Choosing the Right Size Copper Pipe for Air Compressor Lines

When it comes to setting up air compressor lines, choosing the right size copper pipe is crucial. Copper piping is commonly used in air compressor systems due to its durability and ability to handle high pressure. However, selecting the correct pipe size is essential for ensuring optimal performance and efficiency.

One of the main factors to consider when selecting a copper pipe size is the required air flow rate. The size of the pipe will directly affect the flow rate, as a larger diameter pipe allows for greater airflow. It is important to evaluate the specific needs of your air compressor system, taking into account factors such as the number of tools being used, the length of the piping system, and the pressure requirements. In general, larger tools or systems with higher airflow demands will require larger pipe sizes.

Another important consideration when choosing the right size copper pipe is the length of the air compressor lines. The longer the piping system, the greater the pressure loss due to friction. A smaller diameter pipe will result in greater pressure loss, leading to decreased efficiency and reduced performance. It is recommended to consult a pressure loss chart or utilize a pressure drop calculator to determine the appropriate pipe size based on the length of the system.

In addition to flow rate and system length, it is crucial to consider the overall size and capacity of the air compressor itself. The compressor should be matched to the pipe size to ensure compatibility and maximize efficiency. Installing undersized pipes can lead to increased pressure drop and decreased performance, while oversized pipes can result in wasted energy and increased costs.

In conclusion, selecting the right size copper pipe for air compressor lines requires careful evaluation of the required airflow rate, system length, and the size and capacity of the compressor. By considering these factors, you can ensure optimal performance, efficiency, and longevity of your air compressor system.

Importance of Choosing the Right Size

Choosing the right size copper pipe for air compressor lines is crucial for ensuring optimal performance and efficiency. The size of the pipe directly affects the flow rate and pressure of the compressed air, which in turn impact the functionality of the air compressor system.

Flow Rate: The flow rate of compressed air refers to the volume of air that can pass through the pipe per unit of time. If the pipe is too small, the flow rate will be restricted, resulting in slower air delivery and reduced productivity. On the other hand, if the pipe is too large, it can lead to pressure drops and inefficiency. Therefore, selecting the proper pipe size is essential for maintaining adequate flow rates.

Pressure: The pressure of the compressed air must be sufficient to power the tools and equipment connected to the system. If the pipe is undersized, the pressure will drop, causing a decrease in performance and potentially damaging sensitive equipment. Conversely, if the pipe is oversized, the pressure losses may be negligible, but unnecessary costs will be incurred due to the extra material used. It is therefore important to choose a pipe size that balances the flow rate and pressure requirements.

Efficiency: Properly sizing the copper pipe for air compressor lines ensures better efficiency in the overall system. A well-sized pipe minimizes energy losses and pressure drops, allowing the compressor to operate at optimal levels. This not only improves the performance of the air compressor, but also reduces energy consumption, saving both time and money.

Future Expansion: Considering future expansion plans is another important factor when selecting the right size copper pipe. If expansion is likely, it is prudent to choose a larger pipe size to accommodate the increased air demand. This will eliminate the need for costly modifications or upgrades later on, ensuring a more cost-effective and scalable solution.

In summary, choosing the right size copper pipe for air compressor lines is critical for maintaining adequate flow rates, proper pressure, and overall system efficiency. By carefully considering the specific requirements and considering future expansion, users can ensure optimal performance and avoid unnecessary expenses in their air compressor systems.

Understanding Air Compressor Lines

When it comes to air compressors, the selection of the right size copper pipe for the air compressor lines plays a crucial role in ensuring optimal performance. The air compressor lines are responsible for carrying the compressed air from the compressor to the desired application, whether it’s for industrial use or in a residential setting.

One of the key factors to consider when understanding air compressor lines is the flow rate. The flow rate is the amount of air that can pass through the air compressor lines per unit of time. It is important to choose the right size copper pipe to accommodate the required flow rate. Using a pipe that is too small can result in significant pressure drops and reduced efficiency, while a pipe that is too large can lead to excessive energy consumption.

Another important aspect to consider is the pressure rating of the air compressor lines. The pressure rating indicates the maximum pressure that the lines can safely handle. It is crucial to choose copper pipes with the appropriate pressure rating based on the specific requirements of the air compressor system. Using pipes with a lower pressure rating can result in leaks or bursts, while using pipes with a higher pressure rating than necessary can be a waste of resources.

Furthermore, the length of the air compressor lines should be taken into account when selecting the right size copper pipe. The longer the distance that the compressed air needs to travel, the more pressure drops that can occur. It is important to choose a pipe with a larger diameter to minimize pressure drops, especially for longer lines.

In summary, understanding air compressor lines involves considering the flow rate, pressure rating, and length of the lines. Choosing the right size copper pipe is essential to ensure optimal performance and efficiency of the air compressor system. By selecting the appropriate pipe size, the risk of pressure drops, leaks, and energy waste can be minimized, resulting in a reliable and efficient air compressor system.

Factors to Consider

When choosing the right size copper pipe for air compressor lines, there are several factors to consider. These factors include:

- Required airflow: One of the main considerations when selecting the size of the copper pipe is the required airflow. The size of the pipe will determine how much air can flow through it and reach the desired destination. It is important to determine the airflow requirements of the air compressor system to ensure that the chosen pipe size can accommodate the necessary volume of air.

- Length of the pipe: The length of the copper pipe plays a role in determining the size that is required. Longer pipe lengths can result in a greater loss of pressure and a decrease in overall efficiency. It is important to consider the distance between the air compressor and the point of use when choosing the size of the pipe to ensure that sufficient air pressure can be maintained.

- Pressure drop: Pressure drop is another factor that needs to be taken into account. This refers to the decrease in pressure that occurs as the air flows through the pipe. Choosing a pipe size that can minimize pressure drop is crucial to maintain optimal air pressure throughout the system.

- Operating temperature: The operating temperature of the air compressor system can affect the performance of the copper pipe. Higher temperatures can cause the pipe to expand, potentially leading to leaks or damage. It is important to select a copper pipe size that can withstand the expected operating temperature.

- Budget and cost: Finally, the budget and cost considerations cannot be ignored. Larger size copper pipes may be more expensive than smaller sizes, so it is important to balance the required airflow and pressure with the available budget.

In conclusion, when choosing the right size copper pipe for air compressor lines, factors such as required airflow, pipe length, pressure drop, operating temperature, and budget need to be carefully considered. By taking into account these factors, one can ensure that the chosen copper pipe size can effectively meet the needs of the air compressor system while maintaining optimal performance and efficiency.

Calculating the Required Size

When choosing the right size copper pipe for air compressor lines, it is important to calculate the required size based on the specific needs of your system.

1. Determine the Maximum Airflow

To begin, you should determine the maximum airflow that your air compressor will produce. This can be done by referring to the manufacturer’s specifications or consulting an air compressor expert. The maximum airflow is typically measured in cubic feet per minute (CFM).

2. Consider the Length of the Pipe

Next, you should consider the length of the pipe that will be used for your air compressor lines. The longer the pipe, the greater the chance for pressure drop. Pressure drop can have a negative impact on the performance of your air compressor system. Therefore, it is essential to choose a pipe size that will minimize pressure drop.

3. Calculate the Required Pipe Size

Once you have determined the maximum airflow and the length of the pipe, you can calculate the required pipe size. There are several online calculators and charts available that can assist with this calculation. These calculators typically require you to input the maximum airflow and the length of the pipe, and they provide you with the recommended pipe size based on these factors.

It is important to note that using a pipe size that is too small can result in pressure drop and reduced performance, while using a pipe size that is too large can be costly and unnecessary. Therefore, it is crucial to choose the pipe size that is appropriate for your specific needs.

By calculating the required size of your copper pipe for air compressor lines, you can ensure optimal performance and efficiency of your air compressor system.

Determining the Air Flow

1. Calculate the Required Air Flow

To determine the right size copper pipe for air compressor lines, the first step is to calculate the required air flow. This is essential in ensuring that the air compressor can supply sufficient air to meet the demands of your tools and equipment.

To calculate the required air flow, you need to consider the air consumption of each tool or equipment that will be connected to the air compressor. This information is typically provided by the manufacturer and can be found in the tool’s specifications.

Once you have the air consumption for each tool, add them all up to get the total required air flow. This will give you an idea of how much air the compressor needs to deliver to meet your needs.

2. Consider the Pressure Drop

Another important factor to consider when choosing the size of the copper pipe is the pressure drop. When air flows through a pipe, there is some loss of pressure due to friction and other factors.

To ensure that the air compressor can deliver sufficient pressure to the tools and equipment, you need to account for the pressure drop. This can be done by adding a certain percentage to the calculated required air flow. The exact percentage will depend on factors such as the length of the pipe and the number of bends or fittings.

By considering the pressure drop, you can choose a copper pipe size that will provide the necessary pressure at the end of the line, ensuring optimal performance and efficiency.

3. Consult Pipe Sizing Charts

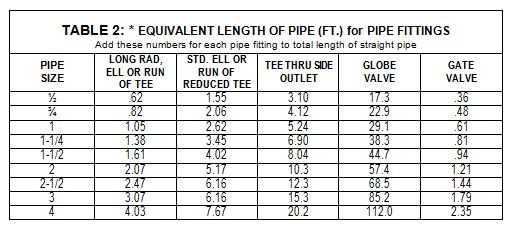

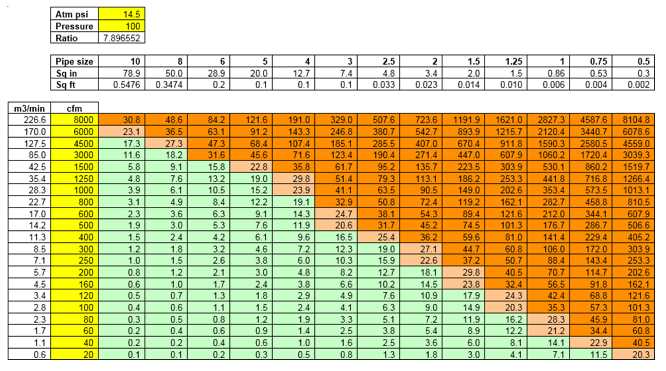

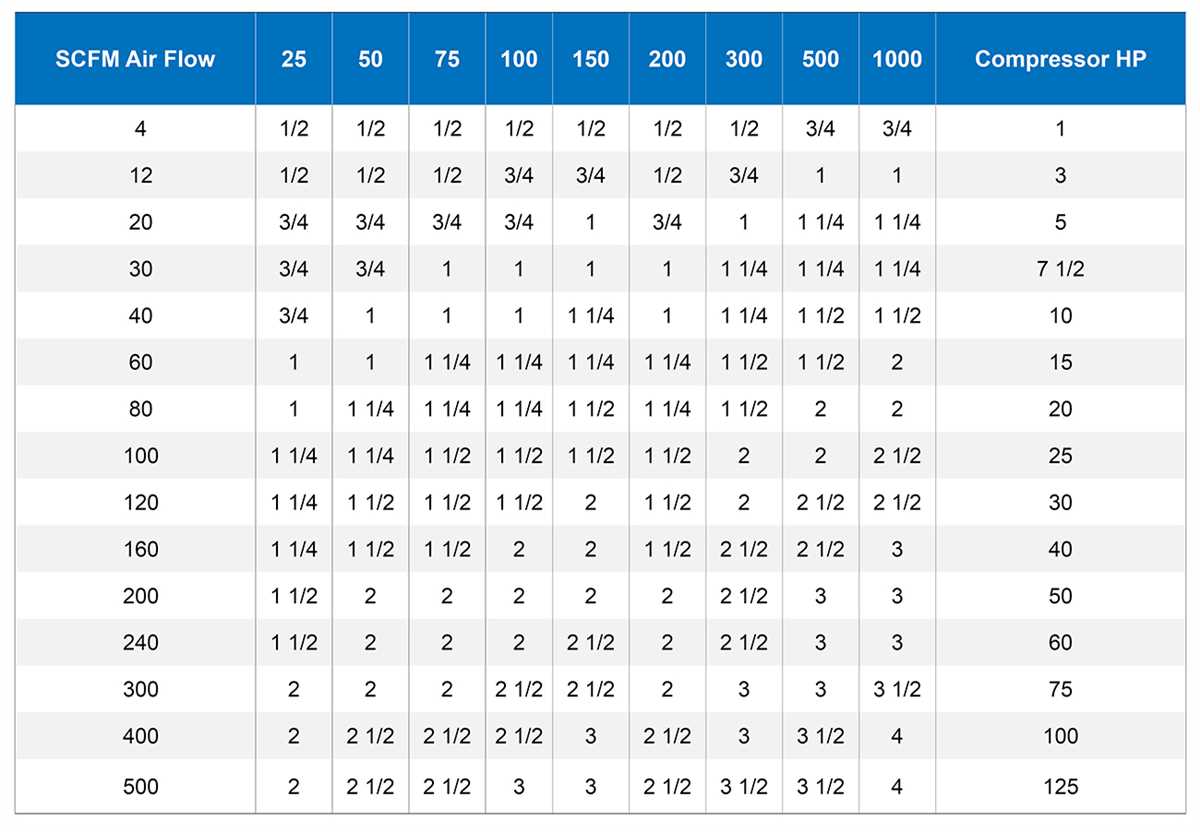

To simplify the process of selecting the right size of copper pipe, consult pipe sizing charts. These charts provide information on the recommended pipe size based on the required air flow and pressure drop.

Pipe sizing charts typically provide values for different pipe lengths and fittings, allowing you to choose the most suitable copper pipe size for your specific installation.

By consulting these charts, you can ensure that the air compressor lines will provide the necessary air flow and pressure without excessive pressure drop, maximizing the performance of your tools and equipment.

In conclusion, determining the air flow is a crucial step in choosing the right size copper pipe for air compressor lines. By calculating the required air flow, considering the pressure drop, and consulting pipe sizing charts, you can select a copper pipe size that will effectively meet the demands of your tools and equipment, ensuring optimal performance and efficiency.

Considering Pressure Drop

Pressure drop is an important factor to consider when choosing the right size copper pipe for air compressor lines. It refers to the decrease in pressure that occurs as the air flows through the pipe. A high pressure drop can result in reduced efficiency and performance of the air compressor system.

When selecting the appropriate size of copper pipe, it is crucial to consider the length of the pipe, the flow rate of the air, and the desired pressure drop. The longer the pipe, the greater the pressure drop will be. Likewise, higher flow rates and lower pressure drops require larger diameter pipes.

One way to determine the pressure drop is to use pressure drop charts provided by pipe manufacturers. These charts show the relationship between pipe diameter, flow rate, and pressure drop. By consulting these charts, one can select the optimal pipe size that will minimize pressure drop while meeting the requirements of the air compressor system.

It is also important to consider the material and quality of the copper pipe. Smooth interior surfaces and minimal obstructions will result in lower pressure drop. High-quality copper pipes that are properly installed and maintained can reduce pressure drop and ensure the optimal performance of the air compressor system.

In conclusion, pressure drop is a critical factor to consider when choosing the right size copper pipe for air compressor lines. By taking into account factors such as pipe length, flow rate, and desired pressure drop, as well as selecting high-quality copper pipes, one can ensure the efficient and effective operation of the air compressor system.

Sizing Recommendations

When selecting the right size copper pipe for your air compressor lines, it is important to consider a few factors. The size of the pipe will determine the overall performance and efficiency of your air compressor system, so it is crucial to choose the correct size.

Airflow

The first factor to consider when sizing your copper pipe is the required airflow. This is typically measured in cubic feet per minute (CFM). It is important to accurately calculate the CFM requirements of your air compressor system, as this will determine the size of the pipe needed to deliver the required airflow.

Tip: To calculate the CFM requirements, consider the air tools and equipment you will be using and their individual CFM ratings. Add up the total CFM of all the tools and equipment to determine the required airflow for your system.

Pressure Drop

Another important factor to consider is pressure drop. Pressure drop refers to the decrease in pressure that occurs as air flows through the pipe. To ensure optimal performance, it is important to minimize pressure drop by selecting the right size pipe.

Tip: To minimize pressure drop, choose a larger diameter pipe. A larger pipe will allow for smoother airflow and reduce resistance, resulting in less pressure drop. Keep in mind that a larger pipe diameter may also require a larger compressor to maintain the desired pressure.

Size Chart

To assist in selecting the appropriate size copper pipe, refer to the following size chart:

| Required CFM | Pipe Size |

|---|---|

| 0-20 CFM | 1/4 inch |

| 20-35 CFM | 3/8 inch |

| 35-60 CFM | 1/2 inch |

| 60-90 CFM | 3/4 inch |

| 90-120 CFM | 1 inch |

Tip: Use this chart as a guide, but always consult the manufacturer’s specifications for your air compressor system to ensure accurate sizing.

By considering the required airflow, pressure drop, and using a size chart as a guide, you can confidently select the right size copper pipe for your air compressor lines. This will help optimize the performance and efficiency of your air compressor system.

Choosing the Optimal Copper Pipe Size

When it comes to choosing the right size copper pipe for air compressor lines, finding the optimal size is crucial. The size of the copper pipe affects the airflow and pressure in the system, which in turn can impact the performance of the air compressor.

Understanding the Flow Requirements

Before selecting the copper pipe size, it is important to understand the flow requirements of the system. This includes considering the maximum airflow needed and the pressure drop that can be tolerated. It is also essential to consider any future expansion plans for the system.

Matching Pipe Size to Compressor Capacity

Choosing the right size copper pipe involves matching the pipe size to the compressor capacity. This can be determined by calculating the airflow requirements of the air compressor based on its horsepower (HP) rating and the compressor’s manufacturer specifications. This information can help determine the optimal pipe size that can handle the required airflow without causing significant pressure drop.

Considering Length and Layout

The length and layout of the air compressor lines should also be taken into account when selecting the copper pipe size. Longer pipe lengths and complex layouts may require larger pipe sizes to minimize pressure drop and ensure adequate airflow. Factors such as bends, elbows, and fittings also contribute to pressure drop and should be considered when determining the optimal pipe size.

Consulting Pipe Size Charts

Consulting pipe size charts can also be helpful in choosing the optimal copper pipe size. These charts provide information on the maximum airflow capacity for different pipe sizes at various pressure levels. They can serve as a guide to selecting the appropriate pipe size based on the desired airflow and pressure requirements.

Seeking Professional Advice

When in doubt, it is always recommended to seek professional advice. Consulting with an experienced plumber or HVAC specialist can help ensure that the right size copper pipe is chosen for the air compressor lines. They have the knowledge and expertise to assess the system requirements and make the best recommendation for optimal performance.

FAQ:

What is the importance of choosing the right size copper pipe for air compressor lines?

Choosing the right size copper pipe for air compressor lines is important because it directly affects the performance and efficiency of the air compressor system. If the pipe size is too small, it can result in reduced airflow and pressure drop, leading to decreased overall performance. On the other hand, if the pipe size is too large, it can increase the cost of materials and installation. Therefore, selecting the appropriate pipe size is crucial for optimal air compressor performance.

How do I determine the right size copper pipe for my air compressor lines?

Determining the right size copper pipe for air compressor lines involves considering several factors. These include the required airflow, operating pressure, pipe length, and allowable pressure drop. To calculate the appropriate pipe size, you can refer to industry standards and tables that provide the correct pipe diameter based on these variables. It is advisable to consult with a professional or refer to manufacturer recommendations to ensure the accurate sizing of the copper pipe for your specific air compressor needs.

What are the common copper pipe sizes used for air compressor lines?

The common copper pipe sizes used for air compressor lines are typically in the range of 1/2 inch to 1 inch. However, the actual size required depends on the specific requirements and demands of the air compressor system. It is crucial to consider factors such as the required airflow, operating pressure, and distance between the compressor and end-use equipment when determining the appropriate copper pipe size for the air compressor lines.

What are the potential issues if the copper pipe size is too small for air compressor lines?

If the copper pipe size is too small for air compressor lines, it can lead to several issues. Firstly, there will be a significant pressure drop due to the restricted flow of compressed air. This can result in decreased performance and efficiency of the air compressor system. Additionally, the increased velocity of the compressed air can cause excess heat, leading to potential damage to the copper pipe and other system components. Therefore, it is essential to choose an adequate pipe size to avoid these problems.

Can I use a larger copper pipe size than recommended for my air compressor lines?

Using a larger copper pipe size than recommended for air compressor lines is generally not recommended. While it may seem like a logical solution to improve airflow, it can result in unnecessary costs for materials and installation. Moreover, a larger pipe size can increase the volume of air that needs to be compressed, leading to longer compressor run times and increased energy consumption. It is best to stay within the recommended pipe size range for optimal air compressor performance.

Video: