Choosing the Right Drill Bit for Woodworking Projects

Woodworking projects can be a rewarding and fulfilling hobby, but one of the most important aspects of any woodworking project is selecting the right tools. When it comes to drilling holes in wood, choosing the right drill bit is crucial for achieving clean and precise results.

There are several factors to consider when selecting a drill bit for woodworking projects. The type of wood you are working with, the size of the hole you need to drill, and the type of drill you are using all play a role in determining the right drill bit for the job.

One of the most common types of drill bits used in woodworking is the twist bit. These bits have a spiral design that helps to create clean holes in wood. They come in a variety of sizes and can be used with both hand drills and power drills.

For larger holes, spade bits or paddle bits are often used. These bits have a flat paddle-like shape that helps to drill larger diameter holes. They are often used for creating holes for dowels or other large fasteners.

Woodworking Projects: A Brief Overview

Woodworking projects involve shaping and crafting wood into various objects or structures. This centuries-old craft has evolved over time and continues to be a popular hobby and profession for many individuals.

Types of Woodworking Projects

Woodworking projects can range from small, simple tasks to complex, elaborate designs. Some common types of woodworking projects include:

- Furniture making: Creating chairs, tables, cabinets, and other functional pieces

- Cabinetry: Building custom kitchen cabinets, bookshelves, and storage units

- Wood carving: Sculpting intricate designs and patterns into wood

- Woodturning: Using a lathe to create bowls, vases, and other rounded objects

- Woodworking for home improvement: Building decks, fences, and other outdoor structures

Woodworking Tools and Techniques

To successfully complete woodworking projects, it is important to have the right tools and knowledge of various techniques. Some common tools used in woodworking include:

- Saws: Including hand saws, circular saws, and miter saws

- Drills and drivers: Used for drilling holes and securing screws

- Chisels: Essential for shaping and carving wood

- Sanders: Used to smooth out surfaces

- Clamps: Hold wood pieces together during assembly

Woodworking techniques vary depending on the project, but may involve measuring and marking, cutting and shaping, joining and assembly, and finishing and sanding.

Benefits of Woodworking Projects

Engaging in woodworking projects offers several benefits:

- Creativity and self-expression: Woodworking allows individuals to bring their ideas to life and showcase their artistic abilities.

- Problem-solving skills: Woodworking requires critical thinking and problem solving to plan and execute projects.

- Hand-eye coordination: Working with tools and manipulating wood improves motor skills and coordination.

- Sense of accomplishment: Completing a woodworking project provides a sense of pride and satisfaction.

Conclusion

Woodworking projects offer a rewarding and fulfilling experience for individuals with a passion for creating and working with wood. Whether it’s building furniture, carving intricate designs, or undertaking home improvement projects, woodworking allows for endless possibilities and a chance to showcase one’s craftsmanship.

The Importance of Choosing the Right Drill Bit

Choosing the right drill bit is crucial for successful woodworking projects. The drill bit you select will determine the size and shape of the hole you create, as well as the overall quality of your work. Whether you are working on a simple DIY project or a large-scale woodworking project, using the correct drill bit is essential. Here are a few reasons why choosing the right drill bit is important:

Precision and Accuracy

Using the wrong drill bit can result in imprecise and inaccurate holes. This can lead to problems such as loose fittings or misaligned pieces. By selecting the correct drill bit, you can ensure that the holes you drill are the right size and shape, allowing you to achieve the desired level of precision in your woodworking projects.

Efficiency

Using the right drill bit will make your drilling process more efficient. Different drill bits have different cutting properties, such as speed and clean cutting. By choosing a drill bit that is designed for the specific material you are working with, you can save time and effort by drilling the hole quickly and cleanly.

Longevity and Durability

The right drill bit is designed to withstand the demands of drilling through wood. Using a drill bit that is not meant for woodworking can result in premature wear and damage to the bit. By selecting a high-quality drill bit that is designed for woodworking, you can ensure that your drill bit will last longer and maintain its sharpness for more extended periods.

Safety

Using the correct drill bit is also essential for safety purposes. When you use the wrong drill bit, it can cause the drill to bind or kickback, increasing the risk of accidents or injury. By selecting the right drill bit for the material you are working with, you can minimize the chances of accidents and ensure a safer woodworking experience.

Overall, choosing the right drill bit is a critical aspect of woodworking. It ensures precision, efficiency, longevity, and safety in your projects. Take the time to understand the different types and sizes of drill bits available and select the appropriate one for your woodworking needs. With the right drill bit, you can enhance the quality of your work and achieve outstanding results.

Types of Drill Bits

- Twist Drill Bits: These are the most common type of drill bits used for woodworking projects. They have a spiral cutting edge that helps to remove material as the bit spins.

- Brad Point Drill Bits: These bits are specifically designed for woodworking applications. They have a sharp point that helps to accurately position the hole, and flutes that help to remove wood chips.

- Spade Bits: Also known as paddle bits, these are flat, paddle-shaped drill bits that are used for boring large holes in wood. They have a centre point that helps to guide the bit and two cutting edges on the sides.

- Forstner Bits: Forstner bits are used for drilling clean and precise flat-bottomed holes in wood. They have a cylindrical shape with a central point and flat cutting edges.

- Hole Saw Bits: These drill bits are used for cutting large holes in wood. They consist of a circular saw blade with teeth and a pilot drill bit that helps to guide the cutting edge.

- Countersink Bits: Countersink bits are used to create a recess for a screw head to sit flush with the surface of the wood. They have a conical shape with multiple cutting edges.

- Auger Bits: Auger bits are designed for drilling deep holes in wood. They have a screw-like shape that helps to pull the bit into the wood and remove chips.

- Forstner Bits: Forstner bits are used for drilling clean and precise flat-bottomed holes in wood. They have a cylindrical shape with a central point and flat cutting edges.

- Spade Bits: Also known as paddle bits, these are flat, paddle-shaped drill bits that are used for boring large holes in wood. They have a centre point that helps to guide the bit and two cutting edges on the sides.

In addition to these common drill bits, there are also specialty bits available for specific woodworking tasks, such as plug cutters, dado cutters, and mortising bits. It’s important to choose the right drill bit for your woodworking project to ensure clean and accurate holes.

Twist Drill Bits

Twist drill bits are the most common type of drill bits used in woodworking projects. They have a spiral-shaped flute that helps to remove the wood chips from the hole as you drill. These bits are versatile and can be used in a variety of materials including wood, metal, and plastic.

Here are a few key points to consider when choosing twist drill bits:

- Size: Twist drill bits come in a range of sizes, typically measured in fractions of an inch. The size you choose will depend on the specific application and the size of the hole you need to drill.

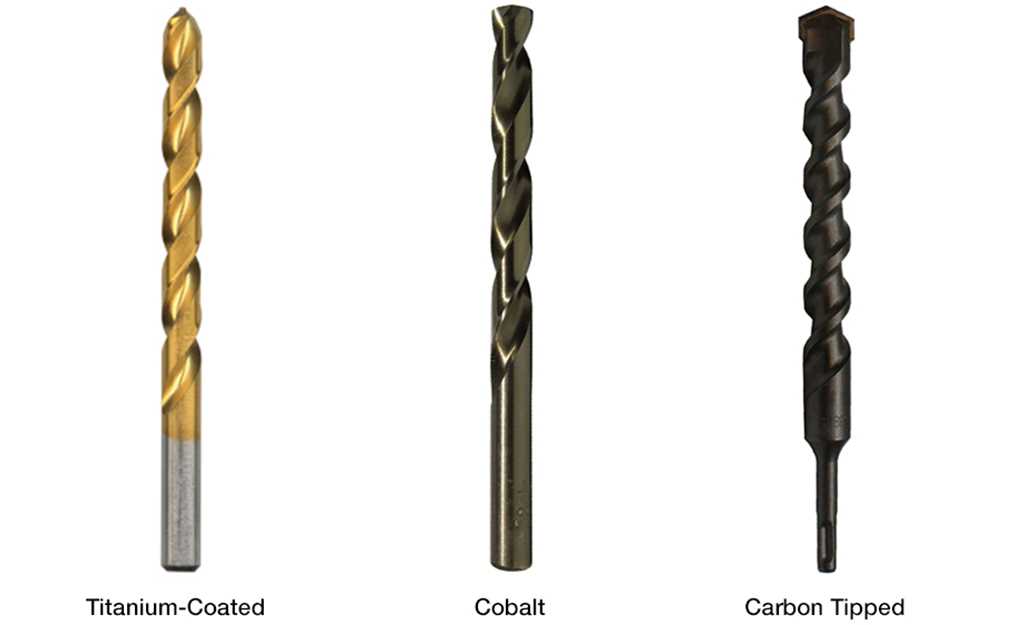

- Material: Twist drill bits are typically made from high-speed steel (HSS) or cobalt. HSS bits are suitable for most woodworking projects, while cobalt bits are more durable and can withstand higher temperatures, making them ideal for drilling into harder materials.

- Point angle: Twist drill bits have a specific point angle that determines the type of material they are designed to drill into. Standard twist bits have a point angle of 118 degrees, which is suitable for drilling into wood and plastic. For drilling into metal, you may need a bit with a point angle of 135 degrees or more.

- Coating: Some twist drill bits have a coating applied to the cutting edge to reduce friction and increase durability. Common coatings include black oxide, titanium nitride (TiN), and cobalt. These coatings can help to extend the life of the bit and provide smoother drilling.

Overall, twist drill bits are a versatile option for woodworking projects. They are readily available and come in a wide range of sizes and materials, making it easy to find the right bit for your needs.

Forstner Bits

Forstner bits are specialized drill bits that are commonly used in woodworking projects. They are designed to create flat-bottomed holes with smooth sides, making them ideal for tasks such as drilling holes for dowels or creating hinge recesses.

These bits have a cylindrical shape with a center point and cutting edges that extend radially from the center. The cutting edges are usually toothed or serrated, which helps in efficiently removing wood material while minimizing splintering.

One of the advantages of using Forstner bits is their ability to drill clean holes without any breakout or tear-out on the surface of the wood. This makes them perfect for projects that require precise and accurate holes, such as cabinetry or furniture making.

How to Use Forstner Bits

To use a Forstner bit, follow these steps:

- Securely attach the bit to your drill or drill press.

- Place the center point of the bit on the desired location on the wood.

- Turn on the drill and slowly lower the bit into the wood, applying firm but gentle pressure.

- Continue drilling until you’ve reached the desired depth.

- Remove the bit from the wood by retracting it slowly.

It’s important to note that Forstner bits are usually used with drill presses due to their large size and power requirements. However, some smaller Forstner bits can be used with handheld drills as well.

Choosing the Right Forstner Bit

When selecting a Forstner bit for your woodworking project, consider the following factors:

- Size: Forstner bits come in various sizes, so it’s important to choose one that matches your hole requirements. Measure the diameter and depth of the hole you need to drill to select the appropriate size.

- Quality: Look for Forstner bits made of high-quality materials, such as carbon steel or high-speed steel. These materials are durable and can withstand the high-speed rotations required for drilling.

- Shank Size: Check the shank size of the Forstner bit to ensure it is compatible with your drill or drill press. Most Forstner bits have a 3/8-inch or 1/2-inch shank, but this can vary.

By choosing the right Forstner bit and using it correctly, you can achieve precise and clean holes in your woodworking projects, adding a professional touch to your finished pieces.

Spade Bits

Spade bits, also known as paddle bits, are a type of drill bit that is primarily used for drilling large holes in wood. They have a flat, paddle-shaped blade that helps to quickly remove material as the bit spins.

Spade bits are typically used for drilling holes for larger screws or dowels, as well as for rough-cutting holes for plumbing and electrical work. They are available in a variety of sizes, ranging from 1/4 inch to 1 1/2 inches or larger.

One of the advantages of spade bits is their speed. Due to their design, they are able to remove material quickly and efficiently, making them a popular choice for many woodworking projects. However, their speed can also make them difficult to control, so it’s important to use them with caution and to secure the workpiece properly.

When using a spade bit, it’s important to keep the bit sharp and clean. Dull or dirty bits can cause the wood to splinter or tear, resulting in a less-than-perfect hole. It’s also important to use a drill with enough power to handle the size of the bit, as using too small of a drill can cause the bit to bind or break.

Overall, spade bits are a versatile and useful tool for woodworking projects. Whether you’re drilling large holes for screws or dowels, or rough-cutting holes for plumbing or electrical work, a spade bit can help you get the job done quickly and effectively.

Brad Point Bits

A brad point bit is a type of drill bit specifically designed for woodworking projects. It features a sharp, pointed tip that helps to accurately locate the center of the hole and prevent the bit from wandering or slipping off the mark. Brad point bits are commonly used for drilling holes in wood, as they create clean and precise holes with minimal tear-out.

Advantages of Brad Point Bits

- Precision: The sharp point of a brad point bit allows for precise placement and drilling. This makes it ideal for tasks such as creating dowel joints or drilling holes for screws.

- Non-slip: The pointed tip of a brad point bit helps to keep the bit in place and prevents it from slipping or wandering while drilling. This ensures accurate results and reduces the risk of damage to the workpiece.

- Clean holes: Brad point bits have fluted cutting edges that help to remove wood chips and prevent clogging. This results in clean and smooth holes with minimal tear-out, making it easier to achieve a professional finish.

Common Uses for Brad Point Bits

Brad point bits are commonly used in a variety of woodworking applications, including:

- Drilling accurate, clean holes for dowels and wooden pegs.

- Creating holes for screws and hardware installations.

- Boring holes for hinge screws and other woodworking fasteners.

- Drilling holes for mortises and tenons.

Tips for Using Brad Point Bits

Here are some tips to keep in mind when using brad point bits:

- Use a center punch to mark the center of the hole before drilling, as this will help guide the brad point bit.

- Apply steady pressure and a slow drilling speed to ensure accurate and clean holes.

- Keep the drill bit clean and free from debris to prevent clogging and maintain optimal cutting performance.

- Consider using a depth stop or adjustable collar on the drill bit to achieve consistent hole depths.

Conclusion

Brad point bits are an essential tool for any woodworker, providing precision, non-slip drilling, and clean hole results. Whether you’re working on a small woodworking project or a larger construction project, brad point bits are a reliable choice for achieving accurate and professional results.

Auger Bits

Auger bits are specially designed drill bits with a spiral shape. They are commonly used for drilling deep holes in wood. The spiral shape of the bit helps to remove wood chips and debris from the hole, making it easier to drill through the material.

Auger bits come in various sizes, typically ranging from 1/4 inch to 1 1/2 inch in diameter. The larger the diameter of the bit, the larger the hole it can drill. This makes auger bits suitable for a wide range of woodworking projects, from small craft projects to larger construction tasks.

Auger bits are also available in different lengths, allowing for drilling holes of varying depths. The length of the bit should be chosen based on the specific requirements of the project. It’s important to select a bit that is long enough to drill the desired depth without causing damage to the workpiece or the drill.

One of the key benefits of using auger bits is their ability to create clean, accurate holes. The spiral shape of the bit allows for easy and efficient chip removal, preventing clogging and ensuring a smooth drilling process. This results in clean, precise holes with minimal tear-out or splintering.

Auger bits can be used with both hand drills and power drills, making them suitable for a range of woodworking applications. However, it’s important to choose the right type of auger bit for the specific drilling task at hand. For example, some auger bits are designed for drilling through softwoods, while others are better suited for hardwoods.

When using auger bits, it’s important to take safety precautions. Always wear appropriate protective gear, such as safety glasses and gloves, to protect yourself from flying debris. Additionally, make sure to secure the workpiece properly before drilling to prevent any accidents or injuries.

Pros:

- Efficient chip removal

- Create clean, accurate holes

- Suitable for a range of woodworking applications

- Available in different sizes and lengths

- Can be used with hand drills and power drills

Cons:

- May be more expensive than standard drill bits

- Requires proper technique and safety precautions

Overall, auger bits are a versatile and reliable option for drilling deep, clean holes in wood. With the right bit and proper technique, they can help you achieve professional results in your woodworking projects.

Countersink Bits

A countersink bit is a type of drill bit that is used to create a conical hole at the surface of a material. This conical hole allows the head of a screw to sit flush with the surface, providing a clean and professional finish to woodworking projects.

Countersink bits are commonly used in woodworking projects where screws or bolts need to be driven into the material without protruding from the surface. They are also useful when creating countersunk holes for decorative purposes.

These bits are available in different sizes and styles to accommodate various screw sizes and head types. They are typically made from high-speed steel or carbide to ensure durability and longevity.

Countersink bits are designed with a drill bit at the center and a tapered cutting edge that creates the conical hole. Some countersink bits have an adjustable depth stop, allowing users to control the depth of the countersink hole.

When using a countersink bit, it is important to select the appropriate size for the screw you are using. The countersink should match the size and shape of the screw head to ensure a proper fit.

Countersink bits can be used with a hand drill or a drill press. To use a countersink bit, simply secure the material you are working with and position the bit at the desired location. Apply steady pressure while drilling to create the countersink hole.

After drilling the countersink hole, you can proceed to drive the screw or bolt into the material. The head of the screw will sit flush with the surface, creating a clean and professional finish.

Overall, countersink bits are essential tools for woodworking projects that involve driving screws or bolts into materials. They help create a professional and finished appearance by recessing the screw heads, improving the overall aesthetics of the project.

Step Drill Bits

A step drill bit, also known as a step bit or a cone drill bit, is a specialized drill bit that features multiple step-like cutting edges. This type of bit allows you to drill holes with different diameters using a single bit.

Features:

- Step drill bits have a conical shape with a graduated series of steps or levels.

- Each step on the bit is a different diameter, allowing you to drill holes of varying sizes without needing to change bits.

- They often have a unique spiral flute design that helps to clear away debris while drilling.

- Step drill bits are commonly made from high-speed steel (HSS) or cobalt, which provides durability and heat resistance.

Advantages:

- Step drill bits are versatile and can be used for various applications, including drilling holes in wood, plastic, metal, and other materials.

- They eliminate the need for multiple drill bits, saving you time and effort.

- As the step increases, the cutting edges gradually increase in size, resulting in smooth and clean holes.

Disadvantages:

- Step drill bits may not be suitable for drilling deep holes as they have a limited overall length.

- They may require additional force to penetrate certain materials, especially metal.

- Step drill bits are generally not recommended for use with high-speed drilling machines as the increased heat and friction can damage the bit.

Common Uses:

Step drill bits are commonly used in woodworking and metalworking projects. Some common applications include:

- Drilling holes for installing door handles and knobs.

- Creating holes for countersinking screws.

- Enlarging existing holes.

- Creating holes for conduit or cable entry.

- Drilling holes for installing pipes or tubes.

Tip:

When using a step drill bit, it’s important to start with a smaller hole size and gradually increase the diameter using each step. This helps to prevent the bit from binding and allows for cleaner cuts.

FAQ:

What is the importance of choosing the right drill bit for woodworking projects?

Choosing the right drill bit for woodworking projects is important because it determines the type of hole the drill will make, the precision of the hole, and the overall quality of the finished project. Different drill bits are designed for different purposes and materials, so selecting the right one ensures efficiency and accuracy in drilling holes for woodworking projects.

How do I know which drill bit is suitable for drilling holes in wood?

When choosing a drill bit for drilling holes in wood, you should consider the type of wood you are working with, the size of the hole you need, and the type of drilling operation you are planning to perform. For general woodworking tasks, a twist drill bit or a brad point drill bit is usually suitable. However, for larger holes or specialized woodworking projects, you may need to choose a spade bit, an auger bit, or a forstner bit.

What are the different types of drill bits available for woodworking projects?

There are several types of drill bits available for woodworking projects, including twist drill bits, brad point drill bits, spade bits, auger bits, and forstner bits. Twist drill bits are versatile and suitable for general woodworking tasks. Brad point drill bits have a sharp point for accurate hole placement. Spade bits are designed for drilling large holes, while auger bits are ideal for deep holes. Forstner bits, on the other hand, are designed for precision drilling and creating clean, flat-bottomed holes.

Can I use a metal drill bit for woodworking projects?

While it is possible to use a metal drill bit for woodworking projects, it is not recommended. Metal drill bits are designed for drilling through metal, and using them on wood may result in a rough and imprecise hole. Moreover, the cutting angle and shape of metal drill bits may cause tear-out or splintering of the wood. It is best to use drill bits specifically designed for woodworking to achieve clean and accurate holes.

What size of drill bit should I use for drilling holes in wood?

The size of the drill bit you should use for drilling holes in wood depends on the specific project and the size of the hole you need. For most general woodworking tasks, a set of twist drill bits ranging in diameter from 1/16 inch to 1/2 inch should be sufficient. However, larger holes may require the use of spade bits, auger bits, or forstner bits in sizes ranging from 1/2 inch to several inches.

How can I ensure the longevity of my drill bits when working on woodworking projects?

To ensure the longevity of your drill bits when working on woodworking projects, you should follow a few simple tips. First, use the appropriate drill bit for the type of wood and the specific drilling operation. Second, avoid excessive heat buildup by using a cutting lubricant or periodically withdrawing the drill bit from the hole to allow it to cool. Third, keep your drill bits clean and sharp by regularly cleaning and sharpening them. Finally, store your drill bits in a clean and dry place to prevent rust and damage.

Are there any safety precautions I should take when using drill bits for woodworking?

Yes, there are some safety precautions you should take when using drill bits for woodworking. Always wear safety goggles to protect your eyes from flying wood chips and debris. Additionally, use clamps or a vise to secure your workpiece firmly in place before drilling to prevent it from spinning or moving. It is also important to keep your hands and fingers away from the drill bit and avoid wearing loose clothing or jewelry that could become entangled in the drill.

Video: