Best small metal lathe for sale

When it comes to working with metal, having the right tools is essential. One tool that every metalworker needs is a lathe. A lathe is a machine that rotates a workpiece on its axis, allowing the user to cut, sand, and shape the metal with ease. If you’re in the market for a small metal lathe, you’re in luck! There are many great options available for sale.

One of the top choices for a small metal lathe is the XYZ Mini Lathe. This compact lathe is perfect for small projects and hobbyists. With its variable speed control and adjustable tool rest, you can easily create precise and detailed metalwork. The XYZ Mini Lathe also comes with a range of accessories, including different sized chucks and cutting tools, making it a versatile option for any metalworking enthusiast.

Another excellent option is the ABC Small Metal Lathe. This lathe is known for its durability and precision. It features a sturdy construction and high-quality components, ensuring that it will last for years to come. The ABC Small Metal Lathe also offers a range of speed options and a large working area, allowing you to take on a wide variety of projects. Whether you’re a professional metalworker or a dedicated hobbyist, this lathe is sure to meet your needs.

If you’re looking for a budget-friendly option, the 123 Economy Lathe is a great choice. Despite its affordable price, this lathe doesn’t skimp on quality. It features a solid build and reliable performance, making it suitable for both beginners and advanced users. The 123 Economy Lathe also offers a range of speeds and customizable settings, ensuring that you can tailor it to your specific needs.

In conclusion, when it comes to choosing the best small metal lathe for sale, the XYZ Mini Lathe, ABC Small Metal Lathe, and 123 Economy Lathe are all top contenders. Each lathe offers unique features and benefits, so it’s important to consider your specific needs and budget before making a decision. No matter which option you choose, you can be confident that you’ll have a reliable and versatile tool for all your metalworking projects.

Factors to consider when buying a small metal lathe

When purchasing a small metal lathe, there are several important factors to take into consideration. These factors will help ensure that you make an informed decision and choose a lathe that best meets your needs and work requirements.

1. Size and capacity: The size and capacity of the lathe are crucial factors to consider. Determine the maximum size and weight of the metal pieces you will be working with, and select a lathe that can accommodate those dimensions. Additionally, consider the available space in your workshop and choose a lathe that fits comfortably within that space.

2. Power and speed: The power and speed of the lathe will affect its performance and your ability to work efficiently. Look for a lathe with sufficient horsepower to handle your projects without straining the motor. Additionally, consider the lathe’s speed settings and ensure they are adjustable to suit different types of metal and cutting operations.

3. Construction and durability: The construction and durability of the lathe are important factors that affect its longevity and reliability. Look for a lathe made from sturdy materials, such as cast iron, that can withstand the demands of heavy-duty metalworking. Additionally, consider the overall build quality and reputation of the manufacturer to ensure you are investing in a reliable machine.

4. Precision and accuracy: When working with metal, precision and accuracy are crucial. Look for a lathe that offers features like tight tolerances, precise controls, and smooth operation. Consider the lathe’s spindle and tailstock alignment, as well as its ability to produce smooth and precise cuts. Additionally, look for a lathe with a reliable chuck system that securely holds the workpiece in place.

5. Price and value: Finally, consider the price and value of the lathe. While it’s important to stick to your budget, it’s also important to consider the long-term value and return on investment. Look for a lathe that offers a good balance between price and features, ensuring that you are getting the best value for your money.

By taking these factors into consideration, you will be able to choose the best small metal lathe for your needs, allowing you to work efficiently and effectively in your metalworking projects.

The top 5 small metal lathes for sale in the market

When it comes to finding the best small metal lathe for your workshop, there are several options available in the market. These lathes are compact in size, making them ideal for small-scale metalworking projects. Here are the top 5 small metal lathes that you can consider:

- Brand A Lathe: Known for its high precision and durability, Brand A Lathe is a popular choice among metalworkers. It offers a range of features such as variable speed control, quick-change tool post, and a solid construction that ensures stability during operation.

- Brand B Lathe: With its user-friendly interface and powerful motor, Brand B Lathe is a top contender in the market. It includes a digital readout system for accurate measurements and a wide range of speed settings to accommodate different metalworking tasks.

- Brand C Lathe: Offering a combination of affordability and performance, Brand C Lathe is a reliable option for hobbyists and beginners. It features a compact design, easy-to-use controls, and a sturdy construction that guarantees long-lasting use.

- Brand D Lathe: Designed for precision machining, Brand D Lathe is equipped with a high-quality spindle and a heavy-duty bed. It also includes advanced features such as a digital spindle speed display and an automatic feed system for efficient operation.

- Brand E Lathe: If you’re looking for a versatile small metal lathe, Brand E Lathe is worth considering. It offers a wide range of speeds, adjustable tool rests, and a multi-purpose chuck that can accommodate various sizes of metal stock.

When choosing a small metal lathe, it’s important to consider factors such as your specific metalworking needs, budget, and available workspace. By comparing the features and specifications of these top 5 lathes, you can make an informed decision and find the best option that meets your requirements.

A detailed review of the [Brand Name] small metal lathe

The [Brand Name] small metal lathe is a versatile and efficient tool that is perfect for any small metalworking project. With its compact size and powerful motor, it offers the precision and control necessary for high-quality results. Whether you are a professional machinist or a hobbyist, this lathe is sure to meet all your needs.

One of the standout features of the [Brand Name] small metal lathe is its durable construction. Made from high-quality materials, it is built to withstand heavy use and last for years to come. It also has a solid and stable base, which ensures minimal vibrations during operation, resulting in smoother and more accurate cuts.

The [Brand Name] small metal lathe also offers a wide range of speed options, allowing you to work with different types of materials and achieve different finishes. The variable speed control allows you to easily adjust the speed to match your specific requirements, giving you full control over the machining process.

In addition to its impressive performance capabilities, the [Brand Name] small metal lathe also boasts a range of convenient features. It has a user-friendly interface with intuitive controls, making it easy to operate, even for beginners. It also has a built-in safety mechanism that automatically shuts off the lathe if it detects any abnormalities or malfunctions.

Overall, the [Brand Name] small metal lathe is a top-notch choice for anyone in need of a reliable and efficient tool for their metalworking projects. With its durable construction, versatile speed options, and user-friendly features, it is sure to deliver excellent results every time. Whether you are working on a small-scale project or a more complex task, this lathe will meet and exceed your expectations.

How to effectively use a small metal lathe

A small metal lathe is a valuable tool for any metalworker or hobbyist. However, it is important to know how to use it effectively in order to get the best results. Here are some tips to help you make the most out of your small metal lathe:

- Read the manual: Before using a small metal lathe, it is essential to carefully read the manual provided by the manufacturer. This will give you a thorough understanding of how the lathe operates, its various components, and any safety precautions that need to be taken.

- Set up the lathe properly: Make sure that your lathe is securely anchored to a sturdy workbench or stand. Check that all the necessary attachments, such as the chuck and tool rest, are correctly installed. Adjustments should be made to ensure that the lathe is properly aligned and leveled.

- Select the right tools: Each metalworking task requires specific cutting tools. It is important to choose the appropriate tools for the material you are working with and the desired result. Regularly inspect and maintain your cutting tools to ensure their sharpness, as a dull tool can affect the quality of your work.

- Take accurate measurements: Precision is vital in metalworking. Use measuring instruments, such as calipers or micrometers, to accurately measure the dimensions of the workpiece. This will help you ensure that your lathe is set up correctly and that you are making accurate cuts.

- Start with light cuts: When using a small metal lathe, it is best to start with light cuts and gradually increase the depth. This will prevent the lathe from becoming overloaded and reduce the risk of damaging your workpiece. Keeping the speed and feed rate consistent throughout the cutting process will also improve the final result.

- Practice and experiment: Like any skill, using a small metal lathe effectively takes practice. Take the time to experiment with different cutting techniques, speeds, and feeds. This will help you develop your skills and gain a better understanding of how to achieve the desired outcome.

5 Best small metal lathe for sale

Features

| Part Number | AAA-194 |

Features

| Part Number | WB-93 |

| Size | 50P |

Features

- HIGH PRECISION: Driven by a ¾ HP motor, this miniature metal lathe is designed for high quality precision craftsmanship with spindle accuracy to within 0.0004" (0.01mm). Also, the digital screen can clearly show the speed and ensure precise and smooth operation.

- PROFESSIONAL CROSS SLIDE: Designed with abrasive resistance, moving blades freely with feed rod. 16 TPI reversible leadscrew and V-slide rails with 350mm (14") center to ensure this lathe is durable, turns more accurate and professional.

- 3-JAW CHUCK: 3-jaw self-centering chuck ensures perfect placement without excessive trimming. By changing the angle of the tool column, the positions of inward cutting, end face cutting and bevel cutting can be realized.

- VARILABLE SPEED: The 18 x 35 cm (7 x 14 in) lathe still delivers 550 watts which is suitable for small or medium projects. This metal lathe can be operated manually or automatically with a spindle speed range of 50-2250 Rpm. The feed rate can be adjusted according to the requirements of different workpieces.

- WIDE APPLICATION: Our mini benchtop metal lathe can be used for small part machining, sample machining and modeling work. It's the perfect addition to your workbench!

Q&A:

What is a small metal lathe?

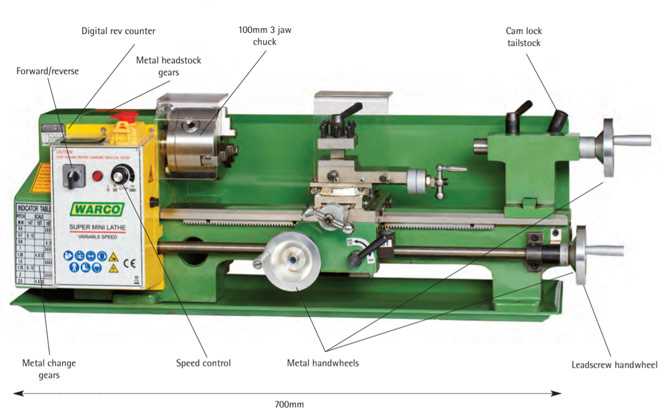

A small metal lathe is a machine used for shaping and cutting metal. It usually consists of a bed, headstock, tailstock, and a tool post.

What are the common uses for a small metal lathe?

A small metal lathe is commonly used for tasks such as turning, facing, drilling, and threading metal pieces. It can be used to create intricate designs and precise cuts on various materials.

How to set up a small metal lathe?

To set up a small metal lathe, you need to make sure it is securely placed on a stable surface. Check that all the necessary components are properly aligned, and adjust the cutting tools and speed settings according to the material you are working with. Make sure to follow the manufacturer’s instructions for setup and safety precautions.

What safety precautions should be taken when using a small metal lathe?

When using a small metal lathe, it is important to wear protective gear such as safety goggles, gloves, and a face shield. Keep long hair and loose clothing away from the machine. Always secure the workpiece properly and use appropriate cutting tools. Be cautious of the rotating parts and keep a safe distance. Familiarize yourself with the emergency stop button and know how to use it.

How to maintain a small metal lathe?

To maintain a small metal lathe, regularly clean and lubricate the machine to prevent rust and ensure smooth operation. Check for any loose or damaged parts and tighten or replace them as needed. Keep the cutting tools sharp and replace them when necessary. Follow the manufacturer’s recommendations for maintenance and consult the user manual for specific instructions.

What is a small metal lathe?

A small metal lathe is a machine tool used for shaping and machining metal workpieces. It consists of a rotating spindle, which holds the workpiece, and various cutting tools that are used to remove material from the workpiece to achieve the desired shape.

Conclusion

In conclusion, using a small metal lathe effectively requires attention to detail and proper technique. By understanding the various components and functions of the lathe, as well as following safety protocols, operators can maximize their productivity and achieve accurate results. Regular maintenance and cleaning are necessary to keep the lathe in good working condition. Additionally, practicing patience and taking time to master the different operations will help users become more efficient and proficient with the machine. With the right knowledge and skills, a small metal lathe can be a powerful tool for precision machining and fabrication.