What Size Wrench Do I Need for a 1/2 Bolt? | Step-by-Step Guide

When it comes to working with bolts and nuts, using the right tools is essential. One common question that arises is, “What size wrench do I need for a 1/2 bolt?” The answer to this question lies in understanding both the measurement system used and the standard sizes of wrenches.

The 1/2 bolt refers to the diameter of the bolt, which is measured in inches. In this case, it means that the bolt’s diameter is half an inch. To find the appropriate wrench size for this bolt, you will need to refer to a wrench size chart or use a method to measure the bolt’s head.

There are different types of wrenches available, including open-end wrenches, combination wrenches, and adjustable wrenches. Each type of wrench has its own corresponding size for a 1/2 bolt. For example, a standard open-end wrench size for a 1/2 bolt is typically 11/16 inches, while a combination wrench may have a size of 9/16 inches for the same bolt.

In this step-by-step guide, we will walk you through the process of determining the exact wrench size you need for a 1/2 bolt. We will provide helpful tips and recommendations to ensure you have the right tool for the job. Whether you are a beginner or an experienced DIY enthusiast, this guide will assist you in finding the perfect wrench size for your 1/2 bolt.

Choosing the Right Wrench Size for a 1/2 Bolt

When working with bolts, it’s essential to use the correct size wrench. Using the wrong size wrench can damage the bolt and make it challenging to remove or tighten. If you are working with a 1/2 inch bolt, here is a step-by-step guide to help you choose the right wrench size:

- Measure the Bolt Diameter: The first step is to accurately measure the diameter of the bolt. In this case, we have a 1/2 inch bolt, which is equivalent to 0.5 inches.

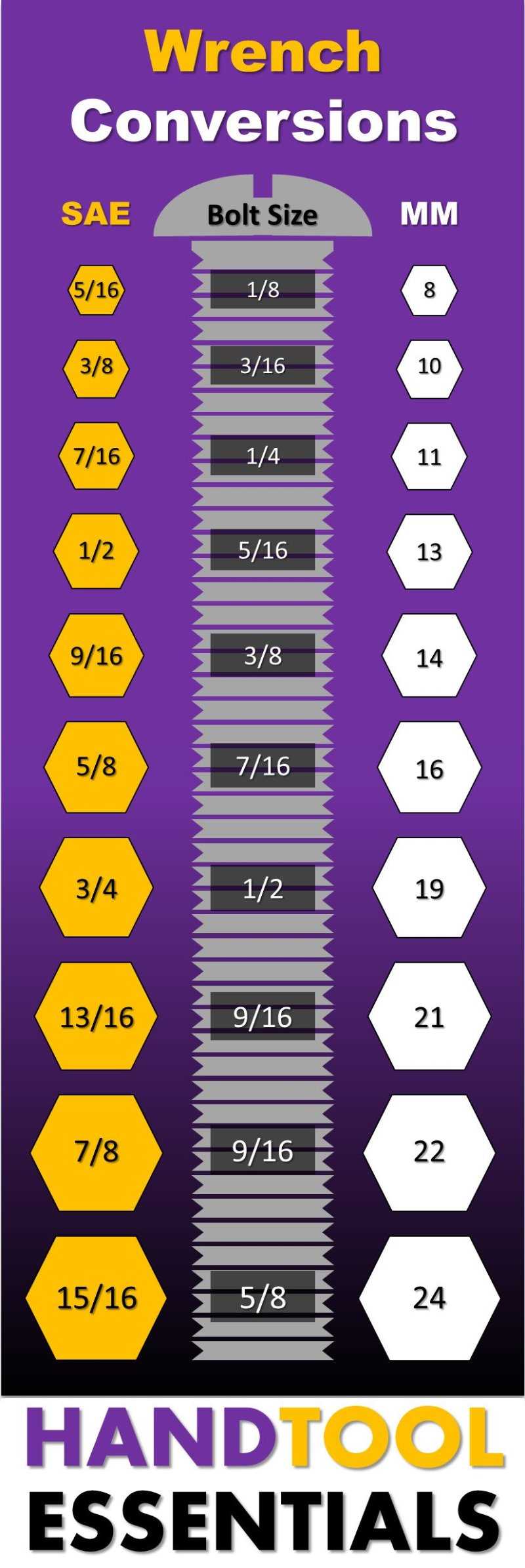

- Convert the Diameter: Convert the bolt diameter from inches to millimeters, as many wrenches are sized in millimeters. To convert, multiply the bolt diameter in inches by 25.4. For a 1/2 inch bolt, the calculation would be: 0.5 inches * 25.4 = 12.7 mm.

- Choose the Closest Wrench Size: Once you have the converted size, you can choose the closest wrench size. In this case, the closest wrench size would likely be 13 mm, as it is slightly larger than the converted bolt diameter of 12.7 mm.

It’s important to note that wrench sizes can vary slightly depending on the brand and type of wrench. In some cases, you may need to use an adjustable wrench or a wrench with a slightly different size to achieve a proper fit. It’s always a good idea to test the wrench on the bolt before applying significant force to ensure a snug and secure fit.

By choosing the right wrench size for a 1/2 inch bolt, you can work efficiently and effectively while minimizing the risk of damaging the bolt or surrounding components.

Step 1: Understanding 1/2 Bolts

Before determining the size wrench you need for a 1/2 bolt, it’s important to understand what a 1/2 bolt actually refers to. In the context of hardware and fasteners, the term “1/2” refers to the diameter of the bolt. A 1/2 bolt has a diameter of 1/2 inch or 12.7 millimeters.

It’s important to note that the size of a bolt refers to its shaft diameter and not the size of its head or threads. The head and the threads of a bolt can have different dimensions, so it’s crucial to consider the specific measurement you need. In this case, we are looking at the size of the bolt shaft, which is 1/2 inch.

Understanding the diameter of the bolt is crucial because it determines the size of the wrench or socket you’ll need to tighten or loosen it. Using an incorrect size wrench can lead to stripped or damaged bolts, as well as potential injuries.

Next, we will move on to Step 2, which will guide you in selecting the correct wrench size for a 1/2 bolt.

Step 2: Determining the Correct Wrench Size

Once you know the size of the bolt you are working with, you can determine the correct wrench size to use. The wrench size refers to the measurement across the flat sides of the bolt head, commonly known as the “across flats” dimension.

To determine the correct wrench size, you have a few different options:

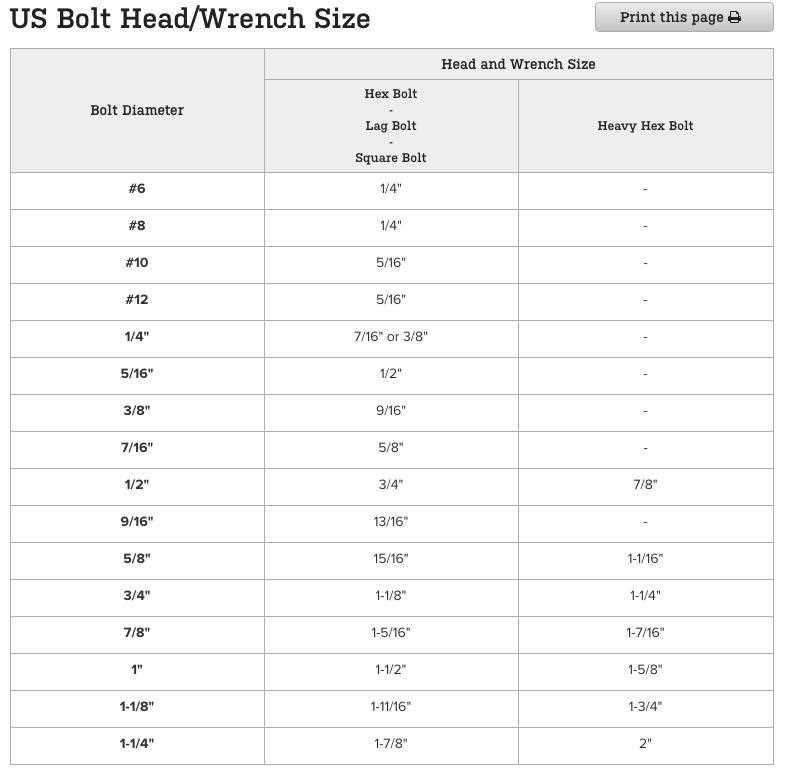

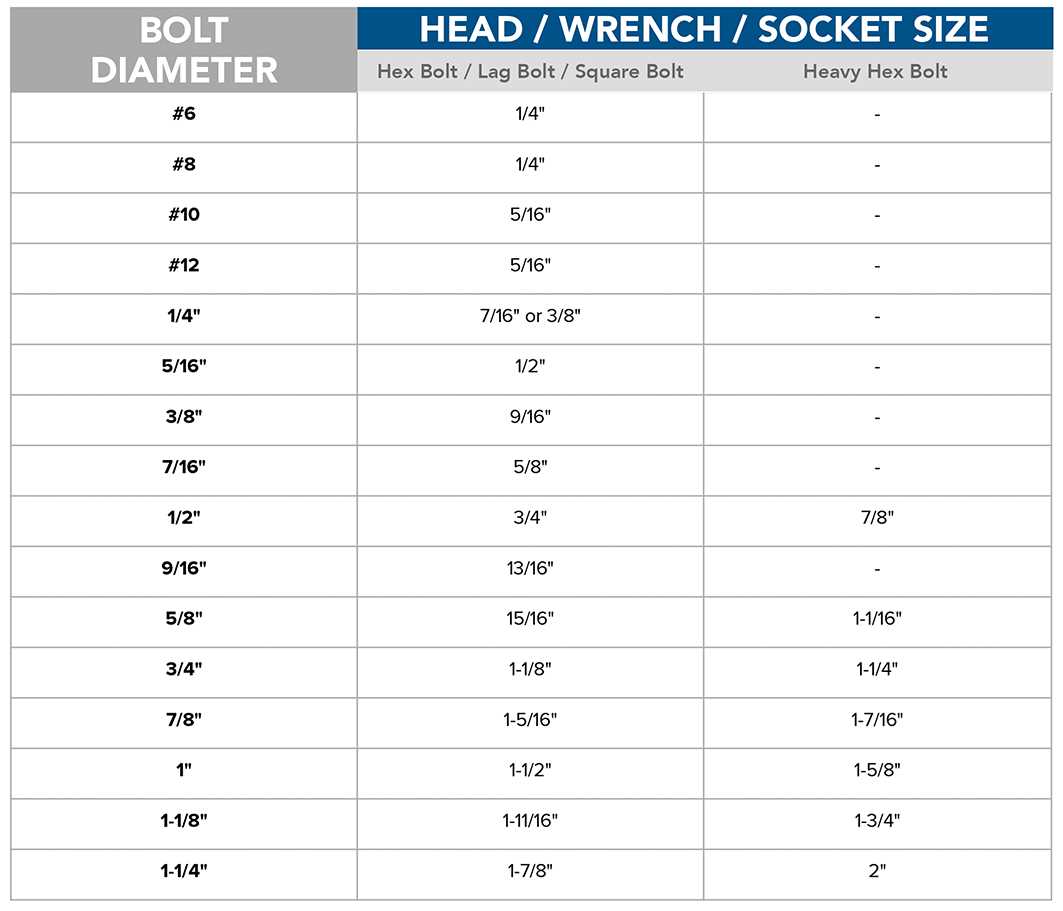

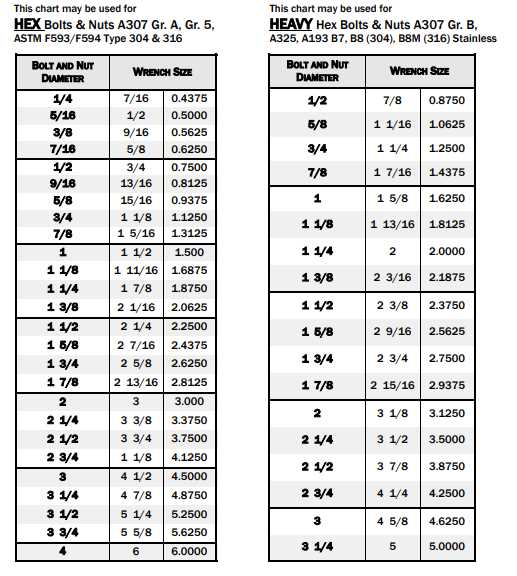

- Option 1: Use a Wrench Size Chart – You can consult a wrench size chart, which provides a list of bolt sizes and their corresponding wrench sizes. This is a quick and convenient way to determine the correct wrench size.

- Option 2: Measure the Bolt Head – If you don’t have access to a wrench size chart, you can measure the bolt head directly. Use a caliper or ruler to measure the distance between two opposite flat sides of the bolt head. This measurement will give you the wrench size you need.

- Option 3: Trial and Error – If you have a few different wrench sizes available, you can try them out and see which one fits snugly on the bolt head. This method may take some time and experimentation, but it can be effective if you don’t have access to a wrench size chart or measuring tools.

Once you have determined the correct wrench size, make sure to select a wrench that matches both the size and type (e.g., adjustable, open-end, or combination) of the bolt head you are working with. This will ensure that you have the proper tool for the job and avoid damaging the bolt or nut.

Step 3: Using the Wrench on the 1/2 Bolt

Once you have determined that you need a 1/2 wrench for the bolt you are working with, follow these steps to properly use the wrench:

- Make sure that the wrench is the correct size for the bolt. A 1/2 wrench should fit snugly around the head of the bolt, allowing for a secure grip.

- Position the wrench so that it is perpendicular to the bolt, with the handle pointing towards you.

- Slide the socket end of the wrench onto the head of the bolt, making sure that it fully engages with the bolt.

- Apply pressure to the handle of the wrench, turning it clockwise to tighten the bolt or counterclockwise to loosen the bolt.

- If the bolt is particularly tight, you may need to use a longer wrench or a cheater bar (a pipe that can be placed over the handle of the wrench for added leverage).

- Continue applying pressure and turning the wrench until the bolt is tightened or loosened to your desired level.

- Once you have finished using the wrench, remove it from the bolt by sliding the socket end off of the bolt head.

Remember to always use caution when using a wrench and make sure to securely grip the wrench handle to avoid any slip and potential injury.

Step 4: Tips for Handling 1/2 Bolts and Wrenches

Working with 1/2 bolts and wrenches requires some skill and knowledge. Here are some tips to help you handle them effectively:

1. Choose the right size wrench

When working with 1/2 bolts, it is crucial to use the correct size wrench. The appropriate wrench size for a 1/2 bolt is typically a 7/8 wrench. Make sure you have the right size wrench before attempting to loosen or tighten the bolt.

2. Use the correct technique

When using a wrench on a 1/2 bolt, it’s important to apply even pressure and avoid using excessive force. Using too much force can damage the bolt or the wrench. Apply firm but controlled pressure to avoid any accidents or injuries.

3. Lubricate the bolt

If the 1/2 bolt is rusty or difficult to turn, applying some lubricant can make the job easier. Use a penetrating oil or another suitable lubricant to help loosen the bolt and make it easier to turn with the wrench. Allow the lubricant to sit for a few minutes before attempting to loosen or tighten the bolt.

4. Use a socket wrench

A socket wrench can be a handy tool when working with 1/2 bolts. It provides more leverage and control compared to an adjustable wrench. Consider using a socket wrench with the corresponding socket size for a 1/2 bolt to make your work easier and more efficient.

5. Safely secure the workpiece

When working with 1/2 bolts, it’s important to ensure that the workpiece is securely held in place. Unsecured workpieces can move or rotate, making it difficult to loosen or tighten bolts. Use clamps or other appropriate tools to secure the workpiece before starting any work on the bolt.

6. Use proper safety precautions

Whenever you’re working with 1/2 bolts and wrenches, it’s essential to follow proper safety precautions. Wear safety goggles to protect your eyes from any debris that may fly off during the process. Consider wearing work gloves to provide a better grip and protect your hands.

By following these tips, you’ll be better equipped to handle 1/2 bolts and wrenches safely and efficiently. Remember to always work with caution and use the appropriate tools and techniques for the job at hand.

Step 5: Safety Considerations

When working with wrenches and bolts, it is important to prioritize safety to avoid any accidents or injuries. Here are some key safety considerations you should keep in mind:

- Wear appropriate protective gear: Always wear safety goggles to protect your eyes from any flying debris, and gloves to protect your hands from sharp edges or hot surfaces.

- Ensure proper lighting and ventilation: Work in a well-lit area to ensure clear visibility of the wrench and bolt. Adequate ventilation is also important to prevent inhalation of any harmful fumes or gases.

- Choose the right wrench size: Using the correct wrench size is crucial for both safety and effectiveness. Using an incorrect size may result in the wrench slipping, causing potential injuries. Refer to the manufacturer’s guidelines or consult a professional if you are unsure about the appropriate wrench size.

- Inspect the wrench and bolt: Before beginning any work, inspect both the wrench and bolt for any signs of damage or wear. A damaged wrench may not provide sufficient torque, while a damaged bolt may fail under load. Replace any worn or damaged tools before use.

- Secure the workpiece: When tightening or loosening a bolt, make sure the workpiece is securely held in place. Unsecured objects may move or rotate unexpectedly, causing accidents or injuries. Use clamps or other securing methods as necessary.

- Use proper technique: Always use the correct technique when operating a wrench. Apply steady and even pressure, and avoid using excessive force. If a bolt is particularly stubborn, use penetrating oil or heat to loosen it instead of excessive force.

- Keep your work area clean and organized: A cluttered work area increases the risk of accidents. Keep your tools and materials organized and clean up any debris or waste as you go.

- Work with a buddy: Having someone nearby to assist you can provide an extra layer of safety. They can help stabilize the workpiece, fetch tools or materials, or offer assistance in case of an emergency.

- Know your limitations: If you are unsure about any aspect of the task or don’t have the necessary experience or skills, it is best to seek help from a professional. Trying to tackle a job beyond your capabilities may result in accidents or further damage.

By following these safety considerations, you can ensure a safer working environment and reduce the risk of accidents or injuries while using a wrench on a 1/2 bolt.

Step 6: Common Mistakes to Avoid

When using a wrench to tighten or loosen a 1/2″ bolt, there are some common mistakes that people often make. Avoiding these mistakes will ensure the job is done effectively and prevent any damage. Here are some common mistakes to avoid:

- Using the wrong size wrench: It is crucial to use the correct size wrench for a 1/2″ bolt. Using a wrench that is too small or too big can result in stripping the bolt or damaging the wrench. Always double-check that you have the right size wrench before starting to work.

- Applying excessive force: While it may be tempting to use all your strength to tighten or loosen a bolt, using excessive force can cause the wrench to slip or the bolt to break. Apply steady and controlled pressure to avoid any mishaps.

- Not using lubrication: Using a lubricant, such as WD-40, can make the job easier by reducing friction between the bolt and the wrench. Not using lubrication can make it more difficult to turn the bolt and increase the likelihood of damaging the bolt or wrench.

- Using a worn-out or damaged wrench: Using a wrench that is worn-out or damaged can lead to slipping or rounding off the bolt edges. Inspect your wrench before use and replace it if necessary.

- Not securing the bolt properly: After tightening or loosening a 1/2″ bolt, it is important to check if it is properly secured. If the bolt is not tightened enough, it can result in loosening over time and potentially cause damage or accidents.

Avoiding these common mistakes will help ensure that you successfully use the correct size wrench for a 1/2″ bolt without any issues or damage to the bolt or wrench. Taking your time and using the right techniques will lead to a job well done.

Step 7: Where to Buy the Right Wrench

Now that you know what size wrench you need for a 1/2 bolt, it’s time to find the right wrench for the job. There are several places you can purchase wrenches, both in-store and online.

In-Store Options:

- Hardware Stores: Visit your local hardware store, such as Home Depot or Lowe’s, and head to the tool section. They should have a wide variety of wrenches available for purchase.

- Auto Parts Stores: If you need the wrench for automotive purposes, consider checking out an auto parts store like AutoZone or Advance Auto Parts. They often carry a selection of wrenches specifically designed for car repairs.

- Tool Stores: Specialty tool stores like Harbor Freight Tools or Northern Tool are also great places to find a wrench. They typically have a large inventory of different types and sizes of wrenches.

Online Options:

- Amazon: One of the largest online marketplaces, Amazon offers a wide range of wrenches from various brands. You can easily filter your search based on size and type of wrench to find the right one.

- Manufacturer Websites: If you have a specific brand in mind, visit their official website. Many manufacturers have an online store where you can purchase their tools directly.

- Online Tool Retailers: Websites like Grainger or MSC Industrial Supply specialize in selling tools. They have a vast collection of wrenches, and you can easily navigate their websites to find the size you’re looking for.

Before making a final purchase, make sure to compare prices and read customer reviews to ensure you’re getting the best quality wrench for the price. Consider factors such as warranty, customer service, and return policy when selecting the right place to buy your wrench.

FAQ

What size wrench do I need for a 1/2 bolt?

To loosen or tighten a 1/2 bolt, you will need a 13mm wrench.

Can I use a different size wrench for a 1/2 bolt?

No, it is important to use the correct size wrench for the bolt to ensure proper tightening or loosening.

Is there a different wrench size for metric and standard 1/2 bolts?

No, both metric and standard 1/2 bolts require a 13mm wrench for effective operation.

What if I don’t have a 13mm wrench?

If you don’t have a 13mm wrench, you can use an adjustable wrench that can be set to the desired size or purchase a 13mm wrench from a hardware store.

Video