Choosing the Right Size Air Compressor for Sandblasting: A Comprehensive Guide

When it comes to sandblasting, having the right size air compressor is essential for achieving optimal results. Whether you are a professional or a DIY enthusiast, understanding the different factors that determine the appropriate size compressor for your sandblasting needs can make all the difference in the efficiency and effectiveness of your work.

One of the key factors to consider when choosing the right size air compressor for sandblasting is the air pressure requirement. Sandblasting requires a high volume of compressed air, and using an air compressor with insufficient pressure can result in inadequate blasting power and slow progress. Therefore, it is important to select a compressor that is capable of generating the necessary air pressure for your specific sandblasting project.

Another factor to consider is the air flow requirement. Sandblasting relies on a continuous flow of compressed air to propel the abrasive material onto the surface being blasted. The amount of air flow needed depends on factors such as the size of the air nozzle and the type of abrasive material being used. It is important to choose an air compressor that can provide the required air flow to ensure efficient and consistent sandblasting.

Lastly, it is crucial to consider the size and capacity of the air compressor tank. Sandblasting is a demanding process that requires sustained air pressure for extended periods of time. A larger tank size can store more compressed air, allowing for longer periods of uninterrupted sandblasting. Additionally, a larger tank can help reduce the frequency of the compressor cycling on and off, which can enhance the overall efficiency of the sandblasting process.

By taking into account these important factors – air pressure requirement, air flow requirement, and tank size – you can choose the right size air compressor that will meet your sandblasting needs and ensure optimal performance. With the right equipment, you can achieve professional-level results and take your sandblasting projects to the next level.

Why Size Matters

When it comes to choosing an air compressor for sandblasting, size truly matters. The size of the air compressor directly affects its performance and efficiency in powering your sandblasting equipment. The right size compressor will ensure that you have adequate air pressure and volume to achieve the desired blasting results.

Air Pressure: The size of the air compressor determines the maximum air pressure it can produce. Sandblasting typically requires a high-pressure air supply to propel the abrasive material against the surface being blasted. If the compressor is too small, it may struggle to maintain the required pressure, resulting in inefficient blasting and unsatisfactory results. On the other hand, if the compressor is too large, it can lead to excessive pressure that may damage the workpiece or the sandblasting equipment.

Air Volume: Another crucial factor to consider is the air volume or capacity of the compressor. Sandblasting consumes a significant amount of compressed air, and having a compressor with sufficient volume ensures continuous and uninterrupted blasting. A compressor with a low air volume may cause air pressure to drop consistently during operation, leading to uneven blasting and reduced productivity. Conversely, a compressor with a high air volume can supply a steady stream of air, allowing for longer blasting sessions without frequent interruptions.

Efficiency and Cost: Choosing the right size of air compressor will also impact its efficiency and cost-effectiveness. A compressor that matches the specific requirements of your sandblasting equipment will operate at peak efficiency, minimizing energy waste and reducing operating costs. Additionally, an appropriately sized compressor will have a longer service life as it won’t be overworked or strained to meet the demands of sandblasting.

Overall, selecting the right size air compressor for sandblasting is essential for achieving optimal blasting results, maintaining efficiency, and prolonging the lifespan of your equipment. Taking into account factors such as air pressure, volume, and cost can help you make an informed decision and ensure that your sandblasting projects are successful.

Understanding Air Compressor Ratings

When choosing an air compressor for sandblasting, it is important to understand the different ratings that are associated with these machines. These ratings can help determine the performance and capabilities of the compressor, allowing you to make an informed decision.

Cubic Feet per Minute (CFM)

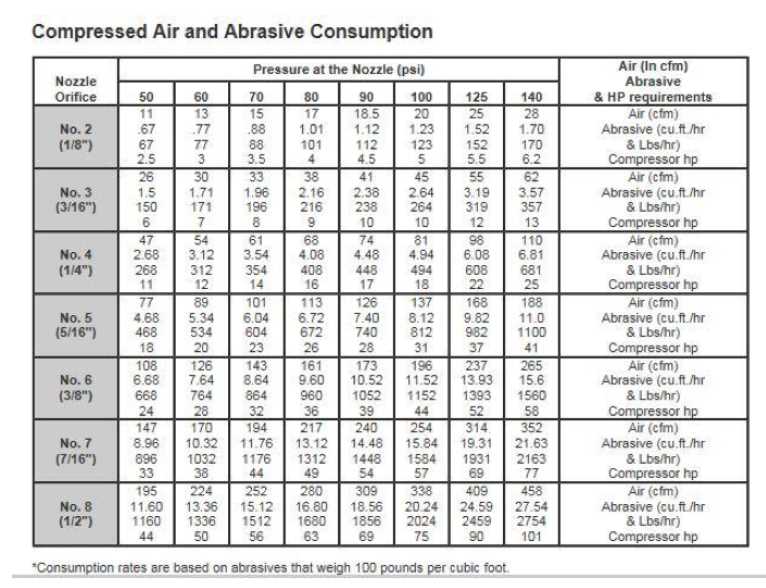

One of the most important ratings to consider is the Cubic Feet per Minute (CFM). This measures the volume of compressed air that the compressor can deliver within a minute. The CFM rating should match or exceed the requirements of your sandblasting equipment. If the CFM is not sufficient, the compressor may not provide enough air pressure, resulting in poor blasting performance.

Horsepower (HP)

The horsepower rating of an air compressor refers to its motor power. A higher horsepower generally indicates a more powerful compressor that can deliver air at a higher pressure. However, it is important to note that horsepower alone is not an accurate indicator of a compressor’s performance. Other factors, such as the CFM and pressure ratings, should also be considered.

Additionally, it is important to consider the voltage and electrical requirements of the air compressor. Ensure that the compressor can be easily powered by the electrical system in your work environment.

Pressure (PSI)

The pressure rating of an air compressor is measured in pounds per square inch (PSI) and indicates the maximum pressure that the compressor can deliver. Different sandblasting tasks may require different pressure levels, so it is important to choose a compressor with a pressure rating that matches your specific needs.

Remember that these ratings should be considered in conjunction with other factors such as tank size, compressor type (oil-free or oil-lubricated), and overall build quality. Taking all these factors into account will ensure that you choose the right size air compressor for your sandblasting needs.

Determining Required Air Flow

When selecting an air compressor for sandblasting, it is essential to determine the required air flow for your specific sandblasting needs. The air flow, measured in cubic feet per minute (CFM), determines the efficiency and effectiveness of the sandblasting process.

Calculating the required air flow:

To calculate the required air flow for your sandblasting project, you need to consider several factors:

- The size of the nozzle: The size of the nozzle will influence the amount of air needed to propel the abrasive material. A larger nozzle size will require a higher CFM rating to achieve the desired performance.

- The material being blasted: Different materials require different air flow rates to achieve optimal results. Harder materials, such as steel, may require a higher CFM rating compared to softer materials like wood or plastic.

- The desired surface finish: The level of surface finish you want to achieve will also impact the required air flow. Finer finishes may require higher CFM ratings to achieve the desired result.

- The blasting pressure: The blasting pressure, measured in pounds per square inch (PSI), is another factor that affects the required air flow. Higher blasting pressures typically require higher CFM ratings to maintain consistent performance.

Once you have considered these factors, you can use the following formula to calculate the required air flow:

Required air flow (CFM) = (Blasting pressure (PSI) x Nozzle size (inches)) / 2

This formula provides a general guideline for determining the required air flow for sandblasting. However, it is important to note that additional factors, such as the length and diameter of the air hose, can also impact the overall air flow and should be taken into consideration.

Considering Tank Capacity

When choosing the right size air compressor for sandblasting, one important factor to consider is the tank capacity. The tank capacity refers to the amount of air that the compressor can hold at one time. Having a larger tank capacity can be advantageous for sandblasting as it allows for longer continuous operation without the need to stop and wait for the tank to refill.

Capacity requirements: The tank capacity you need for sandblasting will depend on the size of your sandblasting project. Smaller projects may only require a tank capacity of around 20-30 gallons, while larger industrial projects may require tanks with capacities of 100 gallons or more.

Continuous operation: If you anticipate needing to sandblast for extended periods of time without interruption, a larger tank capacity is recommended. This will allow the compressor to supply a steady flow of compressed air for a longer duration, minimizing the need for frequent pauses to allow the tank to refill.

Recharge time: It’s also important to consider the recharge time for the tank. After each sandblasting session, the tank will need to refill with compressed air. Smaller tanks with lower capacities may have shorter recharge times, while larger tanks may take longer. This is something to keep in mind if you have time constraints for your sandblasting project.

Multiple tanks: Another option to consider is using multiple tanks instead of one large tank. This can be beneficial if you have limited space or if you need to have different types of abrasive media readily available. By having multiple tanks, you can switch between them as needed, ensuring a constant supply of compressed air for sandblasting.

Evaluating Power Source

When choosing the right size air compressor for sandblasting, it is important to evaluate the power source options available to you. The power source of the air compressor will determine its portability and overall performance.

Electric Power Source

An electric power source is a popular choice for air compressors used in sandblasting. Electric-powered compressors are generally more energy-efficient and quieter compared to other power sources. They are also easier to start and require less maintenance. However, they may have limited portability as they need to be near an electrical outlet. Additionally, electric compressors may not deliver as much power as other types of compressors.

Gasoline Power Source

A gasoline power source provides more portability compared to electric compressors. They can be used in remote areas where electricity is not readily available. Gasoline-powered compressors also tend to deliver higher power outputs, making them suitable for heavy-duty sandblasting applications. However, they can be noisy and emit exhaust fumes, which could be a concern if you are working in an enclosed space or in areas with poor ventilation.

Diesel Power Source

Diesel-powered air compressors are known for their durability and high performance. They are commonly used in industrial settings for sandblasting applications. Diesel compressors offer excellent portability and are ideal for outdoor or off-grid projects. They can deliver high volumes of air and provide consistent power output. However, they can be more expensive and require regular maintenance.

When evaluating the power source for your air compressor, consider the specific needs of your sandblasting project, such as the location, power requirements, and level of portability required. It is recommended to consult with a professional or manufacturer to ensure you choose the right power source that suits your sandblasting needs.

Choosing the Right Nozzle Size

Consider the Material Being Sandblasted

When choosing the right nozzle size for sandblasting, it’s important to consider the material you’ll be working with. Different materials require different nozzle sizes to achieve optimal results. For example, softer materials like wood or plastic may require a smaller nozzle size to prevent damage, while harder materials like metal or concrete may require a larger nozzle size to effectively remove the surface coatings.

Balance Between Blast Power and Precision

The nozzle size also plays a crucial role in finding the right balance between blast power and precision. A larger nozzle size will provide more blast power, allowing for faster material removal, but it may sacrifice precision and may create uneven surfaces. On the other hand, a smaller nozzle size will offer greater precision, but it may take longer to remove coatings or clean the surface. It’s important to find the right balance based on the specific project requirements.

Refer to Manufacturer’s Guidelines

To ensure that you choose the right nozzle size, it’s always recommended to refer to the manufacturer’s guidelines. They will typically provide recommendations based on the type of compressor and sandblasting equipment you’re using. These guidelines take into account factors such as air pressure, compressor capacity, and sandblasting media. By following the manufacturer’s recommendations, you can achieve optimal results and prolong the lifespan of your equipment.

Experiment and Fine-Tune

Choosing the right nozzle size may require some experimentation and fine-tuning. It’s always a good idea to start with a nozzle size that is recommended by the manufacturer and then make adjustments based on the actual performance during sandblasting. By testing different nozzle sizes and observing the results, you can determine the optimal size for your specific needs. Keep in mind that nozzle size is not the only factor affecting the sandblasting process, and other variables such as abrasive media size, air pressure, and technique should also be considered.

Overall, choosing the right nozzle size for sandblasting is a critical step to achieve desired results. It requires considering the material being sandblasted, finding the right balance between blast power and precision, referring to manufacturer’s guidelines, and conducting experimentations to fine-tune the process. With the right nozzle size, you can complete your sandblasting projects efficiently and effectively.

Additional Considerations

When choosing the right size air compressor for sandblasting, there are several additional factors to consider. These considerations include:

- Compressor Power Source: Determine if you will be using an electric or gas-powered air compressor. Electric compressors are typically more suitable for indoor use, while gas-powered compressors are better suited for outdoor applications.

- Compressor Mobility: Consider the portability of the air compressor. If you need to move it frequently, a lightweight and compact compressor would be ideal. However, if it will stay in one location, a larger, stationary compressor may be a better choice.

- Noise Level: Take into account the noise level of the air compressor. If you will be using it in a residential area or in close proximity to others, a quiet compressor may be necessary to minimize disturbances.

- Tank Size and Pressure: Evaluate the tank size and pressure requirements for your sandblasting applications. A larger tank size will allow for longer continuous operation, while higher pressure levels may be necessary for more demanding blasting projects.

- Air Quality: Consider the quality of air produced by the compressor. It is important to ensure that the air is clean and free from contaminants, as these can negatively affect the sandblasting process and the quality of the finished work.

By taking these additional considerations into account, you can choose the right size air compressor for your sandblasting needs that meets your specific requirements and provides optimal performance.

FAQ:

What factors should I consider when choosing the right size air compressor for sandblasting?

There are several factors to consider when choosing the right size air compressor for sandblasting. Some of the important factors include the size of the sandblasting nozzle, the pressure required for the sandblasting job, the air flow rate, and the size of the air tank on the compressor.

How do I calculate the required air pressure for sandblasting?

To calculate the required air pressure for sandblasting, you need to consider the size of the sandblasting nozzle and the material you are blasting. Smaller nozzles and harder materials require higher air pressure. As a general rule, you can start with a pressure of around 100 PSI and adjust as needed.

What is the ideal air flow rate for sandblasting?

The ideal air flow rate for sandblasting depends on the size of the sandblasting nozzle and the type of abrasive material you are using. Typically, a flow rate of around 50-100 cubic feet per minute (CFM) is suitable for most sandblasting applications. However, some larger projects may require higher flow rates.

How important is the size of the air tank on the compressor?

The size of the air tank on the compressor is important because it affects the air storage capacity. A larger air tank allows for longer periods of continuous sandblasting without the need for the compressor to run constantly. This can help prevent overheating and extend the life of the compressor.

What are the drawbacks of using a small air compressor for sandblasting?

Using a small air compressor for sandblasting can result in a decrease in efficiency and productivity. A small compressor may not be able to provide enough air flow and pressure for the sandblasting job, leading to slower and less effective blasting. It can also put more strain on the compressor, potentially causing it to overheat or wear out more quickly.

Can I use a standard household air compressor for sandblasting?

No, a standard household air compressor is typically not suitable for sandblasting. Household compressors are usually designed for light-duty tasks and may not have enough power and capacity to handle the air flow and pressure requirements of sandblasting. It is recommended to use a compressor specifically designed for industrial applications.

How can I ensure I choose the right size air compressor for my sandblasting needs?

To ensure you choose the right size air compressor for your sandblasting needs, it is important to carefully consider the factors mentioned earlier, such as the size of the sandblasting nozzle, the required pressure, the air flow rate, and the size of the air tank. It is also helpful to consult with professionals or experts in sandblasting equipment to get advice and recommendations based on your specific requirements.

Video: