Choosing the Right Size Air Compressor Hose: Everything You Need to Know

When it comes to operating an air compressor, the right size air compressor hose is crucial for optimal performance. An air compressor hose acts as a vital link between the compressor and the air tools, making it essential to choose the correct size for your needs. Whether you are a professional contractor or a DIY enthusiast, understanding the key factors to consider when selecting an air compressor hose can help you achieve the best results.

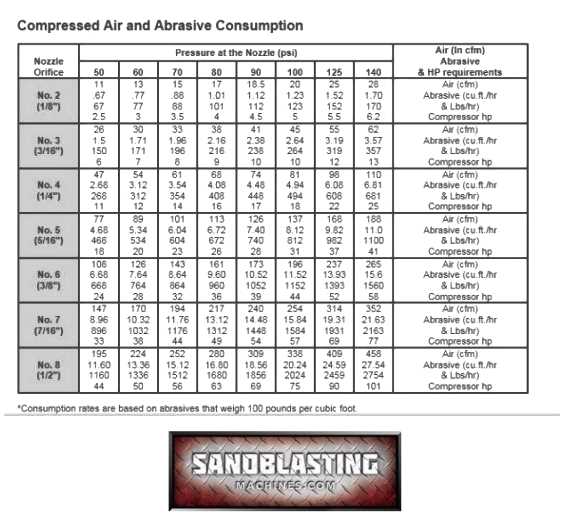

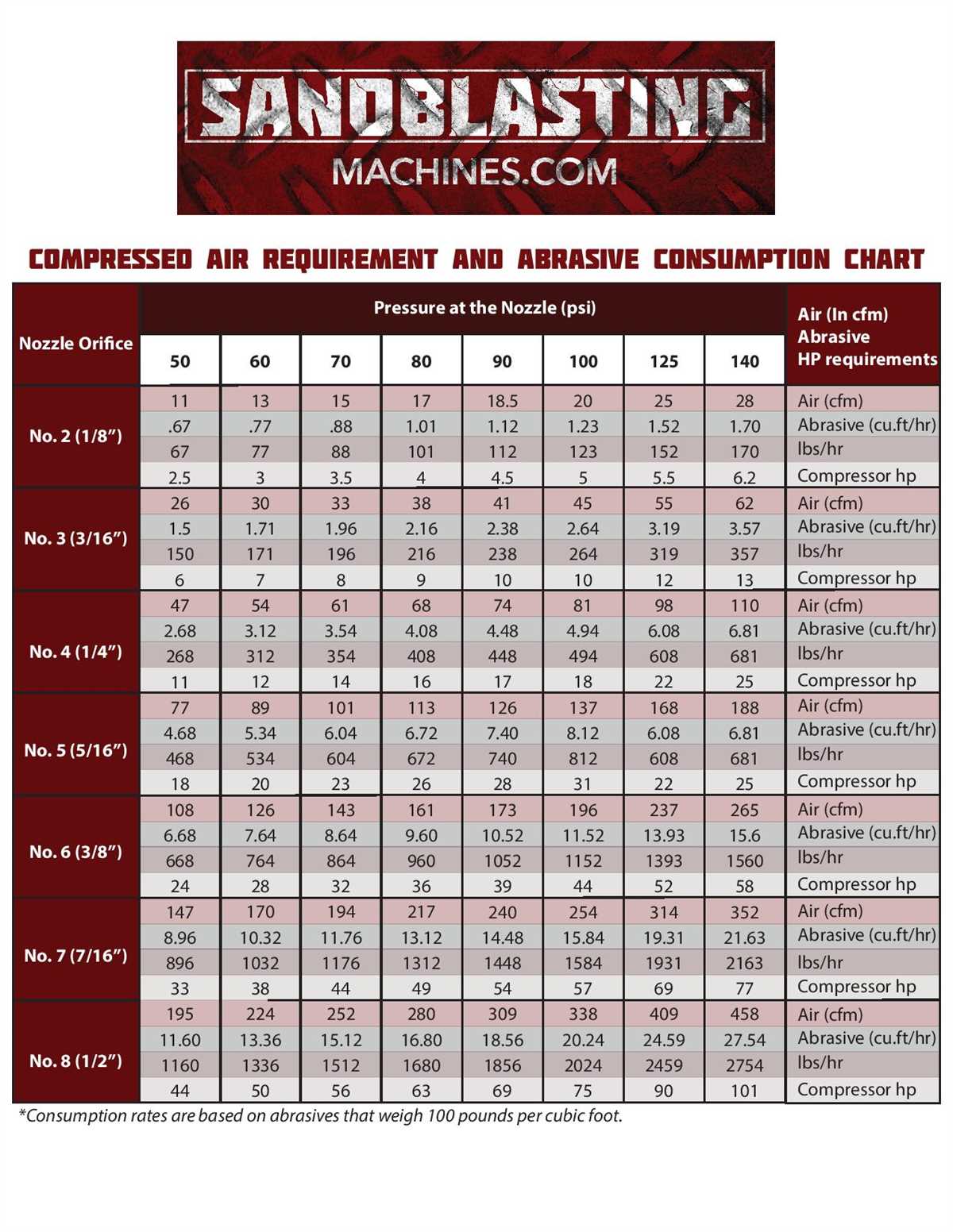

One of the main considerations when choosing an air compressor hose is the diameter. The diameter of the hose affects the overall airflow and pressure that can be delivered to your air tools. A larger diameter hose allows for greater airflow and is ideal for applications that require high volumes of compressed air, such as sandblasting or spray painting. On the other hand, a smaller diameter hose is suitable for applications that require less airflow, such as inflating tires or using a pneumatic staple gun.

Another important factor to consider when selecting an air compressor hose is the length. The length of the hose needed will depend on your specific needs and the distance between the compressor and the tools you plan to use. It’s important to choose a hose that is long enough to reach your desired work area without being too long, as longer hoses can result in pressure drops and loss of performance. Additionally, longer hoses can be more difficult to maneuver and store.

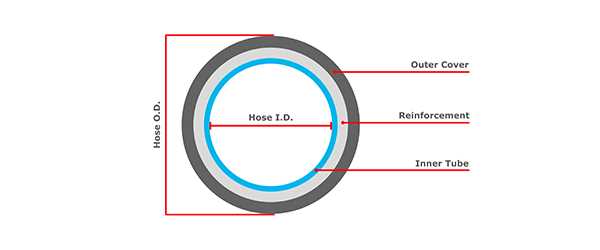

In addition to diameter and length, other factors to consider when choosing an air compressor hose include the material and flexibility. The material of the hose determines its durability and resistance to wear and tear. It’s essential to choose a hose made of high-quality materials that can withstand the demands of your intended applications. Flexibility is another important factor to consider, as a flexible hose allows for easy movement and reduces the risk of kinking and tangling, ensuring a smooth and uninterrupted flow of compressed air.

Importance of Choosing the Correct Size Hose

The size of the air compressor hose is an important factor to consider when choosing the right one for your needs. Using the correct size hose not only ensures optimal performance but also safeguards against potential damage to the air compressor and other tools.

Efficient Air Flow: Selecting a hose that matches the air compressor’s maximum psi (pounds per square inch) rating allows for efficient air flow. When the hose is too small, it may restrict the airflow, resulting in reduced pressure and slower operation of air tools. On the other hand, if the hose is too large, it can lead to excessive pressure drop, wasting energy and reducing the overall efficiency of the system.

Avoiding Pressure Loss: Using the correct size of hose helps prevent pressure loss during operation. Pressure loss occurs when air encounters resistance as it flows through the air compressor and the hose. If the hose is too small, the air will experience greater resistance, leading to pressure loss. This can affect the performance of air tools, causing them to operate below their optimal capacity.

Preventing Damage: Choosing the right size of hose is crucial to safeguarding the air compressor and other tools from potential damage. When the hose is too small, the air compressor will have to work harder to maintain the required pressure, which can lead to overheating and premature wear. Conversely, if the hose is too large, it can cause excessive vibrations and strain on the air compressor, potentially causing damage.

Ensuring Safety: Using the correct size hose is also important for safety reasons. A hose that is either too small or too large may not be able to handle the required airflow, causing it to burst or leak. This can result in accidents and injuries to the operator or damage to nearby equipment. Selecting the appropriate size hose helps ensure a safe and reliable operation.

Overall, choosing the correct size of air compressor hose is essential for achieving optimal performance, preventing pressure loss, protecting the equipment, and ensuring safety. It is recommended to consult the manufacturer’s guidelines and consider factors such as maximum psi rating, airflow requirements, and the specific application when selecting the right size hose for your air compressor.

Factors to Consider

When choosing the right size air compressor hose, there are several factors to consider that can help ensure optimal performance and efficiency.

Diameter

The diameter of the hose is one of the most important factors to consider. A larger diameter allows for more air flow and reduces pressure drop. However, a larger diameter hose can also be heavier and more cumbersome to use. It is important to strike a balance between air flow and ease of use.

Length

The length of the hose is another critical factor to consider. A longer hose will have more resistance and pressure drop, which can reduce the overall efficiency of the air compressor. On the other hand, a shorter hose may limit mobility and restrict the range of the air compressor. It is important to choose a hose length that suits the specific needs of your application.

Material

The material of the hose is also an important consideration. Air compressor hoses are typically made of rubber, PVC, or polyurethane. Rubber hoses are durable and can withstand high temperatures, but they are also heavier and less flexible. PVC hoses are lightweight and flexible, but they may not be able to handle as high temperatures. Polyurethane hoses offer a good balance of durability, flexibility, and temperature resistance.

Pressure Rating

The pressure rating of the hose is another important factor to consider. It is important to choose a hose with a pressure rating that is higher than the maximum pressure of your air compressor. This will ensure that the hose can handle the pressure without any issues and minimize the risk of accidents or damage.

Usage

Finally, it is crucial to consider the specific usage of the air compressor hose. Different applications may have different requirements in terms of air flow, pressure, and temperature. For example, a pneumatic tool may require a higher air flow and pressure than a simple inflator. Understanding your specific usage requirements will help you choose the right size hose for your needs.

Understanding the Pressure and Volume Requirements

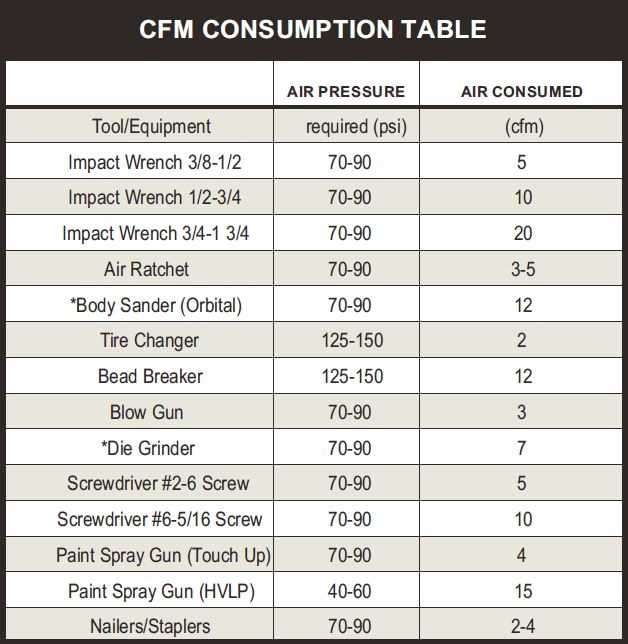

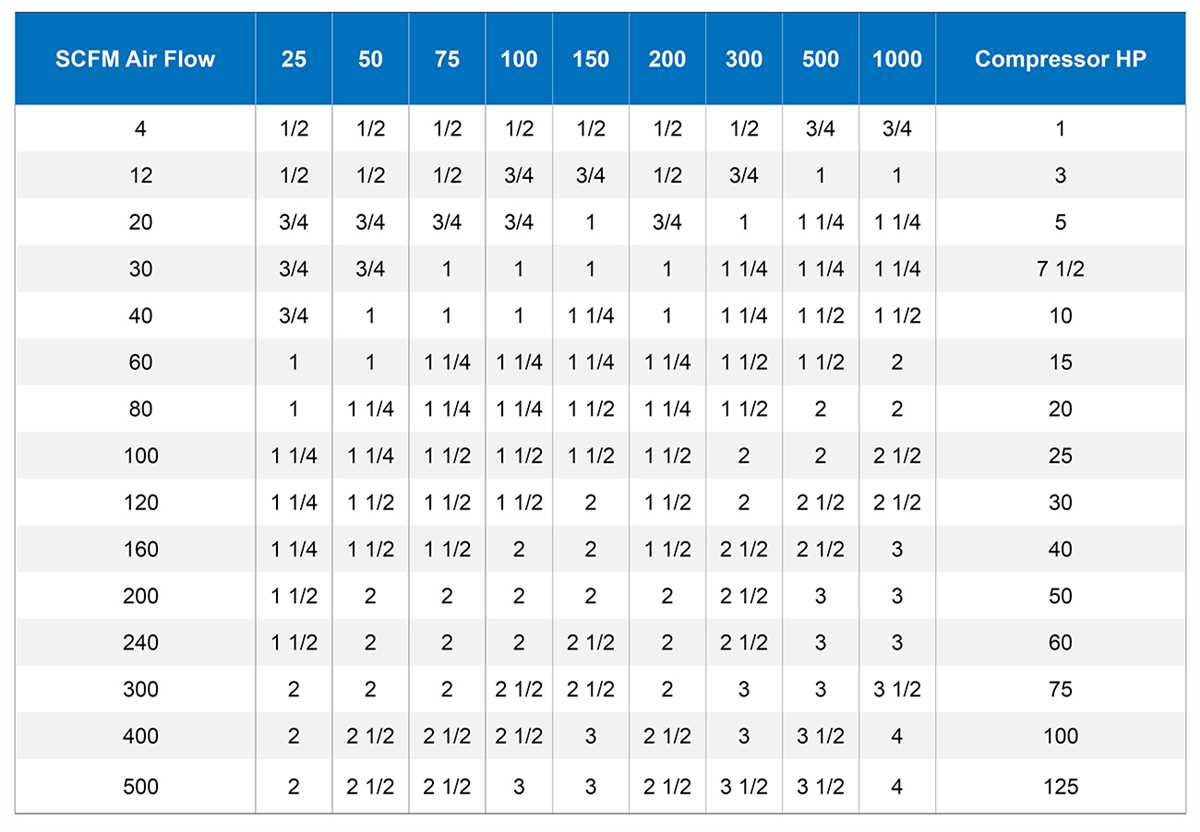

When choosing the right size air compressor hose, it is important to understand the pressure and volume requirements of your air tools or equipment. This will help ensure that your air compressor hose can deliver the necessary airflow and pressure for efficient operation.

The pressure requirement refers to the amount of force that is needed to operate a particular air tool or equipment. Different air tools may have different pressure requirements, usually measured in pounds per square inch (PSI). It is important to choose an air compressor hose that can handle the maximum pressure required by your air tools.

The volume requirement, on the other hand, refers to the amount of air flow that is needed to operate a particular air tool or equipment. This is typically measured in cubic feet per minute (CFM). Some air tools may require a high volume of air flow to operate efficiently, while others may require a lower volume. It is important to choose an air compressor hose that can deliver the necessary volume of air flow for your specific applications.

In order to determine the pressure and volume requirements of your air tools or equipment, you can refer to the manufacturer’s specifications or consult the user manual. These documents will usually indicate the recommended pressure and volume requirements for optimal performance.

Once you have determined the pressure and volume requirements, you can then choose the right size air compressor hose that can meet these requirements. It is important to select a hose with a diameter that is compatible with the airflow and pressure requirements of your air tools. Using a hose with a diameter that is too small can restrict the airflow and reduce the performance of your air tools, while using a hose with a diameter that is too large can result in a loss of pressure.

In addition to the size, you should also consider the length of the air compressor hose. Longer hoses can result in a drop in pressure and volume due to frictional losses. It is advisable to choose a hose that is long enough to reach your work area but not overly long to minimize these losses.

By understanding the pressure and volume requirements of your air tools or equipment, you can choose the right size air compressor hose that can deliver the necessary airflow and pressure for efficient operation.

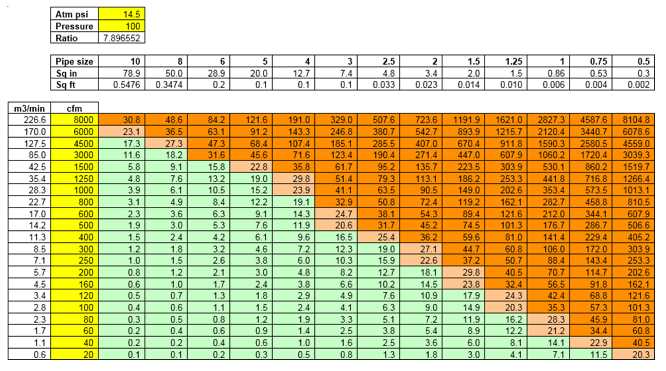

Calculating the Required Hose Diameter

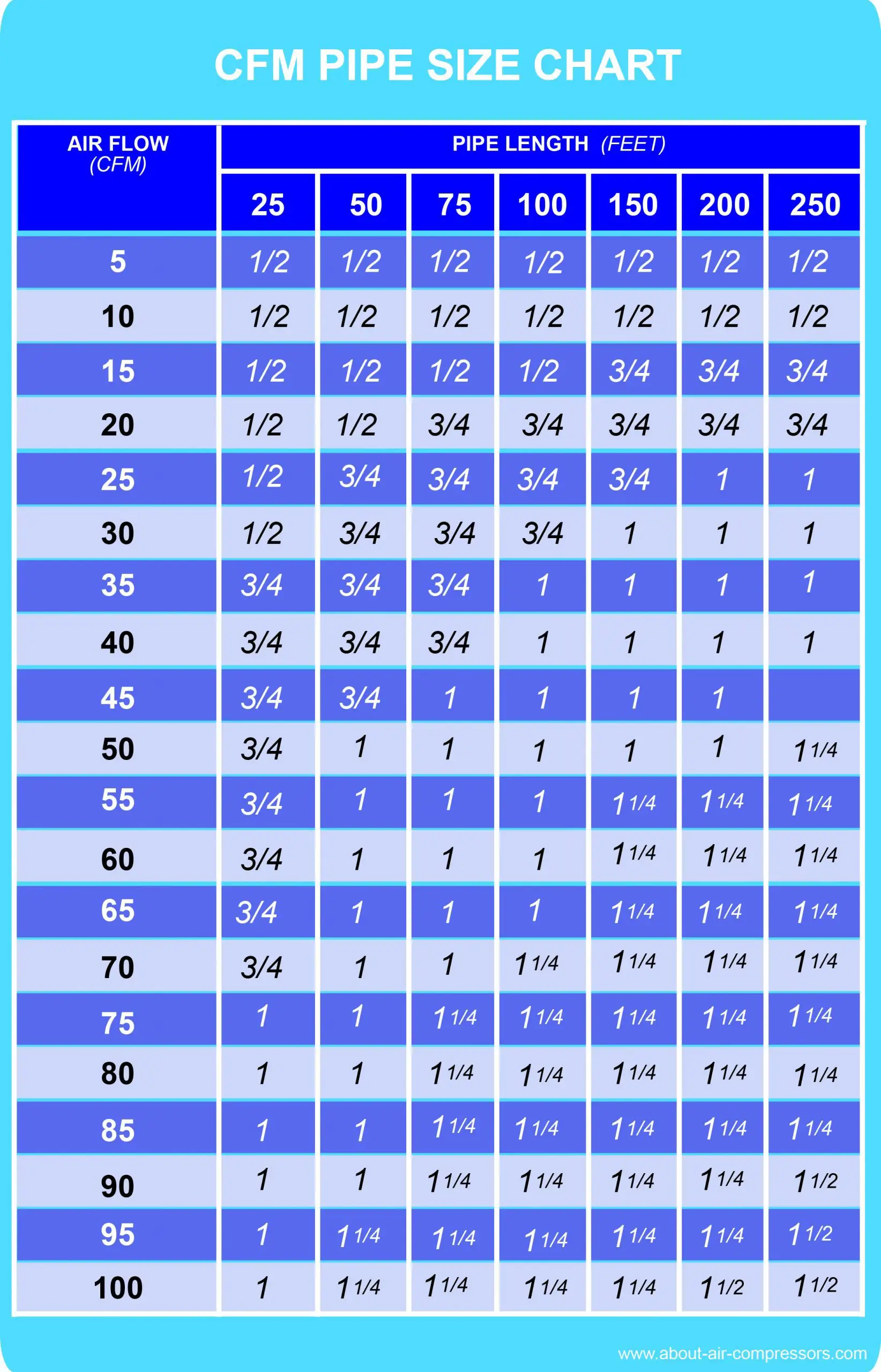

When choosing the right size air compressor hose, it is important to calculate the required diameter to ensure optimal performance. The hose diameter directly affects the airflow and pressure capabilities of the compressor system.

There are several factors to consider when calculating the required hose diameter:

- Compressor output: The first step is to determine the maximum airflow or volume of air that the compressor can produce. This is usually measured in cubic feet per minute (CFM).

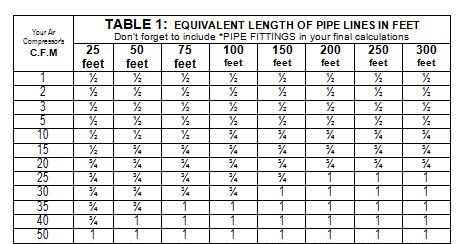

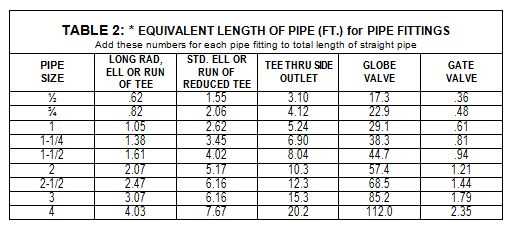

- Length of the hose: The next factor to consider is the length of the hose that will be used. Longer hoses create more resistance and can result in a decrease in airflow and pressure.

- Pressure drop: Pressure drop refers to the decrease in pressure along the length of the hose. It is important to choose a hose diameter that minimizes pressure drop to maintain optimal performance.

- Application requirements: The specific application requirements, such as the tools or equipment being used, will also influence the required hose diameter. Different tools may have different airflow or pressure requirements.

Once these factors are considered, you can use a hose size chart or online calculator to determine the appropriate hose diameter for your air compressor system. The chart or calculator will take into account the compressor output, hose length, and desired pressure drop to recommend the optimal hose size.

It is important to note that using a hose with a larger diameter than necessary can result in inefficiencies and increased costs. On the other hand, using a hose with a smaller diameter can lead to pressure loss and reduced performance. Therefore, it is important to accurately calculate the required hose diameter to ensure optimal performance and efficiency of your air compressor system.

Common Hose Sizes and Their Applications

When it comes to air compressor hoses, there are several common sizes that are used for different applications. Understanding the different sizes and their applications can help you choose the right hose for your needs.

1/4 inch

The 1/4-inch hose is one of the most common sizes and is suitable for most light-duty applications. It is often used for tasks such as inflating tires, operating air tools, and general cleaning.

3/8 inch

A step up from the 1/4-inch hose, the 3/8-inch hose is more durable and can handle higher pressure. It is commonly used for tasks that require more power, such as carpentry, painting, and automotive repair.

1/2 inch

The 1/2-inch hose is the largest size commonly available and is designed for heavy-duty applications. It can handle high pressure and is often used in industrial settings for tasks such as sandblasting, spray painting, and operating large air-powered equipment.

Choosing the Right Size

When choosing the right size hose, it is important to consider the specific application and the air compressor’s output. Using a hose that is too small can restrict airflow and reduce performance, while using a hose that is too large can result in wasted energy and increased costs. It is also important to consider the length of the hose, as longer hoses can result in pressure drop.

Overall, selecting the right size hose is crucial for ensuring optimal performance and efficiency. By understanding the common hose sizes and their applications, you can make an informed decision that meets your specific needs.

Length of the Hose

The length of the air compressor hose is an important factor to consider when choosing the right size. The length determines how far you can move away from the air compressor while using your tools or equipment. A longer hose gives you more freedom to move around and work in different areas without having to constantly move the air compressor.

However, it’s important to keep in mind that a longer hose can also result in a decrease in air pressure. This is because the longer the hose, the more the air has to travel, and this can lead to a loss of pressure. It’s important to strike a balance between the length of the hose and the air pressure you need for your tools or equipment.

When determining the length of the hose, consider the maximum distance you think you’ll need to work from the air compressor. Measure this distance and add a few extra feet to allow for flexibility. It’s better to have a slightly longer hose than one that is too short and limits your mobility.

In addition to length, it’s also important to consider the diameter of the hose. A larger diameter hose can help maintain a higher air pressure over longer distances. This can be particularly beneficial if you’re using tools or equipment that require a higher air pressure to operate efficiently. However, a larger diameter hose may also be heavier and less flexible, so it’s important to find the right balance for your specific needs.

To determine the right length and diameter of the air compressor hose for your needs, it can be helpful to consult the manufacturer’s recommendations or seek advice from a knowledgeable professional. They can take into account the specific requirements of your tools or equipment and help you find the best hose for optimal performance.

Material and Durability

When choosing an air compressor hose, it’s important to consider the material and durability of the hose. The material of the hose will determine how well it can withstand high-pressure air and resist wear and tear.

One common material used for air compressor hoses is rubber. Rubber hoses are known for their flexibility and durability. They can tolerate high pressures and extreme temperatures without cracking or deforming. Rubber hoses also have excellent resistance to oil, which makes them suitable for use in a variety of industrial applications.

Another material option for air compressor hoses is PVC. PVC hoses are lightweight and affordable, making them a popular choice for homeowners and DIY enthusiasts. However, PVC hoses may not be as durable as rubber hoses and can be susceptible to cracking and kinking over time.

For heavy-duty applications, a reinforced hose is recommended. Reinforced hoses are made with additional layers of material, such as polyester or nylon, to enhance their strength and durability. These hoses can handle higher pressures and are less likely to burst or leak.

It’s also important to consider the length of the hose. Longer hoses can be more convenient in certain situations but may result in a decrease in air pressure over long distances. Choosing the right material and durability for your air compressor hose will ensure efficient and reliable performance for your pneumatic tools and equipment.

Maintenance and Care Tips

Regular Inspection and Cleaning

One of the most important maintenance tasks for your air compressor hose is regular inspection and cleaning. Inspect the hose for any signs of wear, such as cracks, leaks, or bulges. If you notice any damage, it is important to replace the hose immediately to prevent further issues. Additionally, make sure to clean the hose regularly to remove any dirt, debris, or moisture that may have accumulated.

Proper Storage

Proper storage is crucial for maintaining the longevity of your air compressor hose. When not in use, it is recommended to store the hose in a cool and dry place, away from direct sunlight. Avoid storing the hose in areas with extreme temperatures, as this can cause the hose to deteriorate faster. Additionally, make sure to coil the hose properly to prevent kinks and tangles.

Use the Right Fittings

Using the right fittings for your air compressor hose is essential for optimal performance and to prevent leaks. Make sure to choose fittings that are compatible with your hose and the air compressor. It is also important to properly tighten the fittings to ensure a secure connection and to prevent air leakage.

Check for Pressure Drops

Periodically check for pressure drops in your air compressor hose. If you notice a significant drop in pressure, it could indicate a problem with the hose, fittings, or air compressor. Inspect the hose for any signs of damage or leaks, and check the fittings for a secure connection. If you are unable to identify the cause of the pressure drop, it is recommended to consult a professional for further inspection and maintenance.

Proper Handling

Proper handling of your air compressor hose is crucial to prevent damage. Avoid dragging or pulling the hose across sharp or rough surfaces, as this can cause abrasions or punctures. Additionally, do not use the hose for purposes other than its intended use, such as lifting heavy objects or towing vehicles. This can put excessive strain on the hose and lead to damage or failure.

FAQ:

What is an air compressor hose?

An air compressor hose is a flexible tube that connects the air compressor to various tools and equipment.

How long should an air compressor hose be?

The length of the air compressor hose depends on your specific needs and the distance between the compressor and the tools. It is recommended to choose a hose that is long enough to reach all areas you need to work in, but not longer than necessary to avoid loss of pressure.

What types of air compressor hoses are available?

There are several types of air compressor hoses available, including PVC, rubber, hybrid PVC/rubber, and polyurethane hoses. Each type has its own advantages and disadvantages, so it’s important to consider factors such as durability, flexibility, and temperature resistance when choosing the right hose for your needs.

What size air compressor hose do I need for painting?

The size of the air compressor hose you need for painting depends on the type of paint gun you are using. Most paint guns require a 3/8-inch hose, but some may require a larger diameter. It’s best to consult the manufacturer’s recommendations or check the specifications of your paint gun to determine the appropriate hose size.

What are the benefits of a larger diameter air compressor hose?

A larger diameter air compressor hose can provide higher airflow and allow for more efficient use of your tools. It can help prevent pressure drop, which can affect the performance of pneumatic tools. Additionally, a larger hose diameter can reduce the risk of overheating and increase the lifespan of the hose.

Video: