Alternative Methods for Enlarging Holes in Metal without a Drill

Enlarging holes in metal can be a challenging task, especially if you don’t have access to a drill. However, there are alternative methods that can help you achieve the desired results. These methods require a bit of patience and creativity, but they can be effective in enlarging holes in metal without the use of a drill.

One alternative method is to use a rotary tool with a grinding or cutting attachment. This tool can be used to slowly and carefully grind away the metal around the existing hole, gradually enlarging it to the desired size. It’s important to wear protective eyewear and work slowly to ensure safety and accuracy.

Another alternative method is to use a file to enlarge the hole. This method involves manually filing away the metal around the hole, little by little, until it reaches the desired size. This method requires patience and precision, as it can take some time to achieve the desired result. It’s important to use a file with sharp teeth and to apply even pressure while filing.

Lastly, if you need to enlarge a hole in thin sheet metal, you can use a hole punch. A hole punch is a specialized tool that can quickly and easily create holes of various sizes in metal. By using a hole punch that is slightly larger than the existing hole, you can enlarge it to the desired size without the need for a drill.

Method 1: Using a Rotary Tool

A rotary tool is a versatile and powerful tool that can be used to enlarge holes in metal without the need for a drill. This method involves using a rotary tool with the appropriate attachment or bit to gradually enlarge the hole to the desired size.

Materials:

- Rotary tool

- Appropriate attachment or bit for enlarging holes

- Safety goggles

- Gloves

Step-by-Step Instructions:

- Put on safety goggles and gloves to protect yourself from any debris.

- Insert the appropriate attachment or bit for enlarging holes into the rotary tool.

- Secure the metal piece firmly in a vice or clamp to prevent it from moving during the process.

- Turn on the rotary tool and hold it at a 90-degree angle to the metal surface.

- Place the tip of the attachment or bit on the edge of the hole to be enlarged.

- Apply a moderate amount of pressure and slowly move the rotary tool in a circular motion around the edge of the hole.

- Continue to move the rotary tool in a circular motion, gradually moving towards the center of the hole.

- Periodically remove the rotary tool to clear away any metal shavings or debris.

- Check the size of the hole frequently to ensure it is being enlarged to the desired size.

- Once the hole has been enlarged to the desired size, turn off the rotary tool and remove the metal piece from the vice or clamp.

- Inspect the hole to ensure it is clean and smooth. If necessary, use sandpaper or a file to remove any rough edges.

Using a rotary tool to enlarge holes in metal is an effective alternative method that provides precise control and allows for gradual enlargement. However, it is important to take proper safety precautions and ensure the metal piece is secured properly before starting the process.

Method 2: Using an Angle Grinder

An alternative method for enlarging holes in metal without a drill is by using an angle grinder. Angle grinders are handheld power tools that can be equipped with different types of cutting discs and attachments, making them versatile for various metalworking tasks.

Materials Needed:

- Angle grinder

- Cutting disc suitable for metal

- Safety glasses

- Marker or pencil

- Ruler or measuring tape

- Clamps (optional)

Steps:

- Put on safety glasses to protect your eyes from sparks and flying debris.

- Measure and mark the desired size of the enlarged hole on the metal surface using a marker or pencil. Use a ruler or measuring tape to ensure accuracy.

- Secure the metal piece in a vise or with clamps to prevent it from moving during the cutting process. This step is optional, but it can provide more stability and control.

- Attach the cutting disc suitable for metal to the angle grinder. Make sure it is securely fastened according to the manufacturer’s instructions.

- Turn on the angle grinder and gently lower the cutting disc onto the marked area of the metal surface. Apply light pressure and let the grinder do the work. Move the grinder in a circular motion to gradually enlarge the hole.

- Periodically lift the grinder to remove any sparks and debris. This will help prevent them from obscuring your view and damaging the cutting disc.

- Continue cutting until the hole is enlarged to the desired size.

- After completing the cutting process, turn off the angle grinder and set it aside in a safe area.

- Inspect the enlarged hole to ensure it meets your requirements in terms of size and smoothness. If needed, you can use a file or sandpaper to remove any sharp edges or rough surfaces.

Important Safety Tips:

- Always wear safety glasses to protect your eyes from potential hazards.

- Follow the manufacturer’s instructions when using an angle grinder.

- Keep your hands away from the cutting disc and any moving parts of the grinder.

- Work in a well-ventilated area or wear a dust mask to avoid inhaling metal dust or particles.

- Be cautious of sparks and hot metal during the cutting process.

This method can be an efficient alternative for enlarging holes in metal when a drill is not available or suitable for the task. However, it requires proper safety precautions and careful handling of the angle grinder to ensure successful results and avoid accidents.

Method 3: Using a Metal File

A metal file is a handheld tool with a rough surface that is used to shape and smooth metal surfaces. It can also be used to enlarge holes in metal without a drill. Here’s how:

- Choose a metal file that is appropriate for the size of the hole you need to enlarge. Files come in various sizes and shapes, so selecting the right one is important for achieving the desired result.

- Position the metal file at the edge of the hole and apply light pressure.

- Move the file back and forth in a sawing motion, focusing on the edges and gradually working your way towards the center of the hole.

- Continue filing until the hole has reached the desired size. It’s important to work slowly and be patient to avoid removing too much material or creating an uneven surface.

- Check the hole periodically to ensure that it is being enlarged evenly and the dimensions are accurate.

- Once the desired size is achieved, use the file to smooth the edges of the hole for a clean finish.

Note: Enlarging holes with a metal file can be time-consuming, especially for larger holes. It requires manual effort and precision. It is recommended to use this method for small holes or when a drill is not available.

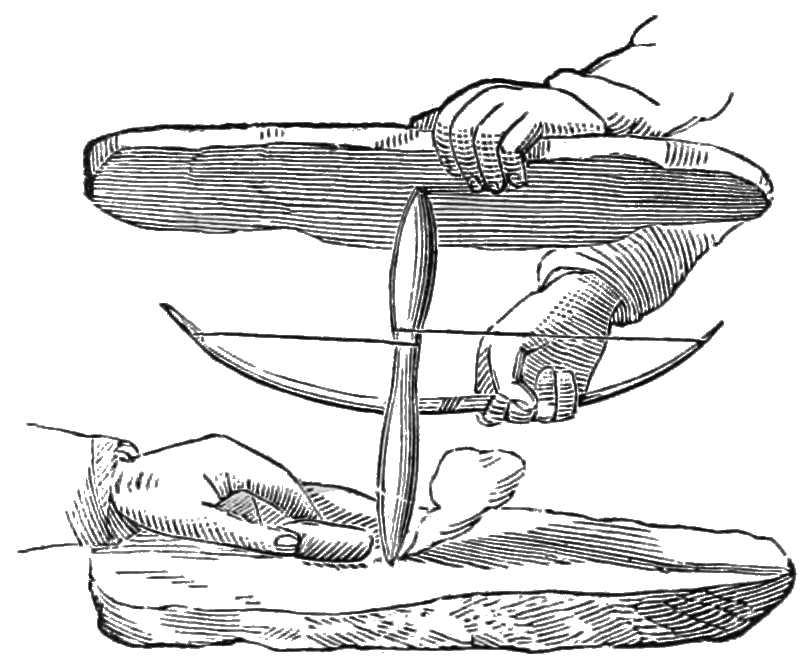

Method 4: Using a Reamer

A reamer is a specialized tool designed for enlarging and finishing holes in metal. It is commonly used in machining operations where precise hole dimensions are required. Here’s how you can use a reamer to enlarge holes in metal without a drill:

- Start by selecting the appropriate reamer size for the desired hole diameter. It is important to choose a reamer that is slightly smaller than the target hole size to allow for the finishing process.

- Secure the metal piece in a vise or clamp to prevent it from moving during the reaming process.

- Apply cutting oil to lubricate the reamer and reduce friction. This will help prolong the life of the tool and ensure smooth operation.

- Position the reamer at the entrance of the existing hole and align it with the axis of the hole.

- Hold the reamer firmly with both hands and apply steady pressure as you rotate it clockwise. The cutting edges of the reamer will gradually remove material and enlarge the hole.

- Continue rotating the reamer until the desired hole diameter is achieved. Take care not to apply excessive force, as this can cause the reamer to become dull or break.

- Throughout the reaming process, periodically withdraw the reamer to remove excess chips and debris. This will help maintain cutting efficiency and prevent clogging.

- Once the hole is enlarged to the desired size, inspect it for any burrs or rough edges. If necessary, use a deburring tool or sandpaper to smooth out the hole.

Using a reamer is a reliable method for enlarging holes in metal without a drill, especially when precision is required. It allows for controlled and gradual material removal, resulting in accurate hole dimensions and a smooth finish.

Method 5: Using a Punch and Hammer

Another alternative method for enlarging holes in metal without a drill is by using a punch and hammer. This method is suitable for small holes and can be done with some basic tools.

Materials Needed:

- A punch

- A hammer

- Safety glasses

- Work gloves

Instructions:

- Put on your safety glasses and work gloves to protect yourself.

- Select a punch that is slightly smaller than the desired size of the hole.

- Position the punch in the center of the existing hole.

- Hold the punch firmly against the metal surface.

- Using a hammer, strike the punch with controlled force to create a depression in the metal.

- Move the punch around the circumference of the hole, striking it with the hammer each time, until the desired size is achieved.

- Inspect the hole to ensure it has been enlarged to the desired size.

Note: This method requires caution and precision. Ensure that you maintain a controlled force while striking the punch with the hammer to avoid damaging the metal or injuring yourself.

Advantages:

- Does not require a drill or power tools

- Requires minimal equipment

- Can be done with basic hand tools

Disadvantages:

- Requires precision and control

- Suitable only for small holes

- Takes longer compared to using a drill

Using a punch and hammer can be an effective method for enlarging small holes in metal without a drill. However, for larger holes or more precise work, it is recommended to use a drill or other appropriate tools. Always prioritize safety and take necessary precautions while working with metal and tools.

Method 6: Using a Hole Saw

A hole saw is a versatile tool that is commonly used for cutting large diameter holes in various materials, including metal. While it is typically used with a drill, it can also be used by hand to enlarge an existing hole in metal. Here’s how:

- Gather the necessary tools: To use a hole saw, you will need the following:

- A hole saw with the desired diameter

- A pilot drill bit

- Masking tape

- A power drill or a brace (if using the hole saw by hand)

- Safety goggles

- Work gloves

- Tape the area: Before using the hole saw, you should tape the area around the existing hole. This can help prevent the saw from slipping and damaging the surrounding metal.

- Secure the hole saw: Insert the pilot drill bit into the center of the existing hole. Then, attach the hole saw to the drill or brace, ensuring that it is securely in place.

- Start slow: If you are using a power drill, set it to a low speed. This will allow you to have better control over the cutting process.

- Begin cutting: Apply light pressure and start cutting with the hole saw. Keep the drill or brace steady and perpendicular to the metal surface. Slowly increase the pressure as you progress, but be mindful not to push too hard to avoid overheating or breaking the hole saw. Remember to periodically remove metal shavings from the hole saw to prevent clogging.

- Finish the cut: Continue cutting until you have enlarged the hole to the desired size. Take breaks if needed to prevent overheating of the hole saw or the metal.

- Clean up: Once you have finished cutting, remove the hole saw from the drill or brace and clean up any remaining metal shavings or debris. Remove the masking tape from the surrounding area.

Using a hole saw is an effective method for enlarging holes in metal without a drill. However, it does require some practice and caution to ensure safe and accurate cuts. Always wear the appropriate safety gear and follow the manufacturer’s instructions and guidelines when using a hole saw.

Method 7: Using Chemical Etching

Chemical etching is a method used to remove material from a metal surface by using chemicals. This process can be used to enlarge holes in metal without the use of a drill.

Materials Needed:

- Chemical etching solution

- Applicator brush or sponge

- Protective gloves

- Safety goggles

- Masking tape

Steps:

- Prepare the metal surface by cleaning it thoroughly to remove any dirt, grease, or debris.

- Using masking tape, cover the areas around the hole that you want to enlarge to protect them from the chemical etching solution.

- Put on protective gloves and safety goggles to protect your hands and eyes from exposure to the chemicals.

- Apply the chemical etching solution to the hole using an applicator brush or sponge. Follow the instructions provided by the manufacturer for the correct application method and duration.

- Allow the chemical etching solution to work on the metal surface according to the recommended time provided by the manufacturer.

- After the recommended time has passed, rinse the metal surface thoroughly with water to remove any remaining chemical etching solution.

- Inspect the enlarged hole to ensure that it is the desired size. Repeat the process if further enlargement is required.

- Once the desired size is achieved, remove the masking tape and clean the metal surface again to remove any residue from the chemical etching process.

Important Note: Chemical etching can be a potentially hazardous process and should be performed with caution. It is essential to follow the safety precautions provided by the manufacturer of the chemical etching solution and to work in a well-ventilated area.

Method 8: Using a Plasma Cutter

A plasma cutter is a powerful tool that can be used to accurately and quickly enlarge holes in metal. It uses a high-temperature plasma arc to cut through various metals, making it an ideal choice for enlarging holes in metal.

Materials Needed:

- Plasma cutter

- Safety gloves and goggles

- Marker or scribe

- Clamps

Steps:

- Put on safety gloves and goggles to protect yourself from sparks and debris.

- Secure the metal piece with clamps to ensure it does not move during the cutting process.

- Identify the specific location where you want to enlarge the hole. Mark it with a marker or scribe.

- Adjust the settings on the plasma cutter according to the thickness of the metal and the desired size of the hole.

- Position the plasma cutter’s torch at the marked spot and start the cutting process.

- Move the plasma cutter’s torch along the marked line, slowly enlarging the hole as you go.

- Continue cutting until you have achieved the desired size of the hole.

- Turn off the plasma cutter and allow the metal to cool down before handling it.

Advantages of Using a Plasma Cutter:

- Highly accurate: Plasma cutters offer precise control over the cutting process, allowing you to create clean and accurate hole enlargements.

- Fast: Plasma cutters are known for their speed, making the hole enlargement process quick and efficient.

- Versatile: Plasma cutters can be used on a variety of metals, including steel, aluminum, and stainless steel.

- Minimal clean-up: The heat from the plasma cutter helps to minimize burrs and rough edges, reducing the need for extensive clean-up after the cutting process.

However, it is important to note that plasma cutters can be expensive and require proper training and safety precautions. Always follow the manufacturer’s guidelines and ensure you have the necessary skills and knowledge to operate a plasma cutter safely.

FAQ:

Is there any alternative method to enlarge holes in metal without using a drill?

Yes, there are several alternative methods that can be used to enlarge holes in metal without using a drill. These include using a reamer, a rotary file, a grinding wheel, a hole-saw blade, or a hand file.

What is a reamer?

A reamer is a tool that is used to enlarge holes in metal. It has a cutting edge on one end and a shank on the other end. The cutting edge is tapered and is used to gradually enlarge the hole to the desired size.

How does a rotary file work to enlarge holes in metal?

A rotary file, also known as a rotary burr, is a cutting tool that is used to remove material from a workpiece. It attaches to a rotary tool and spins at a high speed. When the file is pressed against the metal, it grinds away the material, effectively enlarging the hole.

Can a grinding wheel be used to enlarge holes in metal?

Yes, a grinding wheel can be used to enlarge holes in metal. To do this, you would need to hold the grinding wheel against the edge of the hole and move it back and forth. The grinding wheel will remove material from the metal, gradually making the hole larger.

What are the advantages and disadvantages of using alternative methods to enlarge holes in metal without a drill?

The advantages of using alternative methods include not needing a drill, which can be expensive and require electricity. Additionally, some alternative methods can provide more control and precision when enlarging holes. However, the disadvantages include the potential for slower and more labor-intensive work, as well as the need for additional tools and equipment.

Video: