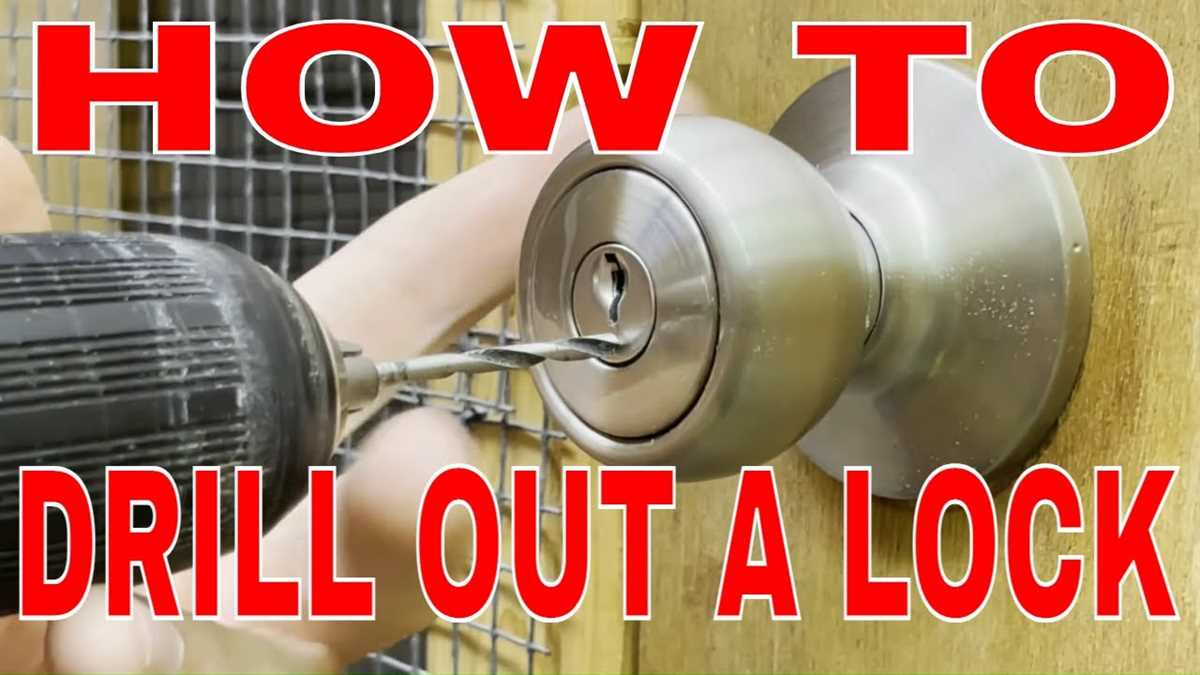

Steps to effectively drill out a deadbolt lock

Drilling out a deadbolt lock is not a task to be taken lightly. It requires precision, patience, and the right tools. Whether you’re a professional locksmith or a homeowner facing a lockout situation, drilling out a deadbolt lock can be a necessary step. In this article, we will guide you through the steps to effectively drill out a deadbolt lock.

Step 1: Assess the situation

Before you begin drilling out the deadbolt lock, it is important to assess the situation. Determine the reason for drilling out the lock, such as a lost key or a malfunctioning lock. Make sure you have the legal authority to drill out the lock if you are not the homeowner. Additionally, gather the necessary tools for the task, such as a drill, drill bits, lubricant, and a screwdriver.

Step 2: Protect the surrounding area

Drilling out a deadbolt lock can cause damage to the surrounding door or frame. To protect the area, cover it with a thick cloth or tape. This will prevent any scratches or dents during the drilling process. It is also important to wear protective goggles and gloves to safeguard yourself from any debris or metal shavings.

Step 3: Choose the right drill bit

The next step is to choose the right drill bit for the job. Deadbolt locks are typically made of hardened steel, so you will need a high-quality drill bit that can handle the material. Consult the lock manufacturer or a hardware store to ensure that you have the correct drill bit size and type for your specific deadbolt lock.

Step 4: Start drilling

Once you have prepared the area and selected the appropriate drill bit, it is time to start drilling. Insert the drill bit into the deadbolt lock’s keyway and apply gentle pressure. Begin drilling at a slow speed to avoid overheating the drill bit. Use lubricant to keep the drill bit cool and to aid in the drilling process. Gradually increase the drilling speed until you penetrate the lock’s pins or tumblers.

Remember to take breaks during the drilling process to allow the drill bit to cool down.

Step 5: Remove the lock

Once the lock’s pins or tumblers have been drilled out, you can remove the lock from the door. Use a screwdriver to unscrew any remaining screws or bolts holding the lock in place. Take caution not to damage the door or frame during this step. Once the lock is removed, you can replace it with a new one or continue with any necessary repairs.

Drilling out a deadbolt lock should be a last resort when all other methods of opening the lock have failed. It is a skilled task that should only be undertaken by experienced individuals, such as locksmiths. Always remember to prioritize safety and caution during the drilling process.

Choosing the Right Tools

When it comes to effectively drilling out a deadbolt lock, having the right tools is crucial. Using the wrong tools can waste time, damage the lock, or even cause injury. Here are some key tools that you will need:

1. Drill

The drill is the most important tool for drilling out a deadbolt lock. It is recommended to use a corded drill with adjustable speed settings. This will allow you to have better control and precision while drilling.

2. Drill Bits

You will need a set of high-quality drill bits in different sizes to effectively drill out a deadbolt lock. It is recommended to use a cobalt or titanium drill bit, as they are more durable and have better heat resistance.

3. Screwdriver

A screwdriver is used to remove the screws that hold the lock in place. Make sure to use a screwdriver that fits the screws properly to avoid damaging them.

4. Pliers

Pliers are useful for gripping and removing any broken pieces or fragments of the lock. They provide better control and precision in removing these small parts.

5. Lubricant

Having a lubricant, such as WD-40 or graphite powder, can make the drilling process smoother and prevent overheating. Apply the lubricant to the drill bit before starting to drill.

Remember, always prioritize safety when working with tools. Wear safety goggles, gloves, and protective clothing. Use tools responsibly and follow the manufacturer’s instructions for safe operation.

Selecting the Right Drill

When it comes to drilling out a deadbolt lock, selecting the right drill is crucial. The type of drill you choose will significantly impact the efficiency and effectiveness of the drilling process. Here are some factors to consider when selecting the right drill for the job:

1. Power

The power of the drill is an essential factor to consider. Deadbolt locks are often made of durable materials such as metal, so you need a drill with sufficient power to penetrate the material without difficulty. Look for a drill with a high wattage or voltage rating for optimal drilling capability.

2. Chuck Size

The chuck size of the drill refers to the diameter of the hole where you insert the drill bit. When drilling out a deadbolt lock, you will likely need a drill bit with a larger diameter to accommodate the size of the lock. Therefore, ensure that the drill you choose has a chuck size that can accommodate the necessary drill bit for the job.

3. Variable Speed

A drill with variable speed settings can be highly advantageous when drilling out a deadbolt lock. Different materials may require different drilling speeds to achieve the best results. With a variable speed drill, you can adjust the speed according to the material you are drilling, ensuring precision and avoiding damage to the lock or other components.

4. Corded or Cordless

Consider whether you prefer a corded or cordless drill. Corded drills have the advantage of consistent power supply, making them suitable for longer drilling sessions. On the other hand, cordless drills offer greater mobility and convenience, as they are not limited by a power cord. Choose the type of drill that best suits your needs and preferences.

5. Impact or Non-Impact

An impact drill uses a hammer mechanism to deliver additional rotational force, making it particularly effective for drilling into hard materials. However, if you are drilling out a deadbolt lock made of softer materials like wood, an impact drill may not be necessary. Consider the type of material you will be drilling into when deciding between an impact or non-impact drill.

By carefully considering these factors, you can select the right drill that will enable you to effectively drill out a deadbolt lock. Remember to prioritize safety and always follow proper drilling techniques to avoid injuries or damage to the lock or surrounding area.

Choosing a Drill Bit

When it comes to drilling out a deadbolt lock, choosing the right drill bit is crucial. The drill bit you use will determine how easily and effectively you can remove the lock.

Types of Drill Bits:

- Twist Drill Bits: These are the most commonly used drill bits and are suitable for drilling through wood, plastic, and soft metals. However, they may not be the best option for drilling through a deadbolt lock, as they may not be strong enough to penetrate the hardened steel often found in locks.

- Cobalt Drill Bits: Cobalt drill bits are made from a high-speed steel alloy that contains cobalt. This makes them more durable and heat-resistant, allowing them to drill through tough materials like hardened steel. They are an excellent choice for drilling out a deadbolt lock.

- Carbide Drill Bits: Carbide drill bits are made from carbide, a compound of carbon and metal. They are extremely hard and can easily drill through materials like hardened steel. Carbide drill bits are a great option for drilling out a deadbolt lock.

Size of Drill Bit:

The size of the drill bit you choose depends on the size of the deadbolt lock’s cylinder. Measure the diameter of the cylinder and choose a drill bit that is slightly larger than that size. This will ensure that the drill bit can penetrate the lock without getting stuck.

Drilling Technique:

When drilling out a deadbolt lock, it’s important to use the correct drilling technique. Start by drilling with a smaller-sized drill bit to create a pilot hole. Then gradually increase the size of the drill bit until you reach the desired size. This will prevent the drill bit from wandering and ensure a clean and accurate hole.

Remember to always wear safety goggles and work in a well-ventilated area when drilling out a deadbolt lock.

Preparing the Deadbolt Lock

1. Gather the necessary tools

Before starting the process of drilling out a deadbolt lock, it is important to gather all the necessary tools. These tools typically include:

- Drill: A drill with various drill bits will be needed to remove the deadbolt lock.

- Protective gear: It is recommended to wear safety goggles and gloves to protect yourself while working.

- Replacement lock: If you plan on replacing the deadbolt lock after drilling it out, make sure to have a replacement lock ready.

- Fasteners: Depending on the type of replacement lock, you may need screws or other fasteners to install it properly.

2. Assess the current lock

Before drilling out the deadbolt lock, it is important to assess its condition and understand how it is installed. Look for any signs of damage or wear that may have caused the lock to malfunction. Determine the type of lock and take note of any unique features or mechanisms it may have.

3. Lubricate the lock

If the deadbolt lock is difficult to turn or feels stuck, it is recommended to apply lubricant to its keyway and moving parts. This can help to loosen any internal components that might be causing the lock to seize up.

Note: Lubrication may not be necessary for locks that are not experiencing any issues.

4. Prepare the work area

Ensure that you have a clean and clutter-free work area before starting the drilling process. This will provide you with enough space to work safely and efficiently. Clear any nearby objects or obstacles that may hinder your movement or cause accidents.

5. Secure the door

Depending on the situation, it may be necessary to secure the door in order to prevent it from swinging open or closing unexpectedly during the drilling process. Consider using doorstops, wedges, or other methods to hold the door in place.

6. Exercise caution

Always exercise caution when working with power tools and sharp objects. Pay attention to your surroundings, follow safety guidelines, and use the appropriate equipment to protect yourself and others.

Removing the Outer Plate

Before you begin, gather all the necessary tools and equipment:

- Drill

- Drill bits

- Screwdriver

- Hammer

- Allen wrench

- Protective eyewear

- Gloves

Step 1: Preparation

Prior to starting, ensure that you have turned off the main power supply to the lock. This will prevent any accidental injuries while working on the deadbolt lock.

Step 2: Remove the Screws

Locate the screws on the outer plate of the deadbolt lock. Use a screwdriver to remove these screws and set them aside safely.

Step 3: Loosen the Cylinder

Use an Allen wrench to loosen the set screw on the side of the cylinder. Once loosened, the cylinder should be able to slide out of the deadbolt lock easily.

Step 4: Insert the Drill Bit

Choose an appropriately sized drill bit based on the diameter of the cylinder hole. Insert the drill bit into the drill and tighten it securely.

Step 5: Drill Out the Cylinder Hole

Position the drill bit at the center of the cylinder hole and apply gentle pressure. Start drilling, being careful not to apply too much force as it may damage the lock. Gradually increase the pressure until the drill bit goes through the outer plate.

Step 6: Remove the Cylinder

Once the drill bit has penetrated the outer plate and reached the inner part of the deadbolt lock, remove the drill from the hole and set it aside. Use a screwdriver or pliers to remove any remaining pieces of the outer plate.

Step 7: Clean the Cylinder Hole

Take a moment to clean out any debris or metal shavings from the drilled-out hole. Use a vacuum cleaner or compressed air to ensure that the hole is clear.

Step 8: Installation

If necessary, continue with the rest of the steps to install a new deadbolt lock or replace the existing one. Consult the lock’s manufacturer instructions for the specific installation steps.

Remember to exercise caution and wear protective gear throughout the process. If you are unsure or uncomfortable about any step, it is recommended to seek the assistance of a professional locksmith.

Lubricating the Lock Cylinder

One important step in effectively drilling out a deadbolt lock is to lubricate the lock cylinder. This helps to reduce friction and make the drilling process smoother.

Here are the steps to lubricate the lock cylinder:

- Remove the key from the lock and ensure that the lock is in the unlocked position.

- Identify the access point to the lock cylinder. This is usually a small hole on the side of the lock housing.

- Choose an appropriate lubricant for the lock cylinder. Graphite-based lubricants or silicone-based lubricants are generally recommended. Avoid using oil-based lubricants as they can attract dirt and debris.

- Apply a small amount of lubricant to a key or a small, narrow object, such as a toothpick or paperclip.

- Insert the key or the lubricated object into the access point and gently wiggle it back and forth to distribute the lubricant inside the lock cylinder.

- Repeat the process a few times to ensure thorough lubrication.

- Remove any excess lubricant from the lock using a clean cloth or paper towel.

- Test the lock to ensure smooth operation. Insert and turn the key in the lock a few times to distribute the lubricant further.

By properly lubricating the lock cylinder, you can make the drilling process easier and prevent damage to the lock and drill bits. Remember to always follow safety precautions and use appropriate tools when drilling out a deadbolt lock.

Drilling the Deadbolt Lock

Step 1: Choose the Right Drill Bit

Before drilling into the deadbolt lock, it’s important to select the right drill bit. A high-speed steel (HSS) or carbide drill bit is ideal for drilling through metal locks. Ensure that the drill bit is sharp to make the drilling process easier.

Step 2: Prepare the Drilling Area

Clear the area around the deadbolt lock to allow easy access for drilling. Protect the surrounding surfaces by covering them with a cloth or tape to prevent any damage during the drilling process.

Step 3: Mark the Drilling Point

Use a pencil or marker to mark the center of the deadbolt lock where you want to drill. Make sure the mark is easily visible to guide your drilling process accurately.

Step 4: Secure the Deadbolt Lock

Hold the deadbolt lock firmly in place to prevent it from moving while drilling. If necessary, use clamps or a vice to secure the lock in position. This will ensure stability and prevent any damage to the surrounding areas.

Step 5: Start Drilling

Place the drill bit on the marked point and start drilling slowly. Apply consistent pressure on the drill to prevent it from slipping. Gradually increase the speed and continue drilling until you penetrate through the lock.

Step 6: Remove the Drill Bit

Once you have drilled through the deadbolt lock, stop the drill and remove it from the hole. Be cautious as the drill bit may be hot. Allow it to cool down before handling.

Step 7: Test the Lock

After drilling, test the lock mechanism to ensure that it has been successfully removed. If necessary, use a screwdriver or similar tool to turn the lock and unlock the door.

Step 8: Replace the Deadbolt Lock

If you need to replace the deadbolt lock, remove the drilled lock from the door and install the new lock following the manufacturer’s instructions. Ensure that the new lock fits securely and functions properly.

Step 9: Clean Up

Once you have finished drilling and securing the new deadbolt lock, clean up the drilling area and remove any debris. Dispose of any materials properly and ensure the area is left in a tidy condition.

Additional Tips:

- Wear safety goggles to protect your eyes from flying debris.

- Apply a lubricant, such as oil or WD-40, to the drill bit to reduce friction and extend its lifespan.

- If you encounter any difficulty while drilling, stop and reassess the situation. Seek professional help if needed.

Marking the Drill Points

Before you begin drilling out a deadbolt lock, it’s important to mark the drill points accurately to ensure successful removal. Follow these steps to mark the drill points:

- Gather the necessary tools for marking the drill points, including a pencil or marker, measuring tape or ruler, and a level.

- Place the level horizontally on the door, ensuring it is straight. This will help you achieve accurate measurements and markings.

- Using the measuring tape or ruler, measure the distance between the edge of the door and the center of the deadbolt lock cylinder. This measurement will typically be stated in the lock manufacturer’s instructions.

- Make a small mark on the door with the pencil or marker at the measured distance. This mark will indicate the center of the deadbolt lock cylinder.

- Measure the distance from the bottom of the door to the center mark you just made. This measurement will typically be stated in the lock manufacturer’s instructions as well.

- Make a second mark on the door with the pencil or marker at the measured distance from the bottom of the door. This mark will indicate the bottom of the deadbolt lock cylinder.

Once you have accurately marked the drill points, you are ready to proceed with the next steps in drilling out the deadbolt lock.

Drilling the Pilot Holes

Before drilling out the deadbolt lock, it is important to create pilot holes. Pilot holes will guide the drill bit and prevent it from slipping or wandering off target. Here is how to drill the pilot holes effectively:

- Gather the necessary tools: To drill pilot holes, you will need a power drill, a drill bit of the appropriate size, a tape measure, and a pencil.

- Measure and mark the hole locations: Use a tape measure to determine the desired locations for the pilot holes. Mark these spots on the door using a pencil. It is recommended to measure and mark at least two pilot hole locations for stability.

- Secure the door: Place the door in a firm and stable position. You can use clamps or have someone hold it securely to prevent any movement during the drilling process.

- Select the drill bit: Choose a drill bit that matches the size of the deadbolt lock hole. Refer to the lock manufacturer’s instructions for the appropriate size.

- Attach the drill bit to the power drill: Insert the drill bit into the drill chuck, then tighten it securely. Ensure that the drill is set to the desired speed for drilling into the door material.

- Begin drilling the pilot holes: Position the drill bit at one of the marked locations on the door. Apply gentle pressure and slowly start drilling. Keep the drill perpendicular to the door surface to create straight and centered pilot holes.

- Repeat the process: After drilling the first pilot hole, move to the next marked location and repeat the drilling process. Remember to maintain a steady hand and drill straight.

- Clean up: Once the pilot holes are drilled, remove any wood debris from the drilling process. This will ensure a clean and safe drilling environment for the next steps.

Following these steps will help you effectively drill the pilot holes for a deadbolt lock. This will set the foundation for the subsequent steps in removing the lock.

Drilling the Final Hole

Once you have successfully drilled out the pilot holes and enlarged them to the appropriate size, you are ready to drill the final hole in the deadbolt lock. This hole will allow you to insert the new deadbolt cylinder and secure it in place.

Before you begin drilling the final hole, make sure you have the appropriate tools and equipment on hand. You will need a power drill with a drill bit that is specifically designed for drilling through metal. Additionally, have a supply of lubricant, such as oil or grease, to keep the drill bit from overheating during the drilling process.

To start drilling the final hole, follow these steps:

- Attach the appropriate drill bit to your power drill. Make sure it is securely fastened.

- Apply a small amount of lubricant to the drill bit. This will help reduce friction and prevent the bit from getting too hot.

- Position the drill bit at the center of the pilot hole on the side of the deadbolt lock.

- Hold the drill securely with both hands and apply steady pressure as you begin to drill. Keep the drill bit perpendicular to the surface of the lock.

- Continue drilling until you have reached the desired depth for the final hole. This will depend on the specific deadbolt lock you are working with, so refer to the manufacturer’s instructions if necessary.

- Once the hole has been drilled, carefully remove the drill bit from the lock.

After drilling the final hole, you can proceed with installing the new deadbolt cylinder. Follow the manufacturer’s instructions for this step, making sure to secure the cylinder firmly in place.

Remember to take appropriate safety precautions while drilling, such as wearing protective eyewear and securing the lock in a stable position to prevent accidents.

FAQ:

What is the purpose of drilling out a deadbolt lock?

The purpose of drilling out a deadbolt lock is to gain access to a locked door when other methods, such as picking or using a key, are not possible.

Is drilling out a deadbolt lock a difficult process?

Drilling out a deadbolt lock can be a challenging task, especially if you are not familiar with the process. It requires the use of specific tools and techniques to avoid damaging the door or lock.

What tools are needed to drill out a deadbolt lock?

To effectively drill out a deadbolt lock, you will need a power drill, drill bits, lubricant, a screwdriver, and a hammer. It is important to use the right size of drill bits to ensure accuracy.

Can drilling out a deadbolt lock damage the door?

Yes, drilling out a deadbolt lock can potentially damage the door if not done correctly. It is important to be careful and precise during the process to minimize any potential damage.

Are there any alternatives to drilling out a deadbolt lock?

Yes, there are alternatives to drilling out a deadbolt lock. These include picking the lock using specialized tools, calling a professional locksmith for assistance, or attempting to remove the lock cylinder using other methods.

Is it possible to drill out a deadbolt lock without professional help?

Yes, it is possible to drill out a deadbolt lock without professional help, but it is recommended to have some knowledge and experience with locksmithing to avoid causing further damage. If you are unsure about the process, it is best to seek the assistance of a professional locksmith.

Video: