Essential Tips for Drilling Through Thick Metal

Drilling through thick metal can be a daunting task, especially if you don’t have the right tools or techniques. Whether you’re a professional metalworker or a DIY enthusiast, it’s important to know how to drill through thick metal effectively and safely. In this article, we’ll share some essential tips to help you get the job done right.

Choose the Right Drill Bit

When it comes to drilling through thick metal, using the right drill bit is crucial. High-speed steel (HSS) drill bits are a popular choice for drilling through metal due to their durability and heat resistance. However, when dealing with extremely thick metal, cobalt drill bits are often recommended. Cobalt drill bits have a higher melting point and can withstand higher drilling speeds, making them ideal for tougher metals.

Pro tip: Before drilling, make sure your drill bits are sharp. Dull drill bits can make drilling through thick metal more difficult and cause excessive heat and friction.

Mark and Center Punch

Precise drilling is crucial when working with thick metal. Before drilling, always mark the spot where you want to drill and center punch it. This will help prevent the drill bit from wandering and ensure that your hole is centered. Use a center punch or a sharp nail to create a small indentation at the center of your mark. This will give the drill bit a starting point and help keep it on track.

Use Cutting Fluid

When drilling through thick metal, friction and heat can build up quickly, leading to dull drill bits and potential damage to the metal. To keep the metal and drill bit cool, it’s recommended to use cutting fluid or lubricant. Apply a small amount of cutting fluid to the area you’re drilling, and periodically add more as needed. This will help prolong the life of your drill bit and prevent overheating.

Pro tip: If you don’t have cutting fluid on hand, you can use a lubricant like motor oil or even dish soap as a substitute.

By following these essential tips, you’ll be well-prepared to tackle any drilling project involving thick metal. Remember to take your time, use the correct drill bit, mark and center punch your drilling spot, and use cutting fluid to ensure smooth and successful drilling. Happy drilling!

Choosing the Right Drill Bit

Drilling through thick metal requires the use of the right drill bit. The type of drill bit you choose will depend on the specific metal you are working with and the size of the hole you need to drill. Here are some important factors to consider when choosing a drill bit for thick metal:

1. Material

The first thing to consider is the material of the drill bit. For drilling through thick metal, you’ll want to use a drill bit made from high-speed steel (HSS) or cobalt. HSS drill bits are suitable for most metals, while cobalt drill bits are more durable and are better suited for harder materials like stainless steel.

2. Size

The size of the drill bit is also important. For thicker metals, you’ll need a larger drill bit to create a hole of sufficient size. Be sure to measure the size of the hole you need before selecting a drill bit. Most drill bits will have size markings on them, so you can easily identify the right size.

3. Twist Design

The twist design of a drill bit refers to the shape and arrangement of the flutes on the bit. For drilling through thick metal, you’ll want a drill bit with a wide and deep twist. This will help to clear away the metal shavings and prevent the bit from getting jammed. Look for drill bits with a “parabolic” or “split-point” twist design for better performance.

4. Coating

Some drill bits come with a coating that helps to reduce friction and increase the lifespan of the bit. For drilling through thick metal, consider choosing a drill bit with a titanium or black oxide coating. These coatings improve the durability of the drill bit and make it more resistant to heat and wear.

5. Shank Type

The shank of the drill bit is the part that fits into the drill chuck. For drilling through thick metal, a drill bit with a 3/8-inch or 1/2-inch shank is recommended. These larger shanks provide better stability and reduce the risk of the bit slipping or breaking during drilling.

By considering these factors, you can choose the right drill bit for drilling through thick metal. Remember to always wear appropriate safety gear and take proper precautions when drilling, as drilling through thick metal can be challenging and potentially dangerous.

Wearing Protective Gear

When drilling through thick metal, it is important to prioritize your safety by wearing the appropriate protective gear. The metal can produce sharp burrs and metal shavings that can cause injuries, so it is crucial to take the necessary precautions.

Safety Glasses

Start by wearing safety glasses to protect your eyes from flying debris and metal particles. Even if you are wearing a face shield, safety glasses are an essential layer of protection. They should be impact-resistant and wrap around your eyes to provide maximum coverage.

Face Shield

In addition to safety glasses, it is highly recommended to wear a face shield. This will protect your entire face, including your eyes, nose, and mouth, from any potential flying metal fragments. Make sure the face shield is properly secured and covers all areas vulnerable to injury.

Ear Protection

Drilling through thick metal can generate a significant amount of noise, which can damage your hearing. Using ear protection, such as earplugs or earmuffs, is essential to prevent long-term hearing loss. Make sure the ear protection you choose has the appropriate noise reduction rating.

Gloves

Wearing protective gloves is necessary to prevent cuts, abrasions, and burns from sharp edges and heated metal surfaces. Choose gloves that are specifically designed for working with metal and ensure they provide a good grip to handle the drill confidently.

Respirator

If you are working in an enclosed space or drilling through materials that produce harmful fumes or dust, a respirator is essential. It will protect your lungs from inhaling any hazardous particles or chemical vapors. Make sure the respirator is properly fitted and adequately filters the specific contaminants you may encounter.

Remember, wearing the appropriate protective gear is crucial when drilling through thick metal. It can help prevent serious injuries and ensure a safe drilling experience. Always prioritize safety and make sure to use the recommended gear for the task at hand.

Preparing the Metal Surface

Before drilling through thick metal, it is important to properly prepare the surface to ensure smooth and precise drilling. Here are some essential steps to follow:

1. Clean the Surface

Prior to drilling, make sure the metal surface is clean and free from any dirt, dust, or debris. Use a cleaning solvent or degreaser to remove any oil or grease that may be present on the surface. This will help prevent the drill bit from slipping or skidding during drilling.

2. Mark the Drilling Points

Once the surface is clean, use a permanent marker or a center punch to mark the exact drilling points. This will ensure accuracy and prevent any drilling mistakes. Take measurements and use a ruler or tape measure to mark the points with precision.

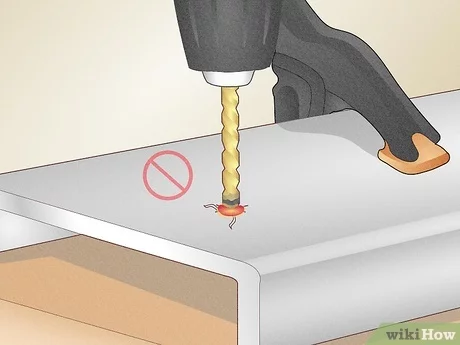

3. Use a Center Punch

Before drilling, use a center punch to create a small indentation at each drilling point. This will act as a guide for the drill bit, preventing it from wandering off course and ensuring the hole is drilled precisely at the intended location.

4. Choose the Right Drill Bit

When drilling through thick metal, it is crucial to use a drill bit specifically designed for metal drilling. High-speed steel (HSS) or cobalt drill bits are recommended for thick metals as they are able to withstand the heat generated during drilling and maintain their sharpness.

5. Lubricate the Drill Bit

Before starting the drilling process, apply a lubricant or cutting oil to the drill bit. This will help reduce friction and heat buildup, prolonging the life of the drill bit and improving drilling performance. Apply the lubricant periodically during drilling to ensure smooth and efficient cutting.

6. Secure the Metal

To prevent the metal from moving or vibrating during drilling, it is important to secure it firmly. Use clamps or a vice to hold the metal in place, ensuring stability and safety while drilling.

7. Start with a Pilot Hole

For thicker metals, it is recommended to start with a pilot hole before drilling the final hole size. This will help guide the drill bit and make drilling easier and more precise. The pilot hole should be smaller in diameter than the final hole size.

8. Use Proper Drilling Technique

When drilling through thick metal, it is important to use the correct drilling technique. Apply steady pressure and maintain a slow and consistent drilling speed. Avoid applying excessive force, as it can lead to overheating and damage the drill bit or the metal surface.

By following these steps and properly preparing the metal surface, you can ensure successful drilling through thick metal with accuracy and efficiency.

Using the Correct Drilling Technique

When drilling through thick metal, it is important to use the correct drilling technique to achieve the best results. Here are some essential tips to keep in mind:

1. Start with a small pilot hole

Before drilling a larger hole, it is advisable to start with a small pilot hole. This will help guide the bit and prevent it from wandering or slipping on the surface of the metal. Use a smaller diameter drill bit for the pilot hole.

2. Use a slow drilling speed

When drilling through thick metal, it is best to use a slow drilling speed. This will prevent the bit from overheating and ensure a cleaner, more precise hole. Set the drill to a low speed and maintain a steady, controlled pressure as you drill.

3. Apply cutting fluid

Applying cutting fluid to the drill bit and the metal surface can help reduce friction and heat buildup. This will make the drilling process smoother and extend the life of your drill bit. Apply cutting fluid periodically throughout the drilling process.

4. Use a center punch

Using a center punch to create a small indentation at the drilling point can help provide a starting point and prevent the drill bit from wandering. Place the center punch on the desired drilling spot and lightly tap it with a hammer to create an indentation.

5. Use a sharp, high-quality drill bit

Using a sharp, high-quality drill bit is crucial when drilling through thick metal. Dull or low-quality bits can cause the drilling process to become more difficult and result in imprecise holes. Invest in a good drill bit designed for drilling through metal.

6. Secure the metal

Before drilling, make sure the metal is securely clamped or held in place. This will prevent it from moving or vibrating during the drilling process, which can lead to inaccurate holes or damage to the metal.

7. Take breaks and cool the drill bit

If you notice the drill bit or metal getting hot during the drilling process, take breaks to let them cool down. This will prevent overheating and prolong the life of your drill bit. You can also dip the drill bit in cold water or use a cooling lubricant to help cool it down.

8. Use the correct drill set-up

Make sure you have the correct drill set-up for drilling through thick metal. This includes using a drill press or a sturdy workbench with a vise to hold the metal securely in place. This will provide stability and accuracy when drilling.

By following these tips and using the correct drilling technique, you can successfully drill through thick metal with ease and precision.

Applying Adequate Pressure

Applying adequate pressure during the drilling process is crucial for successfully drilling through thick metal. Without enough pressure, the drill bit may not be able to penetrate the metal, resulting in a slow and inefficient drilling process. On the other hand, applying too much pressure can cause the drill bit to overheat and become dull more quickly.

Here are some tips for applying adequate pressure when drilling through thick metal:

- Start slow: When starting to drill, begin with a low speed to establish a pilot hole. This will help guide the drill bit and prevent it from slipping off the surface of the metal.

- Use a stable base: Ensure that the metal is securely clamped to a stable base or workbench. This will provide support and prevent the metal from moving or vibrating during the drilling process.

- Apply steady pressure: Once the pilot hole is established, gradually increase the drilling speed while maintaining a steady and consistent pressure. Use both hands to hold the drill and apply pressure evenly.

- Listen and feel: Pay attention to the sounds and vibrations produced by the drilling process. If the drill bit starts to make a squealing or grinding noise, it may indicate that too much pressure is being applied. Similarly, if the drill starts to vibrate excessively, it may be a sign of inadequate pressure.

- Take breaks: Drilling through thick metal can generate a significant amount of heat. To prevent overheating, take short breaks every few minutes to allow the drill bit to cool down.

- Use lubrication: Applying a lubricant, such as cutting oil or WD-40, can help reduce friction and heat buildup during the drilling process. This can extend the life of the drill bit and make drilling through thick metal easier.

- Choose the right drill bit: Using a high-quality drill bit specifically designed for drilling through metal can make a significant difference in the drilling process. Carbide or cobalt drill bits are known for their durability and ability to cut through tough materials.

By following these tips and applying adequate pressure, you can successfully drill through thick metal and achieve clean and precise holes.

Cooling the Drill Bit

When drilling through thick metal, the drill bit can get quite hot. This heat can cause the bit to become dull more quickly and can even lead to the bit breaking. Therefore, it is important to keep the drill bit cool during the drilling process.

There are several ways to cool the drill bit while drilling through thick metal:

- Using lubricants: One common method is to use a lubricant, such as cutting oil, to reduce friction and keep the drill bit cool. Apply the lubricant to the drilling area and let it soak in for a few minutes before starting to drill.

- Using coolant: Coolants, such as water or coolant sprays, can also be used to cool the drill bit. These coolants help dissipate heat generated during the drilling process and can be easily applied using a spray bottle.

- Dipping in water: Another option is to dip the drill bit in water periodically while drilling. This can help cool down the bit and prevent it from getting too hot. Just make sure to dry the bit thoroughly before continuing to drill.

- Note: It’s important to wear safety goggles and gloves when using lubricants, coolants, or dipping the drill bit in water to protect yourself from any splashes or potential hazards.

In addition to cooling the drill bit, it is also important to use the appropriate drilling speed and pressure to prevent overheating. High speeds and excessive pressure can generate more heat, so it is recommended to use a slower speed and apply a steady, even pressure.

By taking these cooling measures and using the right drilling techniques, you can prolong the life of your drill bit and ensure efficient drilling through thick metal.

Clearing Metal Shavings

Drilling through thick metal can produce a large amount of metal shavings or chips. These shavings can be sharp and hazardous, so it is important to take the necessary precautions to clear them away properly.

1. Wear Protective Gear

Before beginning any drilling operation, make sure to wear appropriate protective gear such as safety glasses, gloves, and a dust mask. This will help protect your eyes, hands, and respiratory system from the sharp metal shavings.

2. Use a Vacuum or Dust Collector

To minimize the mess and clear away metal shavings effectively, use a vacuum with a metal chip collection attachment or a dust collector specifically designed for metalworking. Position the vacuum near the drilling area to capture the shavings as they are produced.

3. Lay Down a Protective Cover

To make cleanup easier, lay down a protective cover beneath the drilling area. This can be a drop cloth or a large sheet of cardboard. The cover will catch the majority of the shavings, making it easier to dispose of them later.

4. Regularly Clear Shavings

During the drilling process, periodically pause and clear away the metal shavings to prevent them from accumulating and causing a safety hazard. Use a brush or a shop vac to carefully remove the shavings from the drilling area.

5. Dispose of Shavings Properly

Once you have finished drilling, gather the metal shavings and dispose of them properly. Avoid simply sweeping them up, as they can easily cause injury. Instead, place them in a designated metal chip disposal container or bag and dispose of them according to local regulations.

6. Clean the Drilling Area Thoroughly

After all the shavings have been cleared, clean the drilling area thoroughly to ensure there are no remaining metal particles. Use a damp cloth or a shop vac to remove any remaining residue, ensuring a clean and safe workspace.

By following these tips for clearing metal shavings, you can maintain a tidy and safe work environment while drilling through thick metal.

Inspecting the Drilled Hole

Once you have completed the drilling process on a thick metal surface, it is crucial to inspect the drilled hole. This inspection is important to ensure that the hole meets the necessary requirements and standards.

Visual Inspection

Begin by visually examining the drilled hole. Look for any signs of irregularities, such as cracks, burrs, or rough edges. These issues can weaken the metal and affect the overall integrity of the hole.

Pay close attention to the size and shape of the hole. Measure the diameter and depth of the hole using a caliper or a depth gauge. Compare these measurements with the specifications provided for the project to ensure that the hole meets the required dimensions.

Physical Inspection

In addition to the visual inspection, it is also important to perform a physical inspection of the drilled hole. This involves feeling the edges of the hole for any rough spots or uneven surfaces. Run your finger along the edges to check for any sharp or jagged areas that may need to be smoothed out.

If necessary, use a deburring tool or sandpaper to remove any burrs or rough edges from the drilled hole. This will ensure that the hole is clean and smooth, allowing for a better fit with any fasteners or components that will be inserted into it.

Final Check

Once you have completed the visual and physical inspection of the drilled hole, take a final look to ensure that it meets all the required standards. The hole should have a clean appearance with no visible cracks or irregularities. It should also have the correct dimensions and a smooth, even surface.

If you notice any issues during the inspection, it is important to address them before proceeding with any further steps. This may involve re-drilling the hole to the proper specifications or using additional tools or techniques to correct any defects.

By thoroughly inspecting the drilled hole, you can ensure that it meets the necessary requirements and standards for your project. This will help to ensure the overall quality and integrity of the metal structure or component that you are working on.

FAQ:

What are some essential tips for drilling through thick metal?

Drilling through thick metal requires some special techniques. First, it’s important to use a high-quality drill bit made specifically for metal. It’s also recommended to start with a small pilot hole and gradually increase the size. Lubricating the drill bit with cutting oil can help reduce friction and heat. Using a slower drill speed and applying consistent pressure can also improve drilling performance. Additionally, securing the workpiece firmly and using a backing plate can prevent the metal from deforming or shifting during drilling.

What kind of drill bit should I use for drilling through thick metal?

For drilling through thick metal, it’s best to use a high-quality drill bit made of cobalt or carbide. These materials are known for their durability and ability to withstand high temperatures. Cobalt drill bits are often recommended for drilling through stainless steel, while carbide drill bits are more suitable for hardened steel. High-speed steel (HSS) drill bits can also be used, but they may dull quicker and require more frequent sharpening.

Do I need to use cutting oil when drilling through thick metal?

Using cutting oil is highly recommended when drilling through thick metal. Cutting oil helps to reduce friction and heat, which can improve drilling performance and extend the life of the drill bit. It lubricates the cutting edges of the drill bit, allowing it to move through the metal more smoothly. Applying cutting oil during the drilling process can also help to prevent the drill bit from becoming overheated and dull.

What is the best way to prevent the metal from deforming or shifting while drilling?

To prevent the metal from deforming or shifting while drilling, it’s important to secure the workpiece firmly. Using clamps or a vise to hold the metal in place can help provide stability. Another effective technique is to use a backing plate, such as a piece of scrap wood or metal, placed behind the workpiece. The backing plate helps distribute the pressure evenly and prevents the metal from bending or warping as the drill bit penetrates.

What drill speed should I use when drilling through thick metal?

When drilling through thick metal, it’s best to use a slower drill speed. Higher drill speeds can cause the metal to heat up and increase the risk of the drill bit becoming dull or breaking. A recommended speed is around 500-600 revolutions per minute (RPM) for drilling through thick metal. However, it’s important to adjust the speed based on the specific metal being drilled and the size of the drill bit.

What should I do if the drill bit gets stuck while drilling through thick metal?

If the drill bit gets stuck while drilling through thick metal, it’s important to stop drilling immediately. Applying excessive force or trying to force the drill bit can lead to damage or breakage. To remove a stuck drill bit, you can try loosening the chuck and reversing the drill’s direction. If this doesn’t work, you may need to use a drill bit extractor or seek professional assistance.

Are there any safety precautions I should take when drilling through thick metal?

Yes, there are several safety precautions to keep in mind when drilling through thick metal. Always wear safety glasses or goggles to protect your eyes from flying chips or metal fragments. It’s also recommended to wear gloves to protect your hands and to have a firm grip on the drill. Make sure to work in a well-ventilated area or use a dust mask if necessary to avoid inhaling metal dust. Finally, be cautious of the heat generated during drilling and avoid touching the metal or drill bit immediately after drilling.

Video: