Drilling Carbon Fiber: Tips and Techniques for Success

Carbon fiber is a high-performance material that is widely used in various industries, including aerospace, automotive, and sports. It is known for its exceptional strength-to-weight ratio, making it a popular choice for applications where strength and weight are critical factors. However, drilling carbon fiber can be a challenging task, as the material is prone to delamination and damage when not handled properly.

To successfully drill carbon fiber, it is important to follow certain tips and techniques. One of the key considerations is to use the right type of drill bit. Carbon fiber is a brittle material, and using a standard twist drill bit can cause splintering and delamination. It is recommended to use a carbide or diamond-coated drill bit specifically designed for carbon fiber. These drill bits have sharp edges and are more effective in cutting through the material without causing damage.

Another important factor to consider when drilling carbon fiber is the drilling speed. It is recommended to use a low drilling speed to reduce the risk of heat buildup, which can damage the material. A slower speed also allows for better control and precision. Additionally, using a coolant or lubricant is recommended to further minimize heat and prevent the carbon fiber from becoming brittle.

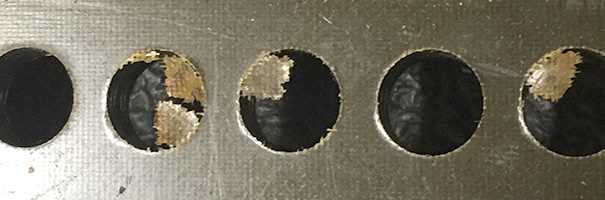

Proper technique is also crucial when drilling carbon fiber. It is important to apply steady pressure and avoid pushing too hard, as this can cause the material to crack or delaminate. Using a backer board or sacrificial material underneath the carbon fiber can provide support and prevent excessive breakout or chipping. It is also advisable to pilot drill a small hole before drilling the final size to ensure accuracy and prevent any unwanted damage.

In conclusion, drilling carbon fiber requires careful consideration and attention to detail to prevent damage to the material. Using the right type of drill bit, drilling at a low speed, and applying proper technique are all essential for success. By following these tips and techniques, you can drill carbon fiber effectively and achieve the desired results without compromising its strength or integrity.

Tips and Techniques for Successful Drilling of Carbon Fiber

1. Choose the Right Drill Bit

When drilling carbon fiber, it’s important to use a drill bit specifically designed for this material. A carbide or diamond-coated drill bit is recommended, as they provide excellent cutting performance and durability.

2. Use Low Speed and High Pressure

When drilling carbon fiber, it’s important to use a low drilling speed to avoid overheating and damaging the material. Apply high pressure to ensure a smooth and clean cut. This will prevent the carbon fiber from delaminating or splintering.

3. Secure the Carbon Fiber

Before drilling, secure the carbon fiber firmly in place to prevent any movement or vibrations. You can use clamps or double-sided tape to hold the carbon fiber securely on a stable surface.

4. Mark the Drilling Points

Use a marker or masking tape to mark the drilling points on the carbon fiber. This will help you accurately position the drill bit and ensure precise holes.

5. Start with a Pilot Hole

When drilling carbon fiber, it’s recommended to start with a pilot hole. This will create a guide for the drill bit and prevent it from wandering or slipping. Use a smaller drill bit to create the pilot hole, and then gradually increase the size to reach the desired diameter.

6. Use a Backing Material

Using a backing material like a scrap piece of wood or plastic can help prevent the carbon fiber from splintering or delaminating. Place the backing material below the carbon fiber to provide support during drilling.

7. Lubricate the Drill Bit

Applying a small amount of cutting fluid or lubricant to the drill bit can help reduce friction and heat buildup. This will extend the lifespan of the drill bit and improve drilling performance.

8. Take Breaks

When drilling carbon fiber, it’s important to take regular breaks to prevent overheating. This will allow the material and drill bit to cool down and prevent any damage or warping.

9. Clean the Drill Bit After Use

After drilling carbon fiber, make sure to clean the drill bit thoroughly to remove any carbon fiber dust or residue. This will help maintain the sharpness and effectiveness of the drill bit for future use.

10. Practice on Scrap Pieces

If you’re new to drilling carbon fiber, it’s recommended to practice on scrap pieces before working on your actual project. This will help you gain confidence and refine your drilling technique.

By following these tips and techniques, you can achieve successful drilling results on carbon fiber projects while maintaining the integrity and quality of the material.

Choosing the Right Drill Bit

When drilling carbon fiber, it is important to choose the right drill bit for the job. Using the wrong drill bit can result in damage to the material or a poor quality hole. Here are some tips for choosing the right drill bit:

1. Carbide Tipped Drill Bit

A carbide tipped drill bit is a popular choice for drilling carbon fiber. This type of drill bit is made with a carbide tip that is much harder than carbon fiber. It can easily cut through the material without causing damage. Carbide tipped drill bits are available in various sizes and can be used for drilling both small and large holes.

2. Diamond-coated Drill Bit

If you need to drill very small holes in carbon fiber, a diamond-coated drill bit can be the best option. These drill bits are coated with tiny diamond particles that make them extremely sharp and durable. They are perfect for drilling precise and clean holes in carbon fiber.

3. High Speed Steel Drill Bit

If you don’t have access to carbide tipped or diamond-coated drill bits, a high speed steel drill bit can also be used. However, it is important to take extra care when using this type of drill bit. High speed steel drill bits can overheat when drilling carbon fiber and cause damage to the material. To prevent overheating, use low rotational speed and apply cutting fluid to lubricate the drill bit.

4. Drill Bit Size

The size of the drill bit you choose will depend on the size of the hole you need to drill. Always use a drill bit that is slightly larger than the diameter of the hole you want to drill. This will help prevent cracking and delamination of the carbon fiber.

5. Test and Practice

Before drilling into your carbon fiber workpiece, it is recommended to test and practice on a scrap piece of carbon fiber. This will help you determine the best drill bit and drilling technique for your specific application.

Remember to always wear appropriate safety gear, such as safety goggles and gloves, when drilling carbon fiber. Follow these tips and choose the right drill bit to ensure success when drilling carbon fiber.

Understanding Carbon Fiber Structure

Carbon fiber is a composite material that is widely used in various industries due to its exceptional strength and lightweight properties. To understand how to drill carbon fiber properly, it is essential to have a basic understanding of its structure.

Fiber Orientation

Carbon fiber consists of thin strands of carbon atoms bonded together in a hexagonal pattern. These strands, called fibers, are incredibly strong and rigid. The fibers are typically woven or layered in a particular orientation to create a composite material with specific characteristics.

Resin Matrix

The fibers alone are not enough to form a useful material. To give carbon fiber its desired properties, such as increased strength and rigidity, it is combined with a resin matrix. The resin matrix acts as a binder, holding the fibers together and providing additional structural integrity.

Laminate Structure

A carbon fiber laminate consists of multiple layers of carbon fiber sheets stacked together. Each layer is oriented in a specific direction to maximize the material’s strength in different directions. This arrangement creates a balanced and reinforced structure that can withstand various types of loads.

Fiber Volume Fraction

The fiber volume fraction refers to the amount of carbon fibers compared to the total volume of the composite material. It influences the overall strength and rigidity of the carbon fiber. Higher fiber volume fractions typically result in stronger and stiffer materials.

Interlaminar Shear Strength

Interlaminar shear strength is the ability of the layers within a carbon fiber laminate to resist sliding past each other. It is an essential property to consider when drilling carbon fiber to ensure that the laminate does not delaminate or weaken at the drill hole.

Fabrication Techniques

Various fabrication techniques can be used to create carbon fiber structures, including hand lay-up, resin infusion, and autoclave curing. Each technique has its advantages and disadvantages, and the choice depends on the specific application and desired properties.

Conclusion

Having a basic understanding of carbon fiber structure is crucial for successfully drilling carbon fiber. By knowing how the fibers are oriented, the role of the resin matrix, and the overall laminate structure, one can select the appropriate drilling techniques and avoid causing damage to the material.

Preparing the Surface for Drilling

Before drilling into carbon fiber, it is important to properly prepare the surface in order to achieve the best results. Preparing the surface will help to prevent damage to the carbon fiber and ensure a clean and accurate hole.

Here are some tips and techniques for preparing the surface:

1. Marking the Hole

Start by marking the exact location where you want to drill the hole. Use a pencil or a marker that is safe for use on carbon fiber. Make sure to accurately mark the center of the hole to ensure precision when drilling.

2. Clean the Surface

Next, thoroughly clean the area around the marked hole. Remove any dirt, dust, or other debris that may be present on the surface. Use a clean cloth or alcohol wipes to ensure a clean and smooth surface for drilling.

3. Masking Tape

Applying masking tape around the marked hole can help to protect the surrounding carbon fiber from accidental scratches or damage during the drilling process. The tape also helps to prevent the carbon fibers from fraying when the hole is being drilled.

4. Pilot Hole

When drilling into carbon fiber, it is recommended to start with a pilot hole. A pilot hole is a small hole that acts as a guide for the larger drill bit. Use a drill bit with a smaller diameter than the final desired hole size to create the pilot hole.

5. Drill Bits

Choosing the right drill bit is important when drilling into carbon fiber. It is recommended to use a carbide drill bit or a specialized drill bit that is designed for drilling carbon fiber. These drill bits are harder and more durable, allowing them to cut through the carbon fiber more effectively.

6. Drilling Technique

When drilling into carbon fiber, it is important to use a slow, steady speed and apply light pressure. Excessive speed or force can cause heat buildup and damage the carbon fiber. It is also important to periodically stop and remove any debris from the hole to prevent clogging and maintain accuracy.

By following these tips and techniques, you can properly prepare the surface for drilling into carbon fiber and achieve clean and accurate holes.

Using the Right Technique

When it comes to drilling carbon fiber, using the right technique is crucial for success. Carbon fiber is a strong and lightweight material, but it can be delicate and prone to cracking if not handled properly. Here are some tips and techniques that can help you achieve the best results when drilling carbon fiber:

1. Start with a pilot hole

Before drilling into the carbon fiber, it’s recommended to start with a pilot hole. This can help reduce the chances of cracking or delamination. Start with a small drill bit and gradually increase the size until the desired hole diameter is achieved.

2. Use a slow speed

When drilling carbon fiber, it’s important to use a slow speed. High speeds can generate heat, which can lead to damage or melting of the material. Set your drill to a slow speed and apply consistent pressure to avoid overheating.

3. Use a sharp drill bit

A sharp drill bit is essential for drilling carbon fiber. Dull drill bits can cause splintering, fraying, or chipping of the material. Make sure to use a high-quality, sharp drill bit specifically designed for drilling carbon fiber.

4. Use a backing material

When drilling carbon fiber, it’s recommended to use a backing material to prevent splintering or chipping on the opposite side of the hole. A piece of scrap wood or plastic can be used as a backing material to provide support during drilling.

5. Apply steady and even pressure

When drilling carbon fiber, it’s important to apply steady and even pressure. Avoid pushing too hard, as this can cause the material to crack or delaminate. Apply consistent pressure and let the drill bit do the work.

6. Use coolant or lubricant

Using a coolant or lubricant can help reduce heat and friction during drilling. This can prevent damage to the carbon fiber and improve the drilling process. Apply a small amount of coolant or lubricant to the drill bit before starting the drilling process.

7. Clean the drilling area

After drilling, make sure to clean the drilling area to remove any dust or debris. This can help prevent contamination or damage to the newly drilled hole. Use a soft cloth or brush to gently clean the area.

By following these tips and techniques, you can ensure success when drilling carbon fiber. Remember to always prioritize safety and take your time to achieve the best results.

Maintaining Proper Speed and Pressure

1. Start with a pilot hole

When drilling carbon fiber, it is important to start with a small pilot hole before using a larger drill bit. This will help prevent cracking or splintering of the material. Use a drill bit that is slightly smaller than the final hole size.

2. Use a slow drilling speed

Carbon fiber is a delicate material that can easily be damaged if the drilling speed is too high. To avoid this, use a slow drilling speed to minimize the risk of overheating and melting the material. Start with a low speed and gradually increase it if necessary.

3. Apply constant, gentle pressure

Applying too much pressure while drilling can also damage the carbon fiber. It is important to apply a constant, gentle pressure to avoid cracking or splintering. Let the drill bit do the work and allow it to slowly cut through the material without forcing it.

4. Use a cutting fluid

Using a cutting fluid can help reduce friction and heat buildup while drilling carbon fiber. Apply a small amount of cutting fluid to the drill bit to lubricate the cutting edge and prolong its lifespan. This will also help prevent the carbon fiber from delaminating or splintering.

5. Take breaks and allow the bit to cool

Drilling carbon fiber can generate heat, especially if the speed is too high. To prevent overheating, take occasional breaks and allow the drill bit to cool down. This will help maintain a steady drilling speed and prevent damage to the material.

6. Clean the drilled hole

After drilling, it is important to clean the drilled hole to remove any debris or dust. Use a brush or compressed air to clean out the hole thoroughly. This will ensure a clean and smooth surface for any further operations.

Cooling and Lubrication

When drilling carbon fiber, it is important to use cooling and lubrication techniques to prevent damage to the material and maintain the integrity of the hole being drilled. Here are some tips for cooling and lubrication:

Cooling:

- Carbon fiber is a heat-sensitive material, so it is essential to keep the temperature of the drilling process as low as possible. High temperatures can cause the resin matrix of the carbon fiber to break down, resulting in delamination and weakening of the structure.

- One method of cooling is to use a coolant or water-based solution specifically designed for drilling carbon fiber. This coolant helps to dissipate heat and reduce friction, resulting in lower drilling temperatures.

- Another cooling technique is to use low RPMs during the drilling process. Slower drilling speeds generate less heat, reducing the risk of damage to the carbon fiber.

Lubrication:

- Lubrication helps to reduce friction between the drill bit and the carbon fiber, preventing the material from tearing or delaminating.

- Avoid using traditional oil-based lubricants, as they can contaminate the carbon fiber and interfere with adhesion of any subsequent bonding or finishing processes. Instead, opt for lubricants specifically designed for use with carbon fiber.

- Apply a small amount of lubricant to the drill bit and the surface of the carbon fiber before drilling. This will help to ensure smoother drilling and prevent the drill bit from becoming stuck.

Remember, proper cooling and lubrication techniques are essential when drilling carbon fiber to minimize the risk of damage to the material and ensure a successful drilling process. Always follow the manufacturer’s recommendations for cooling and lubrication products and techniques.

Handling Fragile Carbon Fiber

Carbon fiber is a lightweight and strong material that is commonly used in various industries, including aerospace, automotive, and sports equipment. However, it is also a fragile material that requires careful handling to avoid damage. Here are some tips for handling fragile carbon fiber:

1. Wear gloves

When handling carbon fiber, it is important to wear gloves to protect the material from oils and dirt on your hands. This will help maintain the integrity of the carbon fiber and prevent any contaminants from affecting its strength.

2. Use a soft cloth or towel

When picking up or moving carbon fiber parts, use a soft cloth or towel to provide a cushion and avoid any direct contact with hard surfaces. This will reduce the risk of scratching, cracking, or chipping the carbon fiber.

3. Avoid excessive bending or twisting

Carbon fiber is a brittle material that can break under excessive bending or twisting. When handling carbon fiber parts, be gentle and avoid putting too much stress on the material. This includes avoiding sharp bends or twists that could potentially lead to damage.

4. Store carbon fiber parts properly

When not in use, carbon fiber parts should be stored properly to prevent any accidental damage. It is recommended to store them in a clean, dry, and padded container or bag to protect them from dust, moisture, and impact.

5. Clean with caution

If you need to clean carbon fiber parts, use a gentle cleaner specifically designed for carbon fiber. Avoid using harsh chemicals or abrasive materials that could scratch or damage the surface. Always follow the manufacturer’s instructions for cleaning and maintenance.

6. Handle with care during installation

During the installation process, be cautious and handle carbon fiber parts with care. Make sure to use the appropriate tools and techniques to avoid over-tightening or causing stress on the material. It is also important to follow the recommended torque specifications provided by the manufacturer.

By following these tips, you can handle fragile carbon fiber with care and ensure its longevity and performance.

Safety Precautions and Protective Equipment

Introduction

Drilling carbon fiber can be a hazardous task due to the nature of the material. Taking proper safety precautions and using appropriate protective equipment is essential to minimize the risk of accidents and injuries. This section will outline the necessary steps to ensure a safe working environment while drilling carbon fiber.

Protective Equipment

- Safety goggles: Wear safety goggles to protect your eyes from debris and fragments that may be produced during drilling. Carbon fiber dust poses a risk to your eyes and can cause irritation or injury.

- Dust mask: Carbon fiber dust can be harmful if inhaled. Wear a dust mask or respirator approved for use with carbon fiber to minimize the risk of respiratory issues.

- Gloves: Wearing gloves not only protects your hands from cuts and abrasions but also helps reduce the transfer of oils and contaminants onto the carbon fiber surface.

- Protective clothing: Consider wearing long-sleeved shirts and pants made of non-flammable materials to protect your skin from any potential injury or contact with carbon fiber dust.

Safety Precautions

- Work in a well-ventilated area: Drilling carbon fiber can release harmful fumes and dust particles. Ensure that you are working in a properly ventilated area to prevent the accumulation of these hazardous materials.

- Secure the workpiece: Use clamps or a vise to secure the carbon fiber workpiece before drilling. This will prevent movement and minimize the risk of accidents caused by slipping or shifting.

- Start with a pilot hole: To reduce the chances of the drill bit slipping, start by drilling a small pilot hole before moving on to a larger one. This will provide better control and accuracy during the drilling process.

- Use low speeds: When drilling carbon fiber, use low speeds to prevent the material from overheating or delaminating. High speeds can generate excess heat, which can damage the structural integrity of the carbon fiber.

- Monitor drilling depth: Keep track of the drilling depth to avoid drilling too far and damaging any underlying structures or components. Use depth stops or marks on the drill bit to maintain control over the drilling process.

- Clean up properly: After drilling, clean up any debris or carbon fiber dust using appropriate methods. Avoid using compressed air, as it can spread the dust particles in the air. Instead, use a vacuum with a HEPA filter or a damp cloth to remove any loose particles.

Conclusion

When drilling carbon fiber, safety should always be the top priority. By following these safety precautions and using the recommended protective equipment, you can create a safer working environment and minimize the risks associated with drilling carbon fiber.

FAQ:

What is carbon fiber made of?

Carbon fiber is made of thin strands of carbon atoms that are tightly woven together to create a strong and lightweight material.

What are the benefits of using carbon fiber?

Using carbon fiber offers several benefits, including high strength-to-weight ratio, excellent stiffness, corrosion resistance, and impact resistance.

Can carbon fiber be drilled?

Yes, carbon fiber can be drilled, but it requires special techniques and tools to prevent damage to the material.

What are some tips for drilling carbon fiber?

Some tips for drilling carbon fiber include using a sharp drill bit, drilling at a slow speed, applying light pressure, and using a backing material to prevent tear-out.

What types of drill bits are suitable for drilling carbon fiber?

Drill bits made of carbide or diamond are suitable for drilling carbon fiber. It is important to use a sharp drill bit to prevent delamination.

Video: