How to Cut Asphalt with an Angle Grinder: A Step-by-Step Guide

If you have a driveway or a road made of asphalt that needs to be repaired or modified, using an angle grinder can be an effective tool to cut through the asphalt. This type of grinder is lightweight, portable, and can easily cut through the tough material. However, it is important to use proper techniques and safety precautions to ensure a successful and safe cut.

Step 1: Safety First

Before starting any cutting operation, it is crucial to wear protective gear, such as safety goggles, earplugs, and gloves. The angle grinder should be equipped with a diamond blade suitable for cutting asphalt. Make sure to read the manufacturer’s instructions for both the grinder and the blade and follow all safety guidelines.

Step 2: Preparing the Work Area

Clean the area where the cutting will take place, removing any loose debris or obstacles. Mark the cutting line on the asphalt using chalk or a marking tool. It is important to have a clear and precise cutting line for accuracy.

Step 3: Setting up the Angle Grinder

Make sure the angle grinder is securely mounted or held in place. Adjust the guard to cover the diamond blade while allowing enough clearance for the cutting depth needed. Set the grinder to the appropriate speed and install the diamond blade according to the manufacturer’s instructions.

Step 4: Cutting the Asphalt

Hold the angle grinder firmly with both hands and position the diamond blade on the marked cutting line. Slowly lower the blade onto the asphalt and begin to cut along the line. Apply consistent pressure and let the grinder and blade do the work. Avoid forcing the blade or pushing too hard, as this can cause damage or kickback.

Step 5: Cleaning up and Finishing Touches

Once the desired cut has been made, turn off the grinder and let the blade come to a complete stop. Use a broom or a wire brush to sweep away any remaining debris. Inspect the cut for any rough edges and use a file or sandpaper to smooth them out if necessary.

In conclusion, cutting asphalt with an angle grinder can be a simple and efficient process when done correctly. Remember to prioritize safety by wearing protective gear and following the manufacturer’s instructions. With proper preparation and technique, you can achieve precise and clean cuts in your asphalt for repairs or modifications.

Choosing the Right Angle Grinder

When it comes to cutting asphalt, choosing the right angle grinder is essential. The angle grinder you choose should have enough power and the right features to handle the job effectively and efficiently. Here are some factors to consider when selecting an angle grinder for cutting asphalt:

- Power: Look for an angle grinder with a high wattage rating, as this will provide the necessary power to cut through the tough asphalt material. A higher wattage will also ensure that the grinder doesn’t get bogged down or overheat during use.

- Diameter: The diameter of the grinder’s disc will determine the depth of the cut you can make. For cutting through thick layers of asphalt, a larger disc diameter is recommended.

- Speed: Look for an angle grinder with variable speed settings, as this will allow you to adjust the speed of the disc based on the thickness of the asphalt and the type of cut you need to make.

- Dust Collection: Cutting asphalt produces a significant amount of dust. To minimize the amount of dust in the air and on the work surface, choose an angle grinder that has a dust collection system or can be easily connected to a vacuum.

By considering these factors and selecting the right angle grinder, you can ensure that your cutting process is efficient, safe, and produces the desired results. Take the time to research and compare different models to find the one that best suits your needs and budget.

Preparing the Area

Before you start cutting asphalt with an angle grinder, it’s essential to properly prepare the area to ensure safety and efficiency. Here are the steps you should take:

-

Clear the area: Remove any obstructions, debris, or loose objects from the area where you will be cutting the asphalt. This will help prevent accidents and ensure a clean and smooth cut.

-

Mark the cutting line: Use chalk or a marking tool to clearly indicate the cutting line on the asphalt. This will serve as a guide, helping you maintain a straight and accurate cut.

-

Secure the area: If possible, cordon off the area where you will be working to prevent others from entering and to minimize the risk of accidents. You can use caution tape or cones to create a safe working zone.

-

Put on safety gear: Before you begin cutting, make sure to put on the necessary safety gear, including safety glasses, gloves, and ear protection. This will help protect you from any potential hazards, such as flying debris or excessive noise.

By taking these steps to prepare the area, you will create a safe and organized environment for cutting asphalt with an angle grinder. This will not only ensure your safety but also contribute to a more efficient and successful cutting process.

Wearing the Right Safety Gear

When cutting asphalt with an angle grinder, it is essential to prioritize safety and protect yourself from potential hazards. Wearing the right safety gear can greatly reduce the risk of injuries and accidents.

First and foremost, it is crucial to wear safety goggles or a face shield to protect your eyes from flying debris. The angle grinder can generate sparks and particles that can cause severe eye injuries. Ensure that the safety goggles or face shield fit properly and provide adequate coverage.

Additionally, it is important to wear ear protection, such as earplugs or earmuffs, to safeguard your hearing. The angle grinder can produce loud noises that may exceed the recommended noise level, leading to hearing damage over time. Protecting your hearing is essential for your long-term well-being.

Another vital piece of safety gear when cutting asphalt is a dust mask or respirator. Cutting asphalt can generate a significant amount of dust and fine particles, which can be harmful if inhaled. A dust mask or respirator will help filter out these particles and protect your respiratory system.

Furthermore, don’t forget to wear sturdy work gloves to provide hand protection. The angle grinder can create vibrations and heat, making it essential to wear gloves that can withstand high temperatures and provide a good grip. This will prevent burns and allow you to have better control over the tool.

Lastly, wearing long-sleeved shirts and long pants is recommended to protect your skin from any potential burns or cuts. The angle grinder can produce sparks that could land on your skin and cause burns. Having your skin covered will minimize the risk of such injuries.

In conclusion, wearing the right safety gear when cutting asphalt with an angle grinder is crucial for your protection. Safety goggles or a face shield, ear protection, a dust mask or respirator, sturdy work gloves, and appropriate clothing will help prevent injuries and ensure a safer working environment. Prioritize your safety by wearing the right gear every time you use an angle grinder.

Marking the Cutting Line

Before you start cutting asphalt with an angle grinder, it’s important to mark the cutting line to ensure accuracy and precision. Marking the cutting line will help guide your cuts and ensure that you don’t deviate from your desired path.

To mark the cutting line, you can use a chalk or a paint stick. Hold the chalk or paint stick firmly and make a straight line on the surface of the asphalt. You can use a straightedge or a ruler to help you draw a straight line, especially if you need a longer and more precise cut.

It’s important to take your time when marking the cutting line and double-check for accuracy. A misaligned or crooked line can result in uneven cuts and a poor end result. Measure twice, cut once.

Additionally, if you are working on a larger project that requires multiple cuts, it can be helpful to mark all the cutting lines before you start cutting. This will help you stay organized and ensure that all the cuts are made in the correct locations.

Once you have marked the cutting line, it’s time to prepare for cutting. Make sure you have all the necessary safety equipment and tools, such as goggles, gloves, and an angle grinder with a diamond blade. Always prioritize safety when working with power tools.

Cutting the Asphalt

1. Prepare the Area

Before you begin cutting the asphalt, it’s important to prepare the area properly. Clear away any debris, loose soil, or vegetation that may be in the way. Make sure the asphalt is clean and free from any oil or other substances that may interfere with the cutting process.

2. Choose the Right Diamond Blade

Using the right diamond blade is crucial for cutting asphalt with an angle grinder. Look for a blade specifically designed for asphalt cutting, as it will have a higher concentration of diamond particles to handle the tough material. Make sure the blade is the correct size for your grinder and securely attached.

3. Wear Safety Gear

Before you start cutting, always remember to wear the appropriate safety gear. This includes goggles or a face shield to protect your eyes from flying debris, a dust mask to prevent inhaling any dust, and earplugs or earmuffs to protect your hearing from the loud noise of the angle grinder.

4. Set the Depth of Cut

Adjust the depth of cut on the angle grinder to the desired thickness of the asphalt you’re cutting. If you’re not sure about the depth, start with a shallow cut and gradually increase it until you reach the desired depth. This will help prevent any accidental damage to the underlying surface.

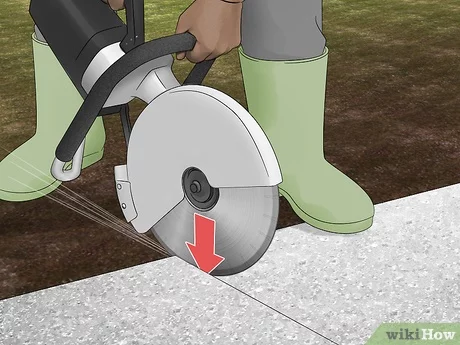

5. Make the Cuts

Start by making a small pilot cut in the asphalt to guide the grinding wheel. Hold the angle grinder firmly with both hands and slowly make the cut along the desired path. Use steady and even pressure, letting the weight of the grinder do the work. Make sure to follow the marked lines accurately to achieve a clean and straight cut.

- Work in small sections, cutting about 1-2 feet at a time before moving on.

- If you encounter any obstacles like cracks or joints, take extra care to cut through them gently.

- Always be mindful of any hidden utilities or pipes that may be present beneath the asphalt surface.

6. Finish the Edges

Once you have made the main cuts, it’s important to finish the edges for a neat and professional-looking result. Use the angle grinder to smooth out any rough edges or uneven areas along the cut. Take your time and be gentle to avoid damaging the surrounding asphalt.

Remember, cutting asphalt with an angle grinder can be a challenging task that requires skill and caution. If you’re not confident in your abilities, it’s always best to hire a professional. Safety should always be your top priority when working with power tools.

Removing the Cut Asphalt Pieces

Once you have completed cutting the asphalt with the angle grinder, you will need to remove the cut pieces from the area. This step is crucial in order to achieve a clean and well-maintained pavement.

First, gather all the cut asphalt pieces into a pile using a broom or a shovel. Be careful while handling the pieces as they can be heavy and sharp.

Next, transfer the pile of cut asphalt pieces into a wheelbarrow or a large bucket for easy transportation. If the amount of asphalt is small, you can use a heavy-duty trash bag to collect and dispose of the pieces.

Before disposing of the cut asphalt, make sure to check your local regulations regarding the proper disposal method. Some areas may require you to take the asphalt pieces to a designated facility for disposal, while others may allow you to dispose of it with regular construction waste.

Remember to wear gloves and appropriate protective gear during the removal process to ensure your safety. Dispose of the cut asphalt pieces responsibly and in accordance with local regulations.

Cleaning the Area

Clearing debris and loose dirt

Before you start cutting asphalt with an angle grinder, it is important to clean the area to ensure a smooth and efficient cutting process. Begin by clearing any debris, loose dirt, or rocks from the surface of the asphalt. This can be done using a broom, rake, or shovel, depending on the size of the area being cleaned. Removing these loose particles will prevent them from interfering with the cutting process and potentially damaging the angle grinder or blade.

Sweeping or blowing away dust and small particles

After clearing the larger debris, it is necessary to remove any dust or small particles that may be present on the surface of the asphalt. This can be accomplished by either sweeping the area with a stiff-bristled broom or using a leaf blower to blow away the dust. Sweeping or blowing will help create a clean and smooth surface, allowing the angle grinder to cut through the asphalt with ease and precision.

Removing oil stains or spills

If there are any oil stains or spills on the asphalt, it is important to remove them before cutting. Oil can interfere with the cutting process and reduce the effectiveness of the angle grinder. To remove oil stains, apply an absorbent material such as cat litter or sawdust to the affected area. Allow it to remain on the stain for a few hours, then sweep or vacuum it up. If necessary, repeat this process until the oil stain is completely removed.

Inspecting the area for any potential hazards

Prior to using the angle grinder, take a moment to inspect the area for any potential hazards or obstacles that may impede the cutting process. Look for any cracks, bumps, or uneven surfaces that could cause the angle grinder to kickback or become unstable. Additionally, ensure there are no underground utilities or cables running beneath the area you plan to cut. Identifying and addressing these potential issues will help ensure a safe and successful cutting operation.

Finalizing the Task

Inspect the Cut

Once you have finished cutting the asphalt with the angle grinder, it is important to inspect your work to ensure that the cut is clean and precise. Look for any jagged edges or uneven cuts that may need to be smoothed out. If necessary, use a chisel or file to remove any rough areas and create a smooth finish.

Clean up the Area

After cutting the asphalt, it is essential to clean up the debris and dust created during the process. Use a broom or a brush to sweep away any loose particles and collect them in a dustpan. Dispose of the debris properly to ensure a safe and clutter-free work area.

Seal or Repave

Depending on the purpose of the cut and the condition of the surrounding asphalt, you may need to seal or repave the area. If the cut was made for a specific installation, such as adding a utility line or repairing a damaged section, make sure to seal the cut with asphalt patch or repair compound to prevent water seepage and further damage. If the cut is part of a larger renovation or repaving project, consult with a professional contractor to determine the best course of action.

Maintain Safety Measures

Even after you have completed the task of cutting asphalt with an angle grinder, it is crucial to maintain safety measures. Store the angle grinder in a secure and appropriate place, away from the reach of children or unauthorized users. Clean and maintain the grinder regularly to ensure its optimal performance for future projects. Always wear safety goggles, gloves, and other protective gear when operating power tools to prevent accidents or injuries.

Reflect on the Process

As you have successfully cut asphalt with an angle grinder, take some time to reflect on the process and learn from your experience. Consider what went well and what could be improved for future projects. This reflection will help you refine your skills and become more efficient in handling similar tasks in the future.

FAQ:

What safety precautions should I take when cutting asphalt with an angle grinder?

When cutting asphalt with an angle grinder, it is important to take several safety precautions. First, make sure you wear protective gear, such as safety glasses, gloves, and a dust mask. Second, secure the area around the asphalt to prevent any accidents or injuries to bystanders. Lastly, before starting the cutting process, inspect the angle grinder to make sure it is in good working condition and the blade is properly installed.

What type of blade should I use for cutting asphalt with an angle grinder?

For cutting asphalt with an angle grinder, you should use a diamond blade specifically designed for cutting through hard materials like asphalt. Diamond blades are known for their durability and can cut through asphalt smoothly and efficiently.

What should I do to prepare the asphalt before cutting it with an angle grinder?

Before cutting the asphalt with an angle grinder, it is important to prepare the surface. Start by cleaning the area to remove any debris or loose asphalt. Then, mark the area you want to cut with a chalk or marker. This will help you stay on track and ensure accurate cuts.

Can I cut curves in asphalt with an angle grinder?

Yes, you can cut curves in asphalt with an angle grinder. To do so, you need to use a steady hand and make small, controlled movements. Start by making a small cut and gradually work your way along the desired curve. It may take some practice to achieve smooth curves, so be patient and take your time.

What are some alternative tools for cutting asphalt?

While an angle grinder is a popular choice for cutting asphalt, there are a few alternative tools you can use. A circular saw with a diamond blade can be used for straight cuts, while a reciprocating saw with a demolition blade is great for removing sections of asphalt. Another option is a concrete saw, which is specifically designed for cutting through tough materials like asphalt.

Is it necessary to wear a dust mask when cutting asphalt with an angle grinder?

Yes, it is highly recommended to wear a dust mask when cutting asphalt with an angle grinder. Cutting asphalt creates a lot of fine dust particles that can be harmful if inhaled. Wearing a dust mask will help protect your lungs and prevent any potential health issues.

Video: