How to Use a Metal Lathe: A Beginner’s Guide

If you are new to machining, using a metal lathe may seem intimidating at first. However, with the right knowledge and practice, you can become proficient in using this versatile tool. In this beginner’s guide, we will walk you through the basic steps of using a metal lathe, from setting up the machine to completing your first project.

Step 1: Familiarize Yourself with the Machine

Before diving into using a metal lathe, take some time to familiarize yourself with the various parts and components of the machine. This includes understanding the different controls, such as the spindle speed control, feed rate, and the direction of the lathe’s movement. Additionally, make sure you are aware of the safety precautions and procedures to follow while operating the lathe.

It is important to note that each metal lathe may have slight variations in its parts and controls, so always refer to the machine’s manual for specific instructions.

Step 2: Set Up the Machine

Once you feel comfortable with the basics of the machine, the next step is to properly set it up. Start by mounting your workpiece securely in the lathe’s chuck or collet. Ensure that it is aligned correctly, and check for any signs of wobbling or movement. Next, adjust the tool rest and tool post to the desired position, keeping in mind the type of cut you want to make and the material you are working with.

Step 3: Select the Right Tools and Inserts

Choosing the right cutting tools and inserts is crucial for achieving accurate and clean cuts on your workpiece. Consider factors such as the material you are machining, the depth of cut, and the desired finish. Different types of cutting tools, such as carbide or high-speed steel, and various inserts will yield different results. Experimenting with different combinations will help you find the best tools and inserts for your specific projects.

Remember to always wear appropriate personal protective equipment, such as safety glasses and ear protection, while operating the metal lathe.

Pro Tip: It is recommended to start with simple projects and gradually work your way up to more complex ones as you gain experience and confidence in using a metal lathe.

With these basic steps, you are now ready to start using a metal lathe. Remember, practice makes perfect, so don’t get discouraged if your first attempts aren’t perfect. Over time, you will become more comfortable with the machine and develop your skills in machining.

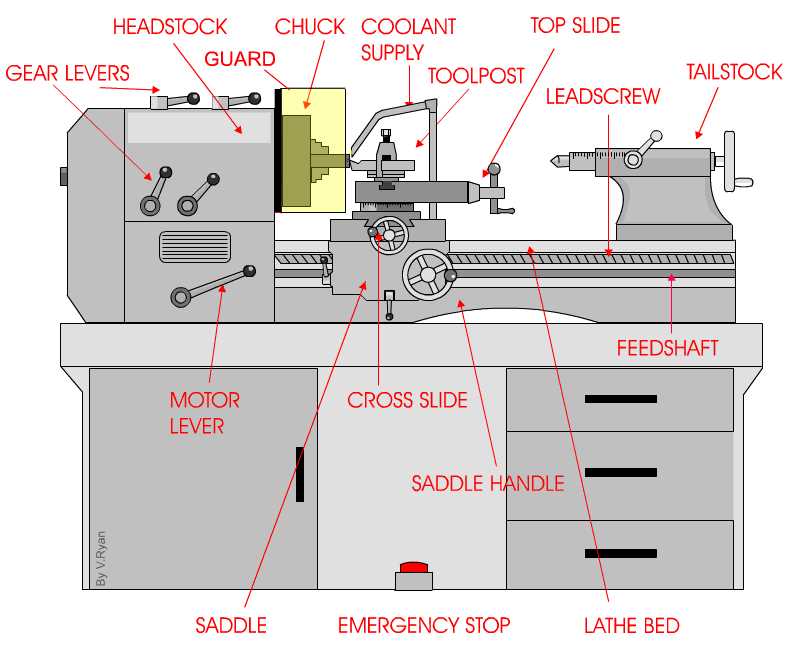

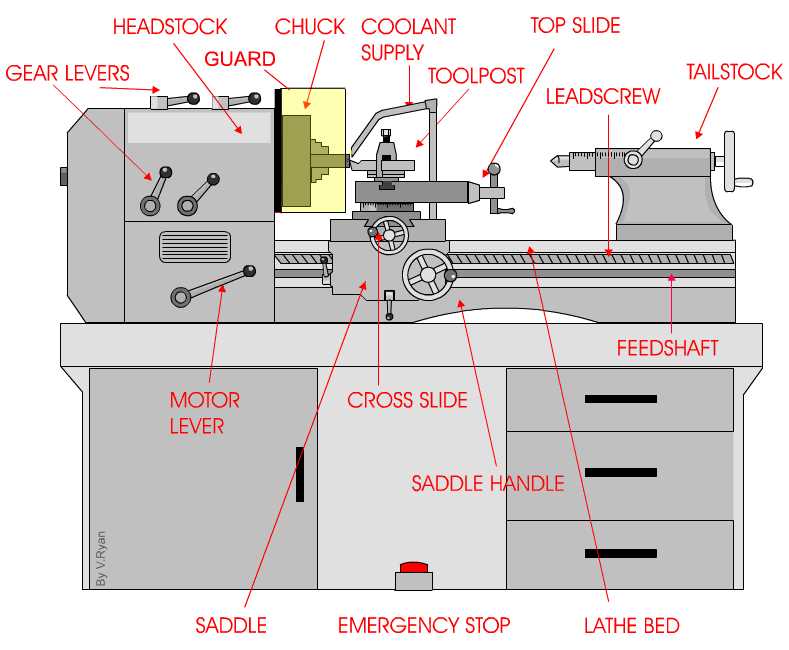

Understanding the Components

Before learning how to use a metal lathe, it’s important to familiarize yourself with its various components. Here are the key components you will find on a typical metal lathe:

1. Bed

The bed is the horizontal base of the lathe that provides support for other components. It is usually made of cast iron and provides stability and rigidity.

2. Headstock

The headstock is located on one end of the bed and houses the main spindle. It is responsible for rotating the workpiece. The headstock also contains the motor that powers the lathe.

3. Tailstock

The tailstock is located on the opposite end of the bed from the headstock. It can be moved along the bed to support the other end of the workpiece. The tailstock may also have a spindle with a live center or a drill chuck for drilling operations.

4. Carriage

The carriage is the main moving component of the lathe and is responsible for moving the cutting tool along the workpiece. It consists of the saddle, which slides along the bed, and the cross-slide, which moves perpendicular to the bed.

5. Chuck

The chuck is a device used to securely hold the workpiece in place. It is usually mounted on the spindle of the headstock. There are different types of chucks available, including three-jaw chucks and four-jaw chucks, which can be used depending on the shape and size of the workpiece.

6. Cutting Tools

The cutting tools are what actually shape the workpiece. They are secured in a tool post mounted on the carriage. There are different types of cutting tools available, including turning tools, boring tools, and threading tools, each with a specific purpose.

7. Feed and Speed Controls

The feed and speed controls allow you to adjust the cutting speed and the rate at which the cutting tool moves along the workpiece. These controls are critical for achieving the desired finish and preventing damage to the workpiece.

8. Coolant System

A coolant system is often present on a metal lathe to remove heat generated during the cutting process. It helps to prolong the life of cutting tools and improves the quality of the finished workpiece. Coolant is usually circulated through the cutting area using pumps and hoses.

By understanding the components of a metal lathe, you will be better equipped to operate and utilize this versatile machine.

Safety Precautions

Using a metal lathe can be a rewarding and satisfying experience, but it is important to prioritize safety. Here are some safety precautions to keep in mind when using a metal lathe:

- Always wear proper safety equipment, such as safety glasses, ear protection, and gloves.

- Make sure the lathe is properly grounded and the power is disconnected before making any adjustments or repairs.

- Keep the work area clean and free of clutter to avoid accidents and injuries.

- Remove any loose jewelry or clothing that could get caught in the lathe’s moving parts.

- Always use the appropriate cutting tools and check them for any damage or wear before use.

- Secure the workpiece tightly before starting the lathe to prevent it from moving or coming loose during operation.

- Do not attempt to adjust or change the workpiece while the lathe is still running.

- Always use the lathe’s cutting tools with caution and avoid applying excessive force.

- When using coolant or lubricant, make sure it is properly contained and not causing any slips or spills on the work area.

- If any abnormal noise or vibration occurs, stop the lathe immediately and investigate the cause.

- Always follow the manufacturer’s instructions and guidelines for safe operation of the metal lathe.

By following these safety precautions, you can ensure a safer and more enjoyable experience when using a metal lathe.

Choosing the Right Cutting Tools

When using a metal lathe, it is crucial to choose the right cutting tools for the job. The type of tool you use will depend on the material you are working with and the desired outcome of the project. Here are some factors to consider when selecting cutting tools:

Material

The material you are machining will determine the type of cutting tool you need. Different materials have different hardness levels, which require specific tooling. For example, carbide cutting tools are ideal for cutting hard materials like steel, while high-speed steel tools are suitable for softer materials like aluminum.

Cutting Operation

The cutting operation you are performing will also influence your choice of cutting tools. There are various cutting operations in metalworking, including turning, facing, boring, threading, and parting. Each operation requires a specific tool geometry and cutting edge design to achieve the desired result.

Tool Geometry

The geometry of the cutting tool, such as the shape and angle of the cutting edge, is essential for achieving efficient cutting and chip removal. Different geometries are suitable for different types of cuts and materials. It is crucial to understand the various tool geometry options and select the one that best suits your specific application.

Cutting Speed and Feed Rate

The cutting speed and feed rate also play a role in tool selection. Cutting speed refers to the speed at which the tool moves relative to the workpiece, while the feed rate determines how much material is removed per revolution of the workpiece. Different cutting speeds and feed rates require different tool types and tool coatings to ensure optimal cutting performance and tool life.

Tool Coatings

Tool coatings can enhance the performance and longevity of cutting tools. Certain coatings, such as titanium nitride (TiN) and aluminum oxide (Al2O3), provide increased hardness and wear resistance. Others, such as titanium carbonitride (TiCN) and titanium aluminum nitride (TiAlN), offer higher temperature resistance and are suitable for high-speed machining.

By considering these factors and understanding the specific requirements of your machining operation, you can choose the right cutting tools to achieve optimal results on a metal lathe.

Setting Up the Metal Lathe

1. Safety Precautions

Before setting up the metal lathe, it is important to take the necessary safety precautions. This includes wearing safety glasses, ear protection, and any other personal protective equipment (PPE) recommended by the manufacturer. Make sure the lathe is located in a well-lit and well-ventilated area, away from any flammable materials.

2. Positioning the Lathe

Ensure that the lathe is placed on a sturdy and level surface. It should be secured to the floor or workbench to prevent any movement or vibration during operation.

3. Power Connection

Connect the lathe to a power source that meets the requirements specified by the manufacturer. Ensure that the power switch is in the OFF position before plugging in the lathe. Follow the manufacturer’s instructions on how to properly ground the lathe to prevent electrical hazards.

4. Tooling and Accessories

Gather all the necessary tooling and accessories required for the specific task at hand. This may include cutting tools, calipers, chucks, center drills, and other attachments. Organize them within easy reach of the lathe to ensure efficiency during operation.

5. Lubrication

Check the lubrication system of the lathe and ensure that it is properly filled with the recommended lubricant. Refer to the manufacturer’s instructions for the appropriate lubrication points and intervals. Regularly check and replenish lubrication as needed during operation.

6. Workholding

Select the appropriate workholding method based on the specific task. This could be a 3-jaw chuck, 4-jaw chuck, collet, or faceplate. Follow the manufacturer’s instructions for proper installation and alignment of the workholding device.

7. Adjustments and Alignments

Perform any necessary adjustments and alignments on the lathe to ensure accuracy and precision. This may include aligning the tailstock with the headstock, adjusting the tool holder, and checking the alignment of the lathe bed. Refer to the lathe’s user manual for specific instructions on these adjustments.

8. Test Run

Before starting any actual work on the metal lathe, perform a test run to ensure that everything is properly set up and functioning correctly. Check for any unusual noises or vibrations and address them before proceeding with actual machining operations.

9. Cleaning and Maintenance

Keep the lathe clean and free from dust, chips, and debris. Regularly clean the lathe bed, gears, and other moving parts with a brush and wipe them down with a clean cloth. Follow the manufacturer’s recommended maintenance schedule for lubrication and other maintenance tasks.

10. Operator Training

Ensure that anyone operating the metal lathe is properly trained in its safe and efficient operation. Provide the necessary training and resources to familiarize operators with the lathe’s controls, safety procedures, and maintenance requirements.

Following these steps will help you properly set up and prepare the metal lathe for safe and accurate machining operations.

Basic Turning Techniques

1. Facing

Facing is the process of creating a flat surface on the end of a workpiece. It is often the first step in many turning projects and helps to ensure that the workpiece is properly aligned with the lathe’s centers.

2. Turning

Turning is the process of removing material from a cylindrical workpiece. This can be done by using a variety of cutting tools, such as a roughing gouge, a skew chisel, or a parting tool. Turning is used to create smooth surfaces, shape the workpiece, or create features such as grooves or threads.

3. Chamfering

Chamfering is the process of creating a beveled edge on the workpiece. This is often done to remove sharp corners or to create a decorative edge. Chamfering can be done using a variety of tools, such as a chamfering tool, a parting tool, or even a file.

4. Boring

Boring is the process of enlarging a hole that has already been drilled or turned. This can be done by using a boring bar, which is a cutting tool that is inserted into the existing hole and used to remove material from the inside diameter. Boring can be used to create precise holes with different diameters or to create tapered holes.

5. Knurling

Knurling is the process of creating a pattern of small ridges on the surface of a workpiece. This is often done to improve the grip or appearance of the workpiece. Knurling is typically done using a knurling tool, which is pressed against the rotating workpiece to create the desired pattern.

6. Parting

Parting is the process of cutting a workpiece off from the main stock. This is often done when creating multiple smaller objects from a larger piece of material. Parting is typically done using a parting tool, which is inserted into the workpiece and used to make a clean cut.

7. Threading

Threading is the process of creating threads on a workpiece. This can be done using a variety of threading tools, such as a threading insert or a threading die. Threading is often used to create screws, bolts, or other threaded components.

8. Taper Turning

Taper turning is the process of creating a tapered shape on a workpiece. This can be done using a taper turning attachment on the lathe or by using a compound rest to gradually adjust the angle of the tool. Taper turning is often used to create conical shapes or to create features such as Morse tapers.

| Tool | Function |

|---|---|

| Roughing Gouge | Removes material quickly |

| Skew Chisel | Creates smooth surfaces |

| Parting Tool | Cuts off a workpiece from the main stock |

| Chamfering Tool | Creates beveled edges |

| Boring Bar | Enlarges existing holes |

| Knurling Tool | Creates knurled patterns |

| Threading Tool | Creates threads |

By understanding and practicing these basic turning techniques, beginners can start to develop their skills and create a wide range of projects on a metal lathe.

Advanced Turning Techniques

Tool Selection

When it comes to advanced turning techniques, choosing the right tools is extremely important. Different tools have different cutting angles and profiles, which allows for more precise and intricate cuts. Carbide tipped tools are often preferred for their durability and ability to maintain a sharp edge for longer periods of time. It is essential to have a variety of tools at hand to tackle different turning tasks.

Using a Mandrel

A mandrel is a useful tool for advanced turning techniques. It is a cylindrical object that is inserted into the workpiece to support it from the inside. This provides extra stability and allows for more intricate and detailed turning. The mandrel can be made of metal or wood and can be adjusted to fit different workpieces. It is important to securely fasten the workpiece to the mandrel to prevent any movement or slipping during the turning process.

Specialized Turning Techniques

Advanced turning techniques include a range of specialized methods to achieve different effects and shapes. Some of these techniques include:

- Off-Center Turning: This technique involves turning the workpiece off-center to create unique shapes and patterns.

- Thread Cutting: Using a special threading tool, threads can be cut into the workpiece to create screw-like features.

- Knurling: Knurling is a technique used to create a textured pattern on the workpiece’s surface, providing better grip and aesthetics.

- Boring: Boring is the process of enlarging an existing hole in the workpiece using a boring tool.

- Grooving: Grooving involves cutting a groove or channel into the workpiece, often to accommodate o-rings or other fittings.

- Parting: Parting is the process of cutting a workpiece into separate parts or removing a section from the workpiece.

Advanced Finishing

After the turning process, a variety of advanced finishing techniques can be applied to the workpiece for a polished and professional look. These techniques include sanding, polishing, and applying various coatings such as oils, waxes, or varnish. Proper finishing not only enhances the aesthetics but also protects the workpiece from wear and tear.

Maintenance and Troubleshooting Tips

Maintenance Tips

- Regularly clean the lathe to remove dust, debris, and metal shavings that can accumulate and interfere with its performance. Use compressed air or a brush to clean hard-to-reach areas.

- Check the oil levels and change the oil as recommended by the manufacturer. Proper lubrication is essential for smooth operation and to prevent excessive wear and tear.

- Inspect the belts for signs of wear and replace them if necessary. Worn-out belts can cause slipping or inefficient power transmission.

- Keep the ways, slides, and other moving parts properly lubricated. Use appropriate lubricants recommended by the lathe manufacturer.

- Check the condition of cutting tools regularly. Replace dull or damaged tools to ensure clean and accurate cuts.

- Inspect and tighten all bolts, screws, and fasteners to prevent loosening during operation.

Troubleshooting Tips

Even with proper maintenance, lathe problems can still occur. Here are some troubleshooting tips to help you identify and resolve common issues:

- If the lathe is making unusual noises or vibrations, check for loose or worn parts. Tighten any loose components and replace any worn-out parts.

- If the lathe is not cutting properly or leaving rough surfaces, check the tool’s alignment. Make sure it is properly aligned and positioned at the correct height for the workpiece.

- If the lathe motor is not starting or has low power, check the electrical connections and ensure that the power supply is adequate.

- If the lathe is producing excessive heat, check the cooling system. Clean or replace any clogged or damaged cooling components.

- If the lathe is not feeding the workpiece properly, check the gears and leadscrew for any damage or obstructions. Clean or replace as needed.

- If the lathe is producing excessive chatter or vibrations during cutting, check the cutting tool. Sharpen or replace the tool to minimize vibrations.

- If you encounter any other issues that you cannot resolve, consult the lathe’s manual or contact the manufacturer’s technical support for assistance.

Conclusion

Regular maintenance is crucial for keeping your metal lathe in optimal condition and ensuring efficient and accurate machining. By following these maintenance and troubleshooting tips, you can extend the lifespan of your lathe and minimize downtime due to mechanical issues.

FAQ

What is a metal lathe?

A metal lathe is a machine tool used to shape metal or wood into desired shapes. It works by rotating the workpiece on its axis and using various cutting tools to remove material, creating the desired shape.

Why would someone want to use a metal lathe?

There are many reasons why someone might want to use a metal lathe. It is a versatile machine that can be used to create precise parts and components for various applications. It is commonly used in manufacturing, machining, and tool making industries.

What are the basic components of a metal lathe?

The basic components of a metal lathe include the bed, headstock, tailstock, carriage, compound rest, cross-slide, tool post, and cutting tools. Each component has a specific function in the lathe’s operation.

How does a metal lathe work?

A metal lathe works by rotating the workpiece on its axis while a cutting tool is fed into the material to remove excess material and shape it according to the desired specifications. The rotation of the workpiece and the movement of the cutting tool are controlled by the operator.

Can a beginner use a metal lathe?

Yes, a beginner can use a metal lathe. However, it is important to receive proper training and guidance before using the machine, as it can be dangerous if not operated correctly. It is recommended to start with simple projects and gradually increase the complexity as you gain experience and confidence.

What safety precautions should be followed when using a metal lathe?

When using a metal lathe, it is important to wear appropriate safety equipment, such as safety glasses and gloves, to protect yourself from flying chips and debris. It is also important to secure the workpiece properly and avoid loose clothing or jewelry that could get caught in the machine. Additionally, the machine should be properly maintained and the work area should be clean and organized.

Are there different types of metal lathes?

Yes, there are different types of metal lathes, including bench lathes, engine lathes, and CNC lathes. Each type has its own unique features and capabilities, and the choice of which type to use depends on the specific requirements and preferences of the user.

Video