How Does a Portable Air Compressor Work?

A portable air compressor is a versatile machine that is used to power various tools and equipment. It is a compact and lightweight device that can be easily transported from one location to another. But how exactly does a portable air compressor work?

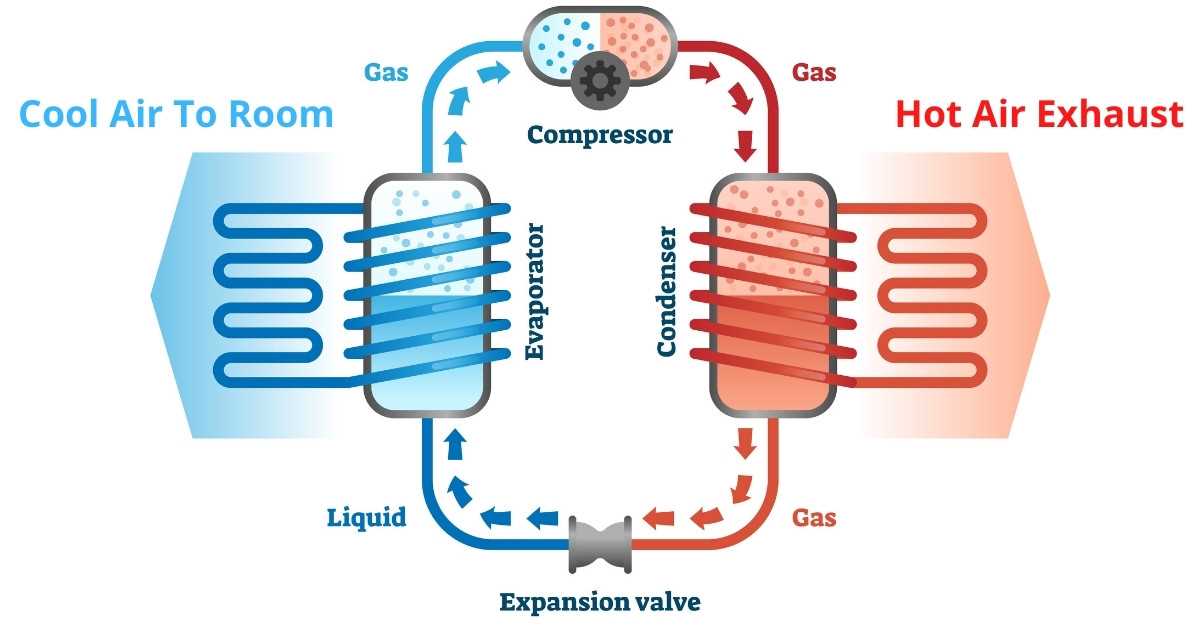

At its core, a portable air compressor consists of an electric or gas-powered motor that drives a piston or a rotary screw. This motor compresses and pressurizes the surrounding air, which is then stored in a tank. The compressed air can later be released through a hose, allowing it to power pneumatic tools, inflate tires, or perform other air-powered tasks.

The compression process begins with the motor turning on and driving the piston or rotary screw. As the piston or screw moves, it decreases the volume of the air, causing its pressure to increase. This compressed air is then forced into the storage tank, where it builds up until it reaches a predetermined pressure level.

When the pressure in the tank surpasses a certain threshold, a pressure switch turns off the motor to prevent over-compression. At this point, the compressed air is ready for use. By connecting a tool or equipment to the hose, the compressed air can be directed to perform a specific task, such as operating a nail gun or inflating a tire.

Overall, a portable air compressor operates by converting electrical or fuel energy into mechanical energy, which is then used to compress and store air. Its portability and versatility make it an essential tool for a wide range of applications, from construction sites to automotive repairs.

Main Components of a Portable Air Compressor

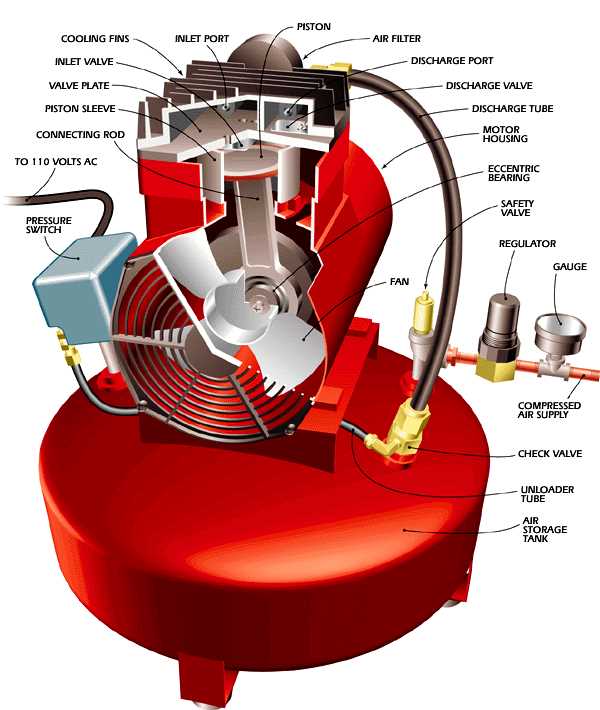

Portable air compressors are versatile tools that are used in various industries and applications. They consist of several main components that work together to compress and store air for use in different tasks. These components include:

1. Motor or Engine

The motor or engine is the power source of the portable air compressor. It supplies the energy needed to drive the compression process. Portable air compressors can be powered by electric motors or gasoline engines, depending on the specific model. The motor or engine converts electrical or chemical energy into mechanical energy to operate the compressor.

2. Air Tank

The air tank is an essential component of a portable air compressor. It is a storage vessel that holds the compressed air generated by the compressor. The tank allows for the accumulation of compressed air, which can then be released at a controlled pressure when needed. The size of the air tank varies depending on the application and desired capacity.

3. Compressor Pump

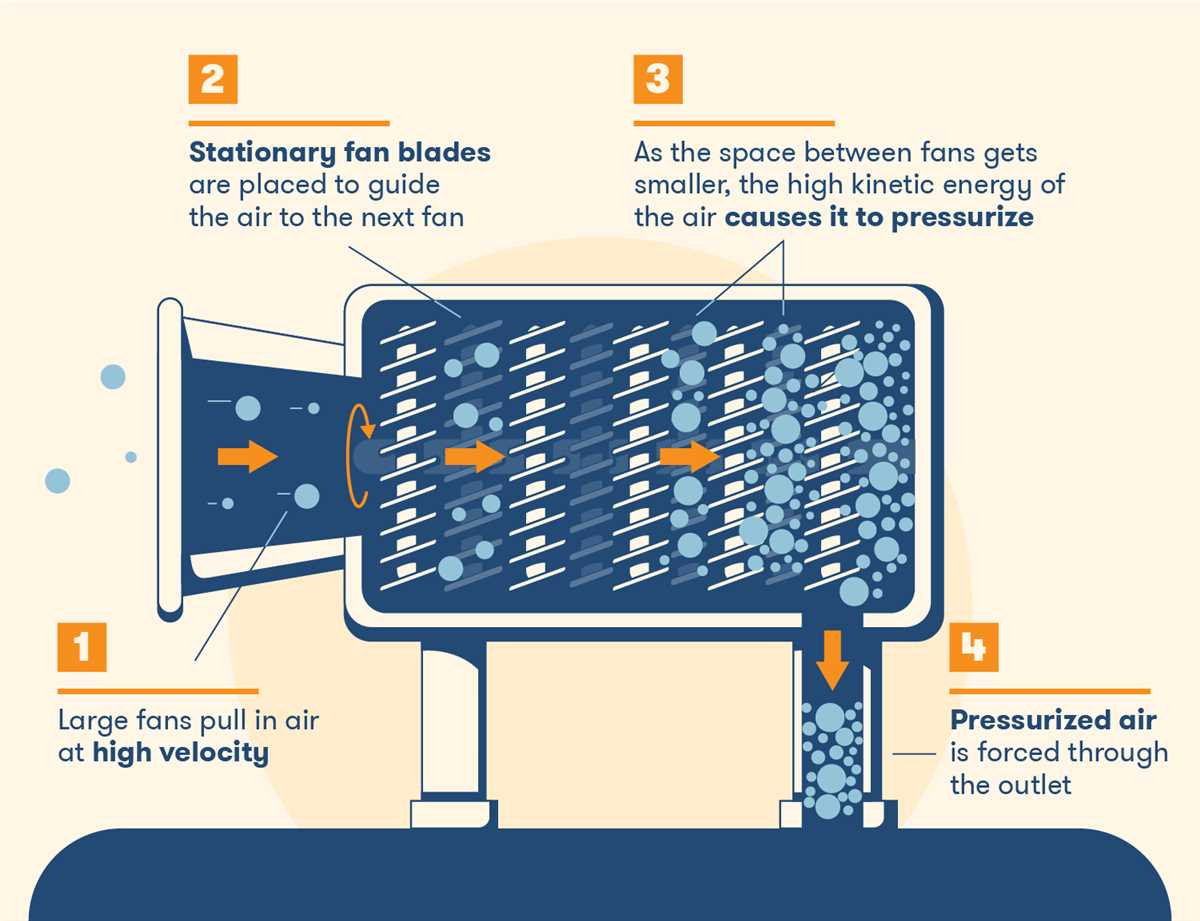

The compressor pump is responsible for compressing the ambient air and delivering it to the air tank. It creates a high-pressure environment by reducing the volume of air, forcing it into a smaller space. The compressor pump can be of different types, such as reciprocating, rotary screw, or centrifugal, depending on the intended use and performance requirements.

4. Pressure Switch

The pressure switch is a safety device that monitors the air pressure inside the tank. It automatically turns the compressor on when the pressure drops below a certain level and shuts it off when the desired pressure is reached. This helps maintain a steady supply of compressed air and prevents over-pressurization of the tank.

5. Regulator

The regulator is a control valve that regulates the pressure of the compressed air before it is released from the tank. It allows the user to adjust the pressure according to the specific requirements of the task at hand. The regulator ensures that the compressed air is delivered at a consistent and controlled pressure, preventing damage to tools or equipment.

These main components work together harmoniously to enable the operation of a portable air compressor. Each component plays a crucial role in the compression and delivery of compressed air, making portable air compressors reliable and efficient tools for various applications.

Working Principle behind Portable Air Compressors

A portable air compressor is a device that converts power from a gasoline engine or an electric motor into potential energy stored in compressed air. It works on a simple principle: air is sucked in from the surroundings and compressed using mechanical force, resulting in an increase in pressure and a decrease in volume.

Portable air compressors typically consist of a motor or engine, an air tank, and various valves and pistons. The motor or engine provides the power needed to drive the compressor, while the air tank acts as a storage vessel for the compressed air.

The working principle of a portable air compressor involves several key steps:

- Air intake: The compressor draws in air from the surrounding environment through an intake valve or filter.

- Compression: The intake air is then compressed using mechanical force generated by pistons or rotors. As the pistons move back and forth, the air is squeezed, reducing its volume and increasing its pressure.

- Air storage: The compressed air is stored in the air tank, where it can be accessed when needed for various applications.

- Release of air: When compressed air is required, it is released from the tank through a valve, which allows it to flow out and power tools or equipment.

- Pressure regulation: Portable air compressors are equipped with pressure regulators that control the output pressure of the compressed air, ensuring it remains within a desired range.

Overall, the working principle behind portable air compressors relies on the conversion of mechanical energy into compressed air, which can then be used for a wide range of applications such as inflating tires, powering pneumatic tools, and operating machinery.

Types of Portable Air Compressors

There are several different types of portable air compressors available on the market. Each type has its own unique features and benefits, making them suitable for different applications. Here are some of the most common types of portable air compressors:

1. Pancake Compressors

Pancake compressors are compact and lightweight, making them easy to transport and store. They have a flat, round-shaped tank that resembles a pancake, hence the name. These compressors are usually oil-free and provide enough power for small to medium-sized tasks, such as inflating tires or operating small air tools.

2. Hot Dog Compressors

Hot dog compressors are similar to pancake compressors in terms of size and portability. They have a cylindrical horizontal tank, resembling a hot dog. These compressors are generally more powerful than pancake compressors and can handle larger jobs. They are commonly used in construction and woodworking applications.

3. Twin-Stack Compressors

Twin-stack compressors are designed with two horizontal cylinders and two air tanks, stacked on top of each other. This type of compressor can store more compressed air than pancake or hot dog compressors, allowing for longer run times. Twin-stack compressors are ideal for jobs that require continuous operation, such as powering pneumatic tools on a work site.

4. Wheelbarrow Compressors

Wheelbarrow compressors are larger and heavier than the previous types mentioned, but they are still portable due to their built-in wheels and handles. These compressors have a horizontal tank and are commonly used for construction and contractor applications. They provide greater power and can handle heavier-duty tasks.

5. Inflators

Inflators are compact and lightweight air compressors designed specifically for inflating tires, sports equipment, and other inflatable items. They are usually cordless and operate on batteries or a 12V DC power source, making them highly portable. Inflators are a convenient option for quick inflation needs on the go.

Overall, when choosing a portable air compressor, consider the intended application and the required power output to determine which type would best suit your needs.

Applications of Portable Air Compressors

Tire Inflation

A portable air compressor is commonly used for tire inflation. Whether it’s a car, bike, or any other vehicle, having properly inflated tires is essential. Portable air compressors can easily be carried in the trunk of a car or stored in a garage, making them convenient and accessible for inflating tires whenever needed.

Powering Pneumatic Tools

Portable air compressors are also used to provide power to pneumatic tools. Pneumatic tools, such as nail guns, drills, and impact wrenches, rely on compressed air to operate. A portable air compressor can easily supply the necessary air pressure for these tools, making them a valuable asset for construction sites, workshops, and DIY projects.

Cleaning and Dusting

Another application of portable air compressors is in cleaning and dusting tasks. With the help of appropriate attachments or nozzles, the compressed air from a portable air compressor can be used to blow away dust, debris, and particles from hard-to-reach areas. This makes it useful for cleaning electronic devices, computer keyboards, car interiors, and workshop surfaces.

Painting and Finishing

Portable air compressors are commonly used in painting and finishing tasks. Compressed air can be used to power paint guns, allowing for efficient and even application of paints and coatings. Whether it’s for automotive painting, furniture refinishing, or artwork, a portable air compressor is an essential tool for achieving professional results.

Outdoor Activities

Portable air compressors also find applications in outdoor activities. They can be used to inflate sporting equipment like balls, inflatable boats, and air mattresses. Additionally, portable air compressors can be used for powering air tools in outdoor settings, such as camping, RVing, and off-roading.

In conclusion, portable air compressors have a wide range of applications ranging from tire inflation and powering pneumatic tools to cleaning and dusting tasks. They are also useful in painting and finishing operations as well as outdoor activities. Their compact size and portability make them versatile and convenient tools for various tasks and settings.

Benefits of Using a Portable Air Compressor

Convenience

One of the major benefits of using a portable air compressor is its convenience. Compared to larger, stationary compressors, portable air compressors are lightweight and easy to carry around. They can be easily transported from one location to another, making them ideal for use in different settings such as construction sites, workshops, and even for personal use at home.

Versatility

Portable air compressors are highly versatile and can be used for a wide range of tasks. They can inflate tires, power pneumatic tools, blow dust and debris, and even spray paint. This versatility makes them a practical and efficient tool for various applications, saving both time and effort.

Energy Efficiency

Portable air compressors are designed to be energy-efficient, making them suitable for long periods of continuous use. They have built-in mechanisms that regulate air output, ensuring that each task is performed with the most efficient use of energy. This not only helps to save electricity but also reduces overall operational costs in the long run.

Space-saving

Compared to larger air compressors, portable ones take up less space and are easier to store. They can be easily stored in a garage, workshop, or even in the trunk of a car. This space-saving feature is especially useful for those with limited storage space or who frequently move their tools from one location to another.

Increased Productivity

With the ability to quickly inflate tires, power tools, and perform various tasks, portable air compressors significantly increase productivity. They eliminate the need for manual labor and speed up the completion of projects, allowing users to accomplish more in less time.

In conclusion, the benefits of using a portable air compressor include convenience, versatility, energy efficiency, space-saving, and increased productivity. Whether it’s for professional use or personal projects, a portable air compressor is a valuable investment that offers a range of practical advantages.

Maintenance and Troubleshooting Tips for Portable Air Compressors

Regular Maintenance

Regular maintenance is crucial for keeping your portable air compressor in optimal working condition. Here are some maintenance tips to follow:

- Check the oil level regularly and top it up if necessary. Consult the manufacturer’s guidelines for the type of oil to use.

- Clean or replace the air filter as recommended by the manufacturer. A dirty air filter can limit airflow and reduce the efficiency of the compressor.

- Inspect the belts for any signs of wear or damage. Replace them if necessary to prevent belt slippage and ensure proper compression.

- Inspect the hoses for any leaks or cracks. Tighten the connections or replace the hoses if needed to maintain airtightness.

Troubleshooting Common Issues

If you encounter any issues with your portable air compressor, here are some troubleshooting tips to help you identify and fix the problem:

- If the compressor does not start, check if it is properly connected to a power source. Ensure that the power switch is turned on and that the circuit breaker is not tripped.

- If the compressor is running but not producing enough pressure, check the air filter for clogs or replace it if necessary. Also, inspect the discharge valve for any obstructions and make sure it is fully closed.

- If the compressor is running but intermittently cutting out, it may be due to a faulty pressure switch. Check the switch for any signs of damage or wear and replace it if needed.

- If the compressor is excessively noisy, it could indicate a problem with the bearings or other internal components. In this case, it is best to consult a professional for repair or replacement.

Safety Precautions

When performing maintenance or troubleshooting on your portable air compressor, it is important to prioritize safety. Here are some safety precautions to keep in mind:

- Always disconnect the compressor from the power source before conducting any maintenance or repairs.

- Wear appropriate safety gear, such as gloves and safety glasses, to protect yourself from potential injuries.

- Follow the manufacturer’s instructions and guidelines provided in the user manual.

- If you are unsure about any aspect of maintenance or troubleshooting, it is best to consult a professional or contact the manufacturer for assistance.

By following these maintenance and troubleshooting tips, you can enhance the longevity and performance of your portable air compressor, ensuring it remains a reliable tool for your various inflation and pneumatic needs.

Choosing the Right Portable Air Compressor for Your Needs

When it comes to choosing a portable air compressor, it’s important to consider your specific needs and requirements. There are several factors to take into account before making a purchase, such as the intended use, power source, and capacity of the compressor.

Identify Your Intended Use

First and foremost, you should determine what you will be using the air compressor for. Are you planning to use it for inflating tires, powering air tools, or for other applications? Understanding your intended use will help you determine the necessary power and capacity requirements.

Choose the Right Power Source

Portable air compressors can be powered by electricity, gasoline, or batteries. Each power source has its own advantages and limitations. Electric compressors are usually more convenient and easier to use, but require a nearby power outlet. Gasoline-powered compressors offer increased portability but may produce more noise and require regular fuel refills. Battery-powered compressors provide ultimate portability but typically have lower power and capacity.

Determine the Required Capacity

The capacity of an air compressor is often measured in terms of CFM (cubic feet per minute) or PSI (pounds per square inch). CFM refers to the amount of air the compressor can deliver at a given pressure, while PSI indicates the maximum pressure that the compressor can generate. Determining the required capacity will depend on the specific tools or equipment you plan to use with the compressor.

It’s important to carefully evaluate your needs and consider the features and specifications of various portable air compressors before making a decision. Additionally, reading reviews and seeking recommendations from professionals in the field can help you make an informed choice that best suits your requirements.

Tips for Efficient and Safe Use of Portable Air Compressors

A portable air compressor is a versatile tool that can be used for various tasks, from inflating tires to powering pneumatic tools. To ensure efficient and safe use of a portable air compressor, here are some tips to keep in mind:

1. Read the User Manual

Before using a portable air compressor, make sure to carefully read the user manual provided by the manufacturer. The manual will contain important instructions on how to operate the compressor safely, as well as maintenance tips and troubleshooting guidelines.

2. Check for Proper Ventilation

When using a portable air compressor, it is important to ensure that it is placed in a well-ventilated area. Compressors generate heat during operation, and proper ventilation will help dissipate the heat and prevent the compressor from overheating.

3. Use the Right Accessories

Using the right accessories, such as hoses and fittings, is crucial for the efficient operation of a portable air compressor. Make sure to use accessories that are compatible with your compressor and that can handle the required pressure and flow rate.

4. Regularly Inspect and Maintain

To ensure the safe and efficient performance of a portable air compressor, it is important to regularly inspect and maintain it. Check for any signs of damage or wear, such as leaks or worn-out components, and address them promptly. Regularly clean the compressor and replace any necessary filters or oil.

5. Monitor the Pressure

When using a portable air compressor, it is essential to monitor the pressure and adjust it as needed. Do not exceed the maximum recommended pressure, as this can cause damage to the compressor or the tools being used. Use a pressure gauge to accurately measure the pressure and make adjustments accordingly.

6. Use Safety Precautions

When operating a portable air compressor, it is important to use proper safety precautions. Wear safety glasses and hearing protection, as compressors can generate noise and projectiles. Keep a safe distance from the compressor to avoid any potential hazards, and avoid pointing the air stream at yourself or others.

By following these tips, you can ensure the efficient and safe use of your portable air compressor, extending its lifespan and maximizing its performance.

FAQ:

What is a portable air compressor?

A portable air compressor is a device that uses an electric motor or an engine to compress and store air in a tank. It is designed to be easily transported and used in various applications that require compressed air.

How does a portable air compressor work?

A portable air compressor works by drawing air into the intake valve, where it is then compressed by a piston or a rotating screw. This compressed air is then stored in a tank, ready to be used for various applications such as inflating tires or powering pneumatic tools.

What are the main components of a portable air compressor?

The main components of a portable air compressor include an electric motor or an engine, an intake valve, a compression mechanism (such as a piston or a screw), a tank to store the compressed air, and various controls such as pressure gauges and regulators.

What are the advantages of using a portable air compressor?

There are several advantages of using a portable air compressor. Firstly, it allows for increased mobility and flexibility in various applications. Secondly, it provides a reliable source of compressed air for tasks such as inflating tires or powering pneumatic tools. Additionally, portable air compressors are often more affordable and easier to maintain compared to larger stationary models.

Video: