How to Determine the Correct Size Hole to Drill in Studs for Wiring

When it comes to electrical wiring, it’s important to drill holes in the studs of your walls to safely pass the wires through. However, drilling the wrong size hole can compromise the structural integrity of the stud and potentially lead to electrical hazards. To ensure you’re drilling the correct size hole, there are a few factors you need to consider.

First and foremost, you need to determine the size of the wire you’re working with. Different wire gauges require different hole sizes, so you’ll need to consult a wire gauge chart or speak to a professional to determine the appropriate size.

Once you know the size of the wire, you need to consider the type of stud you’re drilling into. Most studs are made of wood, but there are also metal and composite studs. Each type of stud may require a different hole size, so it’s important to know what you’re working with.

For wooden studs, it’s best to measure the width of the stud and use a drill bit slightly smaller in diameter. This will ensure a snug fit and prevent any potential splintering or damage to the stud.

If you’re working with metal or composite studs, you may need to consult the manufacturer’s guidelines or a professional to determine the correct hole size.

Remember, when drilling holes in studs for wiring, precision is key. Taking the time to measure and choose the correct hole size will not only ensure the safety of your electrical system but also help maintain the stability of your walls.

Understanding the Importance of Correct Size Holes

When it comes to drilling holes in studs for wiring, it is crucial to choose the correct size hole. Using the wrong size hole can lead to a variety of problems, including compromised structural integrity, increased risk of fires, and difficulties with future electrical work.

Structural Integrity

Studs are an essential component of the framing structure in a building. They provide support and stability for the walls, floors, and ceilings. When drilling holes in studs, it is important to ensure that the holes do not weaken or compromise the structural integrity of the stud. Using a hole that is too large can weaken the stud, making it more susceptible to bending or breaking. This can lead to structural issues and potential safety hazards.

Fire Safety

Another important reason to use the correct size hole when drilling in studs is to mitigate the risk of fires. Electrical wiring that passes through studs can generate heat, especially when there is a high current flow. If the hole is too small, it can cause the wires to overheat, potentially leading to a fire. On the other hand, if the hole is too large, it can allow the wires to move or come into contact with other materials, increasing the risk of shorts and sparks that can ignite nearby combustible materials.

Future Electrical Work

Choosing the correct size hole when drilling in studs also has practical benefits for future electrical work. If the hole is too small, it may be challenging to pull new wires through later or make any necessary repairs or modifications. Conversely, if the hole is too large, it can be difficult to secure the wiring properly, leading to potential loose connections and other electrical issues.

Choosing the Correct Size Hole

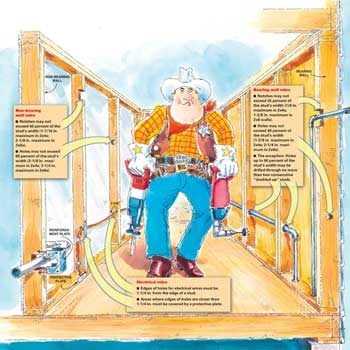

To determine the correct size hole for drilling in studs, it is important to consult local building codes and regulations. These codes often provide guidelines on the maximum allowable hole size based on the dimensions and type of stud being used. The specific wiring requirements and conditions should also be considered when determining the appropriate hole size.

Additionally, it is recommended to use protective measures, such as grommets or bushings, to prevent the wiring from coming into direct contact with the edges of the hole. These protective measures help reduce friction and damage to the wires, ensuring a safer and more secure installation.

- Consult local building codes and regulations for guidance on maximum hole sizes.

- Consider the specific wiring requirements and conditions.

- Use protective measures, such as grommets or bushings, to prevent damage to the wires.

By understanding the importance of using the correct size hole when drilling in studs for wiring, you can ensure the structural integrity of the building, minimize fire risks, and make future electrical work more manageable.

Tools and Materials Needed

- Stud finder

- Drill

- Drill bits

- Measuring tape

- Pencil

- Electrical wire

- Wire strippers

- Electrical boxes

- Screws or nails

- Screwdriver or hammer

- Level

- Protective eyewear

- Gloves

- Wire connectors

Step-by-Step Instructions for Determining the Correct Size Hole

- Identify the size and type of electrical wire you will be using for your project. This is important as different wire sizes will require different size holes.

- Measure the diameter of the electrical wire. Use a measuring tape or caliper to accurately determine the diameter. Make sure to account for any insulation on the wire.

- Determine the minimum hole size required for the electrical wire. Add 1/8 inch to the diameter of the wire to allow for ease of installation and movement.

- Use a drill bit with the appropriate size to create a pilot hole. The pilot hole should be slightly smaller than the minimum hole size calculated in the previous step.

- Drill the pilot hole into the stud at the desired location. Ensure that you are drilling perpendicular to the surface of the stud to prevent any damage to the wire or stud.

- Check the size of the pilot hole using a wire gauge or by inserting the wire into the hole. The wire should fit snugly but not be too tight. If the hole is too small, gradually enlarge it using larger drill bits until the wire fits properly.

- Once the correct hole size has been determined, use a drill bit with that size to drill the final hole in the stud.

- Repeat the above steps for any additional holes needed for your wiring project.

Remember to always take safety precautions when using power tools. Wear protective goggles and gloves, and follow the manufacturer’s instructions for operating the drill.

By following these step-by-step instructions, you can determine the correct size hole to drill in studs for wiring projects. This will help ensure a safe and secure installation of your electrical wires.

Common Mistakes to Avoid

- Not measuring the wire diameter accurately: One common mistake is not accurately measuring the diameter of the wire you will be running through the hole. It is important to measure the diameter of the wire accurately to ensure a snug fit without damaging the wire or making the hole too large.

- Drilling holes too close together: Another mistake is drilling holes too close together. This can weaken the integrity of the stud and make it more prone to splitting or cracking. It is important to follow the recommended spacing guidelines for drilling holes in studs.

- Using the wrong type of drill bit: Using the wrong type of drill bit can lead to a variety of problems. For instance, using a drill bit with a dull or incorrect tip can cause the bit to wander or create an oversized hole. It is important to use a drill bit specifically designed for drilling holes in studs.

- Not using a drill stop: When drilling holes in studs, it is important to use a drill stop to prevent drilling too far into the stud. This can help prevent damage to the wires or other objects behind the stud.

- Not securing the wire properly: After drilling the hole, it is crucial to secure the wire properly to prevent it from moving or rubbing against the edges of the hole. This can help protect the wire from damage and prevent electrical hazards.

- Ignoring building codes and regulations: Finally, it is important to familiarize yourself with local building codes and regulations before drilling holes in studs for wiring. Failure to comply with these codes can result in safety hazards or legal issues.

Tips and Tricks for Success

1. Measure Multiple Times

Before drilling any holes in the studs, it is crucial to measure multiple times to ensure accuracy. Take your time and use a tape measure to get precise measurements. Remember, it is always better to double-check your measurements than to make a mistake that could cause issues later on.

2. Use the Right Drill Bit

Choosing the right drill bit is essential for success. Look for a drill bit that is specifically designed for drilling through wood. These drill bits typically have a sharp point and fluted edges that help remove wood chips as you drill. It is also important to select a drill bit that matches the size of the hole you need to drill for your wiring.

3. Start with a Small Pilot Hole

When drilling into studs for wiring, it is best to start with a small pilot hole before drilling the final hole. This will help prevent the wood from splintering or splitting as you drill. Use a drill bit that is slightly smaller than the final hole size to create the pilot hole.

4. Use a Depth Stop

Using a depth stop on your drill can be helpful to ensure that you do not drill too far into the stud. This will help protect your wiring and prevent any accidents or damage. Adjust the depth stop to the desired depth before drilling the hole.

5. Clear Away Wood Chips

After drilling each hole, make sure to clear away any wood chips or debris. This will help prevent the drill bit from getting stuck or bogged down. Use a brush or cloth to remove the wood chips from the drilled hole.

6. Test the Size

Before running the wiring through the holes, it is crucial to test the size first. Ensure that the hole is the correct size by trying to insert the wire into it. The wire should fit snugly without any gaps or excessive force. If the hole is too small, use a larger drill bit to widen it slightly.

7. Label and Organize

To avoid confusion and make future work easier, label and organize your wiring. Use tags or labels to identify each wire and its corresponding hole. This will help prevent any mix-ups or mistakes when connecting the wiring.

8. Safety First

When drilling into studs for wiring, prioritize safety. Always wear safety goggles to protect your eyes from flying wood chips. Additionally, use caution when drilling near electrical wires or plumbing to avoid any potential hazards.

9. Practice on Scrap Wood

If you are new to drilling holes in studs for wiring, it may be helpful to practice on a piece of scrap wood first. This will give you an opportunity to refine your skills and gain confidence before starting on the actual studs in your walls.

By following these tips and tricks, you can ensure success when determining the correct size hole to drill in studs for wiring.

Additional Considerations

When determining the correct size hole to drill in studs for wiring, there are a few additional considerations to keep in mind:

1. Wire Size

Before drilling a hole, you need to consider the size of the wire you will be running through it. Different wire sizes require different size holes to ensure a proper fit. Make sure to consult the wire manufacturer’s recommendations or a wire sizing chart to determine the appropriate hole size.

2. Number of Wires

If you are running multiple wires through the same hole, you will need to account for the additional space required. This may require a larger hole or multiple smaller holes depending on the size and number of wires.

3. Fire Safety

Drilling holes in studs for wiring can potentially compromise the fire safety of your home. When drilling, it’s important to avoid drilling into any electrical cables already present in the wall, as this can create a fire hazard. Additionally, consider fire-blocking measures such as using fire-resistant caulking or putty to seal the holes and prevent flames from spreading in case of a fire.

4. Building Codes and Regulations

It’s important to check your local building codes and regulations regarding drilling holes in studs for wiring. Some jurisdictions may have specific requirements regarding hole size, placement, or fire safety measures. Be sure to adhere to these regulations to ensure your wiring is up to code and safe.

By considering these additional factors, you can ensure that the holes you drill in studs for wiring are the correct size and meet all relevant safety standards.

FAQ:

What is the correct size hole to drill in studs for wiring?

The correct size hole to drill in studs for wiring depends on the size of the wiring you are using. Generally, for standard house wiring, a 1/2-inch hole is suitable. However, for larger wiring or if you are running multiple wires through the same hole, you may need to use a larger hole.

How do I determine the correct size hole if I am using larger wiring?

If you are using larger wiring, you will need to consult the manufacturer’s instructions or the National Electrical Code (NEC) to determine the minimum hole size required. The NEC provides guidelines for the maximum number and size of wires that can be run through a specific size hole in a stud. Make sure to follow these guidelines to ensure the safety and functionality of your electrical system.

Can I use the same hole to run multiple wires?

Yes, you can use the same hole to run multiple wires if the hole is large enough to accommodate all the wires without causing damage or creating a fire hazard. However, you should be cautious and follow the guidelines provided by the NEC to determine the maximum number and size of wires that can be run through a specific size hole.

What tools do I need to drill a hole in a stud for wiring?

To drill a hole in a stud for wiring, you will need a power drill, a drill bit of the appropriate size, and a stud finder to locate the studs behind the wall. Additionally, you may need a level and a pencil or marker to mark the location of the hole on the studs.

Do I need to be careful not to drill into any existing wires or pipes in the wall?

Yes, it is important to be careful not to drill into any existing wires or pipes in the wall when drilling a hole for wiring. Before drilling, use a stud finder to locate the studs and ensure there are no obstructions in the area where you plan to drill. Additionally, you may want to turn off the power to the area where you are working to minimize the risk of accidental contact with live wires.

What should I do if I accidentally drill into a wire or pipe?

If you accidentally drill into a wire or pipe while drilling a hole for wiring, you should immediately turn off the power to the affected area and assess the damage. Depending on the severity of the damage, you may need to hire a professional electrician or plumber to repair the wire or pipe. It is always best to exercise caution and take proper safety measures to avoid such accidents.

Video: