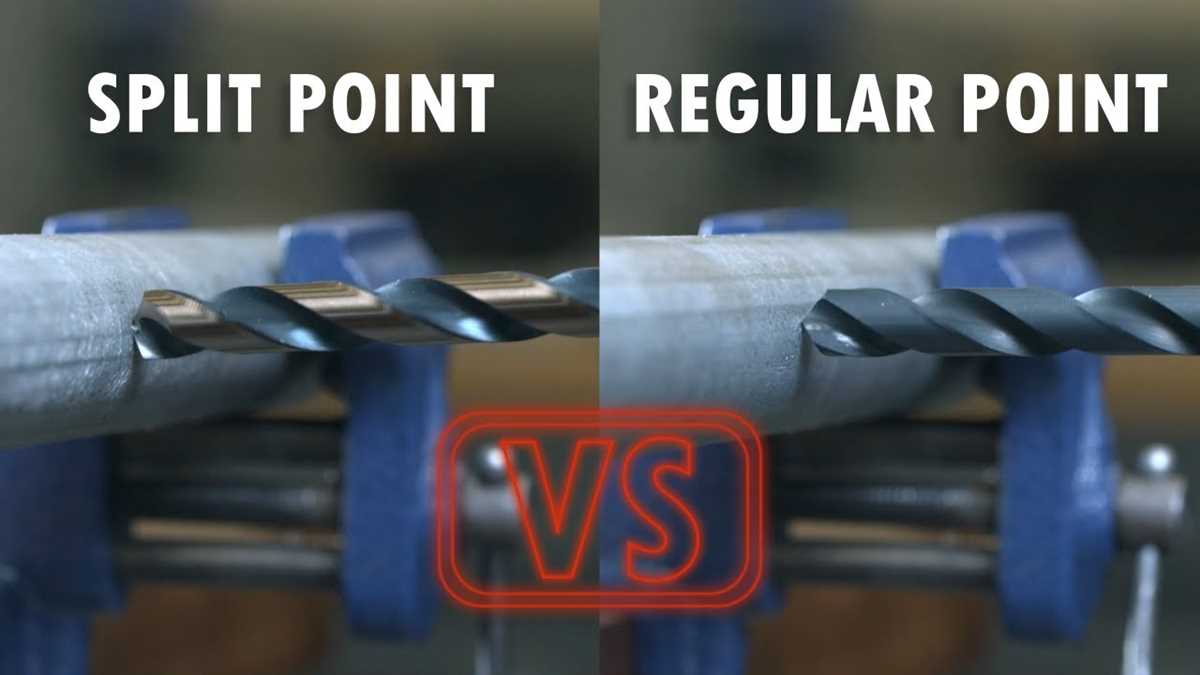

Understanding the Benefits of Split Point Drill Bits

In the world of drilling, efficiency and precision are key. This is where split point drill bits come into play. Split point drill bits are a type of drill bit designed with a pointed tip that is split into two separate cutting edges. This unique design offers a number of benefits over traditional drill bits, making them a popular choice among professionals and DIY enthusiasts alike.

One of the main benefits of split point drill bits is their ability to reduce drilling time. The split point design allows for more efficient cutting, as the two cutting edges work together to penetrate the material. This means that less force and pressure are required to drill through tough materials like metal, resulting in quicker and easier drilling.

Additionally, split point drill bits offer improved accuracy. The pointed tip of the drill bit allows for precise positioning, reducing the likelihood of the drill bit wandering or slipping off-center. This is especially important when drilling delicate or sensitive materials, where precision is crucial.

Another advantage of split point drill bits is their versatility. These drill bits can be used on a wide range of materials, including wood, plastic, and metal. Their ability to provide clean and accurate drilling makes them a go-to choice for many applications, from woodworking to automotive repairs.

In conclusion, split point drill bits offer a range of benefits that set them apart from traditional drill bits. Their ability to increase drilling efficiency, provide precise accuracy, and versatility make them a valuable tool in any drilling project. Whether you’re a professional or a DIY enthusiast, investing in split point drill bits is a decision that will pay off in improved drilling performance and results.

What Are Split Point Drill Bits?

Split point drill bits are a type of drill bit that are designed with a pointed tip that has been split into two separate cutting edges. This design allows the drill bit to start drilling on contact with the surface, reducing the need for a pilot hole or for applying excessive pressure. Split point drill bits are commonly used for drilling through metal, wood, plastic, and other materials.

The split point design of these drill bits offers several benefits compared to traditional drill bits. One of the main advantages is increased accuracy and precision. The split point allows for cleaner and more precise drilling, as it helps to prevent the bit from wandering or slipping off the desired drilling point.

Another benefit of split point drill bits is faster drilling speed. The split point design reduces friction and heat generation, allowing the drill bit to cut through the material more efficiently and quickly. This can save time and effort, especially when drilling multiple holes or working on larger projects.

Split point drill bits are also known for their self-centering capabilities. The split point acts as a self-centering mechanism, ensuring that the drill bit stays in the desired drilling position and does not wobble or deviate from the intended path. This makes them ideal for drilling holes with a high degree of precision.

Additionally, split point drill bits are typically more durable and long-lasting compared to other types of drill bits. The split point design reduces the amount of wear and tear on the bit, as it distributes the cutting load evenly across the two cutting edges. This helps to extend the lifespan of the drill bit, making it a cost-effective choice for both professional and DIY users.

In conclusion, split point drill bits offer several advantages over traditional drill bits. Their design provides increased accuracy, faster drilling speed, self-centering capabilities, and enhanced durability. Whether you are a professional or a DIY enthusiast, these drill bits can be a valuable tool in your toolbox.

The Mechanics Behind Split Point Drill Bits

Split point drill bits are specially designed tools that have a pointed tip with two distinct cutting edges. These drill bits are commonly used in various applications, including woodworking, metalworking, and construction. The unique design of split point drill bits offers several benefits over traditional drill bits, making them a popular choice among professionals and DIY enthusiasts.

- Pointed Tip: One of the key features of split point drill bits is their pointed tip. Unlike traditional drill bits with a flat tip, the pointed tip of split point drill bits enables them to penetrate materials with ease. The sharpness of the tip ensures a precise and accurate start, creating clean holes without any wandering or slipping.

- Two Cutting Edges: Another important characteristic of split point drill bits is their two cutting edges. These cutting edges are located on opposite sides of the drill bit, creating a V-shaped fluted point. The two cutting edges allow for a more aggressive cutting action, reducing the amount of force required during drilling. This design also helps to prevent the drill bit from getting stuck or jammed in the material.

- Reduced Friction: The split point design of these drill bits also helps to reduce friction during drilling. The pointed tip and the two cutting edges work together to create a self-centering effect. As a result, the drill bit stays on track and does not wander or deviate from its targeted position. This self-centering action minimizes the friction between the drill bit and the material, resulting in faster and more efficient drilling.

- Clean Holes: Split point drill bits are known for creating clean and precise holes. The combination of the pointed tip, two cutting edges, and reduced friction allows these drill bits to cut through materials smoothly and cleanly. This is particularly important in applications where a high level of accuracy is required, such as drilling holes for screws or dowels.

Overall, the mechanics behind split point drill bits make them an excellent choice for a wide range of drilling tasks. The pointed tip, two cutting edges, and reduced friction all contribute to faster, more efficient, and more accurate drilling. Whether you’re a professional or a DIY enthusiast, using split point drill bits can greatly enhance your drilling experience and help you achieve the best possible results.

Increased Precision and Accuracy

One of the primary benefits of using split point drill bits is the increased precision and accuracy that they offer. The unique design of these drill bits allows for more precise drilling, reducing the chances of the bit wandering or slipping off track.

The split point design features a pointed tip that is split into two separate cutting edges. This allows for the bit to start drilling immediately with minimal force, reducing the amount of pressure required to begin drilling. As a result, the bit is less likely to wander or deviate from the desired drilling location.

Additionally, the split point design helps to reduce the amount of heat generated during drilling. This is due to the reduced friction between the bit and the material being drilled. The reduced heat helps to prevent the bit from dulling quickly, allowing for more precise and accurate drilling over a longer period of time.

Furthermore, split point drill bits are commonly used in applications that require high levels of precision, such as metalworking and woodworking industries. The precise drilling capabilities of these bits make them ideal for creating clean and accurate holes in various materials.

Overall, the increased precision and accuracy offered by split point drill bits make them a valuable tool in any drilling application where precision is essential. Whether you are working on a DIY project or tackling a professional job, using split point drill bits can greatly enhance your drilling experience.

Faster and Easier Drilling

One of the main benefits of using split point drill bits is that they allow for faster and easier drilling compared to traditional drill bits. These specialized drill bits feature a unique design that sets them apart from conventional options.

The split point design of these drill bits enables them to start drilling immediately without any slipping or walking. The sharp point of the bit makes a small hole in the material, allowing the flutes to guide the bit into the material with precision. This eliminates the need for center punching or pre-drilling, saving time and effort.

The split point also reduces the amount of pressure required to start drilling. With conventional drill bits, users often need to apply significant force to prevent them from slipping and creating inaccuracies. However, with split point drill bits, the point bites into the material without any resistance, ensuring a more efficient drilling experience.

Furthermore, these drill bits have specially designed flutes that help to remove chips and waste material from the hole as drilling takes place. This helps to prevent clogging and overheating, ensuring a smoother and quicker drilling operation. The flutes also contribute to the stability of the drill bit, reducing the chances of it wandering or deviating from the intended drilling path.

Overall, the faster and easier drilling experience provided by split point drill bits can greatly improve productivity and efficiency in various applications. Whether you are a DIY enthusiast or a professional contractor, using these drill bits can save valuable time and effort while achieving precise and clean drilling results.

Reduced Heat and Wear

When it comes to drilling, excessive heat and wear can be common issues. However, split point drill bits are specifically designed to reduce both heat and wear.

One of the main reasons split point drill bits are able to reduce heat is because of their unique design. Unlike traditional drill bits that have a single point, split point drill bits have two flutes that come together to form a point. This split point design helps to dissipate heat more effectively, resulting in cooler operation and reduced heat buildup.

By reducing heat, split point drill bits also minimize the wear and tear on the drill bit itself. Excessive heat can cause the cutting edges of a drill bit to become dull more quickly, resulting in reduced drilling efficiency. With split point drill bits, the reduced heat allows for prolonged sharpness and extended tool life.

Additionally, split point drill bits offer improved chip evacuation. The split point design helps to break up chips and remove them more efficiently, reducing the risk of clogging and further minimizing heat buildup. This improved chip evacuation also contributes to reduced wear on the drill bit as it prevents excessive friction between the bit and the workpiece.

In summary, split point drill bits excel in reducing both heat and wear. With their unique design and improved chip evacuation, split point drill bits provide cooler operation, prolonged sharpness, and extended tool life.

Longer Bit Life

The split point drill bits offer a longer bit life compared to traditional drill bits. This is due to the design of the split point, which allows for better chip evacuation and reduces heat build-up.

When using a traditional drill bit, chips often get trapped in the flutes, causing the bit to overheat and wear out more quickly. The split point design prevents this by creating a smaller surface contact area between the bit and the material being drilled. As a result, the chips are able to escape easily, reducing the friction and heat generated during the drilling process.

With less heat build-up and better chip evacuation, split point drill bits are able to maintain their sharpness and cutting efficiency for a longer period of time. This means that you can complete more drilling tasks without having to constantly replace worn-out drill bits, saving both time and money.

In addition, the longer bit life offered by split point drill bits also leads to improved drilling accuracy. As the bit remains sharp for a longer period of time, it is less likely to wander or deviate from the desired drilling path. This can be especially beneficial when drilling precise holes or working on projects that require high accuracy.

Versatile Applications

Split point drill bits have a wide range of applications due to their versatile design. The self-centering split point tip allows for more accurate drilling on various materials and surfaces.

Here are some of the versatile applications where split point drill bits excel:

- Metal drilling: Split point drill bits are commonly used for drilling holes in metal surfaces. Their ability to reduce walking or drifting makes them ideal for precise drilling on metals such as steel, aluminum, and brass.

- Woodworking: Split point drill bits are also effective in woodworking applications. Their sharp cutting edges and centering abilities make them suitable for drilling holes in wood, plywood, and other wooden materials. They minimize the risk of splitting the wood and provide clean and accurate holes.

- Plastic drilling: When it comes to drilling plastic materials like acrylic, polycarbonate, or PVC, split point drill bits are a popular choice. The split point design helps prevent the plastic from cracking or splintering during the drilling process.

- Masonry drilling: Although split point drill bits are not specifically designed for masonry drilling, they can be used for light masonry applications. For drilling into materials like brick, concrete, or stone, a split point drill bit with carbide or diamond tips is recommended.

Overall, split point drill bits are versatile tools that can be used in a variety of applications. Their ability to reduce walking, center the drill bit, and provide accurate holes makes them a popular choice among both professional and DIY users.

FAQ:

What is a split point drill bit?

A split point drill bit is a type of drill bit that has a specially designed tip. Instead of having a flat or rounded tip like conventional drill bits, a split point drill bit has a pointed tip that is split into two parts.

How does a split point drill bit work?

A split point drill bit works by reducing the amount of friction that is generated when drilling into a material. The split point tip allows the drill bit to penetrate the material more easily and with less force. This results in faster drilling and a cleaner hole.

What are the benefits of using split point drill bits?

There are several benefits of using split point drill bits. Firstly, they provide faster and more efficient drilling compared to conventional drill bits. The split point tip reduces the chance of the bit slipping or wandering, resulting in more accurate holes. Additionally, split point drill bits are less likely to generate heat, which can be beneficial when drilling into materials like metal.

Are split point drill bits more expensive than regular drill bits?

Split point drill bits are generally slightly more expensive than regular drill bits. However, the increased cost is often justified by the improved performance and longer lifespan of split point drill bits. They are a worthwhile investment for those who frequently drill into hard materials or require precise and accurate holes.

Video: