What is a Monkey Wrench Used For? Exploring Its Practical Applications

A monkey wrench is a versatile tool that has been used for centuries in various industries and households. Its distinctive design and adjustable jaw make it a valuable tool for a wide range of applications.

One of the main purposes of a monkey wrench is to tighten or loosen nuts and bolts. The adjustable jaw allows the user to fit the wrench around different sizes of fasteners, providing a secure grip and allowing for efficient tightening or loosening. This makes it an essential tool in plumbing, automotive repair, and construction industries.

In addition to its primary use, a monkey wrench can also be used as a lever or a clamp. Its long handle provides leverage, allowing users to apply more force when needed. This makes it ideal for tasks that require extra torque, such as loosening stuck or rusted bolts. Furthermore, the adjustable jaw can be used as a clamp to hold objects in place, making it a useful tool for woodworking and other precision tasks.

Another practical application of a monkey wrench is in emergency situations. Its versatility and durability make it an essential tool for emergency preparedness kits. In case of a natural disaster or other emergencies, a monkey wrench can be used to turn off gas or water valves, securing the safety of those affected.

Overall, the uses of a monkey wrench are diverse and valuable. From plumbing and automotive repairs to emergency situations, this versatile tool has proven to be an invaluable asset in various industries and households.

What is a Monkey Wrench Used For?

A monkey wrench is a versatile hand tool that is primarily used for gripping and turning objects such as nuts, bolts, and pipes. It is a type of adjustable wrench, meaning that the width of its jaw opening can be adjusted to fit various sizes of fasteners.

1. Plumbing

One of the main applications of a monkey wrench is in plumbing tasks. It is commonly used to tighten or loosen pipe fittings, faucets, and other plumbing fixtures. The adjustable jaw allows the user to easily grip and turn objects of different sizes, making it a useful tool for a wide range of plumbing repairs and installations.

2. Automotive Repair

Monkey wrenches are also commonly used in automotive repair and maintenance tasks. They can be used to loosen or tighten nuts and bolts, making them an essential tool for tasks such as changing tires, replacing spark plugs, and adjusting various engine components.

3. General Construction

In general construction, monkey wrenches can be used for a variety of purposes. They can be used to tighten or loosen bolts and nuts in structural components, assemble or disassemble scaffolding, and adjust various mechanical systems. The adjustable jaw makes it easy to work with different sizes of fasteners, making the monkey wrench a valuable tool for construction professionals.

4. Household Maintenance

Monkey wrenches are also useful for everyday household maintenance tasks. They can be used to tighten or loosen screws, nuts, and bolts in furniture, appliances, and other household items. The adjustable jaw makes it easy to work with different sizes of fasteners, making it a versatile tool for a range of household repairs.

5. Industrial Applications

In industrial settings, monkey wrenches are widely used for various applications. They can be used to tighten or loosen nuts and bolts in machinery, facilitate the assembly and disassembly of equipment, and make adjustments to industrial systems. The adjustable jaw allows for flexibility in working with different sizes of fasteners, making the monkey wrench a valuable tool in industrial environments.

In conclusion, a monkey wrench is a versatile tool that has a wide range of applications. From plumbing and automotive repair to general construction and household maintenance, its adjustable jaw and gripping capabilities make it an essential tool for various tasks.

Basic Definition and Purpose

A monkey wrench is a type of adjustable wrench that is commonly used to tighten or loosen nuts and bolts of various sizes. It is a versatile tool that can be adjusted to fit different sizes of fasteners.

The primary purpose of a monkey wrench is to provide a strong grip on nuts and bolts, allowing for effective tightening or loosening. The adjustable jaw allows the wrench to accommodate a wide range of sizes, making it a useful tool in a variety of situations.

The name “monkey wrench” is derived from its invention in the 19th century, when it was used primarily by mechanics to work on steam engines and other machinery. The term “monkey” was colloquially used to describe any small, adjustable tool during that time period.

Today, monkey wrenches are still widely used in various industries, including automotive repair, plumbing, and construction. They are an essential tool for professionals and DIY enthusiasts alike, providing a reliable means of tightening or loosening nuts and bolts.

In addition to its primary function, a monkey wrench can also be used as a lever for additional torque, allowing for increased force to be applied when needed. However, it is important to use the wrench correctly and not apply excessive force, as this can result in damage to both the wrench and the object being worked on.

Overall, the basic definition and purpose of a monkey wrench is to provide a versatile and adjustable tool for tightening or loosening nuts and bolts of different sizes. Its reliability and ease of use make it an indispensable tool in many industries.

Historical Background and Evolution

The monkey wrench is a versatile hand tool that has been used for centuries. Its origins can be traced back to ancient civilizations, where similar devices were used to tighten or loosen bolts and nuts. However, it wasn’t until the 19th century that the modern monkey wrench as we know it today was developed.

The term “monkey wrench” itself is believed to have originated from the tool’s similarity in shape to the jaws of a monkey. It was first used by inventor Charles Moncky, who patented his design in 1820. Moncky’s wrench featured an adjustable jaw that could be moved using a worm gear mechanism, allowing it to grip objects of various sizes with ease.

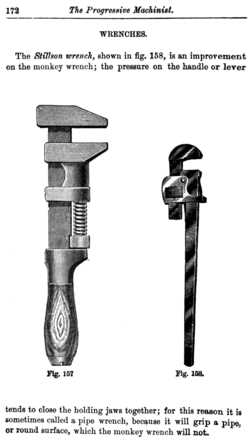

Over time, the design of the monkey wrench continued to evolve and improve. In the mid-19th century, mechanical engineer and inventor Daniel C. Stillson created a new type of wrench that revolutionized the industry. Stillson’s wrench featured a self-adjusting jaw, which allowed it to automatically adapt to different sizes of bolts and nuts. This innovation made the monkey wrench even more versatile and efficient.

The popularity of the monkey wrench grew rapidly, as it became an essential tool in various industries such as construction, plumbing, and automotive repair. Its versatility and ability to apply a strong grip made it invaluable for tasks that required loosening or tightening bolts, pipes, and other fasteners.

In the 20th century, advancements in technology and manufacturing processes led to the production of monkey wrenches made from high-quality steel, which further improved their durability and performance. Today, monkey wrenches are available in various sizes and designs, including adjustable and non-adjustable models.

Despite the advancements in power tools, the monkey wrench continues to be widely used due to its simplicity, reliability, and affordability. Its design has remained largely unchanged over the years, proving that sometimes the simplest tools can be the most effective.

Dimensions and Types

1. Dimensions

The dimensions of a monkey wrench can vary depending on the specific model and brand. Generally, monkey wrenches are available in different sizes to accommodate various types of nuts and bolts. The length of the handle can range from around 8 inches to 18 inches, while the jaw opening can typically range from about 1 inch to 2 inches in diameter.

2. Types

Monkey wrenches come in different types, each designed to serve specific purposes. Here are a few common types:

- Standard Monkey Wrench: Also known as an adjustable wrench, this type has a fixed upper jaw and an adjustable lower jaw that can be moved by sliding a worm gear along the handle. It allows for easy adjustment to fit various sizes of nuts and bolts.

- Pipe Monkey Wrench: This type is specifically designed for working with pipes. It features serrated jaws that grip the pipe securely, allowing for tightening, loosening, and turning without damaging the pipe’s surface.

- Stillson Monkey Wrench: The Stillson monkey wrench, also known as a pipe wrench or plumber’s wrench, is a heavy-duty variant designed for heavy-duty plumbing work. It features adjustable serrated jaws that provide a strong grip on various pipe sizes.

- Crowfoot Monkey Wrench: This type of monkey wrench has a unique crowfoot-shaped jaw. It is often used in tight spaces where conventional wrenches cannot fit, such as automotive or machinery maintenance.

These are just a few examples of monkey wrench types. There may be other specialized variations available for specific applications or industries.

Plumbing and Pipe Fitting

A monkey wrench is an essential tool in the plumbing and pipe fitting industry. It is commonly used by plumbers and pipefitters for various tasks, such as tightening or loosening nuts, bolts, and fittings.

Common Applications

- Tightening or loosening pipe fittings: A monkey wrench is capable of providing the necessary grip and leverage to tighten or loosen various types of pipe fittings, such as couplings, unions, and connectors.

- Repairing leaking pipes: When dealing with leaking pipes, a monkey wrench can be used to disassemble and reassemble pipes and fittings for repairs or replacements.

- Threaded connections: Monkey wrenches are commonly used to tighten or loosen threaded connections, such as those found in water supply lines and gas pipes.

Types of Pipe Fittings

In the plumbing and pipe fitting industry, there are various types of pipe fittings that require the use of a monkey wrench, including:

| Pipe Fitting Type | Description |

|---|---|

| Couplings | Used to connect two pipes of the same diameter. |

| Unions | Similar to couplings but allow for easy disassembly. |

| Tees | Used to create a T-shaped junction between three pipes. |

| Elbows | Used to change the direction of the pipe. |

| Reducers | Used to connect pipes of different diameters. |

| Valves | Used to control the flow of water or gas through a pipe. |

Each type of fitting requires proper tightening or loosening, which can be achieved using a monkey wrench.

Precautions

When using a monkey wrench for plumbing and pipe fitting tasks, it’s important to take certain precautions:

- Choose the right size: Ensure that the monkey wrench is the appropriate size for the specific fitting to avoid damaging it.

- Apply proper force: Use the wrench to apply enough force to tighten or loosen the fitting, but avoid excessive force that could cause damage.

- Use caution with fragile materials: If working with fragile materials, such as plastic pipes, be careful not to overtighten and crack the pipes.

- Maintain the wrench: Regularly clean and inspect the monkey wrench to ensure its proper functioning. Lubricate any movable parts as necessary.

By following these precautions, a monkey wrench can be an effective tool for various plumbing and pipe fitting tasks, making it an indispensable tool in the industry.

Automotive Repair and Maintenance

Introduction

In the field of automotive repair and maintenance, a monkey wrench is a versatile tool that is commonly used by mechanics and automotive enthusiasts. This tool is designed to provide a tight grip on nuts and bolts, making it easier to loosen or tighten them during various repair and maintenance tasks.

Changing Tires

One of the primary applications of a monkey wrench in automotive repair and maintenance is during the process of changing tires. When removing or installing lug nuts, the wrench can be used to securely hold the nuts in place and ensure a proper fit.

Engine Repair

During engine repair, the monkey wrench can be used to tighten or loosen various bolts and fittings. It provides the necessary torque to securely fasten components such as the manifold, spark plugs, or timing belt. This tool allows mechanics to access and work on different parts of the engine easily.

Suspension System Maintenance

The suspension system of a vehicle requires regular maintenance to ensure a smooth and comfortable ride. A monkey wrench is often utilized to adjust and tighten bolts and nuts associated with the suspension components. This allows mechanics to properly align and secure the shocks, struts, or control arms.

Brake System Repairs

When working on the brake system, a monkey wrench is an essential tool for mechanics. It can be used to remove and install calipers, adjust brake lines, or tighten brake pads. This tool helps ensure the safe and efficient operation of the vehicle’s braking system.

General Maintenance

Apart from specific repair tasks, a monkey wrench is also used for general maintenance of vehicles. It allows mechanics to tighten or loosen various nuts and bolts found in different areas of the vehicle, such as the chassis, exhaust system, or battery terminals.

Conclusion

In automotive repair and maintenance, a monkey wrench proves to be an invaluable tool. Its ability to provide a secure grip and apply torque to nuts and bolts makes it an essential tool for various tasks, ranging from tire changes to engine repairs. Whether you are a professional mechanic or a DIY enthusiast, a monkey wrench should be a part of your automotive toolbox.

Household and DIY Projects

1. Furniture Assembly

One common household project where a monkey wrench comes in handy is furniture assembly. Whether you’re putting together a new table, bookcase, or chair, a monkey wrench can help tighten screws and bolts securely. Its adjustable jaw allows you to fit it onto various sizes of nuts and bolts, making it a versatile tool for assembling furniture.

2. Plumbing Repairs

Another practical application of a monkey wrench is in plumbing repairs. If you need to loosen or tighten plumbing fittings, such as pipe joints or connectors, a monkey wrench can provide the necessary grip and torque. Its adjustable jaw allows you to work with different pipe sizes, making it useful for various plumbing tasks like fixing leaks or replacing pipes.

3. Car Maintenance

A monkey wrench is also useful for basic car maintenance tasks that involve tightening or loosening nuts and bolts. For example, when changing a tire, you can use the monkey wrench to remove the lug nuts. Additionally, it can be used for other DIY car repairs like replacing brake pads or working on the exhaust system. Its adjustable jaw and sturdy build make it suitable for handling automotive tasks.

4. Home Renovations

If you’re undertaking home renovations or remodeling projects, a monkey wrench can be a valuable tool. It can help with tasks such as removing old faucets, tightening or loosening bolts on furniture or fixtures, and assembling items like shelves or cabinets. Its versatility and adjustable jaw make it suitable for a wide range of projects within the home.

5. Gardening and Outdoor Projects

Even in outdoor settings, a monkey wrench can come in handy. When working on gardening projects, it can be used to tighten or loosen nuts and bolts on garden furniture, tools, or equipment. Whether you’re assembling or disassembling outdoor objects or making repairs, the adjustable jaw of a monkey wrench makes it a practical tool for outdoor DIY projects as well.

Conclusion

A monkey wrench is a versatile tool with numerous practical applications around the house and for various DIY projects. From furniture assembly to plumbing repairs, car maintenance, home renovations, and gardening projects, it provides the necessary grip, torque, and adjustability to handle a wide range of tasks. Whether you’re a DIY enthusiast or a homeowner, a monkey wrench is a valuable addition to your toolkit.

Industrial and Construction Applications

Monkey wrenches are widely used in various industrial and construction settings due to their adjustable nature and ability to deliver high torque. Here are some of the common applications of monkey wrenches in these fields:

Assembly and Disassembly

- Monkey wrenches are invaluable tools for assembling and disassembling machinery and equipment in industrial environments. Their adjustable jaws allow for a tight grip on different-sized nuts and bolts, making it easier to tighten or loosen them.

- They are commonly used in automotive assembly lines to tighten and adjust various components.

Pipe Fitting

- In the construction industry, monkey wrenches are commonly used for pipe fitting tasks. They can grip and turn pipe fittings of different sizes securely, ensuring a watertight connection.

- Plumbers often rely on monkey wrenches to tighten or loosen pipe fittings during installation or repair work.

Heavy Machinery Maintenance

- Monkey wrenches find extensive use in maintenance and repair of heavy machinery, such as construction equipment and manufacturing machinery.

- They are effective in loosening and tightening bolts, nuts, and other fasteners that hold machinery components together.

Structural Steelwork

- When erecting steel structures, monkey wrenches are commonly used to tighten and adjust bolts that connect steel beams and columns.

- The adjustable jaws of the wrench enable workers to work with bolts of various sizes, making it an essential tool for structural steelwork.

Industrial Plumbing

- Monkey wrenches are used by industrial plumbers to install and repair plumbing systems in factories, warehouses, and other industrial settings.

- They are instrumental in loosening and tightening various plumbing fittings and connectors, ensuring a secure and leak-free connection.

Equipment Maintenance

- Monkey wrenches are indispensable tools for equipment maintenance tasks in a wide range of industries.

- They are used to tighten or loosen bolts, nuts, and other fasteners on machinery and equipment to ensure proper operation and prevent equipment failure.

In conclusion, monkey wrenches are versatile tools with numerous applications in industrial and construction settings. Their adjustable jaws and strong grip make them ideal for various tasks, including assembly, disassembly, pipe fitting, heavy machinery maintenance, structural steelwork, industrial plumbing, and equipment maintenance.

Safety Tips and Maintenance

Safety Tips:

- Always wear appropriate safety gear such as gloves and safety glasses to protect yourself from potential injuries while using a monkey wrench.

- Make sure the work area is well-lit and free from any hazards that could cause accidents or injuries.

- Ensure that the wrench is in good condition and free from any defects before using it. Inspect the handle, jaws, and adjustment mechanism for signs of damage or wear.

- Use the wrench only for its intended purpose and avoid using excessive force that could result in the wrench slipping or causing damage.

- When using a monkey wrench, keep a firm grip on the handle to maintain control and prevent any accidents.

- Avoid using the wrench on rusty or corroded fasteners as this can make it difficult to loosen or tighten them properly. Use rust dissolvers or penetrating oils if necessary.

- Never use a monkey wrench on live electrical wires or near sources of electricity to prevent the risk of electric shock.

- Keep the wrench clean and free from any debris to ensure its optimal functionality. Regularly inspect and clean the jaws to remove any dirt or foreign objects that could affect its performance.

- Store the wrench in a dry and secure place to prevent it from being damaged or causing injuries.

Maintenance:

To ensure the longevity and performance of your monkey wrench, it’s important to perform regular maintenance tasks:

- Inspect the wrench before and after each use to identify any signs of wear or damage. Pay attention to the adjustment mechanism, jaws, and handle.

- Apply a light coat of lubricant on the moving parts of the wrench to prevent rust and keep the mechanism smooth.

- Clean the jaws and handle using a soft cloth to remove any dirt or debris. Avoid using harsh chemicals that could damage the wrench.

- If you notice any loose or worn parts, repair or replace them as soon as possible to prevent further damage.

- Store the wrench in a designated toolbox or case to protect it from moisture, dust, and other elements that could cause corrosion or damage.

| Task | Frequency |

|---|---|

| Inspect for wear or damage | Before and after each use |

| Apply lubricant | Every few months |

| Clean jaws and handle | As needed |

| Repair or replace parts | As needed |

FAQ

What is a monkey wrench?

A monkey wrench is a type of adjustable wrench that is used for tightening or loosening nuts and bolts.

How does a monkey wrench work?

A monkey wrench works by using a movable jaw that can be adjusted to fit different sizes of nuts and bolts. This jaw is then used to grip and turn the object.

What are the practical applications of a monkey wrench?

A monkey wrench is commonly used in plumbing, automotive repairs, and construction. It is especially useful for tasks that require loosening or tightening fasteners.

Can a monkey wrench be used for other purposes?

While a monkey wrench is primarily designed for working with nuts and bolts, it can also be used as a makeshift hammer or lever in certain situations. However, it is not recommended to use it for tasks that it is not specifically designed for.

Are there different types of monkey wrenches?

Yes, there are several different types of monkey wrenches, including the straight wrench, the offset wrench, and the pipe wrench. Each type has its own unique features and is designed for specific applications.

Video