Step-by-step guide on cutting metric threads on an imperial lathe

If you have an imperial lathe but need to cut metric threads, don’t worry – it’s possible! Cutting metric threads on an imperial lathe may seem daunting, but with the right approach and tooling, it can be done accurately and efficiently. In this step-by-step guide, we will walk you through the process of cutting metric threads on an imperial lathe, so you can confidently tackle any metric threading project.

Before we begin, it’s important to note that cutting metric threads on an imperial lathe requires the use of a thread dial indicator. This tool allows you to accurately engage the half-nuts and synchronize the rotation of the spindle with the forward movement of the cutting tool. If you don’t have a thread dial indicator, it’s essential to get one before attempting to cut metric threads on your imperial lathe.

Step 1: Prepare your lathe by ensuring it is properly lubricated and set up for threading. Make sure the appropriate gears or change gears are in place to achieve the desired pitch for the desired thread. Consult your lathe’s manual for the specific gear combination required for cutting metric threads.

Step 2: Mount the workpiece securely in the lathe’s chuck or collet. The workpiece should be centered and aligned properly to ensure accurate and symmetrical threading. Use a center gauge or edge finder to ensure precise alignment.

Step 3: Engage the thread dial indicator and adjust the half-nuts to synchronize the rotation with the forward movement of the cutting tool. This is crucial for achieving accurate thread pitch. Follow the instructions provided with your thread dial indicator to properly set it up and use it.

Understanding the basics

Before diving into the process of cutting metric threads on an imperial lathe, it is important to understand some basic concepts and terms related to threading. This section will provide a brief overview of these fundamentals:

Threads

Threads are spiral ridges or grooves that wrap around the outside or inside of a cylindrical object to allow for easy connection, fastening, or tightening. They are commonly used in screws, bolts, and nuts.

Pitch

Pitch refers to the distance between two successive threads on a screw or a bolt. It is usually measured in millimeters (mm) and denotes the size of the thread. The pitch can be coarse or fine, depending on the distance between the threads.

Thread Angle

The thread angle refers to the angle at which the threads are inclined from the perpendicular axis of the cylindrical object. The most common thread angle is 60 degrees for metric threads.

Thread Form

Thread form refers to the shape and design of the threads. There are several types of thread forms, including V-threads, U-threads, and trapezoidal threads. Metric threads typically have a V-thread form.

Thread Measurement

Threads are measured using various tools, such as thread gauges, pitch gauges, and calipers. These tools help in determining the pitch, diameter, and other dimensions of the threads.

Imperial Lathe

An imperial lathe is a type of lathe that is primarily used for machining or cutting threads with imperial measurements, such as inches or tpi (threads per inch). Though designed for imperial measurements, it is possible to cut metric threads on an imperial lathe by using the proper conversion techniques.

Now that you have a basic understanding of the terminology and concepts related to threading, you can proceed to learn the step-by-step process of cutting metric threads on an imperial lathe.

Gathering the necessary tools

Before you begin cutting metric threads on an imperial lathe, it is important to gather all the necessary tools. Having the right tools will ensure that the process goes smoothly and efficiently. Here is a list of tools you will need:

- A metric thread cutting tool

- An imperial lathe

- A set of metric threading gears

- Calipers or a dial gauge for measuring dimensions

- A metric pitch gauge for checking the thread pitch

- A cutting tool holder

- Thread cutting oil for lubrication

- Safety glasses or goggles to protect your eyes

Having these tools on hand will ensure that you have everything you need to successfully cut metric threads on your imperial lathe. It is important to double-check that all the tools are in good working condition and that the thread cutting tool is sharp and properly aligned.

Setting up the lathe

Step 1: Prepare the lathe

Before starting the thread cutting process, make sure that your lathe is properly set up and ready to use. Here are the steps to follow:

- Ensure that the lathe is securely anchored to a workbench or stand to prevent any movement during operation.

- Check that the lathe’s headstock and tailstock are properly aligned and adjusted.

- Make sure that the cutting tool and other attachments are in good condition and securely fastened to the lathe.

- Check the lathe’s settings and make any necessary adjustments to the speed, feed rate, and depth of cut based on the material you will be working with.

Step 2: Select the correct threading gears

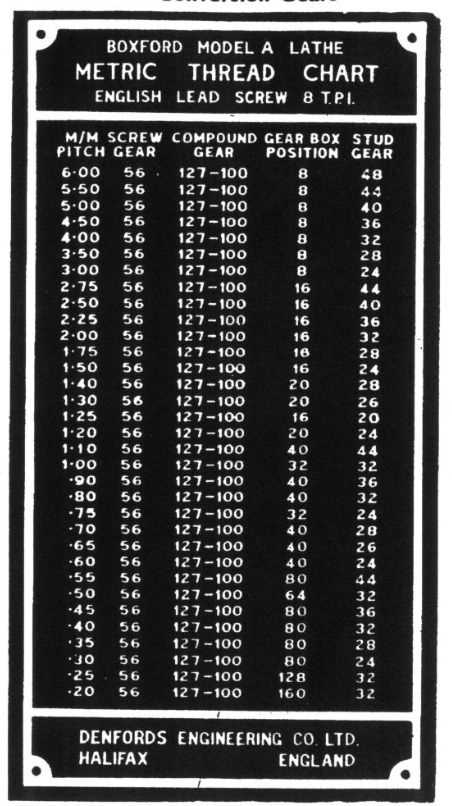

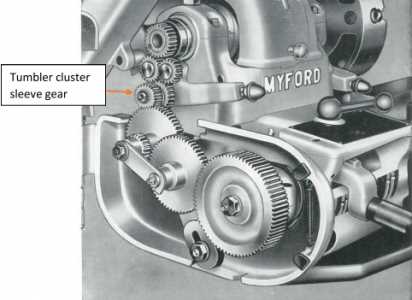

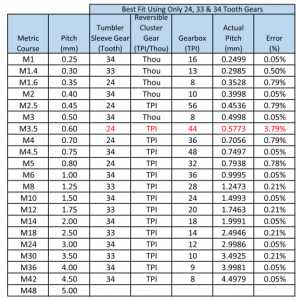

Since you are using an imperial lathe to cut metric threads, you will need to use the appropriate threading gears to achieve the desired pitch. Refer to your lathe’s manual or threading gear chart to determine the correct gears to use.

Ensure that the gears are clean and in good condition before proceeding.

Step 3: Install the threading gears

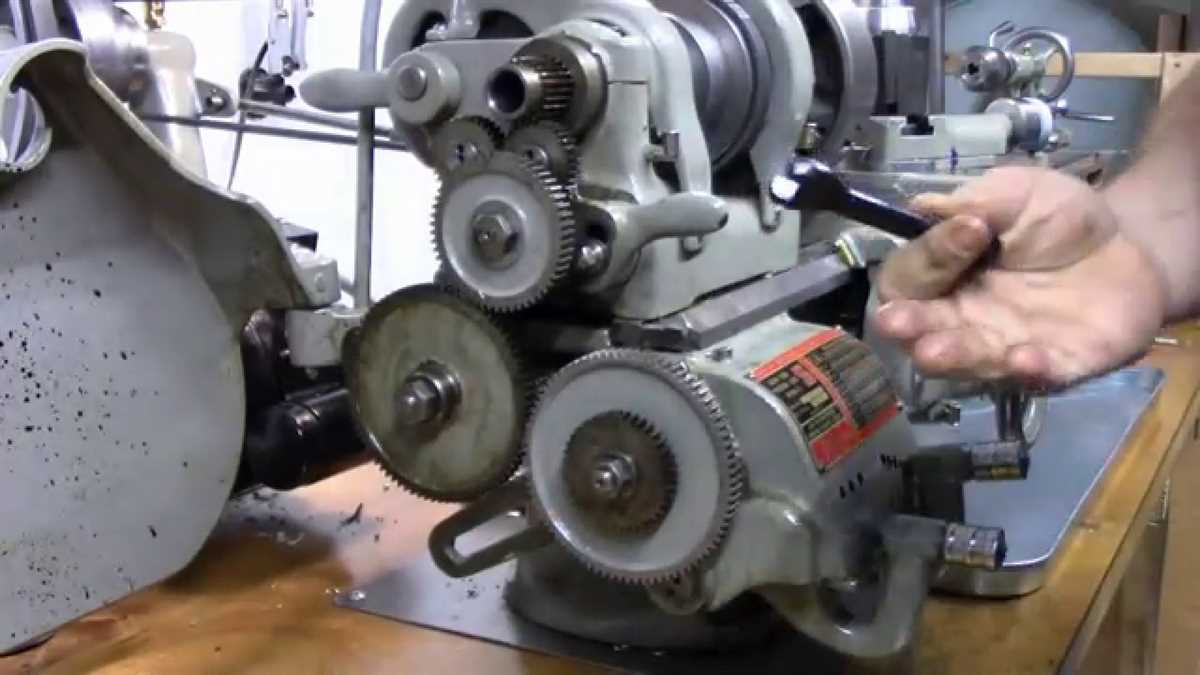

Follow these steps to install the threading gears:

- Remove any gears currently installed on the lathe.

- Refer to your lathe’s manual or threading gear chart to determine the specific placement of the gears for cutting metric threads.

- Install the gears onto the appropriate gears shafts, making sure they are securely tightened.

- Double-check the gear placement to ensure they are engaged correctly.

Step 4: Set the lathe for threading

Now that the gears are installed, you can set up the lathe for threading:

- Engage the lathe’s threading lever or engage the power cross-feed mechanism, depending on your lathe’s design.

- Adjust the cross-slide and compound rest to position the cutting tool perpendicular to the workpiece.

Step 5: Test the thread cutting setup

Before starting the actual thread cutting process, it is recommended to perform a test run to ensure everything is set up correctly:

- Select a scrap piece of material similar to the one you will be working with.

- Set the lathe to the desired thread pitch and speed.

- Engage the lathe and observe the tool’s movement. Check for any abnormalities or issues that could affect the thread cutting process.

- If everything looks good, proceed to the actual thread cutting process. If not, make any necessary adjustments and repeat the test run until satisfied.

Once you have completed the above steps, your lathe will be properly set up for cutting metric threads on an imperial lathe. Now you can move on to the next step of the process, which is the actual cutting of the metric threads.

Preparing the workpiece

Before you begin cutting metric threads on an imperial lathe, it is important to properly prepare the workpiece. This involves the following steps:

- Select the appropriate material: Choose a material that is suitable for the thread size and pitch you want to cut. Common choices include mild steel, stainless steel, and brass.

- Measure and mark the workpiece: Use a ruler or a caliper to measure the length of the workpiece and mark the starting point for cutting the thread.

- Secure the workpiece: Use a vise or a chuck to securely hold the workpiece in place. Make sure it is aligned properly and tightened securely.

- Apply cutting fluid: Before starting the cutting process, apply cutting fluid to the workpiece. This helps to reduce friction, prevent overheating, and improve the quality of the thread.

By properly preparing the workpiece, you can ensure that the cutting process goes smoothly and the resulting threads are accurate and precise.

Calculating the pitch

Before cutting metric threads on an imperial lathe, it is important to calculate the pitch accurately. The pitch refers to the distance between adjacent thread crests and is typically measured in millimeters. Here are the steps to calculate the pitch:

- Determine the desired thread pitch: The first step is to determine the desired pitch for the metric thread you want to cut. This information can usually be found in engineering specifications or it can be specified by the project requirements.

- Convert the pitch to inches: Since an imperial lathe uses inches for measurement, it is necessary to convert the metric pitch to inches. One inch is equivalent to 25.4 millimeters, so divide the desired pitch by 25.4 to obtain the pitch in inches.

- Calculate the gear ratio: To cut a metric thread on an imperial lathe, you need to adjust the lathe’s gear train to match the desired pitch. This requires calculating the gear ratio. To do this, divide 127 (the number of teeth on the gear responsible for longitudinal movement) by the number of threads per inch in the lathe’s lead screw.

- Find the appropriate translation change gears: Once you have the gear ratio, you can look up the appropriate combination of change gears to achieve the desired pitch. Lathe manuals usually provide a chart that shows the gear combinations for different thread pitches. Match the gear ratio with the closest combination of change gears listed in the chart.

- Set up the change gears: Install the change gears onto the lathe’s gear train according to the selected combination. Make sure they are properly meshed and securely tightened.

- Test the setup: Before cutting the actual thread, it is important to test the setup by making a trial cut. Measure the pitch of the trial cut using a thread pitch gauge to ensure it matches the desired pitch. Make any necessary adjustments to the gear combination if the pitch is not accurate.

By following these steps, you can accurately calculate the pitch for cutting metric threads on an imperial lathe. It is important to double-check the calculations and make any necessary adjustments to ensure precise and accurate thread cutting.

Cutting the threads

1. Set up the lathe

Before cutting the threads, you need to set up the lathe properly. Make sure the lathe is adjusted to the correct speed for the material you are working on. Attach the threading tool to the tool post and position it at the appropriate angle for the desired thread pitch.

2. Determine the thread parameters

Before you start cutting the threads, you need to know the thread parameters, such as the pitch, diameter, and thread type. Refer to the thread specifications or use a thread pitch gauge and a Vernier caliper to measure the pitch and diameter.

3. Calculate the depth of cut

To calculate the depth of cut, you can use the formula:

Depth of Cut (DOC) = 0.6495 * (1 / Thread Pitch)

This formula will give you the maximum depth of cut for a single pass. However, for safety reasons, it is recommended to make multiple shallower cuts instead of a single deep cut.

4. Set the correct feed rate

When cutting the threads, it is important to set the correct feed rate. The feed rate determines how fast the tool moves along the workpiece. The proper feed rate depends on the lathe’s capabilities, the material being cut, and the desired thread quality. Generally, a slower feed rate will produce a better surface finish, but it will take longer to complete the cut.

5. Engage the half-nut

Before starting the thread cutting process, engage the half-nut lever on the lathe carriage. The half-nut lever is used to engage and disengage the lead screw, which controls the movement of the carriage. Make sure to engage it at the correct moment when the threading tool is aligned with the workpiece.

6. Start cutting the threads

Once everything is set up, you can start cutting the threads. Slowly advance the carriage using the lead screw while the threading tool cuts into the workpiece. Make sure to monitor the progress and adjust the feed rate or depth of cut if necessary. Keep cutting until the desired thread length is achieved.

7. Use a thread gauge to check the thread quality

After finishing the thread cutting, use a thread gauge to check the thread quality. The thread gauge will help you verify that the threads are cut to the correct pitch and depth. Check for any defects or deviations from the specifications and make adjustments if necessary.

8. Finish the threads

After cutting the threads, you might need to remove any burrs or sharp edges left by the threading tool. Use a deburring tool or a file to smooth out the thread surface. This will ensure a proper fit when assembling threaded components.

9. Clean the workpiece

Finally, make sure to clean the workpiece from any chips or debris that might have accumulated during the thread cutting process. Use a brush or compressed air to remove any remnants and ensure a clean and precise thread.

Finishing touches

After completing the steps for cutting metric threads on an imperial lathe, it is important to pay attention to the finishing touches to ensure the final product meets the desired specifications.

1. Clean the thread

Before measuring the thread, it is crucial to clean it properly. Use a thread cleaning tool or a brush to remove any chips, debris, or cutting fluids that may be present on the threads. This will help get accurate measurements and prevent any issues during assembly.

2. Measure the thread pitch

Using a thread pitch gauge or a micrometer with a thread pitch attachment, measure the thread pitch. This will help verify that the correct thread pitch has been cut. Compare the measured value with the desired pitch to ensure accuracy.

3. Check the thread depth

Verify the thread depth by using a thread depth gauge or a depth micrometer. Make sure the depth matches the requirements specified in the design. If the thread is too shallow or too deep, adjustments may need to be made.

4. Inspect for burrs or imperfections

Inspect the thread for any burrs, unevenness, or imperfections. These can be removed using a deburring tool or a file. Smooth out any rough edges or burrs to ensure proper function and fit when the threaded part is assembled.

5. Lubricate the thread

Apply a lubricant to the thread to reduce friction and ensure smooth operation when assembling the threaded part with other components. This will help prevent galling or seizing of the threads during use.

6. Test the threaded part

As a final step, test the threaded part by assembling it with the corresponding component. Ensure that the threads engage smoothly and securely. If any issues are encountered, reassess the thread cutting process and make any necessary adjustments.

By following these finishing touches, you can ensure that the metric threads cut on an imperial lathe meet the required specifications and function properly in the intended application.

Troubleshooting and tips

1. Problems with thread fit

One common issue when cutting metric threads on an imperial lathe is getting the correct thread fit. Since metric threads have a different pitch than imperial threads, the resulting fit may not be ideal. Here are some tips to troubleshoot this problem:

- Check the pitch settings on your lathe to ensure they are correctly aligned with the metric thread you’re cutting.

- Consider using a thread pitch gauge to verify the pitch of the threads you’ve cut.

- If the fit is too loose, you may need to increase the angle of the compound slide to reduce the pitch of the thread.

- If the fit is too tight, you may need to decrease the angle of the compound slide to increase the pitch of the thread.

- Experiment with different settings and make small adjustments until you achieve the desired thread fit.

2. Problems with thread depth

Another common issue when cutting metric threads on an imperial lathe is achieving the correct thread depth. Here are some tips to troubleshoot this problem:

- Verify that the depth of cut is set correctly to match the desired thread depth.

- Check the tool angle and ensure it is appropriate for cutting metric threads.

- Inspect the cutting tool for wear and replace if necessary.

- Ensure that the material being threaded is securely held and properly lubricated.

- If the thread depth is too shallow, increase the depth of cut slightly and retest.

- If the thread depth is too deep, decrease the depth of cut slightly and retest.

3. Problems with thread quality

If you are getting poor thread quality when cutting metric threads on an imperial lathe, consider the following tips:

- Ensure that the lathe is properly calibrated and all components are in good working condition.

- Check the speed and feed rates to ensure they are appropriate for cutting metric threads.

- Inspect the cutting tool and replace if necessary.

- Use cutting fluids or lubricants to improve the cutting process and extend tool life.

- Consider using precision thread inserts or dedicated metric threading tools for better results.

By following these troubleshooting tips, you can overcome common challenges when cutting metric threads on an imperial lathe and achieve accurate and high-quality results.

FAQ

What is an imperial lathe?

An imperial lathe is a type of lathe that measures dimensions in inches and uses the imperial system of measurement.

Can you cut metric threads on an imperial lathe?

Yes, it is possible to cut metric threads on an imperial lathe by making some adjustments and using the correct gear ratio.

What are the steps to cut metric threads on an imperial lathe?

The steps to cut metric threads on an imperial lathe include selecting the correct gear ratio, setting the thread cutting tool to the correct angle, and making multiple passes to achieve the desired thread profile.

How do I determine the gear ratio for cutting metric threads on an imperial lathe?

You can determine the gear ratio by using a conversion chart or formula that takes into account the pitch of the metric thread and the number of teeth on the gears available on your lathe.

What tools do I need to cut metric threads on an imperial lathe?

You will need a thread cutting tool, a set of gears with the desired gear ratio, a dial indicator for accuracy, and a wrench or spanner to adjust the gears.

Are there any limitations to cutting metric threads on an imperial lathe?

Yes, there may be limitations in terms of the range of metric threads that can be cut on an imperial lathe, depending on the available gear ratios and the capabilities of the lathe.

Video