Effective Ways to Reduce Chatter on a Lathe and Enhance Job Quality

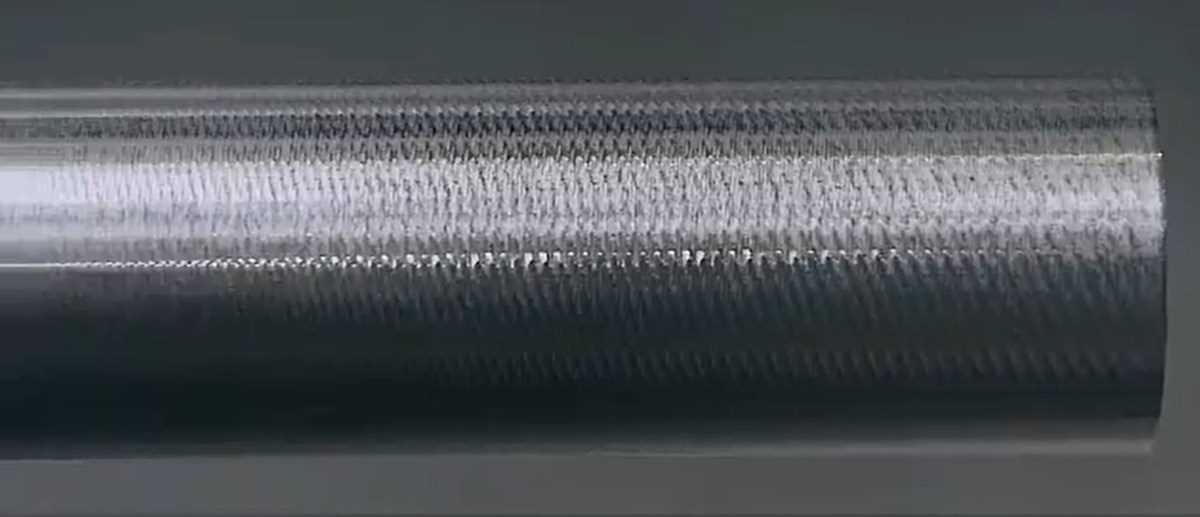

Chatter is a common problem that can occur when using a lathe, and it can have a negative impact on the quality of the finished job. Chatter can cause vibrations in the machine, leading to irregular cuts and a rough surface finish. This can be frustrating for machinists and can result in wastage of time and materials.

However, there are several effective ways to reduce chatter on a lathe and enhance the overall job quality. One of the key factors in reducing chatter is selecting the appropriate cutting tools. Using sharp tools with the correct geometry can minimize vibrations and produce smoother cuts. It is also important to use the right cutting speeds and feeds, as excessive cutting forces can contribute to chatter. Machinists should consider the material being machined and the desired finish when determining the optimal cutting parameters.

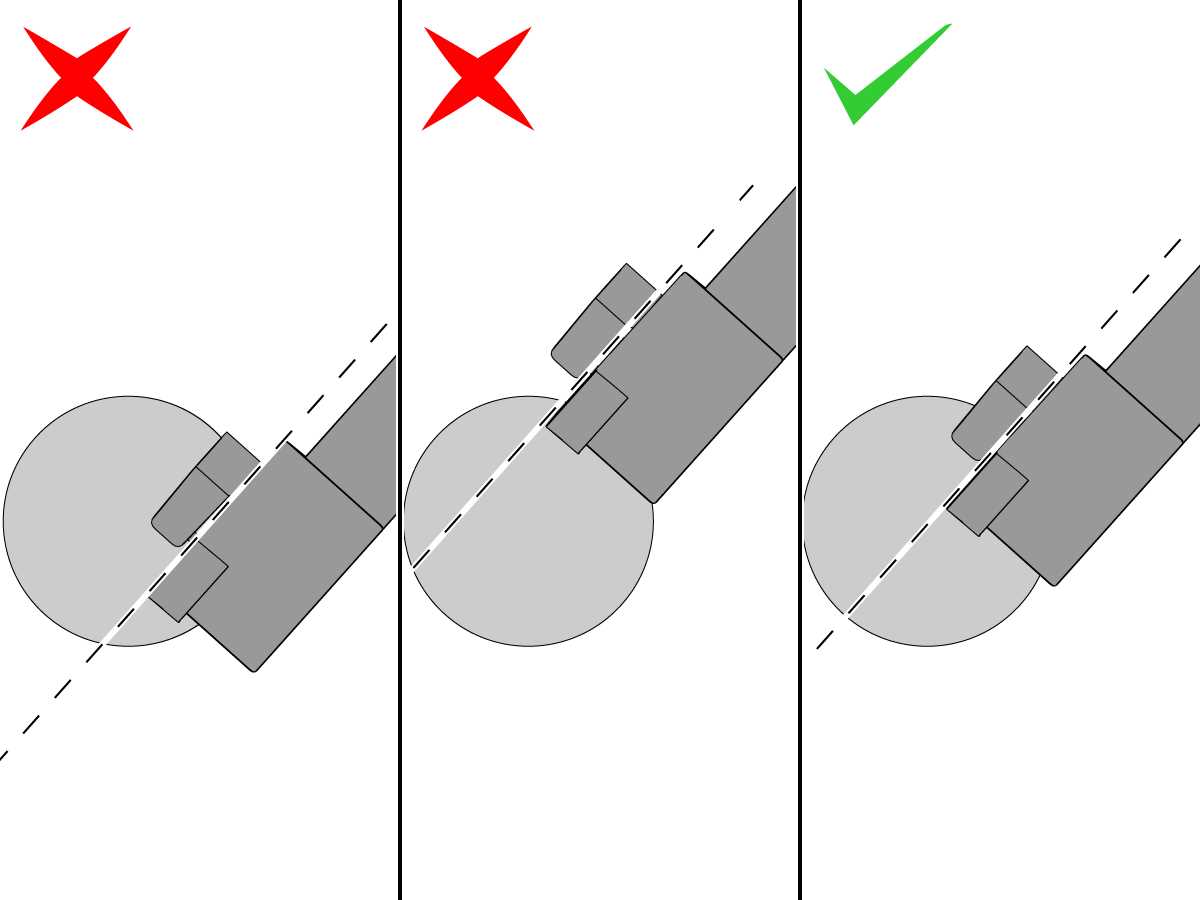

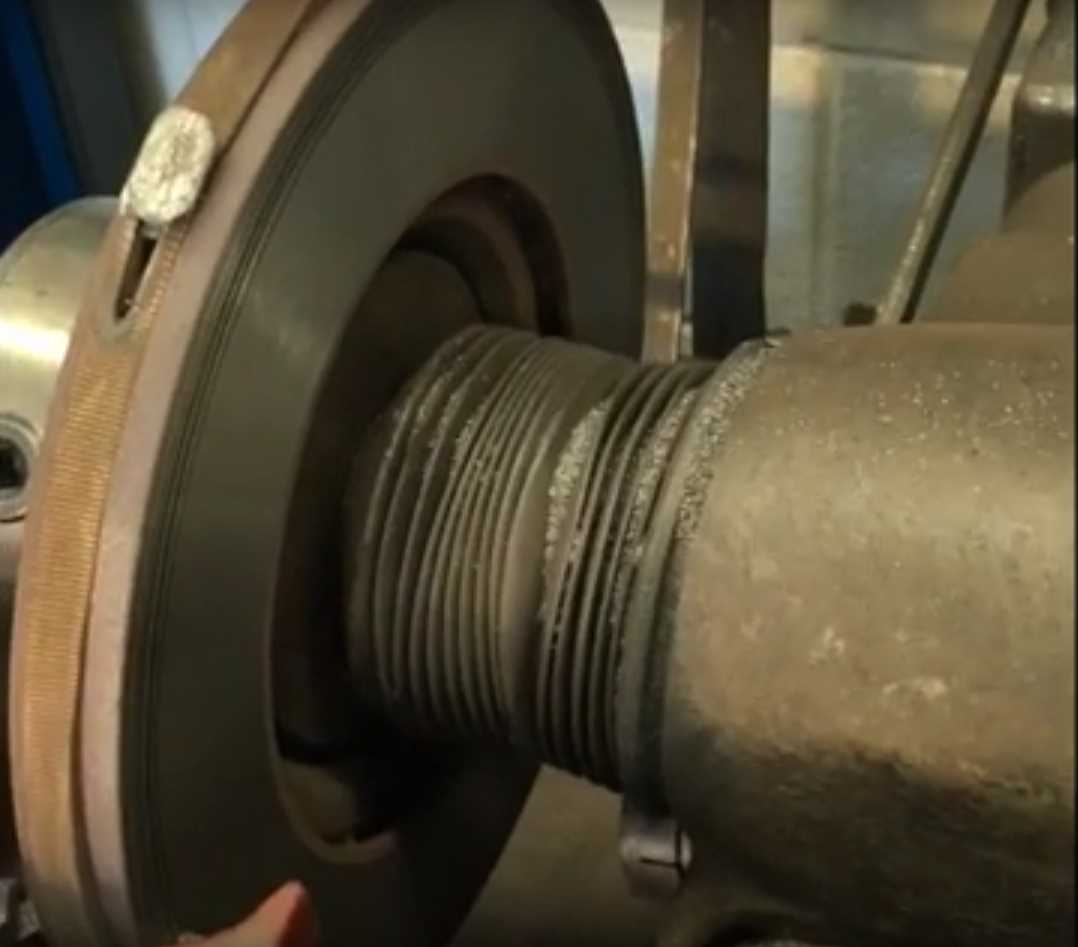

Another method to reduce chatter is to increase the rigidity of the lathe setup. This can be achieved by ensuring that the workpiece and the toolholder are securely clamped and properly aligned. Using a sturdy lathe bed and properly tensioned belts can also help to minimize vibrations. Additionally, placing the lathe on a stable foundation and using vibration-damping materials, such as rubber pads, can further reduce chatter.

In some cases, modifying the lathe itself can help to reduce chatter. Adding damping mechanisms, such as vibration-absorbing materials or internal steady rests, can help to dampen vibrations and minimize chatter. Using advanced cutting techniques, such as trochoidal milling or high-speed machining, can also reduce the occurrence of chatter. It is important for machinists to stay updated with the latest industry practices and technologies to effectively address chatter on a lathe and enhance job quality.

In conclusion, reducing chatter on a lathe and enhancing job quality requires a combination of factors, including selecting the appropriate cutting tools, optimizing cutting parameters, increasing rigidity of the setup, and staying updated with industry advancements. By implementing these effective methods, machinists can overcome the challenges posed by chatter and achieve higher-quality results in their lathe operations.

FAQ

What are some effective ways to reduce chatter on a lathe?

Some effective ways to reduce chatter on a lathe include: ensuring proper tooling and workpiece alignment, increasing the rigidity of the setup, reducing the cutting speed, using sharp cutting tools, and applying a cutting fluid or coolant.

Why is chatter a problem on a lathe?

Chatter is a problem on a lathe because it can negatively affect the surface finish of the workpiece, result in dimensional inaccuracies, and reduce tool life. It can also lead to increased noise levels and vibrations, making the machine operation less efficient and potentially causing damage to the lathe.

How can I enhance job quality on a lathe?

To enhance job quality on a lathe, you can follow several steps. Firstly, ensure the lathe is properly calibrated and aligned. Secondly, use high-quality cutting tools and regularly maintain and sharpen them. Additionally, properly secure and align the workpiece, and use appropriate cutting parameters such as feed rate and depth of cut. Finally, consider using cutting fluids or coolants to improve chip evacuation and reduce heat buildup.

What are the common causes of chatter on a lathe?

Common causes of chatter on a lathe include improper tooling and workpiece alignment, weak setup rigidity, excessive cutting speed, dull cutting tools, inadequate use of cutting fluids or coolants, and machine resonance or vibration.

Does the type of material being machined affect chatter on a lathe?

Yes, the type of material being machined can affect chatter on a lathe. Some materials, such as those with low stiffness or high-temperature sensitivity, are more prone to chatter. Additionally, different materials may require specific cutting parameters and tooling to minimize chatter and achieve optimal job quality.

Can reducing the cutting speed help to reduce chatter on a lathe?

Yes, reducing the cutting speed can help to reduce chatter on a lathe. Lower cutting speeds reduce the forces acting on the tool and workpiece, reducing the likelihood of vibrations and chatter. However, it is important to balance the cutting speed with other factors such as material hardness and tool life.

What are some signs that chatter is occurring during lathe operation?

Some signs that chatter is occurring during lathe operation include excessive noise and vibrations, poor surface finish on the workpiece, increased tool wear or breakage, and irregular or inconsistent chip formation.

Video