Preventing Water Buildup in Your Air Compressor: A Comprehensive Guide

When it comes to operating an air compressor, one of the most common challenges is dealing with water buildup. Water can accumulate in the compressor tank and air lines, leading to a range of issues, including decreased efficiency, corrosion, and damage to tools and equipment. However, there are several effective methods you can employ to prevent water buildup and keep your air compressor running smoothly.

Regular Drainage: One of the simplest yet most crucial steps in preventing water buildup is to regularly drain the tank. As the compressor operates, it produces condensate, which collects in the tank. By draining this condensate before it has a chance to accumulate, you can significantly reduce the risk of water buildup. Make sure to follow the manufacturer’s instructions for proper drainage procedures.

Proper Ventilation: Another important aspect to consider is the ventilation of your compressor area. If your compressor is placed in a poorly ventilated area, excess heat and moisture can become trapped, leading to increased condensation. To prevent this, ensure that the compressor is situated in a well-ventilated space, away from any potential sources of moisture or heat.

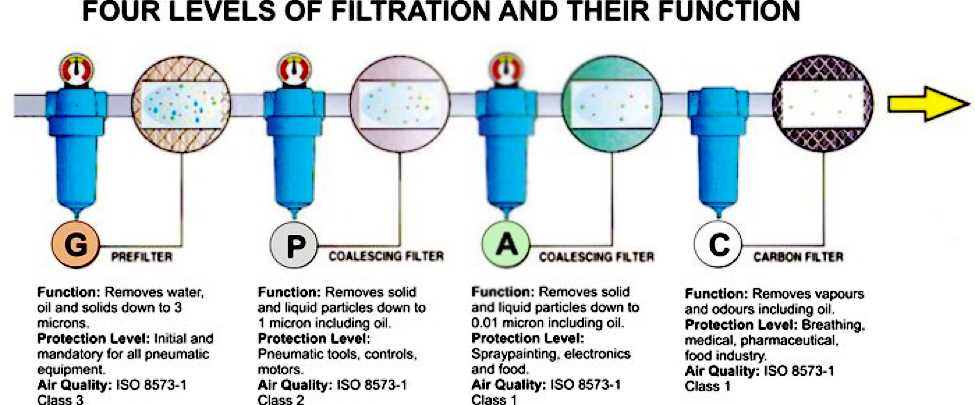

Effective Filtration: Investing in high-quality filtration equipment is essential for preventing water buildup in your air compressor. An efficient moisture separator and dryer will help remove moisture from the compressed air, preventing it from entering the tank and air lines. Regularly inspect and clean the filters to ensure optimal performance.

Proper Maintenance: Regular maintenance is key to ensuring your air compressor functions properly and remains free from water buildup. This includes checking and replacing worn-out components, inspecting for leaks, and lubricating moving parts. By following a comprehensive maintenance schedule, you can extend the lifespan of your compressor and mitigate the risk of water-related issues.

Utilize an Air Dryer: In cases where moisture buildup is a persistent problem, utilizing an air dryer is highly recommended. Air dryers effectively remove moisture from the compressed air, preventing it from condensing and causing water buildup. There are different types of air dryers available, including refrigerated, desiccant, and membrane dryers, each with their own advantages and applications.

In conclusion, water buildup in an air compressor can lead to various problems, but by implementing proper drainage, ventilation, filtration, maintenance, and utilizing an air dryer if necessary, you can effectively prevent water accumulation and ensure the optimal performance and longevity of your air compressor.

Troubleshooting Water Buildup in Air Compressors

1. Check for Leaks

One of the primary reasons for water buildup in air compressors is internal or external leaks. Inspect the entire system, including pipes, fittings, valves, and connections, for any signs of leakage. Listen for hissing sounds or feel for air escaping. Repair or replace any damaged or faulty components to prevent water buildup.

2. Drain the Tank Regularly

Water can accumulate in the air compressor’s tank over time, leading to increased water buildup. To prevent this, drain the tank regularly. Follow the manufacturer’s instructions for proper drainage procedures. This will remove any accumulated water and help maintain the efficiency of the compressor.

3. Install a Moisture Separator

A moisture separator is a device that helps separate water vapor from the compressed air. Install a high-quality moisture separator in your air compressor system to prevent water buildup. This will ensure that the air you receive is dry and free from moisture, protecting your tools and equipment from damage.

4. Use Refrigerated Air Dryers

A refrigerated air dryer is another effective solution for preventing water buildup in air compressors. These devices cool the compressed air, reducing its temperature and condensing the moisture. The condensed water can then be drained away from the compressor. Consider installing a refrigerated air dryer, especially if your compressor operates in high-humidity environments.

5. Check the Ambient Temperature

Extreme temperatures can also contribute to water buildup in air compressors. If the ambient temperature is too high, the compressed air is more likely to retain moisture. Ensure that your compressor is installed in a properly ventilated area and consider using additional cooling measures, such as fans or air conditioning, to maintain a suitable temperature.

6. Regular Maintenance and Inspections

Perform regular maintenance and inspections on your air compressor system to identify any potential issues that may cause water buildup. Regularly clean or replace filters, check for clogs or blockages, and lubricate moving parts as necessary. An efficient and well-maintained compressor is less likely to experience water buildup.

7. Adjust the Pressure

High-pressure settings can increase the likelihood of water buildup in air compressors. Check the pressure settings on your compressor and adjust them according to the recommended levels. Lowering the pressure can help decrease the amount of moisture held in the compressed air.

In conclusion, troubleshooting water buildup in air compressors involves checking for leaks, regular tank drainage, installing moisture separators and refrigerated air dryers, considering ambient temperature, performing regular maintenance, and adjusting the pressure settings. By following these steps, you can effectively prevent water buildup and ensure the optimal performance of your air compressor system.

Understanding the Importance of Preventing Water Buildup

1. Protecting Your Air Compressor:

Preventing water buildup is crucial in maintaining the performance and lifespan of your air compressor. When water accumulates in the compressor, it can cause corrosion, rust, and damage to the internal components. This can lead to decreased efficiency and potential breakdowns, resulting in costly repairs or replacement.

2. Ensuring Optimal Air Quality:

Water buildup in the air compressor can also affect the quality of the compressed air it produces. Moisture in the compressed air can lead to contamination, which can cause issues in various applications. For example, if you are using the air compressor in painting or pneumatic tools, water can mix with the paint or interfere with the tool’s functionality, leading to subpar results.

3. Preventing Water Contamination:

By preventing water buildup in the air compressor, you can avoid potential water contamination in your compressed air system. Water can carry contaminants such as dirt, oil, and other particles which can adversely affect the performance and lifespan of downstream equipment. This is especially important in industries where clean and dry compressed air is essential, such as food and beverage manufacturing or pharmaceuticals.

4. Enhancing Efficiency and Productivity:

Water buildup can also impact the efficiency and productivity of your air compressor. When moisture collects in the compressor, it creates additional resistance in the air flow, leading to increased energy consumption. This can result in higher operating costs and reduced productivity as the compressor works harder to compensate for the decreased efficiency.

5. Extending Maintenance Intervals:

Preventing water buildup can help extend the intervals between maintenance tasks on your air compressor. When water is present, it can lead to more frequent oil changes, filter replacements, and other maintenance activities. By keeping water out of the system, you can reduce the frequency of these tasks, saving time and resources in the long run.

In conclusion, preventing water buildup in your air compressor is essential for protecting the equipment, ensuring optimal air quality, preventing contamination, enhancing efficiency and productivity, and extending maintenance intervals. Implementing proper water drainage and filtration systems will help you achieve these benefits and prolong the lifespan of your air compressor.

Choosing the Right Location for Your Air Compressor

Considerations for selecting the location

When choosing a location for your air compressor, there are several factors to take into consideration. The following are some important points to think about:

- Accessibility: Ensure that the location provides easy access to the air compressor. This will make it easier for maintenance and repairs, as well as for operating the equipment.

- Ventilation: It is crucial to place the air compressor in a well-ventilated area. Proper ventilation will prevent the buildup of heat and maintain the optimal operating temperature of the compressor.

- Temperature: Avoid locating the air compressor in extreme temperature conditions, such as areas with high humidity or extreme cold. These conditions can negatively affect the performance and lifespan of the compressor.

- Noise: Consider the noise level produced by the air compressor and choose a location that minimizes the impact on the surrounding environment or working areas.

- Power supply: Ensure that the chosen location has a reliable power supply that can adequately support the electrical requirements of the air compressor.

- Space: Make sure to allocate enough space for the compressor to operate safely and efficiently. Leave sufficient room for airflow and maintenance tasks.

Recommended locations

Based on the considerations above, here are some recommended locations for your air compressor:

- Garage or workshop: These indoor spaces often provide good accessibility, ventilation, and power supply options. They can also be easily adapted to accommodate the noise and space requirements.

- Equipment room: If available, an equipment room can be an ideal location for the air compressor. These rooms are typically well-ventilated, have controlled temperatures, and are designed to handle the noise and power requirements of various equipment.

- Outdoor shed or enclosure: If a suitable indoor location is not available, consider installing the air compressor in a well-protected outdoor shed or enclosure. Ensure that the structure offers protection from the elements and is properly insulated.

In conclusion, choosing the right location for your air compressor is crucial for its longevity and efficient operation. Consider the various factors discussed above and select a location that meets the specific requirements of your compressor and work environment.

Installing an Effective Drainage System

When it comes to preventing water buildup in your air compressor, installing an effective drainage system is crucial. Without a proper drainage system, water can accumulate within the compressor tank, leading to potential damage and reduced performance.

Choosing the Right Drain Valve

To install an effective drainage system, start by selecting the right drain valve. There are several types of drain valves available, including manual valves, automatic valves, and electronic valves. Manual valves require manual operation to release the accumulated water, while automatic valves have a built-in mechanism that releases water periodically. Electronic valves can be controlled remotely, allowing for convenient and precise drainage.

Positioning the Drain Valve

Once you have chosen the appropriate drain valve, it is important to position it correctly. The drain valve should be placed at the lowest point of the compressor tank to ensure that all the water is fully drained. This will help prevent any residual water from causing corrosion or other damage to the tank or other components.

Implementing Regular Maintenance

An effective drainage system is not just about the initial installation; it also requires regular maintenance. It is recommended to inspect and test the drainage system periodically to ensure its proper functioning. This includes checking for any leaks, cleaning the drain valve, and addressing any issues that may arise.

Additionally, it is important to consider the environmental impact of the drained water. If the drained water contains oil or other contaminants, it should be properly collected and disposed of following local regulations and guidelines.

In conclusion, installing an effective drainage system is crucial for preventing water buildup in your air compressor. By choosing the right drain valve, positioning it correctly, and implementing regular maintenance, you can ensure that your compressor functions optimally and avoids potential damage caused by water accumulation.

Regularly Checking and Maintaining Your Compressor’s Air Filters

One important aspect of preventing water buildup in your air compressor is regularly checking and maintaining its air filters. Air filters play a crucial role in keeping the air clean and free from contaminants that can contribute to water accumulation. By ensuring the filters are in good condition, you can help prolong the lifespan of your compressor and improve its overall performance.

Inspecting the Air Filters

To begin, start by inspecting the air filters for any signs of dirt, dust, or debris buildup. Over time, these particles can clog the filters and restrict proper airflow, leading to decreased efficiency and potential water accumulation. Use a flashlight to examine the filters closely, looking for any visible signs of contamination.

Cleaning or Replacing the Filters

If you notice significant dirt or debris on the filters, it’s time to clean or replace them. Cleaning can often be done by gently tapping the filters to remove loose particles or by using compressed air to blow away any trapped debris. However, if the filters are heavily soiled or damaged, it’s best to replace them with new ones to ensure optimal performance. Refer to the manufacturer’s instructions for the specific cleaning or replacement procedures for your compressor’s air filters.

Regular Filter Maintenance Schedule

To maintain the efficiency and effectiveness of your air compressor, it’s essential to establish a regular filter maintenance schedule. How often you should check and clean or replace the filters will depend on various factors such as the operating conditions, environment, and usage frequency of your compressor. However, a general guideline is to inspect the filters at least once a month and clean or replace them as needed.

By regularly checking and maintaining your compressor’s air filters, you can ensure optimal airflow, prevent contaminants from entering the system, and reduce the risk of water buildup. This simple maintenance task can go a long way in prolonging the life and improving the performance of your air compressor.

Using a High-Quality Air Dryer

One effective way to prevent water buildup in your air compressor is by using a high-quality air dryer. An air dryer is a device that removes moisture from the compressed air, ensuring that only dry air flows through the system.

A high-quality air dryer uses various methods to remove moisture from the compressed air. One common method is through refrigeration. The air is cooled down, causing the moisture to condense and separate from the air. The condensed water is then drained from the system, leaving only dry air behind.

Another method used by air dryers is desiccant drying. This involves passing the compressed air through a desiccant material, which adsorbs the moisture from the air. The desiccant material can be silica gel, activated alumina, or other drying agents. Periodically, the desiccant material needs to be regenerated or replaced to maintain its effectiveness.

Using a high-quality air dryer not only helps prevent water buildup in your air compressor but also improves the overall quality of the compressed air. Dry air is essential for many applications where moisture can cause damage or affect performance, such as painting, pneumatic tools, and instrument air systems.

When choosing an air dryer, it is important to consider the air flow rate and the level of moisture removal needed for your specific application. Additionally, regular maintenance and monitoring of the air dryer are necessary to ensure optimal performance and prevent potential issues.

Implementing Proper Compressor Shutdown Procedures

Properly shutting down your air compressor is essential for preventing water buildup and maintaining its efficiency. Follow these steps to implement the correct shutdown procedures:

1. Release Pressure

Before shutting down your compressor, release the pressure in the system. This will help prevent any potential water buildup and ensure a safe shutdown. To release the pressure, turn off the power to the compressor and open the drain valve to release any excess air.

2. Drain Moisture

After releasing the pressure, it is important to drain any moisture that may have accumulated in the system. This can be done by opening the drain valve and allowing the moisture to drain out completely. Make sure to do this regularly to prevent water buildup.

3. Check for Leaks

While shutting down the compressor, take the opportunity to check for any leaks in the system. Inspect all connections, hoses, and fittings for any signs of leakage. Addressing leaks promptly will prevent water buildup and ensure the efficiency of your compressor.

4. Clean and Maintain

Regular cleaning and maintenance are crucial for preventing water buildup in your air compressor. Clean the filters, oil separators, and other components regularly as per the manufacturer’s instructions. This will help maintain the proper functioning of your compressor and reduce the risk of water accumulation.

Implementing these proper shutdown procedures will help prevent water buildup in your air compressor and ensure its optimal performance. Make it a routine to follow these procedures regularly to maintain the efficiency and longevity of your compressor.

Considering External Factors That Contribute to Water Buildup

Humidity

One external factor that can contribute to water buildup in your air compressor is humidity. Humidity refers to the amount of moisture present in the air. When the air is humid, it contains more water vapor, which can condense and accumulate in the compressor tank. This can lead to water buildup and affect the performance of your air compressor.

Ambient Temperature

The ambient temperature can also play a role in water buildup. When the temperature drops, the air becomes cooler and has a lower capacity to hold moisture. As a result, water vapor can condense more easily and accumulate in the compressor tank. It is important to monitor the ambient temperature and take appropriate measures to prevent water buildup.

Air Quality

The quality of the air entering the compressor can also contribute to water buildup. If the air contains a high concentration of moisture or contaminants, such as oil or dust, it can increase the likelihood of water condensation. Using proper filtration systems and regularly maintaining the compressor can help reduce these external factors and prevent water buildup.

Compressor Placement

The placement of the air compressor itself can also affect water buildup. If the compressor is located in a damp or humid area, it is more likely to accumulate moisture. Additionally, if the compressor is placed in an area with poor air circulation, it can hinder the evaporation of moisture and lead to water buildup. It is important to consider the environment in which the compressor is placed and take appropriate measures to mitigate these factors.

Condensate Drainage

The effectiveness of the condensate drainage system can play a crucial role in preventing water buildup. If the drainage system is not properly installed or maintained, it can lead to water accumulation in the compressor tank. Regularly checking and cleaning the drainage system can help ensure its proper functioning and prevent potential issues related to water buildup.

By considering these external factors and taking appropriate measures, you can effectively prevent water buildup in your air compressor and maintain its optimal performance.

FAQ:

Why is water buildup in an air compressor a problem?

Water buildup in an air compressor can cause corrosion and damage to the compressor and other equipment. It can also affect the quality of compressed air and decrease the efficiency of the compressor.

How does water get into an air compressor?

Water can enter an air compressor through the intake air, as moisture in the ambient air is compressed. It can also come from the condensation of moisture within the compressor itself.

What are some signs of water buildup in an air compressor?

Some signs of water buildup in an air compressor include decreased performance, water or moisture in the compressed air, and rust or corrosion in the compressor or attached equipment.

What are the different methods to prevent water buildup in an air compressor?

There are several methods to prevent water buildup in an air compressor. These include using an air dryer or moisture separator, draining the compressor regularly, maintaining proper ventilation, and using ambient air heaters or coolers.

How often should I drain my air compressor to prevent water buildup?

The frequency of draining an air compressor depends on various factors, such as the compressor’s usage and operating conditions. It is generally recommended to drain the compressor at least once a day or as needed to remove any accumulated water.

Can I use a moisture separator alone to prevent water buildup in my air compressor?

Using a moisture separator alone may not be sufficient to prevent water buildup in an air compressor. It is often recommended to use additional methods, such as an air dryer or regularly draining the compressor, for more effective water removal.

Video: