Understanding the Inner Workings of an Air Conditioner Compressor

An air conditioner compressor plays a vital role in the cooling process of an air conditioning system. It is responsible for compressing the refrigerant gas, which allows the system to remove heat from the indoor environment and transfer it outside. Compressors are often referred to as the “heart” of an air conditioner since they are responsible for the circulation and circulation of refrigerant throughout the system.

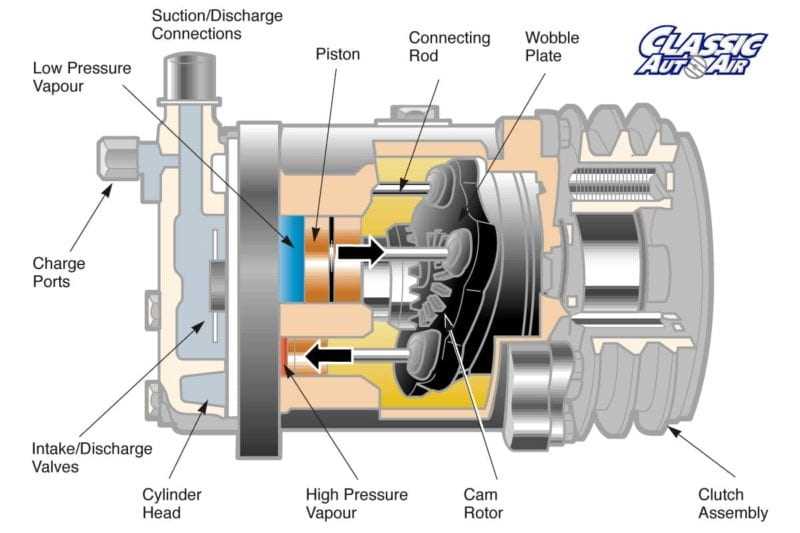

The inner workings of an air conditioner compressor can be complex and involve several key components. One of the main components is the motor, which provides the power to drive the compressor. This motor is typically powered by electricity and is designed to withstand the high pressures and temperatures that are involved in the compression process.

Another important component is the refrigerant gas. This gas is responsible for absorbing heat from the indoor environment and transferring it outside. The compressor compresses the refrigerant gas, causing its temperature and pressure to increase. As the compressed gas moves through the system, it releases heat to the outside environment, thereby cooling the indoor environment.

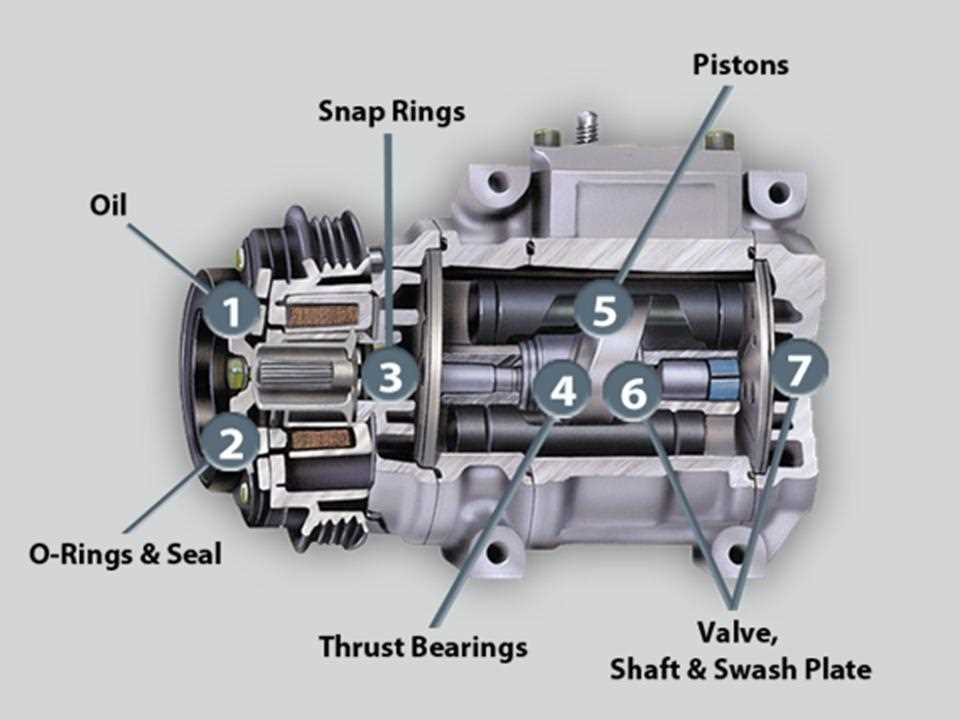

The compressor also contains valves and pistons that help regulate the flow of refrigerant gas. These valves and pistons open and close at specific times to ensure the proper circulation and compression of the refrigerant. Additionally, the compressor may have a crankshaft that converts the linear motion of the pistons into rotary motion, which allows the compressor to function efficiently.

In conclusion, understanding the inner workings of an air conditioner compressor is crucial for maintaining and repairing air conditioning systems. The compressor’s ability to compress the refrigerant gas and circulate it throughout the system is essential for effective cooling. By understanding how the compressor functions, technicians can diagnose and troubleshoot any issues that may arise and ensure the optimal performance of an air conditioning system.

How Does an Air Conditioner Compressor Work?

An air conditioner compressor is a vital component of an air conditioning system that plays a crucial role in the cooling process. It is responsible for compressing refrigerant, a cooling agent, in order to remove heat from the indoor environment and transfer it outside. This process allows the air conditioner to lower the temperature and provide a comfortable living or working space.

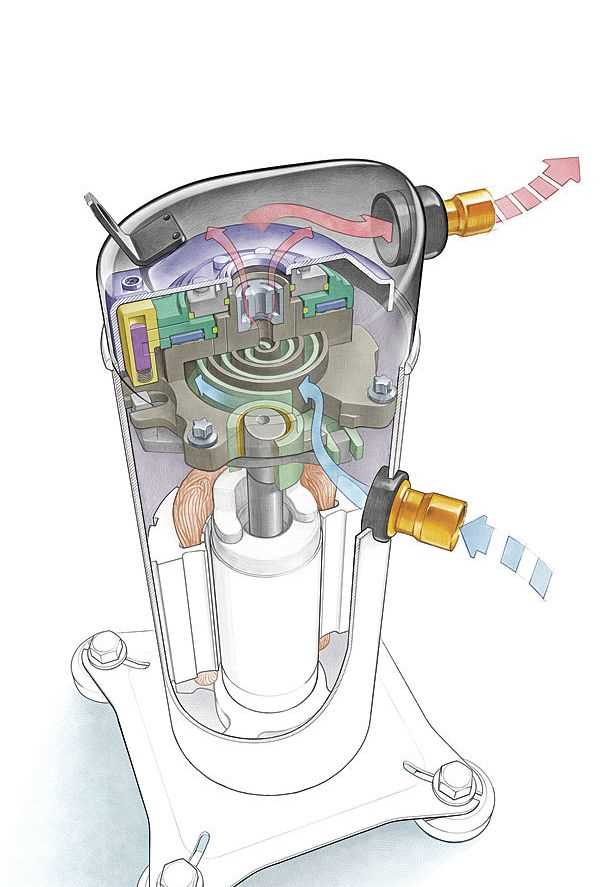

The compressor works by using a motor to drive a piston or scroll, which compresses the refrigerant gas. As the refrigerant passes through the compressor, the pressure and temperature increase significantly. This high-pressure gas then flows into the condenser, where it releases heat and condenses into a liquid state.

The compressor operates based on the principles of Boyle’s Law, which states that when the volume of a gas decreases, its pressure increases. When the piston or scroll compresses the refrigerant gas, the volume decreases, causing the pressure to rise. This process intensifies the refrigerant’s ability to absorb heat from the indoor air.

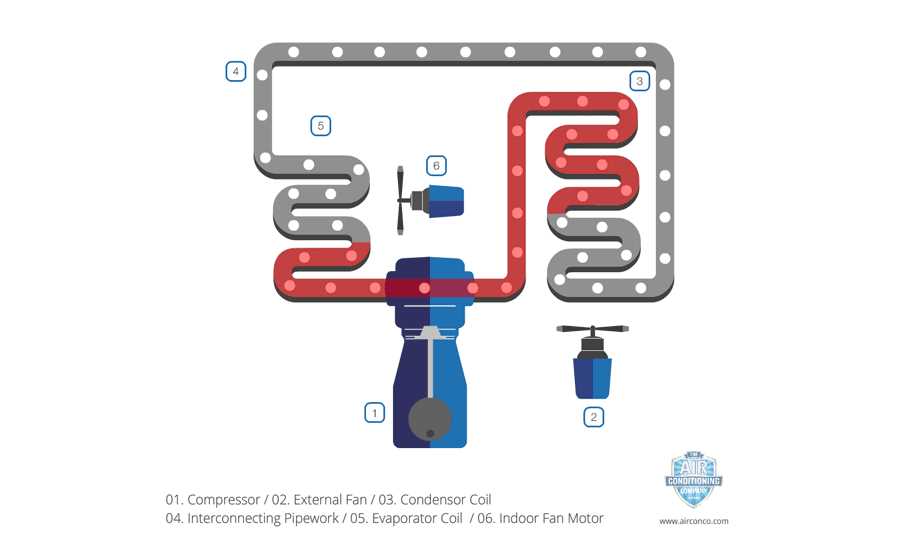

In addition to compressing the refrigerant, the compressor also circulates the refrigerant throughout the air conditioning system. It creates a continuous cycle of compression, condensation, expansion, and evaporation, allowing the refrigerant to remove heat from the indoor air and cycle back to the compressor to repeat the process.

An air conditioner compressor requires regular maintenance to ensure optimal performance. This includes checking for any leaks, cleaning the coils, and lubricating the moving parts. By keeping the compressor in good condition, it can effectively cool the air and maintain a comfortable indoor environment.

Mechanism of an Air Conditioner Compressor

An air conditioner compressor plays a crucial role in the cooling process of an air conditioning system. It is responsible for compressing the refrigerant gas, which allows the system to absorb heat from the indoor air and release it outdoors.

The compressor consists of several important components that work together to facilitate the compression process. These components include the compressor motor, the pistons, the valves, and the crankshaft. The motor powers the compressor and drives the rotation of the pistons. The pistons move up and down within the cylinders, compressing the refrigerant gas as it flows in and out of the system.

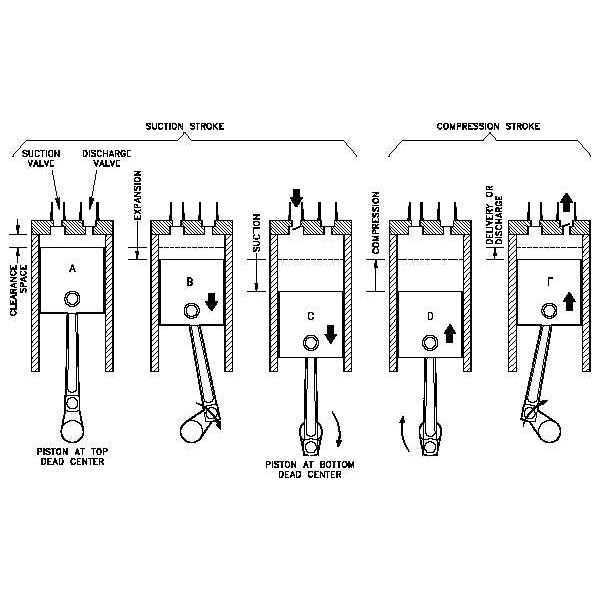

The valves, known as suction and discharge valves, are located at the top of the cylinders and help to control the flow of refrigerant gas. The suction valve allows the gas to enter the cylinder during the suction stroke, while the discharge valve allows the compressed gas to exit during the compression stroke.

The compression process is achieved through a series of steps:

- Suction Stroke: During this phase, the piston moves downward, creating a vacuum in the cylinder. As a result, the suction valve opens, and the refrigerant gas is drawn into the cylinder.

- Compression Stroke: Once the piston reaches the bottom of the stroke, it starts moving upward, compressing the refrigerant gas. As the gas is compressed, its temperature and pressure increase.

- Discharge: At the top of the stroke, the discharge valve opens, allowing the compressed gas to exit the cylinder and enter the condenser.

This continuous process allows the air conditioning system to maintain a consistent flow of refrigerant gas, which is essential for efficient cooling. It is important to note that the compressor consumes a significant amount of energy, making it a crucial component to consider when selecting an air conditioning system.

Understanding the Role of Refrigerant in an Air Conditioner Compressor

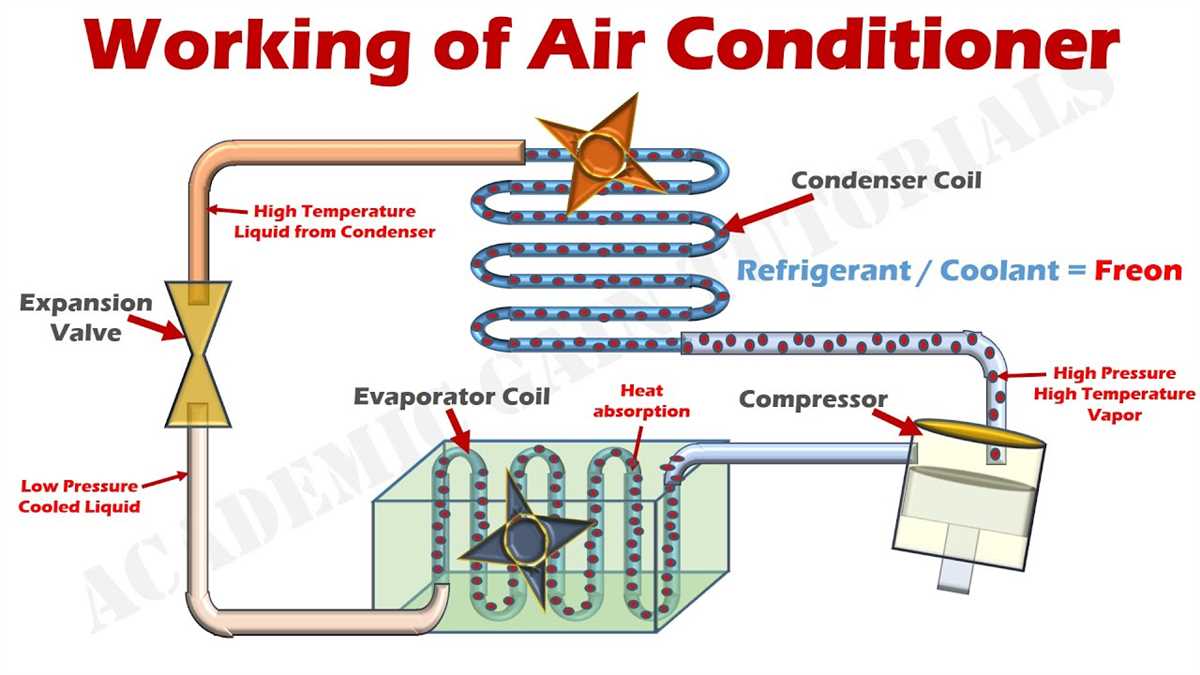

Refrigerant plays a crucial role in the operation of an air conditioner compressor. It is a special chemical compound that undergoes a phase change from a gas to a liquid and vice versa, absorbing and releasing heat in the process. The main purpose of refrigerant is to transfer heat from indoor spaces to the outdoors, effectively cooling the air and maintaining a comfortable temperature within the room.

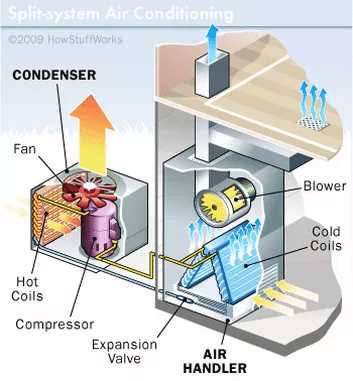

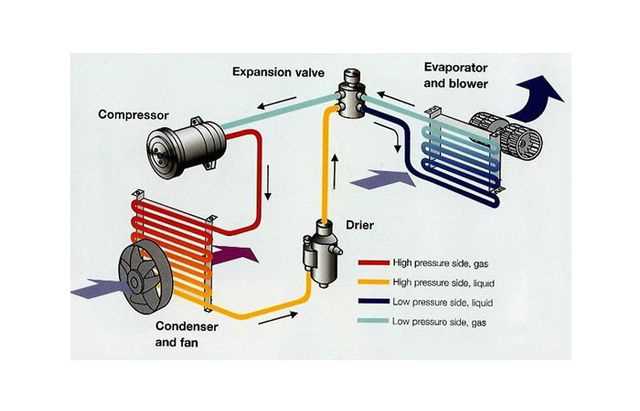

When the air conditioner is turned on, the refrigerant travels through a closed loop system, known as the refrigerant cycle. The cycle begins with the compressor, which is responsible for pressurizing and circulating the refrigerant. The compressor applies mechanical energy to the refrigerant, increasing its pressure and temperature.

As the high-pressure refrigerant moves to the condenser, it releases heat to the surroundings, causing it to condense into a liquid state. The condenser acts as a heat exchanger, allowing the heat to dissipate into the outdoor air. This process is crucial for cooling the refrigerant and preparing it for the next phase of the cycle.

Next, the liquid refrigerant passes through an expansion valve or metering device, which rapidly reduces its pressure. This pressure drop causes the refrigerant to evaporate, transforming it back into a gas. During this phase change, the refrigerant absorbs heat from the indoor air, cooling it down in the process.

The evaporated refrigerant then returns to the compressor to begin the cycle anew. This continuous circulation of refrigerant allows the air conditioner to maintain a consistent cooling effect, effectively regulating the indoor temperature.

In summary, refrigerant plays a vital role in the air conditioner compressor by absorbing heat from indoor spaces, releasing heat to the surroundings, and facilitating the cooling process. Without the proper amount and type of refrigerant, the compressor would not be able to function optimally, impacting the overall performance of the air conditioner.

The Importance of a Compressor in Air Conditioner Performance

The compressor is a vital component in the performance of an air conditioner. It plays a crucial role in the cooling process by compressing the refrigerant gas, raising its temperature and pressure. This process allows the refrigerant to release heat and cool the indoor air.

One of the key benefits of a compressor is its ability to efficiently circulate the refrigerant throughout the air conditioning system. This ensures that the cooling effect is evenly distributed, providing a comfortable and consistent temperature in the room. Without a properly functioning compressor, the air conditioner would struggle to cool the space effectively.

The compressor also helps to maintain optimal energy efficiency in an air conditioner. By compressing the refrigerant, it increases the pressure and temperature, allowing the system to transfer heat more efficiently. This means that the air conditioner can cool the indoor space without consuming excessive amounts of electricity.

Additionally, the compressor helps to regulate the refrigerant flow in the air conditioning system. It controls the rate at which the refrigerant is compressed and pumped through the system, ensuring a steady and controlled cooling process. This helps to prevent system malfunctions and breakdowns, as well as prolong the lifespan of the air conditioner.

In conclusion, the compressor plays a crucial role in the performance of an air conditioner. It is responsible for compressing the refrigerant gas, circulating it efficiently, maintaining energy efficiency, and regulating the refrigerant flow. Without a properly functioning compressor, the air conditioner would struggle to cool the room effectively and efficiently.

Types of Compressor Used in Air Conditioners

There are several types of compressors that are commonly used in air conditioners. Each type has its own unique characteristics and advantages. Here are some of the most common types:

1. Reciprocating Compressor

A reciprocating compressor is one of the oldest and most commonly used types of compressors in air conditioners. It works by using a piston that moves back and forth inside a cylinder to compress the refrigerant. Reciprocating compressors are known for their durability and reliability, but they can be noisy and have a limited capacity.

2. Rotary Compressor

A rotary compressor is a quieter and more efficient alternative to a reciprocating compressor. It uses a rotating impeller to compress the refrigerant. Rotary compressors have a higher capacity and are more energy-efficient, making them suitable for larger air conditioning systems. However, they can be more expensive and require regular maintenance.

3. Scroll Compressor

A scroll compressor is a type of rotary compressor that uses two spiral-shaped scrolls to compress the refrigerant. It is known for its smooth and quiet operation. Scroll compressors have a higher efficiency and better cooling capacity compared to reciprocating compressors. They are commonly used in residential air conditioning units.

In addition to these three main types, there are also other specialized compressors used in certain air conditioning applications, such as centrifugal compressors for large commercial buildings and screw compressors for industrial systems. The choice of compressor depends on factors such as the cooling capacity required, energy efficiency, noise level, and budget.

Factors That Affect the Efficiency of an Air Conditioner Compressor

An air conditioner compressor is a crucial component of an air conditioning system that plays a key role in its overall efficiency. Several factors can impact the efficiency of an air conditioner compressor, which in turn affects the cooling performance and energy consumption of the system.

1. Size

The size of the compressor is an important factor that affects its efficiency. A compressor that is too small for the cooling load of a space may struggle to effectively cool the area, leading to increased energy consumption. On the other hand, a compressor that is too large for the cooling load may cycle on and off frequently, wasting energy and causing unnecessary wear and tear on the compressor.

2. Refrigerant Charge

The refrigerant charge, or the amount of refrigerant in the system, also affects the efficiency of the compressor. If the compressor is undercharged, it may not be able to achieve the desired cooling temperature, resulting in decreased efficiency. Conversely, an overcharged compressor can lead to poor cooling performance and higher energy consumption.

3. Airflow

The airflow over the condenser coil and the evaporator coil can have a significant impact on the efficiency of the compressor. Insufficient airflow can cause the compressor to work harder to cool the space, leading to decreased efficiency and increased energy consumption. Regular maintenance and cleaning of the coils can help ensure optimal airflow and improve the efficiency of the compressor.

4. Ambient Temperature

The ambient temperature, or the temperature of the surrounding environment, can also affect the efficiency of the air conditioner compressor. Higher ambient temperatures can put additional strain on the compressor, causing it to work harder and reduce its efficiency. In hot climates, it is important to choose a compressor that is designed to handle the higher temperatures.

5. Maintenance

Maintaining the air conditioner compressor and the entire system regularly is essential for optimal efficiency. Proper lubrication, clean filters, and regular inspection can help identify and address any issues that may affect the compressor’s efficiency. Regular maintenance can also help prolong the lifespan of the compressor and reduce the risk of breakdowns.

Maintenance and Troubleshooting of an Air Conditioner Compressor

Regular Maintenance

Maintaining an air conditioner compressor is essential to ensure its proper functioning and longevity. Regular maintenance involves cleaning and inspecting various components of the compressor. One important task is to clean the compressor coils, both inside and outside, to remove dust and debris that may restrict airflow. Additionally, checking and replacing the air filters is crucial as clogged filters can put strain on the compressor, leading to reduced cooling efficiency and potential damage.

Another important maintenance task is lubricating the compressor motor and bearings. This helps in reducing friction and heat buildup, resulting in smoother operation and improved energy efficiency. It is recommended to use manufacturer-approved lubricants and follow the guidelines provided in the user manual for proper lubrication intervals.

Troubleshooting

When an air conditioner compressor malfunctions, it can lead to various issues such as insufficient cooling, strange noises, or frequent system shutdowns. Troubleshooting the compressor involves identifying the root cause of the problem and taking appropriate corrective actions.

One common issue is low refrigerant levels, which can cause the compressor to work harder and potentially overheat. Checking and replenishing refrigerant levels can help resolve this problem. Another common problem is electrical issues, such as faulty wiring or damaged capacitors. Inspecting and repairing or replacing these electrical components can often solve the issue.

If troubleshooting the compressor does not resolve the problem, it may be necessary to seek professional help from a qualified HVAC technician. They can perform in-depth diagnostics and repairs to ensure the compressor operates efficiently and effectively.

Regular maintenance and troubleshooting of an air conditioner compressor are crucial for its optimal performance and longevity. By following these guidelines and being proactive in addressing any issues, homeowners can ensure that their air conditioning system provides consistent and reliable cooling throughout its lifespan.

Common Issues with Air Conditioner Compressors and How to Fix Them

1. Compressor won’t start

If your air conditioner compressor won’t start, there could be a few possible causes. Firstly, check if there is power going to the compressor. A blown fuse or tripped circuit breaker could be the culprit. Check the electrical connections and replace any faulty components.

If the power supply is fine, the issue could be with the start capacitor or the motor itself. Test the capacitor and replace it if necessary. If the motor is faulty, it may need to be replaced by a professional technician.

2. Compressor is making strange noises

If your air conditioner compressor is making strange noises, it could indicate a problem. A buzzing or humming sound could be a sign of an electrical issue, such as a loose wire or a failing motor. Check the electrical connections and tighten any loose wires. If the motor is failing, it may need to be replaced.

Another possible cause of strange noises is a damaged compressor coil. Inspect the coil for any signs of damage or wear and replace it if necessary.

3. Compressor is leaking refrigerant

A leaking compressor is a serious issue that can affect the performance of your air conditioner. If you notice refrigerant leaks around the compressor, it is important to fix the problem as soon as possible. Inspect the refrigerant lines and connections for any leaks or damage. Repair any leaks and replace any damaged components. It is recommended to hire a professional technician to handle refrigerant-related issues.

4. Compressor is short cycling

Short cycling is when the compressor turns on and off frequently, which can strain the system and reduce its efficiency. One possible cause of short cycling is a dirty or clogged air filter. Check the air filter and clean or replace it if necessary.

Another possible cause is an oversized or undersized air conditioner unit. An oversized unit will cool the space too quickly, causing the compressor to shut off prematurely. An undersized unit may not be able to cool the space effectively, causing the compressor to work harder. In both cases, it may be necessary to consult a professional to properly size the unit for your space.

5. Compressor is frozen

If your air conditioner compressor is frozen, it is likely due to a lack of airflow or low refrigerant levels. Check the air filter and clean or replace it if necessary. Ensure that all vents and registers are open and unobstructed.

If the problem persists, it could be a refrigerant issue. Low refrigerant levels can cause the evaporator coil to freeze. It is important to hire a professional technician to diagnose and fix refrigerant-related issues.

If you experience any of these issues with your air conditioner compressor, it is best to consult a professional technician for proper diagnosis and repair. Attempting to fix these issues without proper knowledge and experience can lead to further damage or injury. Regular maintenance and inspection can help prevent some of these common issues and ensure the efficient operation of your air conditioner compressor.

Benefits of Regularly Servicing an Air Conditioner Compressor

1. Improved Efficiency: Regular servicing of an air conditioner compressor helps maintain its optimal performance. Over time, dust, dirt, and debris can accumulate in the compressor, causing it to work harder and consume more energy. By cleaning and lubricating the compressor’s moving parts, a professional technician can help improve its efficiency, reducing energy consumption and saving you money on utility bills.

2. Extended Lifespan: By regularly servicing your air conditioner compressor, you can help prolong its lifespan. During a service appointment, a technician will inspect the compressor for any signs of wear or damage and address any issues before they become major problems. This proactive approach can prevent costly repairs or even premature replacement of the compressor.

3. Enhanced Cooling Performance: Servicing the air conditioner compressor can help ensure that it cools your space effectively. Over time, the compressor’s performance may deteriorate due to wear and tear or clogged components. By cleaning or replacing filters, checking refrigerant levels, and conducting overall maintenance, a technician can optimize the compressor’s cooling capacity, ensuring maximum comfort in your home or business.

4. Improved Air Quality: Regular servicing of the air conditioner compressor can also improve the quality of the air you breathe. During maintenance, a technician will clean the compressor’s filters, removing dirt, dust, pollen, and other allergens. This helps prevent these particles from circulating in the air, reducing the risk of respiratory issues or allergies.

5. Cost Savings: Investing in regular servicing for your air conditioner compressor can ultimately save you money. By keeping the compressor clean and well-maintained, you can avoid costly repairs or replacements down the line. Additionally, an efficiently working compressor consumes less energy, resulting in lower utility bills.

6. Peace of Mind: Knowing that your air conditioner compressor is in top condition can give you peace of mind. Regular servicing allows you to catch and address any potential issues before they become major problems. This means you can enjoy a comfortable and cool environment without worrying about unexpected breakdowns or malfunctions.

7. Compliance with Warranty Requirements: Many air conditioner compressors come with a warranty that requires regular servicing. By scheduling regular maintenance, you ensure that you are meeting the warranty requirements, protecting your investment, and potentially avoiding any warranty voids.

In conclusion, regular servicing of an air conditioner compressor offers numerous benefits, including improved efficiency, extended lifespan, enhanced cooling performance, improved air quality, cost savings, peace of mind, and compliance with warranty requirements. Don’t overlook the importance of servicing your air conditioner compressor to ensure optimal performance and comfort.

FAQ:

What is an air conditioner compressor?

An air conditioner compressor is a device that is responsible for compressing the refrigerant gas in the air conditioning system.

How does an air conditioner compressor work?

An air conditioner compressor works by pumping the refrigerant gas from the evaporator coil to the condenser coil, increasing its pressure and temperature in the process.

What are the different types of air conditioner compressors?

There are three main types of air conditioner compressors: reciprocating compressor, scroll compressor, and rotary compressor.

What are the signs of a faulty air conditioner compressor?

Some signs of a faulty air conditioner compressor include loud noises, warm air instead of cold air, and frequent on/off cycles of the compressor.