Where to Install Water Separator on Air Compressor: Best Placement Guide

When it comes to using an air compressor, one of the most important tasks is to ensure that the air being pumped out is free from any moisture or water vapor. This can be accomplished by installing a water separator, also known as a moisture separator, in the air compressor system. The water separator works by removing any moisture from the compressed air, preventing damage to equipment and ensuring better performance.

But where exactly should you install the water separator on your air compressor? The placement of the water separator is crucial for its effectiveness. Ideally, it should be installed close to the air compressor outlet, as this is where the air is hottest and carries the highest amount of moisture. Placing the water separator in this location allows for maximum moisture removal before the air is used for any applications.

In addition to the location, it is also important to consider the orientation of the water separator. The airflow direction must be taken into account to ensure proper functionality. The water separator should be installed with the inlet pointing downwards, which allows for gravity to assist in the separation process. This allows the moisture to collect at the bottom of the separator, where it can be easily drained out.

Furthermore, it is recommended to install a water separator with a drain valve for easy maintenance. This allows you to periodically release any accumulated moisture without having to disassemble the separator. Most water separators come with a drain valve already installed, but if yours doesn’t, it is worth considering adding one for convenience.

In conclusion, the placement of a water separator on an air compressor is crucial for maintaining the quality of compressed air. By installing it close to the compressor outlet, with the inlet pointing downwards, and ensuring it has a drain valve, you can effectively remove moisture from the air and improve the performance and longevity of your equipment.

Where to Install Water Separator on Air Compressor

If you own an air compressor, you may be wondering where to install the water separator for optimal performance. A water separator is an important component of an air compressor system as it helps remove water vapor and other impurities from the compressed air. Installing the water separator in the right location is crucial to ensure it effectively removes moisture and contaminants.

Locating the Air Intake

The first step in determining where to install the water separator is to locate the air intake of your air compressor. The air intake is where the air enters the compressor system and it is usually equipped with a filter to prevent debris from entering the compressor. The water separator should be installed after the air intake, as close to the compressor as possible.

Avoiding High-Temperature Areas

When choosing the installation location for the water separator, it is important to avoid high-temperature areas. High temperatures can cause the moisture in the compressed air to condense, defeating the purpose of the water separator. Therefore, it is recommended to install the water separator in a cool and dry location, away from the compressor motor and other heat sources.

Positioning the Water Separator

Once you have identified the appropriate location, you can position the water separator accordingly. It is generally recommended to install the water separator in a vertical position to allow for proper drainage of collected water. This helps prevent water from accumulating and potentially damaging the components of the water separator.

Additionally, you can consider installing a drain valve at the bottom of the water separator to manually release any collected water. This allows for easier maintenance and ensures the optimal performance of the water separator.

In conclusion, the water separator should be installed after the air intake and as close to the compressor as possible. It should be positioned in a cool and dry location, away from high-temperature areas. Installing the water separator vertically with a drain valve at the bottom ensures effective removal of moisture and contaminants from the compressed air.

Importance of Water Separation

Preventing Equipment Damage

Effective water separation is crucial for the proper functioning and longevity of air compressors and associated equipment. When moisture enters the compressed air system, it can cause corrosion and damage to internal parts, leading to costly repairs and downtime. By installing a water separator at the appropriate location, you can prevent water from reaching sensitive components and ensure optimal performance.

Improving Air Quality

Water vapor in compressed air can contaminate the final output, affecting the quality of the air supplied to pneumatic tools, machinery, and other applications. The presence of water can cause issues such as corrosion, rust, and blockages in air lines, leading to reduced efficiency and potential product defects. By effectively separating water from the compressed air, you can maintain a clean and dry air supply, preventing these problems and ensuring the highest quality output.

Enhancing System Efficiency

Water in compressed air can lead to energy wastage and reduced efficiency. As moisture accumulates in the system, it can cause pressure drops, increased friction, and diminished airflow. This results in increased energy consumption and decreased overall system performance. By properly separating water from the air stream, you can improve system efficiency, reduce energy costs, and enhance productivity.

Extending Equipment Lifespan

Prolonged exposure to moisture can significantly shorten the lifespan of air compressors and related equipment. Water can cause corrosion and damage to critical components such as valves, cylinders, and air tools. By effectively removing water from the compressed air, you can mitigate the risks of equipment deterioration and extend its usable life. This in turn reduces the need for frequent repairs or replacements, saving both time and money in the long run.

Compliance with Industry Standards

In many industries, compliance with certain air quality standards is mandatory. Water separation is an essential requirement for meeting these standards and ensuring the safety and reliability of compressed air systems. By installing a water separator at the recommended location, you can adhere to industry regulations, avoid potential penalties, and maintain the integrity of your operations.

Best Placement for Water Separator

When it comes to installing a water separator on an air compressor, the placement of the separator is crucial for optimal performance and efficiency. Here are a few recommendations for the best placement of a water separator:

Close to the Air Compressor Outlet

One of the best places to install a water separator is directly at the outlet of the air compressor. This placement allows the separator to remove as much moisture as possible before the compressed air travels further through the system. By removing moisture at this early stage, you can prevent issues such as rust, corrosion, and damage to downstream equipment.

Before Air Treatment Devices

If your air compressor system includes additional air treatment devices, such as filters or dryers, it is recommended to install the water separator before these devices. This placement ensures that the water separator can remove any moisture before it reaches the filters or dryers, allowing them to work more efficiently and prolonging their lifespan.

Downstream of Air Receiver Tanks

Installing the water separator downstream of air receiver tanks can also be a good option. Air receiver tanks help store compressed air and allow for the settling of moisture, which can then be removed by the water separator. This placement helps ensure that the compressed air entering the system is as dry as possible.

Overall, the best placement for a water separator will depend on the specific configuration and needs of your air compressor system. It is recommended to consult the manufacturer’s guidelines and consider the factors mentioned above to determine the most suitable location for your water separator.

Near the Compressor Outlet

Placing the water separator near the compressor outlet is a common and effective choice. This location allows for the separation of water from compressed air as it exits the compressor. By installing the water separator in this position, you can ensure that most of the moisture is captured before the air is sent through the distribution system.

Advantages:

- Efficient separation of water from compressed air at the source

- Prevents moisture from entering the air distribution system

- Reduces the chances of corrosion and damage to downstream equipment

- Improves the quality of compressed air for downstream applications

Considerations:

- The water separator should be installed with proper drainage to remove collected water periodically.

- Regular maintenance and inspection of the water separator are essential to ensure its proper functioning.

- It is recommended to install a coalescing filter or additional moisture removal equipment downstream of the water separator for enhanced moisture control.

After the Air Receiver Tank

One of the most common places to install a water separator on an air compressor is after the air receiver tank. The air receiver tank is where the compressed air is stored before it is distributed throughout the system. Installing the water separator after the tank ensures that any moisture that has accumulated in the tank is removed before the air is sent out to the various tools and equipment.

Installing the water separator after the air receiver tank also helps to protect the downstream components of the air compressor system. Moisture can cause damage to air tools, valves, and other equipment, leading to decreased performance and increased maintenance costs. By installing the water separator in this location, any moisture that may have been present in the tank is removed, reducing the risk of damage to downstream components.

When installing the water separator after the air receiver tank, it is important to consider the flow rate and capacity of the separator. The size of the separator should be chosen based on the maximum flow rate of the compressor system to ensure that it can effectively remove moisture from the compressed air. Additionally, the water separator should be installed in a location that is easily accessible for maintenance and draining any accumulated water.

In conclusion, installing a water separator after the air receiver tank is a common and effective placement for this important component of an air compressor system. It helps to remove moisture from the compressed air, protecting downstream components and ensuring optimal performance. Proper installation and maintenance of the water separator are crucial for its effectiveness in removing moisture and maintaining the overall efficiency of the air compressor system.

Before the Air Tools and Equipment

Before you start using air tools and equipment, it is essential to make sure that your air compressor is equipped with a water separator. A water separator is a device that helps remove moisture from the compressed air, ensuring that only dry air reaches your tools. This is important because moisture in the air can cause damage to the tools and affect their performance.

When installing a water separator on your air compressor, it is important to consider the best placement for optimal functionality. The water separator should be installed as close to the compressor outlet as possible, preferably within a few feet. Placing it close to the compressor outlet allows it to catch the moisture before it has a chance to travel through the air hoses and reach your tools.

Another important factor to consider when deciding where to install the water separator is the direction of airflow. The water separator should be installed in a vertical position, with the inlet at the bottom and the outlet at the top. This allows the moisture to collect at the bottom of the separator, where it can be drained out easily.

To ensure proper functionality and effectiveness of the water separator, it is essential to regularly drain the collected moisture. Most water separators have a drain valve at the bottom, which can be opened to release the accumulated water. It is recommended to drain the moisture daily or as per the manufacturer’s instructions to prevent any buildup and maintain optimal performance.

In addition to installing a water separator, it is also recommended to use an additional air dryer or filter to further remove any remaining moisture from the compressed air. This can help prevent any potential damage to your air tools and equipment and ensure their longevity.

In conclusion, before using air tools and equipment, it is crucial to install a water separator on your air compressor. Consider the best placement, close to the compressor outlet, and ensure proper airflow direction. Regularly drain the accumulated moisture and consider using an additional air dryer or filter for optimal performance.

Away from Heat Sources

Air compressors generate a significant amount of heat during operation. It is essential to install the water separator away from any heat sources to prevent damage to its components and ensure optimal performance.

Heat sources such as direct sunlight, furnaces, boilers, and other hot equipment can increase the temperature around the water separator, leading to potential malfunctions. It is recommended to find a cool and well-ventilated area for installation.

Avoid placing the water separator near heat-generating machinery or in areas with poor airflow. High temperatures can cause the separator’s filter element or other parts to deteriorate quickly, reducing its efficiency in removing water and contaminants from compressed air.

Additionally, heat can also promote condensation, which can impact the effectiveness of the water separator. Placing it away from heat sources helps maintain the temperature balance and prevent excessive condensation from occurring.

In summary, placing the water separator away from heat sources is essential for ensuring its longevity and optimal performance. It keeps the separator at a suitable operating temperature and prevents potential damage or decreased efficiency caused by high temperatures or excessive condensation.

Easy Access for Maintenance

Proper maintenance is essential for the efficient operation of an air compressor, including the water separator. To make maintenance tasks easier, it is important to ensure easy access to the water separator.

Close to the Air Compressor

One of the key considerations for the placement of the water separator is to position it as close to the air compressor as possible. This allows for easy access and minimizes the length of piping required.

Accessible Height

Another factor to consider is the height at which the water separator is installed. It is important to position it at a height that allows for easy reach during maintenance. This could be at a comfortable height for the operator or at a height that makes it easy to access with the help of a ladder or step stool.

Clearance Space

In addition to proximity and height, it is crucial to provide adequate clearance space around the water separator. This ensures that there is enough space to maneuver and perform maintenance tasks without any obstructions. A minimum clearance of at least a few feet in all directions is recommended to ensure easy access.

Labeling and Documentation

Lastly, it can be helpful to label the water separator and provide clear documentation outlining the maintenance procedures. This helps in quickly identifying the equipment and following the necessary steps for maintenance. Clear labeling and documentation save time and improve the efficiency of maintenance tasks.

In conclusion, easy access for maintenance of the water separator is crucial for the proper functioning of an air compressor. By positioning it close to the compressor, at an accessible height, with adequate clearance space, and providing clear labeling and documentation, maintenance tasks can be carried out efficiently and effectively.

Final Words

When it comes to installing a water separator on your air compressor, the placement is key. You want to ensure that it is installed in a location that allows for easy access and maintenance. Additionally, you want to make sure that it is installed in a spot where it can effectively remove water from the compressed air.

Based on our discussion, the best placement for a water separator is after the compressor and before any additional equipment or tools. This ensures that any water or moisture is removed from the air before it reaches your tools or machinery, thus preventing any potential damage or corrosion.

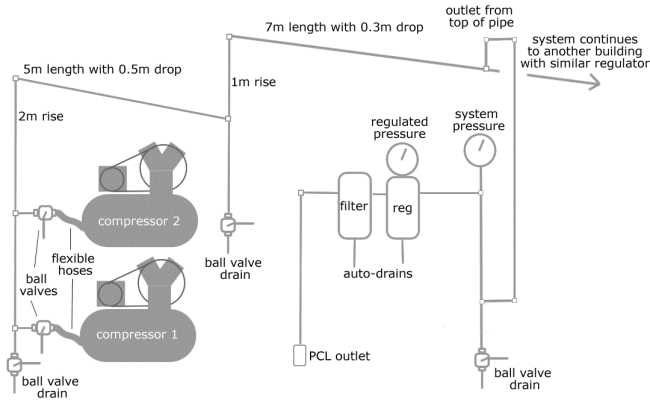

It is also important to consider the length and size of the piping when determining the placement of the water separator. You want to make sure that there is sufficient distance between the compressor and the separator to allow for proper cooling and condensation. Additionally, you want to ensure that the piping leading up to the separator is of the appropriate size to handle the flow of air.

Lastly, don’t forget to regularly inspect and clean your water separator to ensure its optimal performance. Over time, debris and sediment can accumulate, affecting its efficiency. By regularly maintaining and cleaning your water separator, you can prolong its lifespan and ensure that it continues to effectively remove water from your compressed air.

In conclusion, the placement of a water separator on your air compressor is crucial for its effectiveness and longevity. By following the guidelines mentioned in this guide, you can ensure that your water separator is installed in the best possible location for optimal performance.

FAQ:

What is a water separator and why is it important for an air compressor?

A water separator is a device that removes water vapor from the compressed air. It is important for an air compressor because water in the compressed air can lead to corrosion and damage to the equipment, as well as negatively affect the performance of air-powered tools and machinery.

Where is the best place to install a water separator on an air compressor?

The best place to install a water separator on an air compressor is as close to the compressor outlet as possible. This allows the separator to effectively remove water vapor before it travels through the compressed air system.

Can I install a water separator on the compressor tank?

It is not recommended to install a water separator directly on the compressor tank. The tank is not the ideal location to remove moisture from the compressed air. It is better to install the separator closer to the compressor outlet to ensure more efficient water removal.

Video: