Understanding the Purpose and Functionality of a Drill Jig

A drill jig is a specialized tool used in woodworking, metalworking, and other industries to ensure accurate and precise drilling. It is an essential tool for professionals and DIY enthusiasts alike who require consistent and reliable results.

The primary purpose of a drill jig is to guide the drill bit into the desired position and angle, ensuring that each hole is drilled with precision. This is particularly important when drilling multiple holes or when drilling in hard materials such as metal or wood. By using a drill jig, the user can avoid mistakes and ensure that every hole is aligned correctly.

Drill jigs come in various shapes and sizes, depending on the specific task at hand. Some jigs are designed for drilling holes at specific angles, while others are used for drilling holes at specific depths. There are also jigs available for drilling holes in curved or irregular surfaces. The versatility of drill jigs makes them indispensable tools in many industries.

In addition to ensuring accuracy, drill jigs also offer other benefits. They can increase productivity by reducing the time it takes to measure and mark each hole before drilling. They also help to extend the lifespan of drill bits by preventing them from wandering off course and breaking. Furthermore, drill jigs provide a safer working environment by stabilizing the drill and minimizing the risk of injury.

In conclusion, a drill jig is a valuable tool that helps professionals and hobbyists achieve accurate and precise drilling results. Its purpose is to guide the drill bit and ensure that each hole is drilled with precision. Furthermore, it offers other benefits such as increased productivity, extended drill bit lifespan, and enhanced safety. Whether you’re a professional or a DIY enthusiast, a drill jig can greatly improve your drilling experience and help you achieve professional-grade results.

Definition and Explanation of a Drill Jig

A drill jig is a device used in the field of machining and woodworking to guide the drilling of holes in a precise and accurate manner. It is also known as a drilling template or drill guide. The main purpose of a drill jig is to ensure consistency and repeatability in hole placement, making it an essential tool for many industries.

Functionality of a Drill Jig

A drill jig is typically made of a rigid material, such as metal or plastic, and consists of two main components: the jig body and the drill bushing. The jig body is the base where the drill bushing is mounted, and it provides the necessary stability and support during the drilling process. The drill bushing, on the other hand, is the part of the jig that guides the drill bit and determines the exact location and angle of the hole.

By using a drill jig, the user can quickly and accurately position the holes to be drilled, ensuring precise alignment and consistent hole dimensions. This is particularly useful for tasks that require repetitive drilling, such as creating holes for screws, dowels, or other fasteners.

Types of Drill Jigs

There are several types of drill jigs available, each designed for specific applications and requirements:

- Simple drill jig: This type of jig is the most basic and consists of a single drill bushing mounted on the jig body. It is suitable for drilling holes with a fixed distance and angle.

- Template drill jig: A template drill jig utilizes a pre-made template or pattern to guide the drilling process. It is commonly used for tasks that require drilling a series of holes with precise spacing and alignment.

- Angle drill jig: An angle drill jig is designed to drill holes at specific angles. It is useful for applications that require drilling holes at non-standard angles, such as for joinery or angled dowel holes.

- Production drill jig: A production drill jig is designed for high-volume manufacturing processes. It is often automated and can accommodate multiple drill bushings to increase productivity.

Benefits of Using a Drill Jig

The use of a drill jig offers several benefits:

- Precision: By guiding the drill bit, a drill jig ensures precise and accurate hole placement. This is crucial for tasks that require precise alignment, such as assembling parts or creating fixtures.

- Efficiency: A drill jig allows for quick and consistent drilling, saving time and effort. It eliminates the need for manual measurements and alignment, making the drilling process more efficient.

- Repeatability: With a drill jig, the user can easily reproduce the same hole pattern multiple times, ensuring consistent results. This is particularly advantageous in manufacturing processes that require mass production.

- Reduced errors: Using a drill jig minimizes the risk of errors, such as drilling off-center or at the wrong angle. This helps to avoid costly mistakes and increases overall accuracy.

In conclusion, a drill jig is an essential tool in machining and woodworking industries for precise and accurate hole drilling. It provides consistency, efficiency, and repeatability, making it a valuable asset in various applications.

Purpose of a Drill Jig

Overview

A drill jig is a tool used in manufacturing and woodworking industries to guide the drilling process and ensure accurate hole placement. It is a specialized device that helps in maintaining precision and consistency in hole drilling operations.

Ensuring Accuracy

One of the main purposes of a drill jig is to ensure accuracy in hole drilling. It provides a predefined guide for the drill bit, eliminating the need for manual alignment. This helps in avoiding errors and achieving precise hole placement every time.

Increased Efficiency

By eliminating the need for manual alignment and providing a reliable guide, a drill jig helps in increasing efficiency in drilling operations. It minimizes the time and effort required to set up and execute drill cycles, resulting in improved productivity.

Repeatability

A drill jig offers the advantage of repeatability in hole drilling. Once a jig is properly set up, it can be used repeatedly to drill multiple holes with consistent accuracy. This is particularly beneficial in mass production scenarios where hundreds or thousands of identical holes need to be drilled.

Reducing Human Error

Human error is a common factor in manual drilling operations. With a drill jig, the dependency on the operator’s skill and precision is minimized. The drill jig acts as a foolproof guide, reducing the chances of errors caused by human factors.

Cost Savings

While a drill jig may require an upfront investment, it can result in significant cost savings in the long run. By reducing errors, increasing efficiency, and improving productivity, a drill jig helps in minimizing material waste and rework, ultimately saving money for the manufacturer.

Conclusion

A drill jig is a versatile tool with a range of benefits. It ensures accuracy, increases efficiency, offers repeatability, reduces human error, and provides cost savings. Its purpose is to facilitate precise and consistent hole drilling, making it an indispensable tool in various industries.

Benefits of Using a Drill Jig

Precision and Accuracy

One of the main benefits of using a drill jig is the increased precision and accuracy it provides. A drill jig is designed to hold the drill bit in the correct position and at the correct angle, ensuring that each hole is drilled with consistent accuracy. This is particularly important when working on projects that require multiple holes to be drilled at specific locations. By using a drill jig, you can ensure that the holes are drilled exactly where they need to be, resulting in a more professional and precise finished product.

Time Saving

Using a drill jig can also save a significant amount of time compared to drilling holes freehand. A drill jig allows you to set up the position and angle of the drill bit once, and then quickly and easily replicate this for each subsequent hole. This eliminates the need for measuring and marking each hole individually, resulting in a much faster drilling process. Additionally, because a drill jig ensures consistent accuracy, there is less time wasted on re-drilling or making corrections.

Improved Safety

Drilling holes freehand can be risky, particularly if you are working with larger drill bits or on more delicate materials. A drill jig provides a secure and stable platform for the drill bit, reducing the risk of the bit slipping or the material becoming damaged. This can help prevent accidents and injuries, making the drilling process safer overall.

Increased Efficiency

Using a drill jig can also increase overall efficiency in a workshop or production setting. By eliminating the need for manual measuring and marking of each hole, you can streamline the drilling process and complete more work in less time. This can be especially beneficial for projects that require a large number of holes or repetitive drilling tasks. The increased efficiency provided by a drill jig can help improve productivity and reduce the overall time needed to complete a project.

Versatility and Adaptability

Most drill jigs are versatile tools that can be used for a wide range of drilling tasks. They can be adjusted to accommodate different drill bit sizes and angles, making them suitable for various projects and applications. This adaptability allows you to use your drill jig for multiple purposes, saving you money on purchasing specialized jigs for different tasks. Additionally, drill jigs can be easily stored and transported, making them a convenient tool to have on hand in any workshop or job site.

Clean and Professional Finish

Lastly, using a drill jig can help ensure a clean and professional finish to your drilled holes. The precise positioning and angle provided by a drill jig result in holes that are neat and uniform in appearance. This can be particularly important for aesthetic reasons, such as when drilling holes for mounting hardware or creating a decorative pattern. The clean finish achieved with a drill jig can enhance the overall appearance of your project and give it a more polished and professional look.

How a Drill Jig Works

Introduction

A drill jig, also known as a drilling fixture, is a tool that helps to guide a drill bit accurately and precisely during drilling operations. It is commonly used in woodworking, metalworking, and other industries where the creation of precisely aligned holes is required. A drill jig allows for consistent hole placement and ensures that each hole is drilled at the correct depth and angle.

Components

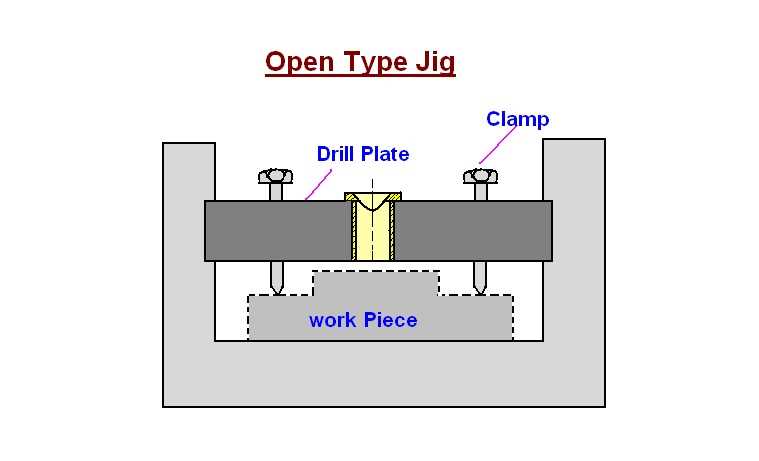

A typical drill jig consists of several key components:

- Base Plate: The base plate provides a stable platform for the workpiece and the jig itself. It is usually made of a sturdy material such as metal or plastic.

- Guide Bushing: The guide bushing is a hollow cylindrical component that houses the drill bit. It serves as a guide for the drill bit, ensuring that it remains centered and aligned during drilling.

- Clamping Mechanism: The clamping mechanism holds the workpiece securely in place on the base plate. It prevents any movement or shifting during the drilling process.

- Guide Pins: Guide pins are used to locate the workpiece accurately on the base plate. They fit into corresponding holes or slots on the workpiece, ensuring precise positioning.

Operation

When using a drill jig, the following steps are typically followed:

- Secure the drill jig to the work surface using clamps or screws, ensuring that it is stable and level.

- Place the workpiece onto the base plate, aligning it with the guide pins for accurate positioning.

- Secure the workpiece to the base plate using the clamping mechanism.

- Insert the drill bit into the guide bushing and adjust its depth as needed.

- Align the drill bit with the desired hole location on the workpiece.

- Apply pressure to the drill and plunge it into the workpiece, allowing the guide bushing to guide the drill bit accurately.

- Repeat the drilling process for each desired hole.

Advantages

The use of a drill jig offers several advantages:

- Precision: A drill jig ensures precise hole placement, depth, and angle, resulting in consistent and accurate drilling.

- Efficiency: By eliminating the need for manual alignment and measurements for each hole, a drill jig speeds up the drilling process.

- Repeatability: With a drill jig, the same hole pattern can be easily replicated, allowing for the production of multiple identical workpieces.

- Security: The clamping mechanism of a drill jig holds the workpiece securely in place, reducing the risk of slippage or movement during drilling.

Conclusion

A drill jig is a valuable tool in various industries where precision drilling is essential. By providing accurate guidance and maintaining consistent hole placement, a drill jig helps to streamline the drilling process and ensure high-quality results.

Components of a Drill Jig

A drill jig is a specialized tool used in manufacturing and construction processes to guide the drill bit into the desired location accurately. It consists of several components that work together to ensure precise drilling and repetitive hole placement.

1. Base Plate

The base plate is the foundation of the drill jig. It provides a stable and flat surface for the workpiece and helps to maintain the alignment of the guide bushings and drill bits. The base plate is usually made of a rigid material such as aluminum or steel.

2. Guide Bushings

Guide bushings, also known as drill bushings, are cylindrical sleeves inserted into the drill jig’s base plate. They serve as guides for the drill bit and determine the position and angle of the hole being drilled. Guide bushings are typically made of hardened steel to resist wear and provide accurate hole placement.

3. Drill Guide

The drill guide is a component that holds the drill bit in place and aligns it with the guide bushing. It ensures that the drill bit stays at the correct angle and prevents it from wandering during the drilling process. The drill guide can be adjustable to accommodate different drill bit sizes and hole depths.

4. Clamping Mechanism

The clamping mechanism is used to secure the workpiece to the drill jig’s base plate. It ensures that the workpiece remains in position and provides stability during the drilling process. The clamping mechanism may include clamps, screws, or other fastening devices depending on the design of the drill jig.

5. Depth Stop

A depth stop is a feature that limits the drilling depth. It ensures that all holes drilled using the drill jig have consistent depth, which is essential for maintaining accuracy and uniformity in the drilled holes. The depth stop can be adjustable to accommodate different drilling depths.

6. Center Marking Device

A center marking device is an optional but useful component of a drill jig. It helps to mark the center point on the workpiece before drilling and ensures accurate hole placement. The center marking device can be a punch, a center drill, or any other tool that leaves a visible mark on the surface of the workpiece.

7. Indexing Mechanism

In some drill jigs, an indexing mechanism is included to allow precise hole placement at specific intervals. The indexing mechanism may consist of a rotary table, index pin, or any other mechanism that can be adjusted to create equally spaced holes. This feature is particularly useful when drilling multiple holes in a repetitive pattern.

8. Accessories

In addition to the main components mentioned above, a drill jig may include various accessories to enhance its functionality. These can include handles for easy positioning and adjustment, auxiliary fences or guides for additional support, and built-in measuring devices such as scales or rulers for precise hole positioning.

Overall, the components of a drill jig work together to ensure accurate and repeatable drilling operations. By using a drill jig, operators can achieve consistency and efficiency in their drilling processes, which is crucial for many manufacturing and construction applications.

Step-by-Step Guide to Using a Drill Jig

1. Gather Your Materials

Before you begin using a drill jig, make sure you have the necessary materials on hand. You will need:

- A drill jig

- A drill

- Drill bits

- Workpiece

- Clamps or vice

- Safety goggles

2. Secure Your Workpiece

Place your workpiece on a stable surface, such as a workbench. Use clamps or a vice to securely hold the workpiece in place. This will ensure stability and prevent movement during drilling.

3. Align Your Drill Jig

Position the drill jig on top of the workpiece in the desired location for drilling. Ensure that the jig is aligned properly and perpendicular to the surface of the workpiece. Use a square or ruler to double-check the alignment if needed.

4. Secure the Drill Jig

Once the drill jig is properly aligned, use clamps or a vice to secure it in place. This will prevent any movement or shifting during the drilling process.

5. Select the Correct Drill Bit

Choose the appropriate drill bit for the desired hole size and material. Make sure the drill bit is compatible with your drill and securely insert it into the drill’s chuck.

6. Set the Drill Depth

Adjust the depth stop or collar on the drill to the desired drilling depth. This will ensure consistent and accurate hole depths throughout the drilling process.

7. Begin Drilling

Hold the drill firmly and position the drill bit into the guide hole on the drill jig. Start the drill at a slow speed and gradually increase the speed as needed. Apply steady pressure and drill straight down into the workpiece.

8. Repeat if Necessary

If you need to drill multiple holes, repeat the process by repositioning the drill jig and securing it in the desired location. Make sure to align the drill jig properly each time.

9. Clean Up

Once you have finished drilling, remove the drill jig from the workpiece and clean up any debris or shavings. Store the drill jig and other materials in a safe and organized manner for future use.

By following these step-by-step instructions, you can effectively use a drill jig to accurately and efficiently drill holes in your workpiece.

Common Applications of Drill Jigs

Drill jigs are versatile tools that are widely used in various industries for precise drilling operations. Here are some common applications of drill jigs:

- Woodworking: In woodworking, drill jigs are used to ensure accurate and consistent hole placement for dowels, screws, and other fasteners. They help in creating joints, assembling cabinets, and building furniture.

- Metalworking: Drill jigs find extensive use in metalworking industries for drilling holes in metal components. They are often used in the production of automotive parts, aerospace components, and other metal assemblies.

- Electronics: Electronic circuit boards often require precise drilling of holes for components such as capacitors, resistors, and connectors. Drill jigs aid in achieving accurate hole placements, ensuring proper connectivity and functionality of the circuit boards.

- Plastic Processing: Drill jigs are used in industries that involve plastic processing, such as injection molding and extrusion. They help in drilling holes in plastic parts with high precision, ensuring proper fit and functionality.

- Medical Devices: Drill jigs play a vital role in the production of medical devices. They are used to drill holes for screws and other fasteners in implants, surgical tools, and prosthetics, ensuring precise alignment and secure attachment.

Overall, drill jigs are essential tools in many industries where precise and accurate hole drilling is required. They help in improving efficiency, reducing errors, and ensuring consistent results in various manufacturing processes.

Industrial Applications

Manufacturing

Drill jigs are widely used in the manufacturing industry for various purposes. They are essential tools in processes such as drilling, tapping, and reaming holes in metal or plastic components. By using drill jigs, manufacturers can achieve consistent hole placement and accuracy, ensuring the quality and functionality of their products.

Drill jigs also play a critical role in mass production, where precision and efficiency are crucial. They allow manufacturers to quickly and accurately drill holes in multiple workpieces, increasing productivity while maintaining consistent quality.

Aerospace and Automotive

In industries such as aerospace and automotive, where safety and reliability are paramount, drill jigs are widely used. These industries require complex and precise hole patterns in various materials, including metals and composites. Drill jigs provide the necessary guidance and stability for drilling these intricate holes, ensuring structural integrity and performance.

For example, in aircraft manufacturing, drill jigs are used to drill holes for rivets and fasteners, ensuring the proper alignment and strength of critical components. In the automotive industry, drill jigs are used for tasks such as drilling holes for bolts, sensors, and electrical components.

Electronics

The electronics industry heavily relies on drill jigs for the production of printed circuit boards (PCBs). PCBs require precise hole patterns to accommodate components such as resistors, capacitors, and integrated circuits. Drill jigs provide the necessary accuracy and repeatability for drilling these holes in PCBs.

Furthermore, drill jigs are used in the manufacturing of electronic enclosures and chassis. These components often need precise holes for connectors, switches, and control panels. Drill jigs enable manufacturers to achieve the required hole placement and alignment in these critical electronic components.

Medical Devices

The medical device industry utilizes drill jigs for the production of various medical instruments and implants. Drill jigs are used for drilling holes in surgical instruments, ensuring precise alignment and functionality. They are also used in the production of orthopedic implants, such as bone screws and plates, where precise hole placement is crucial for optimal performance.

Drill jigs in the medical device industry help maintain consistency and accuracy in the manufacturing process, ensuring the safety and effectiveness of the final products.

Woodworking

Although drill jigs are commonly associated with metal and plastic workpiece drilling, they also have applications in woodworking. Woodworkers use drill jigs for tasks such as drilling dowel holes, pocket holes, or even for creating intricate joinery.

By using drill jigs, woodworkers can ensure precise hole placement and alignment, resulting in stronger, more professional-looking joints. Drill jigs also help woodworkers improve efficiency during repetitive drilling tasks in cabinetry, furniture making, and other woodworking projects.

Overall, drill jigs find extensive applications in various industries, ranging from manufacturing and aerospace to electronics, medical devices, and woodworking. Their ability to provide precision and repeatability makes them indispensable tools for achieving high-quality results in diverse industrial settings.

DIY and Home Improvement Applications

A drill jig is a versatile tool that can be used in various DIY and home improvement projects. Here are some common applications where a drill jig can come in handy:

1. Furniture assembly

When assembling furniture, precision and accuracy are essential for a sturdy and professional-looking result. A drill jig can help ensure that the holes for screws or dowels are drilled at the correct angles and distances, making the assembly process much easier and more successful.

2. Cabinet installation

Installing cabinets requires drilling holes for hinges, handles, and other hardware. A drill jig can be used to maintain consistency and alignment, ensuring that all the cabinet doors and drawers are properly aligned and functional.

3. Woodworking projects

A drill jig is an essential tool for woodworking enthusiasts. Whether you’re building shelves, tables, or even small accessories, a drill jig can help you achieve precise and accurate holes for joinery, dowels, or other fasteners.

4. Electrical installations

When installing electrical outlets, light switches, or any other electrical fixtures, it’s crucial to drill precise holes to accommodate the wiring. A drill jig can ensure that the holes are aligned and positioned correctly, minimizing the risk of errors and enhancing the safety of the electrical installation.

5. Plumbing projects

Whether you’re installing pipes or fixing leakages, a drill jig can be incredibly helpful. It allows you to accurately drill holes for pipe fittings, ensuring a secure and leak-free connection.

6. DIY crafts and hobbies

A drill jig can also be used in various craft and hobby projects. Whether you’re creating wooden models, jewelry, or other intricate designs, a drill jig can assist in drilling small and precise holes to enhance the accuracy and quality of your creations.

In summary, a drill jig is a versatile tool that finds numerous applications in DIY and home improvement projects. From furniture assembly to woodworking, electrical and plumbing installations, a drill jig can greatly enhance precision, accuracy, and overall project success.

FAQ:

What is the purpose of a drill jig?

A drill jig is used as a guide to assist in drilling holes in a precise and accurate manner. It helps to maintain the correct alignment and spacing of the holes, ensuring that they are drilled in the right location and at the right angle.

How does a drill jig work?

A drill jig typically consists of a hardened metal template with holes that correspond to the desired hole pattern. The workpiece is placed on top of the jig, and the drill bit is inserted into the hole in the jig. When the drill is activated, the guide holes on the jig ensure that the drill bit stays aligned and enables the user to drill multiple holes with consistent precision.

What are some common applications of drill jigs?

Drill jigs are commonly used in various industries and applications. They are used in woodworking to drill holes for dowels or screws, in metalworking to create precise holes for fasteners or components, in electronics manufacturing for PCB assembly, and in automotive and aerospace industries for drilling holes in parts and assemblies.

Can a drill jig be customized for specific hole patterns?

Yes, drill jigs can be customized for specific hole patterns. Depending on the complexity of the hole pattern, a drill jig can be designed and manufactured to accommodate the required hole sizes, angles, and spacing. Companies that require repetitive drilling operations often opt for custom drill jigs to improve efficiency and accuracy.

Video:

![Intolerable Cruelty [DVD] [2003]](https://m.media-amazon.com/images/I/51ZIQxk6VML._SS520_.jpg)