Best lathe for making pool cues

When it comes to crafting the perfect pool cue, having the right tools is essential. One of the most important tools for cue-making is a lathe. A lathe is a machine that rotates a workpiece on its axis, allowing the craftsman to shape and cut the material to precise specifications. Finding the best lathe for making pool cues can greatly enhance the quality and accuracy of your work.

There are several factors to consider when choosing a lathe for cue-making. One important aspect is the size and capacity of the lathe. Pool cues are typically long and slender, so it’s important to choose a lathe with enough length and stability to handle the cue blanks. A lathe with a bed length of at least 36 inches is recommended to accommodate the length of the pool cue.

In addition to size, the lathe’s motor power is another crucial consideration. Cue-making requires precise and detailed cutting, which requires a powerful and consistent motor. Look for a lathe with a motor of at least 1 horsepower for optimal performance. A strong motor will ensure smooth and accurate cuts, resulting in a high-quality finished product.

Another feature to look for in a lathe for cue-making is versatility. Pool cues come in various styles and designs, so a lathe that allows for customization and creativity is ideal. Features like variable speed control, adjustable tool rests, and multiple spindle options can provide the flexibility needed to create cues with unique designs and details.

Choosing the Ideal Lathe for Crafting Pool Cues

When it comes to crafting high-quality pool cues, having the right lathe is essential. A lathe is a machine that rotates a workpiece on its axis, allowing for precise shaping and finishing. To create the best pool cues, you need a lathe that offers both accuracy and control. Here are some key factors to consider when selecting the ideal lathe for making pool cues.

1. Speed Control:

An important feature to look for in a lathe for making pool cues is speed control. Different stages of the cue-making process require varying levels of speed. For example, rough turning requires a higher speed, while fine finishing and sanding demand slower speeds. Look for a lathe that offers a variable speed control option, allowing you to adjust the rotation speed according to your specific needs.

2. Precision and Stability:

Pool cues require intricate detailing and precise measurements, making stability and precision crucial when choosing a lathe. Look for a lathe with a sturdy and rigid construction, as this will help minimize vibrations and ensure accurate cuts. Additionally, consider a lathe with features like a robust tool rest and tailstock, which will contribute to the overall stability of the machine.

3. Versatility:

While a lathe dedicated solely to cue-making might be ideal for professionals, for hobbyists or beginners, a versatile lathe that can also handle other projects is a practical choice. Look for a lathe that offers enough swing capacity and bed length to accommodate different cue lengths. Additionally, consider a lathe with a range of compatible accessories, such as steady rests and faceplates, which will allow you to take on various cue-making techniques.

4. Material Compatibility:

Pool cues can be made from a variety of materials, including wood, carbon fiber, and fiberglass. When selecting a lathe, ensure that it can handle the specific materials you plan to work with. For example, if you primarily work with exotic hardwoods, you’ll need a lathe with enough power and a robust motor to handle the dense grains. On the other hand, if you work with composite materials, look for a lathe that offers adjustable tool settings to prevent damage or splintering.

- Speed control: Choose a lathe that offers variable speed control for optimal cue-making.

- Precision and stability: Look for a lathe with a rigid construction to minimize vibrations and ensure accurate cuts.

- Versatility: Consider a lathe that can handle other projects and offers various accessories for cue-making.

- Material compatibility: Ensure the lathe can handle the specific materials, such as wood or composite, that you plan to use.

Why Choosing the Right Lathe for Making Pool Cues is Important

The process of making pool cues requires precision and attention to detail. Every aspect of the cue, from the taper of the shaft to the shape of the tip, can greatly influence the player’s performance. One crucial factor that often gets overlooked is the choice of lathe for cue making. Having the right lathe can make a significant difference in the quality and accuracy of the finished product.

A high-quality lathe specifically designed for cue making offers several advantages. Firstly, it allows for precise control over the cutting process. The lathe should have adjustable speed settings and a smooth, consistent rotation, allowing the cue maker to shape and refine the wood with ease. This precision is particularly important when creating the taper of the shaft, as even subtle variations can affect the cue’s balance and feel.

Additionally, a suitable lathe should have a stable and robust construction. Pool cues are typically made from dense and heavy woods that require substantial cutting forces. A sturdy lathe will minimize vibrations and flex, ensuring that the cue maker has full control over the cutting process. This stability also contributes to the longevity of the lathe, as it will be able to withstand the repeated use and stresses associated with cue making.

When it comes to making pool cues, every detail matters. By selecting the right lathe, cue makers can ensure that their craftsmanship shines through in the final product. With precision control and a stable construction, a suitable lathe will provide the necessary tools to create cues that perform at the highest level, delighting players and enthusiasts alike.

Factors to Consider When Selecting a Lathe for Making Pool Cues

When it comes to making pool cues, selecting the right lathe is crucial in ensuring the quality and precision of the end product. There are several factors that should be considered when choosing a lathe for this specific task.

1. Size and Capacity

One important factor to consider is the size and capacity of the lathe. Pool cues are typically long and slender, so the lathe should have a bed length that can accommodate the length of the cue, as well as a spindle bore that can hold the cue securely. It is also important to consider the swing over the bed, as this will determine the maximum diameter of the cue that can be turned.

2. Speed Control

Another crucial factor to consider is the speed control of the lathe. Pool cues require precision and finesse, so having the ability to control the speed of the lathe is essential. Look for a lathe that offers variable speed options, preferably with a wide range of speeds, so that you can adjust it according to the specific requirements of the cue you are making.

3. Spindle and Tailstock Alignment

It is important to ensure that the spindle and tailstock of the lathe are aligned properly. This will result in accurate and consistent turnings. Look for a lathe that has a robust and reliable alignment system, such as dual locking systems or precision-ground bedways, to ensure the best possible alignment for your pool cue turning projects.

4. Accessibility and Ease of Use

Consider how accessible and user-friendly the lathe is. Look for features such as easy-to-read controls, conveniently located switches, and a user-friendly interface. Additionally, consider the ease of changing tools and accessories, as this can greatly affect the efficiency and enjoyment of the turning process.

5. Price and Budget

Finally, consider your budget and the overall cost of the lathe. Set a budget that you are comfortable with and look for a lathe that offers the best value for your money. Remember to consider not only the initial cost of the lathe but also any additional accessories or tools that may be needed for cue turning.

By considering these factors when selecting a lathe for making pool cues, you can ensure that you choose a machine that meets your specific needs and requirements, resulting in high-quality and precise pool cue turnings.

Key Features to Consider when Choosing a Lathe for Making Pool Cues

When it comes to selecting a lathe for making pool cues, it’s important to consider several key features that will ensure precision and efficiency in the cue making process. These features can greatly impact the quality of the cues you produce, as well as the overall experience of using the lathe. Here are some top features to look for:

1. Variable Speed Control

Having a lathe with variable speed control is essential for cue making. Different portions of a pool cue require different speeds to properly shape and finish. With variable speed control, you can adjust the rotation speed based on the type of wood, desired cut, or specific technique you’re using. This feature allows for greater accuracy and versatility in the cue making process.

2. Sturdy Construction and Vibration Dampening

A pool cue lathe should be constructed with a solid and sturdy frame that can withstand the vibrations generated during the turning process. This helps to prevent any unwanted movements or vibrations that could affect the precision of the cut. Look for lathes with features such as cast iron or heavy-duty steel bed, which provide stability and reduce vibrations.

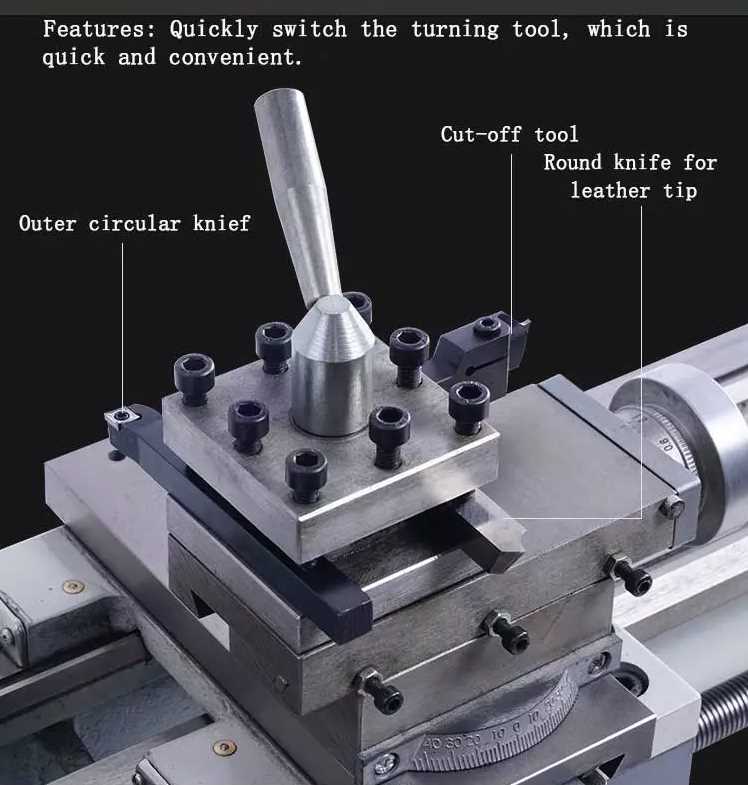

3. Adjustable Tool Rest

An adjustable tool rest is crucial for achieving precise and consistent cuts when making pool cues. It allows you to position the cutting tool at the desired angle and height, ensuring accurate shaping and turning. Look for a lathe with a tool rest that can be easily adjusted and locked in place to accommodate different cue designs and cutting techniques.

4. Multiple Chuck Options

Having different chuck options on a lathe allows for versatility in holding and securing the cue blanks. Look for a lathe that offers different chuck sizes or adaptable accessories, such as collets or faceplates, to accommodate different cue diameters and lengths. This will give you the flexibility to work with various cue designs and materials.

5. Digital Readout and Measurement System

Having a lathe with a digital readout or measurement system can greatly improve accuracy and efficiency in cue making. This feature allows you to easily track the dimensions and progress of your cues, ensuring consistent shaping and tapering. Look for a lathe with precise measurement markings and digital displays that are easy to read and operate.

By considering these key features, you can ensure that the lathe you choose for making pool cues provides you with the precision, versatility, and efficiency needed to create high-quality cues that meet your specifications and expectations.

5 Best lathe for making pool cues

Features

| Part Number | K11-100 |

| Model | K11-100 |

Features

| Part Number | 8R-UHAS-Z6MT |

Q&A:

What are the top features to look for in a lathe for making pool cues?

Some top features to look for in a lathe for making pool cues include a sturdy construction to minimize vibrations, precise speed control for accurate turning, a variety of tool rests for different cue designs, a reliable chuck system for secure workholding, and a variable spindle speed for working with different materials.

Why is a sturdy construction important in a lathe for making pool cues?

A sturdy construction is important in a lathe for making pool cues because it helps minimize vibrations during the turning process. Vibrations can negatively affect the accuracy and quality of the cue, so a sturdy lathe will provide a more stable platform for precise turning.

Why is precise speed control important in a lathe for making pool cues?

Precise speed control is important in a lathe for making pool cues because different cue designs and materials require different turning speeds. Being able to accurately control the speed allows for better control and ensures a smoother turning process.

What is the importance of having a variety of tool rests in a lathe for making pool cues?

Having a variety of tool rests in a lathe for making pool cues is important because different cue designs require different angles and positions for turning. Having multiple tool rests allows for greater versatility and the ability to create different shapes and profiles on the cue.

Why is a reliable chuck system important in a lathe for making pool cues?

A reliable chuck system is important in a lathe for making pool cues because it ensures secure workholding. Pool cue blanks are often turned with a hollow core, and a reliable chuck system will hold the blank tightly and securely in place, preventing any shifting or movement during the turning process.

What are the top features to look for in a lathe for making pool cues?

When choosing a lathe for making pool cues, there are several important features to consider. Firstly, look for a lathe with a variable speed control, as this will allow you to adjust the rotation speed to match the specific requirements of cue making. Additionally, a lathe with a solid and stable bed construction is crucial for accurate and precise turning. A tool rest that can be easily adjusted and locked in place is also important for achieving consistent cuts and shaping. Finally, consider a lathe with a reliable and smooth-running motor, as this will contribute to a better overall turning experience.

Conclusion

In conclusion, when looking for a lathe for making pool cues, there are several key features to consider. First and foremost, the lathe should have precise and accurate measurements to ensure that the pool cue is made to the correct specifications. Additionally, a variable speed control is important for different types of cuts and finishes. A sturdy and durable construction is also crucial to ensure the longevity of the lathe. Lastly, it is beneficial to have a lathe with multiple tool rest positions and a good centering system for ease of use. By considering these top features, pool cue makers can find a lathe that meets their needs and produces high-quality cues.