Understanding the Working Mechanism of a Lathe Machine

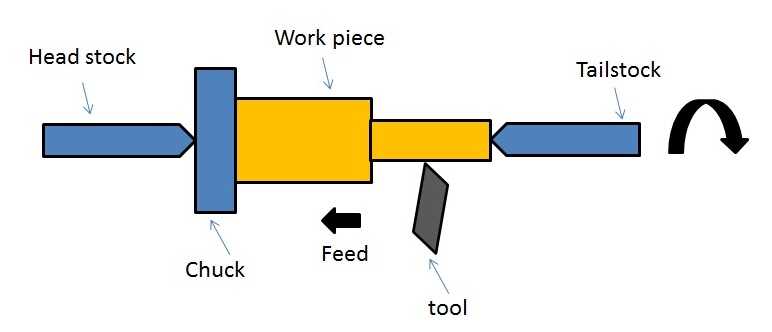

A lathe machine is a versatile tool commonly used in the machining industry. It is a machine tool that rotates a workpiece on its axis to perform various operations, such as cutting, drilling, facing, and turning. Understanding the working mechanism of a lathe machine is essential for anyone looking to operate or work with this powerful equipment.

The main components of a lathe machine include the bed, headstock, tailstock, carriage, and toolpost. The bed forms the base of the machine and provides support to all the other parts. The headstock houses the main spindle, which holds the workpiece and rotates it. The tailstock is located at the opposite end of the headstock and provides additional support to the workpiece. The carriage moves along the bed and holds the cutting tool, allowing it to move across the workpiece. The toolpost holds the cutting tool and can be adjusted to achieve different cutting depths.

The working mechanism of a lathe machine involves several steps. First, the workpiece is securely mounted on the spindle of the headstock. The power is then turned on, and the spindle starts rotating at a desired speed. The cutting tool is positioned using the carriage and the toolpost. The operator then controls the movement of the carriage to guide the cutting tool across the workpiece. This allows the cutting tool to remove material and shape the workpiece according to the desired specifications.

There are different types of lathe machines, each designed for specific purposes. For example, a center lathe is used for general purpose turning operations, while a turret lathe is specifically designed for intricate and repetitive tasks. CNC (Computer Numerical Control) lathe machines are equipped with computerized controls, allowing for precise and automated operations.

Understanding the working mechanism of a lathe machine is crucial for operators, machinists, and anyone involved in the machining industry. It enables them to effectively use this versatile tool, ensuring accurate and efficient machining operations. Whether it’s creating intricate parts or simple shapes, a lathe machine is an invaluable asset in any machining workshop.

The Basics of Lathe Machine: A Comprehensive Overview

Introduction

A lathe machine is a versatile and essential tool in the field of metalworking. It is used for various purposes, including shaping and machining cylindrical workpieces. Understanding the basics of how a lathe machine works is crucial for operating and utilizing its potential to the fullest.

Components of a Lathe Machine

A typical lathe machine consists of several key components, including:

- Bed: The bed is the base of the machine, providing support and stability.

- Headstock: The headstock houses the main spindle, which holds the workpiece.

- Tailstock: The tailstock serves as a support for the opposite end of the workpiece.

- Carriage: The carriage moves along the bed and holds the cutting tool.

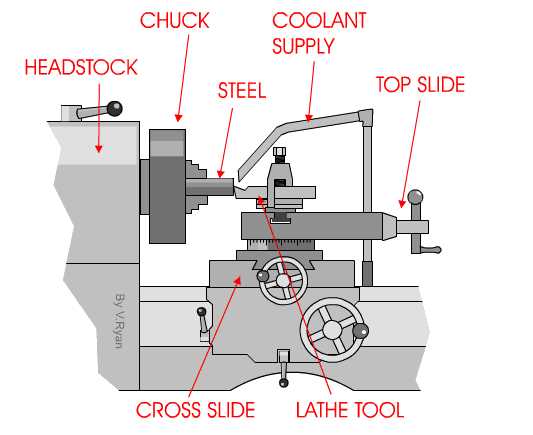

- Cross Slide: The cross slide moves perpendicular to the length of the bed, allowing for precise cutting.

- Apron: The apron contains various controls and mechanisms for operating the machine.

- Chuck: The chuck is used to hold and rotate the workpiece.

Working Principle

The basic principle behind the operation of a lathe machine involves rotating a workpiece against a cutting tool. The cutting tool is held in the carriage and moves along the workpiece to remove material, creating the desired shape or dimension. The rotation of the workpiece is controlled by the headstock, while the movement of the carriage and cross slide is controlled by the operator.

Types of Lathe Machines

There are several types of lathe machines available, each designed for specific applications. Some common types include:

- Engine Lathe: The most common type of lathe machine used in general-purpose machining.

- Turret Lathe: A lathe machine with a turret head that holds multiple cutting tools, allowing for quick tool changes.

- Gap Bed Lathe: A lathe machine with a removable section in the bed, enabling the machining of larger workpieces.

- CNC Lathe: A lathe machine controlled by computer numerical control (CNC), providing high precision and automation.

Applications of Lathe Machines

Lathe machines find applications in various industries, including manufacturing, automotive, aerospace, and more. Some common uses of lathe machines include:

- Turning and facing operations

- Threading and tapping

- Knurling

- Boring

- Drilling

- Taper turning

Conclusion

In conclusion, a lathe machine is a versatile tool used for shaping and machining cylindrical workpieces. Understanding its components, working principle, and different types can help individuals make the most of this essential machine in various applications and industries.

What is a Lathe Machine?

A lathe machine is a type of machine tool used to shape and cut various materials, such as wood, metal, and plastic. It is commonly used in machining and manufacturing processes to produce precise cylindrical and conical objects. The lathe machine is known for its versatility and can perform a wide range of operations, including turning, facing, drilling, boring, and threading.

The basic principle of a lathe machine involves rotating the workpiece against a cutting tool to remove material and create the desired shape. The workpiece is held securely in a chuck or a collet, and it rotates on its axis while the cutting tool is manually or automatically fed into the workpiece to remove material. The cutting tool can move longitudinally, transversely, or radially to produce different shapes and sizes.

Components of a Lathe Machine:

- Bed: It is the base of the lathe machine that provides support and rigidity to the other components.

- Headstock: It is located at the left end of the lathe and houses the main spindle, which rotates the workpiece.

- Tailstock: It is located at the right end of the lathe and provides support to the other end of the workpiece. It can be moved along the bed to adjust the position and ensure proper alignment.

- Carriage: It is located between the headstock and the tailstock and moves along the bed. It carries the cutting tool and can be moved longitudinally and transversely to perform various operations.

- Tool Post: It is mounted on the carriage and holds the cutting tool securely.

Lathe machines can range from small tabletop models to large industrial-sized machines. They are widely used in industries such as automotive, aerospace, and construction for manufacturing various components, such as shafts, cylinders, and threaded parts.

History and Evolution of Lathe Machines

The lathe machine is one of the oldest and most important tools in the field of machining. Its history can be traced back to ancient Egypt, where wooden lathes were used to shape objects out of wood. These early lathes were operated manually, with the wood being rotated by a rope or cord while the craftsman shaped it using hand tools.

Later on, during the Industrial Revolution in the 18th century, the development of metalworking lathes revolutionized the manufacturing industry. These early metal lathes were powered by water, steam, or hand-cranked mechanisms. They allowed for the production of more precise and complex metal parts, leading to advancements in various industries such as textiles, transportation, and agriculture.

In the 19th century, the introduction of the steam engine and the improvement of cutting tools further enhanced the capabilities of lathe machines. The steam-powered lathe machines enabled faster and more efficient production, as they eliminated the need for manual labor and increased the rotational speed of the workpiece.

With the advent of electricity in the late 19th century, new possibilities arose for lathe machines. Electric motors replaced steam engines, making the machines more reliable and easier to operate. This led to further advancements in the design and functionality of lathe machines.

In the 20th century, the introduction of computer numerical control (CNC) technology revolutionized the field of machining, including lathe machines. CNC lathes are controlled by computer programs, which provide precise instructions for the machining process. This technology allowed for increased automation, faster production, and improved accuracy.

Today, lathe machines are used in various industries, such as automotive, aerospace, and medical, for a wide range of applications. They have come a long way from their humble beginnings as manual wooden lathes to highly advanced CNC machines that can perform complex operations with minimal human intervention.

- The history of lathe machines can be traced back to ancient Egypt.

- Wooden lathes were used to shape objects out of wood manually.

- Metalworking lathes were developed during the Industrial Revolution.

- Steam-powered lathes increased production speed and efficiency.

- The advent of electricity led to the development of electric-powered lathe machines.

- The introduction of CNC technology revolutionized lathe machines.

- Lathe machines are widely used today in various industries for different applications.

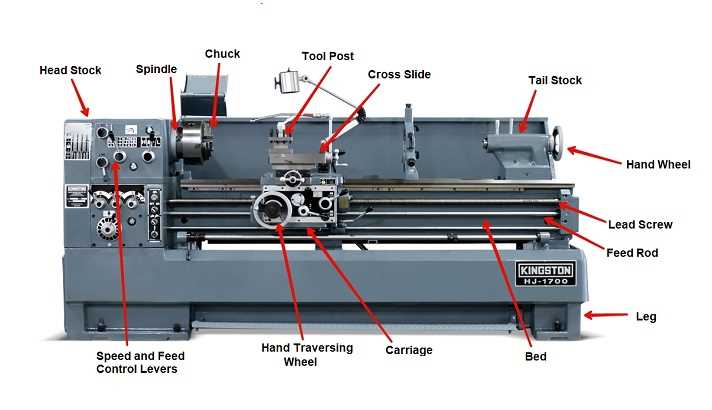

Parts and Components of a Lathe Machine

A lathe machine is a versatile tool used in machining operations to shape, cut, or drill a workpiece. It consists of various parts and components that work together to perform different functions. Understanding these parts and their functions is essential for operating a lathe machine effectively. Here are the main parts of a lathe machine:

1. Bed

The bed is the base of the lathe machine, providing a rigid support for other components. It is typically made of cast iron and is designed to withstand heavy loads and vibrations.

2. Headstock

The headstock is located at the left end of the lathe machine’s bed. It houses the main spindle, which rotates and holds the workpiece. The headstock also contains various gears and mechanisms to control the speed and feed of the spindle.

3. Tailstock

The tailstock is located at the right end of the lathe machine’s bed, opposite the headstock. It provides support to the other end of the workpiece and can be moved along the bed to adjust the length of the workpiece. The tailstock usually contains a spindle and a mechanism to lock it in place.

4. Carriage

The carriage is mounted on the bed and can move along it through the use of handwheels or power feeds. It consists of several components, including the saddle, cross-slide, and toolpost, which hold and position cutting tools for machining operations.

5. Toolpost

The toolpost is attached to the carriage and holds the cutting tools in place. It can be adjusted and locked at different angles and heights to achieve the desired cutting operations.

6. Apron

The apron is located on top of the carriage and contains various mechanisms for controlling the movement of the carriage and cross-slide, such as feed rate adjustment, direction reversal, and automatic threading mechanisms.

7. Chuck

The chuck is a clamping device mounted on the spindle of the headstock. It securely holds the workpiece, allowing it to rotate with the spindle during machining operations. Chucks come in different types, such as three-jaw chucks, four-jaw chucks, and collet chucks.

8. Leadscrew

The leadscrew is a long threaded shaft located along the bed. It engages with the carriage and allows for precise and controlled movement of the carriage along the bed. The leadscrew is usually driven by a gear mechanism connected to the spindle.

9. Feed Rod

The feed rod is a shaft connected to the leadscrew that allows for the manual or automatic feeding of the cutting tool. It can be used to control the depth of cut and the feed rate during machining operations.

10. Tailstock Quill

The tailstock quill is a hollow spindle located in the tailstock. It can be extended or retracted by using a handwheel or lever mechanism, allowing for the precise positioning and support of the workpiece.

These are the main parts and components of a lathe machine. Each part plays a crucial role in the overall functioning of the machine and contributes to its versatility in machining operations.

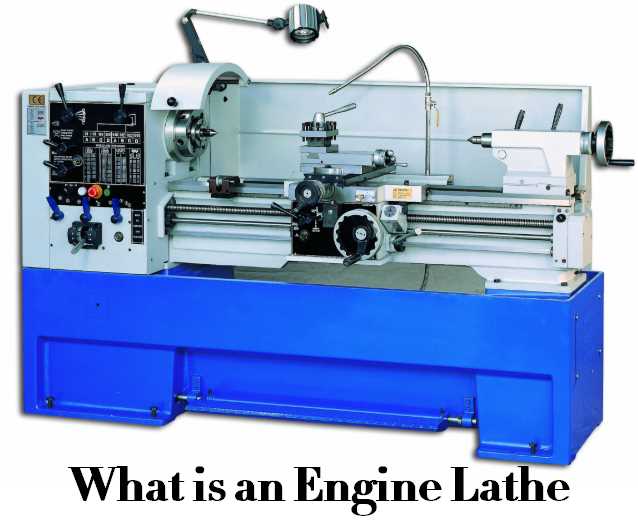

Types of Lathe Machines and their Applications

1. Engine Lathe

An engine lathe is the most common type of lathe machine. It is used for a wide range of general-purpose machining operations. This type of lathe is versatile and can perform various tasks such as turning, boring, facing, threading, and tapering.

2. Turret Lathe

A turret lathe is a type of lathe machine equipped with a turret or a tool post that can hold multiple tools. This allows for quick tool changes, reducing setup time and increasing productivity. Turret lathes are commonly used for repetitive machining operations, such as producing symmetrical parts and mass production.

3. CNC Lathe

A CNC (Computer Numerical Control) lathe is a lathe machine that is controlled by a computer and can execute complex machining operations with great accuracy. CNC lathes can be programmed to perform precise turning, milling, drilling, and other operations. They are widely used in manufacturing industries for producing high-precision components and parts.

4. Vertical Lathe

A vertical lathe, also known as a vertical turning center (VTC), is a lathe machine with a vertical axis. Unlike traditional lathes that have a horizontal spindle, vertical lathes have a vertical spindle. This design allows for the machining of large, heavy workpieces with ease. Vertical lathes are commonly used for turning and boring operations on large cylindrical or disc-shaped workpieces.

5. Speed Lathe

A speed lathe is a type of lathe machine that is specifically designed for high-speed operations. It is usually small in size and lightweight, making it portable and convenient for small-scale machining tasks. Speed lathes are commonly used for tasks such as polishing, centering, and drilling small holes.

6. Bench Lathe

A bench lathe is a compact lathe machine that is designed to be used on a workbench or table. It is smaller in size and lower in horsepower compared to other types of lathes. Bench lathes are commonly used for light-duty machining tasks, such as shaping, grooving, and threading small workpieces.

7. Capstan and Turret Lathe

A capstan and turret lathe is a type of lathe machine that combines the features of a turret lathe and a capstan lathe. It has a hexagonal turret or a capstan drum that can hold multiple tools and be indexed to bring the desired tool into the cutting position. Capstan and turret lathes are commonly used for high-speed, mass-production operations where quick tool changes are required.

8. Automatic Lathe

An automatic lathe is a lathe machine that is capable of automatically repeating machining operations without manual intervention. It is typically used for high-volume production of small, repetitive parts. Automatic lathes can perform tasks such as turning, drilling, chamfering, and threading in a highly efficient and automated manner.

These are just some of the different types of lathe machines and their applications. Depending on the specific machining requirements, different types of lathe machines can be used to achieve desired results in terms of precision, production volume, and efficiency.

Important Safety Measures while Operating a Lathe Machine

1. Wear Proper Protective Gear

When operating a lathe machine, it is essential to wear the proper protective gear to ensure your safety. This includes:

- Safety glasses or goggles to protect your eyes from flying debris.

- Earplugs or earmuffs to protect your ears from loud noise.

- A face shield to protect your face from any potential hazards.

- Appropriate clothing, such as long-sleeved shirts and pants, to protect your body from cuts or burns.

- Gloves to provide grip and protect your hands from any sharp objects or hot materials.

2. Ensure Proper Machine Setup and Maintenance

Before operating a lathe machine, ensure that it is set up correctly and that all components are in good condition. This includes:

- Checking that the workpiece is securely fastened to the lathe machine.

- Verifying that the cutting tools are sharp and properly aligned.

- Inspecting the machine for any loose or damaged parts.

- Ensure that the lathe machine is properly lubricated to reduce friction and heat.

3. Use the Lathe Machine in a Well-ventilated Area

Operating a lathe machine can produce dust, fumes, and other airborne particles. To avoid any health hazards, it is important to use the machine in a well-ventilated area. Make sure there is adequate airflow to prevent the accumulation of harmful substances.

4. Follow Safe Operating Procedures

Always follow safe operating procedures when using a lathe machine. This includes:

- Operating the machine at the recommended speed for the material being worked on.

- Avoiding sudden movements or excessive force that could cause the workpiece or tool to break.

- Using the appropriate cutting tools and techniques for the specific task.

- Never leaving the lathe machine unattended while it is still running.

5. Keep the Work Area Clean and Organized

A cluttered or messy work area can increase the risk of accidents. Keep the work area clean and organized by removing any debris, tools, or materials that are not being used. This will help prevent tripping hazards and improve overall safety during operation.

6. Avoid Distractions

When operating a lathe machine, it is important to stay focused and avoid distractions. Avoid using a mobile phone, listening to music, or engaging in any other activities that may divert your attention away from the machine. Concentrate on the task at hand to reduce the risk of accidents.

7. Receive Proper Training and Supervision

Operating a lathe machine requires proper training and supervision. Make sure you have received the necessary training on how to safely operate the machine. If you are new to using a lathe machine, it is advised to work under the supervision of an experienced operator until you have gained sufficient skill and confidence.

8. Be Aware of Emergency Procedures

In case of any emergencies, such as a sudden power failure or a workpiece getting stuck, it is important to be aware of the emergency procedures. Familiarize yourself with the location of the emergency stop button and other safety features of the lathe machine. If an emergency occurs, follow the appropriate procedures to mitigate any potential risks.

By following these important safety measures, you can ensure a safe working environment while operating a lathe machine and minimize the risk of accidents or injuries.

Common Issues and Troubleshooting Techniques

1. Machine Vibrations

Vibrations during the operation of a lathe machine can lead to poor surface finish, inaccurate cuts, and excessive tool wear. This can be caused by various factors such as unbalanced workpieces, loose or worn out machine components, or improper cutting parameters. To troubleshoot this issue:

- Check for any loose or worn out components such as belts, gears, or bearings and tighten or replace them as necessary.

- Ensure that the workpiece is securely clamped and properly balanced to minimize vibrations.

- Adjust the cutting parameters, such as cutting speed and feed rate, to optimal values for the specific workpiece and tool being used.

- Consider using damping techniques, such as adding vibration-absorbing materials or using specialized tool holders.

2. Tool Chatter

Tool chatter is another common issue in lathe machines, which results in a poor surface finish, tool breakage, and reduced tool life. It occurs when there is excessive vibration or chatter between the cutting tool and the workpiece. To troubleshoot tool chatter:

- Check the tool for any signs of wear or damage and replace it if necessary.

- Ensure that the tool is properly secured and tightened in the tool holder.

- Reduce the cutting parameters, such as cutting speed or feed rate, to minimize the load on the tool.

- Consider using tools with higher rigidity or using vibration-damping tool holders.

3. Poor Surface Finish

A poor surface finish can be caused by various factors, including improper tool geometry, incorrect cutting parameters, or worn out cutting tools. To troubleshoot poor surface finish:

- Inspect the cutting tool for any signs of wear or damage and replace it if necessary.

- Ensure that the tool has the correct geometry, such as the proper nose radius or rake angle, for the specific operation.

- Adjust the cutting parameters, such as cutting speed, feed rate, and depth of cut, to optimize the surface finish.

- Use cutting fluids or lubricants to improve the cutting performance and reduce friction between the tool and the workpiece.

4. Inaccurate Cuts

Inaccurate cuts can be caused by various factors, including misalignment of machine components, worn out or damaged cutting tools, or incorrect cutting parameters. To troubleshoot inaccurate cuts:

- Check for any misalignment of machine components, such as the tool post, tailstock, or tool holder, and adjust or realign them as necessary.

- Inspect the cutting tool for any signs of wear or damage and replace it if necessary.

- Ensure that the workpiece is securely clamped and properly aligned to the machine axes.

- Adjust the cutting parameters, such as cutting speed, feed rate, and depth of cut, for optimal cutting performance.

5. Motor or Drive Failure

In some cases, lathe machines may experience motor or drive failures, which can prevent the machine from operating properly. To troubleshoot motor or drive failures:

- Check the power supply and ensure that it is providing the correct voltage and frequency.

- Inspect the motor and drive components for any signs of damage or wear and replace them if necessary.

- Check and clean the motor or drive cooling systems to ensure proper heat dissipation.

- Consult the machine’s manual or contact a professional technician for further assistance.

Conclusion

Understanding and troubleshooting common issues in a lathe machine is essential for ensuring optimal performance and extended machine lifespan. By following the troubleshooting techniques outlined above, operators can address these issues effectively and avoid costly downtime.

Future Trends and Advancements in Lathe Machine Technology

1. Automation and Robotics Integration

The future of lathe machine technology lies in the integration of automation and robotics. With advancements in artificial intelligence and robotics, lathe machines will become more efficient, precise, and autonomous. Automation will eliminate the need for human intervention in repetitive tasks and increase productivity.

2. Internet of Things (IoT) Integration

Lathe machines will soon be integrated with the Internet of Things (IoT) technology, allowing them to connect to the internet and communicate with other machines and systems. This connectivity will enable remote monitoring, predictive maintenance, and real-time data analysis, enhancing productivity and reducing downtime.

3. Advanced Control Systems

The control systems used in lathe machines will become more advanced, offering features like predictive maintenance, self-learning algorithms, and adaptive machining. These systems will analyze data in real-time, optimize cutting parameters, and adjust machine settings for improved accuracy and efficiency.

4. Additive Manufacturing Capabilities

Future lathe machines will incorporate additive manufacturing capabilities, allowing them to create complex geometries and intricate designs. This integration will offer more flexibility and versatility, making lathe machines suitable for a wider range of applications, including rapid prototyping and low-volume production.

5. Enhanced Tooling Systems

Improved tooling systems will play a significant role in the future of lathe machine technology. The development of advanced materials, coatings, and tool geometries will result in longer tool life, higher cutting speeds, and better surface finishes. Additionally, tool monitoring and wear detection systems will enable proactive tool replacement and reduce downtime.

6. Energy Efficiency

Future lathe machines will prioritize energy efficiency, with advancements in motor technology, power management systems, and energy-saving features. Manufacturers will strive to reduce energy consumption and minimize environmental impact, resulting in more sustainable and cost-effective lathe machines.

7. Augmented Reality (AR) and Virtual Reality (VR) Integration

AR and VR technologies will find applications in lathe machine training and operation. These technologies will provide immersive and interactive experiences, allowing operators to simulate machine operations, visualize tool paths, and troubleshoot issues before actually performing them on the machine.

8. Data Analytics and Predictive Maintenance

Lathe machines will leverage the power of data analytics and predictive maintenance algorithms to optimize performance, reduce downtime, and prevent equipment failures. Real-time monitoring of machine parameters, tool wear, and vibration patterns will enable proactive maintenance, minimizing unplanned downtime and maximizing productivity.

9. Collaborative and Safe Operation

Future lathe machines will prioritize safety and offer collaborative operation capabilities. Advanced sensor technologies and machine learning algorithms will enable machines to detect and avoid collisions, making them safer to operate. Collaborative robots will also be integrated into lathe machines, working alongside human operators to improve productivity and efficiency.

10. Cloud-Based Solutions

Cloud-based solutions will become more prevalent in lathe machine technology, enabling data storage, remote monitoring, and data analysis. Manufacturers will have access to real-time machine performance data, allowing them to make informed decisions, optimize processes, and improve overall equipment efficiency (OEE).

In conclusion, future trends and advancements in lathe machine technology will revolve around automation and robotics integration, IoT connectivity, advanced control systems, additive manufacturing capabilities, enhanced tooling systems, energy efficiency, AR/VR integration, data analytics, collaborative operation, and cloud-based solutions. These advancements will significantly improve productivity, accuracy, and efficiency in the machining industry.

FAQ

What is a lathe machine?

A lathe machine is a tool that is used in metalworking and woodworking to shape and cut various materials. It works by rotating the workpiece against a fixed cutting tool, which can be moved along the length of the workpiece to create the desired shape.

How does a lathe machine work?

A lathe machine works by rotating the workpiece on its axis while a fixed cutting tool is moved along the length of the workpiece to shape and cut it. The cutting tool can be controlled manually or automatically depending on the type of lathe machine. The rotation of the workpiece and movement of the cutting tool are controlled by a motor, gearbox, and various other components.

What are the different parts of a lathe machine?

A lathe machine consists of several important parts including the headstock, which holds and drives the workpiece; the tailstock, which supports the other end of the workpiece; the bed, which is the base of the machine; the carriage, which holds the cutting tool and can be moved along the length of the workpiece; and the spindle, which rotates the workpiece.

What are the applications of a lathe machine?

A lathe machine is used in various applications including metalworking, woodworking, and machining. It is commonly used for turning, drilling, grooving, threading, and facing operations. It is also used in the production of cylindrical components such as shafts, rods, and bushings.

Video