Best speed for drilling metal

When it comes to drilling metal, choosing the right speed is crucial for achieving optimum results. Metal drilling requires precision and efficiency in order to create clean and accurate holes. The speed at which the drill rotates plays a major role in determining the success of the drilling process.

Slow Speed: Drilling metal at a slow speed is often preferred when working with harder metals such as stainless steel or hardened steel. Slow speeds allow for better control and help prevent the drill bit from overheating or becoming unnecessarily worn. The slow speed also reduces the risk of the drill bit slipping or wandering off the desired drilling location.

Medium Speed: For softer metals like aluminum or brass, a medium drilling speed is generally recommended. This speed provides a good balance between control and efficiency, allowing the drill bit to penetrate the metal smoothly without causing excessive heat or wear. Medium speed is commonly used in applications such as automotive repairs or DIY projects.

High Speed: When drilling thin sheets of metal or working with non-ferrous metals like copper or zinc, high drilling speeds are often preferred. The high speed minimizes the risk of the drill bit binding or catching on the metal, resulting in a clean and precise hole. However, it is important to note that high speeds may generate more heat, so cooling the drill bit with cutting fluid is recommended to avoid overheating.

Understanding the Importance of Speed in Drilling Metal

When it comes to drilling metal, speed plays a crucial role in ensuring efficient and effective results. The speed at which the drill bit rotates can greatly impact the performance of the drilling process, affecting factors such as accuracy, productivity, and tool lifespan.

First and foremost, drilling metal at the right speed helps to achieve accurate and precise holes. The rotational speed of the drill bit should be properly adjusted to match the hardness and thickness of the metal being drilled. If the speed is too high, it can cause the drill bit to wander, leading to imprecise holes and potentially damaging the workpiece. On the other hand, if the speed is too low, it may result in excessive friction and heat, causing the drill bit to wear out faster and compromising its cutting ability.

In addition to accuracy, drilling metal at the optimal speed also improves productivity and efficiency. A higher rotational speed allows the drill bit to remove material more quickly, reducing the overall drilling time. This is particularly important when drilling through thick or hard metals, as slower speeds can prolong the drilling process and increase the risk of overheating. By adjusting the drilling speed to match the specific metal, operators can maximize their productivity and minimize downtime.

Furthermore, choosing the right drilling speed helps to prolong the lifespan of the drill bit. Different metals have different optimal drilling speeds, and using the correct speed can prevent excessive wear and tear on the cutting edges of the drill bit. By avoiding unnecessary stress and friction, the drill bit can maintain its sharpness and cutting efficiency for a longer period, saving both time and money on frequent replacement.

Factors to consider when determining the right drilling speed

When it comes to drilling metal, determining the right drilling speed is crucial for achieving the best results. There are several factors that need to be considered when selecting the appropriate speed for drilling metal.

1. Material type: Different types of metals have varying hardness and characteristics, which will influence the drilling speed. So, it is essential to determine the specific type of metal you are dealing with before selecting the drilling speed.

2. Drill bit type: The type of drill bit being used also plays a significant role in determining the drilling speed. Some drill bits are designed specifically for high-speed drilling, while others may be better suited for slower speeds. It is important to choose the right drill bit that matches the intended drilling speed.

3. Cutting speed: The cutting speed, which refers to the speed at which the drill bit rotates, is a critical factor to consider. Too high of a cutting speed can cause excessive heat, leading to premature wear or even breakage of the drill bit. On the other hand, too low of a cutting speed may result in poor drilling performance and slower progress.

4. Feed rate: The feed rate, which refers to how quickly the drill bit advances into the metal, also affects the drilling speed. A higher feed rate can increase the material removal rate but may require a higher cutting speed correspondingly. It is essential to find the right balance between the cutting speed and feed rate to prevent overheating or chattering.

5. Desired hole quality: The quality of the hole being drilled is another factor to consider. For example, if a clean and precise hole is required, a lower drilling speed with steady feeding may be necessary. On the other hand, if speed is prioritized over hole quality, a higher drilling speed with a faster feed rate may be suitable.

Considering these factors will help in determining the right drilling speed for drilling metal, ensuring a successful and efficient drilling operation.

Common mistakes to avoid when drilling metal at high speeds

Drilling metal at high speeds requires precision and attention to detail. It is important to avoid making common mistakes that can result in damage to the tool, the workpiece, or even injury to yourself. Here are some mistakes to avoid when drilling metal at high speeds:

- Using the wrong drill bit: Using the wrong drill bit can result in a poor-quality hole or even cause the bit to break. It is important to choose the appropriate drill bit for the type of metal you are drilling, taking into consideration factors such as hardness and thickness.

- Applying too much pressure: While it may be tempting to apply excessive pressure when drilling metal at high speeds, this can lead to overheating, dulling of the drill bit, and decreased drilling efficiency. It is important to let the drill bit do the work and apply steady, even pressure.

- Using improper lubrication: Lubrication is essential when drilling metal at high speeds to reduce heat and friction. Using the wrong type or amount of lubricant can negatively impact the drilling process. It is important to follow manufacturer recommendations for lubrication.

- Not using proper safety equipment: Drilling metal at high speeds can be hazardous. Not wearing appropriate safety equipment, such as safety goggles and gloves, can put you at risk of injury from flying metal chips or accidents. It is crucial to prioritize safety and wear the necessary protective gear.

- Not properly securing the workpiece: Failing to properly secure the workpiece can result in movement or slipping, which can lead to inaccurate holes or damage to the material. It is important to use clamps or a vice to securely hold the workpiece in place before beginning to drill.

Avoiding these common mistakes when drilling metal at high speeds will help ensure a smooth and successful drilling process. By using the correct drill bit, applying appropriate pressure, using proper lubrication, wearing safety equipment, and securing the workpiece, you can achieve precise and efficient results.

Recommended Speed Range for Different Types of Metal

When it comes to drilling metal, it is important to choose the right speed for the job. The speed at which you drill can greatly affect the efficiency and quality of the hole. Different types of metal require different speeds to achieve the best results.

For softer metals such as aluminum, brass, and copper, a higher speed is recommended. These metals are more malleable and can be drilled at a faster rate without causing excessive heat or chipping. A speed range of 1000 to 3000 revolutions per minute (RPM) is typically suitable for drilling these softer metals.

On the other hand, harder metals like steel, stainless steel, and cast iron require a slower drilling speed. These metals are more resistant and can generate a lot of heat when drilled at high speeds. It is best to use a speed range of 500 to 1500 RPM when drilling these harder metals to ensure precision and avoid any damage to the drill bit or the material being drilled.

It is important to note that these speed recommendations may vary depending on the specific type and thickness of the metal being drilled. It is always advisable to refer to the manufacturer’s guidelines or consult with an expert for the optimal speed range for drilling a particular type of metal.

Tips and techniques for achieving optimal drilling speed

Drilling metal requires careful consideration of several factors to achieve optimal speed and efficiency. The right drilling speed will depend on the type of metal, the size of the hole being drilled, and the type of drill bit being used. Here are some tips and techniques to help you achieve the best drilling speed for metal:

- Use a high-quality drill bit: Investing in a high-quality drill bit specifically designed for metal will ensure better performance and durability. Look for drill bits made from materials like cobalt or titanium, which are known for their hardness and ability to withstand the rigors of drilling through metal.

- Choose the appropriate drill bit size: The size of the drill bit will significantly impact the drilling speed. Select a drill bit that matches the size of the hole you need to create, as using a larger drill bit than necessary can slow down the drilling process and lead to inaccurate results.

- Lubricate the drilling area: Applying a suitable lubricant, such as cutting oil or a water-based coolant, to the drilling area can help reduce friction and heat buildup. This will extend the life of the drill bit and improve drilling speed by minimizing resistance.

- Start with a smaller pilot hole: When drilling larger holes, it’s often beneficial to start with a smaller pilot hole. This will help guide the larger drill bit and reduce the likelihood of the bit slipping or wandering off course. Starting with a pilot hole also allows for more precise drilling and faster speed.

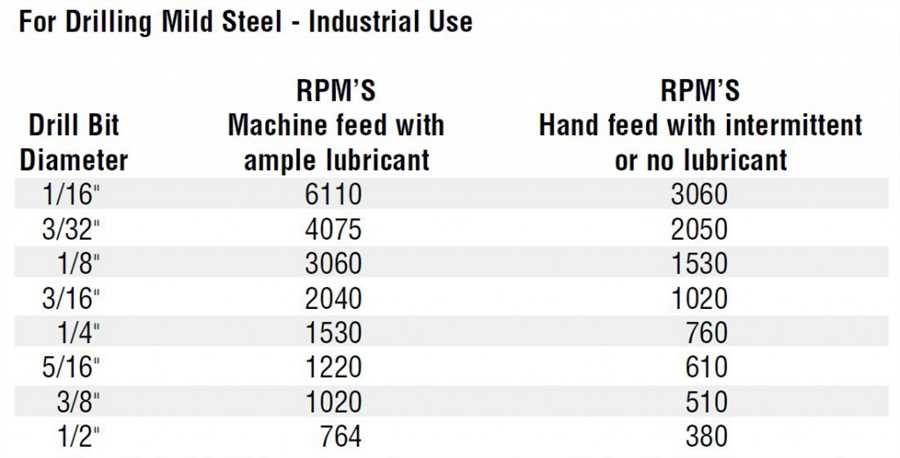

- Use the appropriate drilling speed: Different metals require different drilling speeds. For example, aluminum can be drilled at higher speeds than stainless steel. Consult the manufacturer’s recommendations or reference a drilling speed chart to determine the optimal speed for the specific metal you are working with.

- Apply consistent pressure: Maintaining steady and consistent pressure while drilling will help keep the drill bit cutting smoothly and prevent it from getting stuck or binding. Avoid excessive force, as this can lead to overheating, and may cause the drill bit to break or wear out prematurely.

By following these tips and techniques, you can achieve optimal drilling speed when working with metal. Remember to always prioritize safety by wearing appropriate protective gear, such as safety glasses and gloves, and securing the workpiece in place to prevent any accidents or injuries.

5 Best speed for drilling metal

Features

| Part Number | Drill Bit Set |

| Language | English |

Features

| Part Number | 2607019442 |

| Model | 2607019442 |

| Color | Black |

| Release Date | 2008-11-13T00:00:01Z |

| Language | Italian |

Features

| Part Number | WZ-DRILL-LGUK-010501 |

| Model | cordless hammer drill |

| Energy Efficiency Class | A+++ |

Features

| Size | Cordless Drill Set with 2 Batteries |

Question and answer:

What factors affect drilling speed?

Several factors can affect drilling speed, including the hardness and thickness of the material being drilled, the type of drill bit being used, the drilling technique employed, and the power and speed settings of the drilling machine.

How can I achieve optimal drilling speed?

To achieve optimal drilling speed, it is important to use the right drill bit for the material being drilled, regularly sharpen or replace worn drill bits, maintain the correct speed and power settings on the drilling machine, and use the appropriate drilling technique for the job.

What drilling techniques can help improve drilling speed?

Some drilling techniques that can help improve drilling speed include using proper feed pressure, maintaining a consistent drill speed, using cutting fluids to cool the drill bit and lubricate the cutting area, and peck drilling in harder materials to avoid overheating.

Are there any tips for drilling through harder materials?

When drilling through harder materials, it is important to use the appropriate drill bit designed for that specific material, reduce the drill speed and increase the feed pressure, use cutting fluids to cool and lubricate the drill bit, and periodically pull out the drill bit to remove debris and prevent overheating.

Why is it important to maintain the drill bits?

Maintaining the drill bits by regularly sharpening or replacing them is important for achieving optimal drilling speed. Dull or worn drill bits can slow down the drilling process, cause overheating, and lead to poor quality holes. Sharp and properly maintained drill bits ensure efficient drilling and prolong the life of the drilling machine.

What are some tips for achieving optimal drilling speed?

Some tips for achieving optimal drilling speed include: using sharp drill bits, applying the right amount of pressure, using the correct drilling technique, maintaining a consistent speed, and lubricating the drill bit and material being drilled.

What techniques can help in achieving optimal drilling speed?

Techniques that can help in achieving optimal drilling speed include: using a drill with a high RPM (rotations per minute), pre-drilling pilot holes, using the appropriate drill bit for the material being drilled, avoiding excessive heat buildup, and using a steady and controlled hand during drilling.

Conclusion

In conclusion, achieving optimal drilling speed is crucial for maximizing productivity and efficiency in various industries. By following the tips and techniques outlined in this article, professionals can enhance drilling operations and reduce downtime. Proper planning, equipment selection, and maintenance, as well as an emphasis on safety, are all key factors in ensuring optimal drilling speed. Additionally, continuously monitoring drilling parameters and making necessary adjustments, as well as utilizing advanced technologies, can further improve drilling efficiency. By implementing these strategies, operators can significantly increase their drilling speed and ultimately improve overall project performance.