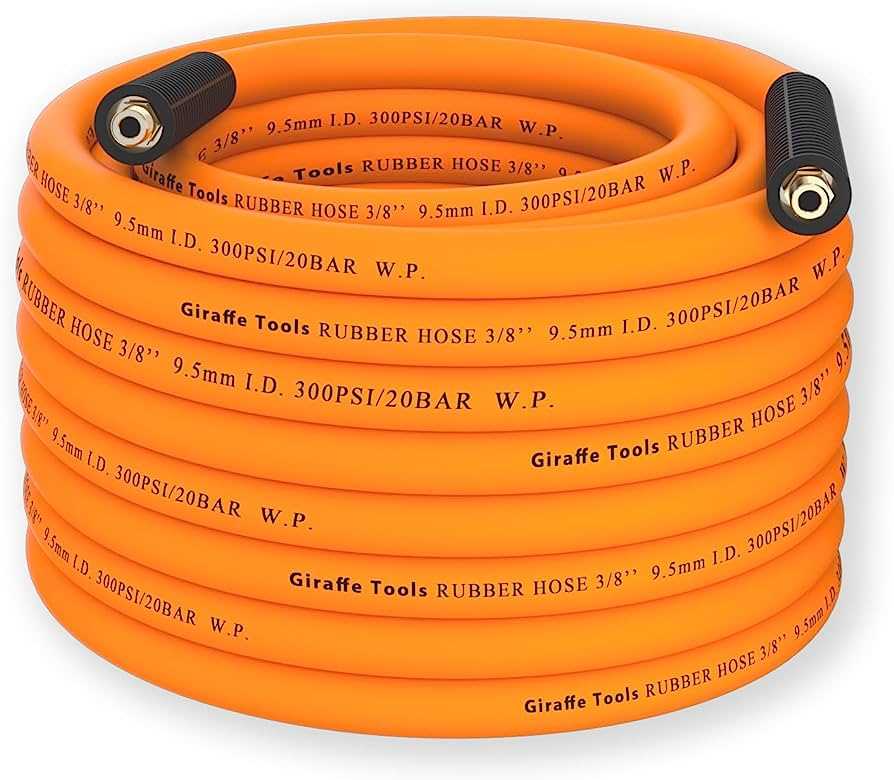

The diameter of the air hose is another crucial factor to consider. A larger diameter allows for increased airflow and reduced pressure drop, resulting in better performance. For most pancake compressors, a 3/8 inch diameter hose is typically recommended as it strikes a good balance between airflow and maneuverability.

3. Hose Material:

The material of the air hose can also impact its overall performance and durability. Rubber hoses are often preferred for their flexibility and resistance to abrasion. However, they can be heavier and less maneuverable compared to PVC or hybrid hoses. PVC hoses are lightweight and offer good flexibility, but they may not be as durable in harsh working conditions. Hybrid hoses combine the best of both worlds, offering flexibility and durability.

4. Hose Pressure Rating:

It’s important to choose an air hose that can handle the maximum pressure output of your pancake compressor. Check the pressure rating of the hose and make sure it exceeds the maximum pressure that your compressor can produce. This will prevent the hose from bursting or failing under high pressure.

5. Fittings and Connections:

Consider the type of fittings and connections on both ends of the air hose. Ensure that the fittings match the ones on your pancake compressor and any accessories you plan to use. Quick-connect fittings are commonly used as they allow for easy and secure connections.

By considering these factors when choosing an air hose for your pancake compressor, you can ensure that you have a hose that meets your specific needs and provides optimal performance for your projects.

Optimal Air Flow and Pressure Requirements

When choosing the right size air hose for your pancake compressor, it is important to consider the optimal air flow and pressure requirements for your specific tasks. The flow rate and pressure needed will depend on the type of tool or equipment you are using, as well as the nature of your work.

One factor to consider is the required air flow rate, measured in Cubic Feet per Minute (CFM). Different tools have different CFM requirements, so it is important to check the manufacturer’s specifications for each tool you plan to use. Using an air hose that is too small can result in a drop in pressure, leading to inefficient and ineffective tool operation.

Another consideration is the required air pressure, measured in pounds per square inch (PSI). Similar to CFM, different tools require different PSI levels to operate optimally. Using an air hose that cannot handle the required pressure can cause the tool to underperform or even fail to work altogether.

It is also worth noting that longer air hoses can result in a drop in both air flow and pressure due to friction and resistance. Therefore, when working with longer distances, it may be necessary to use a larger diameter hose to compensate for these losses.

In summary, selecting the right size air hose for your pancake compressor involves understanding the optimal air flow and pressure requirements of your tools and equipment. By ensuring that your air hose can meet these requirements, you can achieve efficient and effective operation while avoiding potential performance issues.

Length and Size Compatibility

When choosing the right size air hose for your pancake compressor, it is important to consider both the length and size compatibility. The length of the air hose can greatly affect the performance and efficiency of your compressor. If the hose is too short, you may not be able to reach certain areas where you need to use the air tools. On the other hand, if the hose is too long, it can cause a drop in pressure, resulting in reduced power and slower performance.

Size compatibility

The size of the air hose refers to the inner diameter of the hose, which determines the airflow capacity. It is important to choose the right size that matches your air tools and the requirements of your compressor. Using an air hose with a smaller diameter than recommended can cause a restriction in airflow, leading to decreased power and efficiency. Conversely, using a larger diameter hose than necessary can result in wasted energy and increased pressure drop.

Matching the length and size:

It is crucial to match the length and size of the air hose to ensure optimum performance of your pancake compressor. The longer the hose, the larger the diameter should be to compensate for the pressure drop. For shorter hoses, a smaller diameter may be sufficient to maintain the required airflow. It is recommended to consult the manufacturer’s guidelines or consult with an expert to determine the appropriate length and size for your specific needs.

Considerations:

When considering the length and size compatibility, there are a few factors to keep in mind:

- Pressure requirements of your air tools

- Length of the hose needed

- Type of air tools you will be using

- Operating conditions, such as temperature and humidity

By considering these factors and ensuring the proper length and size compatibility, you can maximize the performance and efficiency of your pancake compressor and air tools.

Material Durability and Flexibility

The material used to make an air hose plays a significant role in its durability and flexibility. It is important to choose a hose made from a strong and durable material to ensure that it can withstand the pressures and strains that air compressors can generate.

One common material used for air hoses is rubber, which offers excellent durability and flexibility. Rubber hoses are able to withstand high temperatures and are resistant to abrasions, making them suitable for use in various environments. They also have good resistance to kinks and twists, allowing for smooth and uninterrupted airflow.

Another popular material option for air hoses is PVC (polyvinyl chloride). PVC hoses are lightweight and highly flexible, making them easy to maneuver and store. While PVC hoses may not be as durable as rubber hoses, they are still suitable for many applications and offer good resistance to wear and tear.

When choosing an air hose for your pancake compressor, consider the specific demands of your work environment and the type of tasks you will be performing. If you anticipate working in harsh conditions or with heavy-duty equipment, opting for a rubber hose may be the best choice for long-term durability. However, if flexibility and portability are more important considerations, a PVC hose may be a better option.

It is also worth noting that there are hybrid air hoses available on the market, which combine the benefits of both rubber and PVC materials. These hoses are designed to offer a balance between durability and flexibility, making them a versatile option for various applications.

Fittings and Connectors

When choosing the right size air hose for your pancake compressor, it is important to consider the fittings and connectors that will be used. Fittings and connectors are essential components of the air hose system, as they provide the means to connect the hose to the compressor and the tools or equipment being used.

There are different types of fittings and connectors available, each with its own specific purpose and compatibility. The most common types of fittings and connectors for air hoses include:

- Quick-Connect Fittings: These fittings are designed for easy and fast connections. They have a mechanism that allows for quick attachment and detachment of the air hose, making them ideal for frequent tool changes or when multiple tools will be used.

- Threaded Fittings: Threaded fittings have male and female threads that screw together for a secure connection. They are commonly used in applications where a tight seal is required, such as when working with high-pressure air or when using air-powered tools that generate a lot of vibration.

- Barbed Fittings: Barbed fittings have ridges or barbs that grip the inside of the air hose when inserted. They are often used with hose clamps to ensure a secure connection. Barbed fittings are commonly used in low-pressure applications and when working with flexible hoses that are more prone to leakage.

It is important to select fittings and connectors that are compatible with both the air hose and the compressor. This includes matching the size and thread type of the fittings to the corresponding ports on the compressor and tools. Improperly sized or incompatible fittings can result in leaks, decreased air pressure, and potential safety hazards.

When purchasing fittings and connectors, it is advisable to consult the manufacturer’s recommendations or seek the assistance of a knowledgeable professional. They can provide guidance on the appropriate fittings and connectors for your specific pancake compressor and air hose setup.

Furthermore, regular inspection and maintenance of the fittings and connectors are essential to ensure their proper functioning. This includes checking for signs of wear or damage, tightening any loose connections, and replacing any faulty or worn components.

Maneuverability and Storage

When choosing the right size air hose for your pancake compressor, it’s important to consider the maneuverability and storage of the hose. A larger hose may provide more air flow, but it can also be more cumbersome to move around and store. On the other hand, a smaller hose may be more portable and easier to handle, but it may sacrifice air flow capacity.

One factor to consider is the length of the hose. A longer hose can allow you to reach further distances, but it can also be more difficult to maneuver and store. If you primarily work in a small workshop or garage, a shorter hose may be more practical as it will be easier to handle and store.

Another factor to consider is the diameter of the hose. A larger diameter hose can provide higher air flow, which may be necessary for certain applications that require a higher volume of air. However, a larger diameter hose can also be heavier and more difficult to maneuver. If you primarily work on small projects that don’t require a lot of air flow, a smaller diameter hose may be sufficient and more convenient to handle.

Lastly, consider the material of the hose. Some hoses are made of rubber, while others are made of PVC or polyurethane. Rubber hoses are generally more flexible and durable, but they can also be heavier. PVC and polyurethane hoses are more lightweight and may be easier to maneuver, but they may not be as durable in the long run.

Overall, when choosing the right size air hose for your pancake compressor, it’s important to strike a balance between air flow capacity and maneuverability/storage. Consider your specific needs and workspace limitations to determine the best size hose for your requirements.

Temperature and Climate Considerations

When choosing the right size air hose for your pancake compressor, it is important to consider the temperature and climate conditions in which you will be using it.

Extreme temperatures can have an impact on the performance and durability of the air hose. In colder climates, the air hose may become stiff and less flexible, which can make it difficult to maneuver and use. On the other hand, in hotter climates, the air hose may become more pliable, but this can also increase the risk of it becoming brittle and prone to cracking.

Additionally, humidity levels can affect the air hose’s performance. High humidity can cause moisture to condense inside the hose, which can lead to issues such as corrosion and decreased air flow. In such conditions, it may be necessary to use a moisture filter or dryer to prevent these problems.

Furthermore, the type of environment in which you will be using the air hose should also be taken into consideration. If you will be working in a dusty or dirty environment, it is important to choose an air hose that is resistant to abrasion and can withstand exposure to these contaminants.

Considering the temperature and climate conditions, as well as the environmental factors, will help you choose the right size air hose that can withstand the specific demands of your job or project.

Noise and Vibration Reduction

Noise and vibration reduction is an important consideration when choosing the right size air hose for your pancake compressor. Compressors can generate high levels of noise and vibration, which can be both distracting and potentially harmful to your health. To minimize this, it is essential to select an air hose that can help reduce noise and vibration.

Choosing the right material: One way to reduce noise and vibration is to select an air hose made from materials that have good noise insulation properties. Rubber or polyurethane hoses tend to provide better noise reduction compared to PVC hoses, which can transmit noise and vibration more easily.

Considering the length and diameter: The length and diameter of the air hose can also affect noise and vibration levels. Longer hoses can help to distance the compressor from your work area, reducing the amount of noise and vibration that reaches you. Additionally, using a hose with a larger diameter can help to minimize restrictions in airflow, reducing noise and vibration as a result.

Using anti-vibration pads: Another option to reduce noise and vibration is to use anti-vibration pads. These pads can be placed under the compressor to absorb and dampen vibrations, minimizing their transmission to the surrounding area. This can help create a quieter and more comfortable working environment.

Regular maintenance: Lastly, it is important to regularly maintain your equipment to ensure optimal performance and minimize noise and vibration. This includes checking for air leaks, lubricating moving parts, and cleaning or replacing filters. By keeping your compressor in good condition, you can help reduce excess noise and vibration.

In conclusion, when selecting the right size air hose for your pancake compressor, it is important to consider noise and vibration reduction. By choosing the right material, length, and diameter, using anti-vibration pads, and regularly maintaining your equipment, you can create a quieter and more comfortable working environment.

Budget and Cost Effectiveness

When considering the size of an air hose for your pancake compressor, budget and cost effectiveness are important factors to consider. While it may be tempting to go for the largest and most expensive hose, it is essential to evaluate your needs and consider your budget.

Choosing a larger size air hose may seem like the best option, as it allows for maximum airflow and reduces the risk of pressure drop. However, larger hoses can be significantly more expensive, not only in terms of the initial purchase cost but also in terms of ongoing maintenance and replacement costs.

On the other hand, opting for a smaller size air hose can be a more budget-friendly choice. Smaller hoses are generally more affordable and readily available, making them a cost-effective option for those on a tight budget. Additionally, smaller hoses are easier to handle and store, which can save you time and effort in the long run.

It’s also important to consider the cost effectiveness of the air tools you will be using with the air hose. If you primarily use lightweight air tools that require a lower airflow, a smaller size air hose might be sufficient and more cost-effective. However, if you frequently use heavy-duty air tools that require a higher airflow, investing in a larger hose may be a better long-term financial decision to ensure optimal performance and longevity of your tools.

In conclusion, when choosing the right size air hose for your pancake compressor, budget and cost effectiveness should be taken into account. Carefully assess your needs, consider your budget, and weigh the costs and benefits of different hose sizes to make an informed decision that meets both your financial and operational requirements.

FAQ:

What is a pancake compressor?

A pancake compressor is a type of air compressor that is characterized by its compact, flat, and round shape, resembling a pancake. It is commonly used for small-scale tasks and is popular among DIY enthusiasts and hobbyists.

Why is it important to choose the right size air hose for a pancake compressor?

Choosing the right size air hose for a pancake compressor is important because it affects the efficiency and performance of the compressor. If the air hose is too small, it can restrict the airflow and put additional strain on the compressor, resulting in reduced power and longer operating times. On the other hand, if the air hose is too large, it can lead to pressure drops and wasted energy. Therefore, selecting the appropriate size air hose ensures optimal operation of the pancake compressor.

What factors should be considered when choosing the size of the air hose for a pancake compressor?

Several factors should be considered when choosing the size of the air hose for a pancake compressor. These include the maximum airflow required for the intended applications, the length of the air hose, the inner diameter of the hose, and the type of fittings used. It is important to determine the specific needs and requirements of the tasks that will be performed with the pancake compressor to select the appropriate size air hose.

What are the common sizes of air hoses for pancake compressors?

The common sizes of air hoses for pancake compressors typically range from 1/4 inch to 3/8 inch in diameter. These sizes are suitable for most small to medium-scale tasks and provide sufficient airflow for various applications. It is important to note that the length of the air hose can also affect the performance, so it is recommended to choose a size that is appropriate for the length of the hose as well.

Can I use a larger air hose with a pancake compressor to increase the airflow?

While it may seem logical to use a larger air hose with a pancake compressor to increase the airflow, it is not always the best solution. Using a larger air hose than necessary can lead to pressure drops and wasted energy. It is important to select the appropriate size air hose based on the specific needs and requirements of the tasks that will be performed with the pancake compressor.

Is it possible to use a smaller air hose with a pancake compressor?

Using a smaller air hose with a pancake compressor is possible, but it can restrict the airflow and put additional strain on the compressor. This can result in reduced power, longer operating times, and potentially damage the compressor over time. It is recommended to select the appropriate size air hose for optimal operation and performance of the pancake compressor.

Video: