Best self drill woodscrews

Self-drill woodscrews are an essential tool for any woodworking project. Whether you’re building a shelf, repairing furniture, or constructing a deck, these screws are designed to make your job easier and more efficient. With their sharp point and threaded body, they can create their own pilot hole as they are driven into the wood, eliminating the need for pre-drilling.

One of the key benefits of self-drill woodscrews is their versatility. They can be used with a wide range of wood types, including hardwoods, softwoods, and composite materials. This makes them an excellent choice for both professional carpenters and DIY enthusiasts. The self-drilling feature also makes them ideal for applications in tight spaces or hard-to-reach areas where using a drill may be difficult or impractical.

When choosing the best self-drill woodscrews, it’s important to consider factors such as length, gauge, and material. Longer screws are typically used for thicker pieces of wood, while thicker gauges provide increased strength and stability. Additionally, choosing screws made of high-quality materials ensures durability and prevents them from corroding over time, especially in outdoor applications.

In conclusion, self-drill woodscrews are an indispensable tool for any woodworking project. Their ability to create their own pilot hole saves time and effort, while their versatility allows for use with a variety of wood types. By choosing the right length, gauge, and material, you can ensure the success and longevity of your woodworking projects.

Understanding Self Drill Woodscrews

The use of self drill woodscrews has become increasingly popular in the construction industry due to their efficiency and ease of use. These screws are designed to eliminate the need for pre-drilling a hole before screwing into wood, saving time and effort during the installation process.

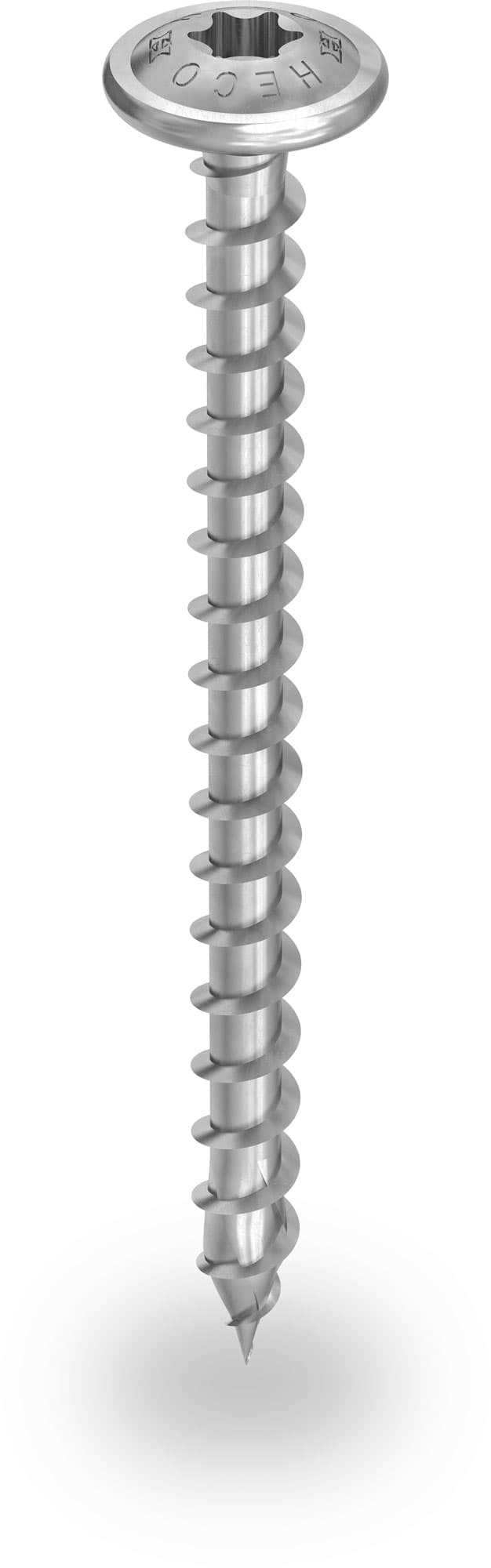

Self drill woodscrews feature a sharp and pointed tip that allows them to penetrate wood without the need for a pilot hole. This tip is often coated with a special material, such as zinc or ceramic, to improve the screw’s cutting and drilling abilities. The thread of the screw is designed to provide maximum grip, ensuring a secure and durable connection between the screw and the wood.

One of the main advantages of using self drill woodscrews is their versatility. They can be used in a wide range of applications, including framing, decking, furniture assembly, and general woodworking. These screws are available in various sizes, lengths, and head styles to accommodate different project requirements.

When using self drill woodscrews, it is important to choose the correct size and length for the specific application. It is also advisable to use a drill with an adjustable clutch to prevent over-tightening and damaging the wood. Additionally, using a screwdriver with a magnetic tip can make the installation process easier by helping to hold the screw in place.

In conclusion, self drill woodscrews are a convenient and reliable solution for fastening wood without the need for pre-drilling. Their sharp tips and effective threading allow for quick and secure installations in various woodworking projects. By understanding the features and benefits of self drill woodscrews, professionals and DIY enthusiasts alike can achieve efficient and durable results.

Factors to Consider When Choosing Self Drill Woodscrews

When it comes to choosing the best self drill woodscrews for your project, there are several factors that you should consider. These factors can ensure that you select the right screws for the job, providing you with a secure and durable connection.

Material Compatibility

One of the most important factors to consider when choosing self drill woodscrews is the compatibility of the screw material with the material you are working with. The screw should be specifically designed for use with wood, ensuring that it can effectively penetrate and fasten the material without causing any damage. Additionally, you should also consider the coating or finish of the screw, as this can impact its durability and resistance to corrosion.

Screw Size and Length

The size and length of the screw are crucial considerations when selecting self drill woodscrews. The screw should be long enough to securely fasten the materials together, but not too long that it protrudes or causes splitting. Additionally, you should also consider the diameter of the screw, as this can affect its holding power. Choosing the right size and length of screw will ensure a strong and stable connection.

Thread Type

Another factor to consider is the type of thread on the screw. Self drill woodscrews often have either a coarse thread or a fine thread. The choice of thread will depend on the type of wood and the desired holding power. Generally, coarse thread screws are better for softer woods, while fine thread screws are more suitable for hardwoods. Understanding the different thread types and selecting the appropriate one for your project can enhance the overall performance of the screws.

Driving Method

Lastly, consider the driving method of the self drill woodscrews you are considering. Common driving methods include Phillips, square, and Torx. Each driving method has its advantages and disadvantages, and selecting the right one depends on your personal preference and the tools you have available. Choosing a driving method that you are comfortable with can make the installation process smoother and more efficient.

In conclusion, choosing the right self drill woodscrews involves considering factors such as material compatibility, screw size and length, thread type, and driving method. By carefully evaluating these factors, you can ensure that you select the best screws for your project, resulting in a strong and long-lasting connection.

Features to Consider When Choosing Self Drill Woodscrews

When it comes to choosing the best self drill woodscrews, there are several key features to look for. These features can ensure that you have reliable and high-quality screws that will effectively drive into wood without the need for pre-drilling.

1. Self-Drilling Design

One of the most important features to consider is a self-drilling design. This means that the screws have a drill-like point that can effectively penetrate wood without the need for a separate pilot hole. This feature saves both time and effort, making the screwing process quicker and more efficient.

2. Material Quality

Another crucial feature to look for is the quality of the materials used in the screws. High-quality screws are made of durable materials, such as stainless steel or hardened steel, that can withstand the constant pressure and torque during drilling. Choosing screws made of subpar materials can result in breakage or stripped heads, leading to a frustrating and ineffective screwing experience.

3. Thread Type

The type of thread on the self drill woodscrews is also an essential factor to consider. Different thread types are suitable for specific applications, such as coarse threads for softwoods and fine threads for hardwoods. It is important to choose screws with the appropriate thread type to ensure a secure and robust connection.

4. Corrosion Resistance

Considering the potential exposure to moisture or outdoor elements, choosing self drill woodscrews with corrosion resistance is vital. Screws made of materials like stainless steel or coated with corrosion-resistant finishes will help prevent rust and degradation over time, ensuring long-lasting and reliable performance.

5. Head Type

The head type of the screws should also be taken into account. Common head types include flat heads, pan heads, and countersunk heads. The choice of head type depends on personal preference and the specific requirements of the project. Ensuring compatibility with the tools and desired aesthetic appearance is crucial in selecting the appropriate head type.

- Consider a self-drilling design for quick and efficient installation.

- Choose screws made of high-quality materials to ensure durability.

- Be mindful of the thread type to match the application.

- Opt for screws with corrosion resistance for outdoor or moisture-exposed projects.

- Select the appropriate head type based on personal preference and project requirements.

Best Self Drill Woodscrews for Different Materials

When it comes to securing materials together, using the right type of woodscrew is essential. Self-drill woodscrews are particularly popular because they eliminate the need for pre-drilling holes, making the installation process faster and more efficient. However, not all self-drill woodscrews are created equal, and different materials require different types of screws for optimal performance.

For hardwood materials: Hardwood materials like oak, maple, or teak can be quite dense and tough to penetrate. In this case, it is recommended to use self-drill woodscrews with sharp points and a high-quality hardened steel construction. These types of screws provide excellent penetration and ensure a secure and long-lasting connection.

For softwood materials: Softwood materials like pine or cedar are generally easier to work with, but they can still benefit from self-drill woodscrews specifically designed for softwood applications. These screws typically have coarse threads to provide a strong grip, as well as a corrosion-resistant coating to protect against moisture and other environmental factors.

- For metal materials: Securing wood to metal requires special self-drill woodscrews with a specific design. These screws often have a hardened steel construction to handle the rigidity of metal, along with a corrosion-resistant coating to prevent rust and deterioration. They may also feature a special thread design that allows for easy installation and a secure connection.

- For plastic materials: When working with plastic materials, it is crucial to use self-drill woodscrews that won’t crack or damage the material. Screws with a self-tapping design and a low-profile head are ideal for plastic applications. They should also have a corrosion-resistant coating to withstand environmental factors and provide a long-lasting connection.

Overall, selecting the best self-drill woodscrews for different materials is essential for ensuring a secure and reliable connection. Consider the material you are working with and choose screws that are specifically designed for that type of material. This will help you achieve a professional and durable result in your projects.

5 Best self drill woodscrews

Features

| Part Number | 1 |

| Size | 4 x 45 |

Features

| Part Number | Mo-ZGLS-240 |

| Color | Silver |

Features

| Part Number | 1 |

Features

| Part Number | UK-7-FHT-A-013 |

| Color | Brass |

Question and answer:

What are the best self-drill woodscrews for softwood?

The best self-drill woodscrews for softwood are typically those made of carbon steel with a sharp point and coarse thread. These screws are designed to easily penetrate softwood without the need for pre-drilling.

Which self-drill woodscrews are suitable for hardwood?

For hardwood, it is recommended to use self-drill woodscrews made of hardened steel with a sharp point and fine thread. These screws provide better penetration and grip in harder materials.

Are there any self-drill woodscrews suitable for metal?

Yes, there are self-drill woodscrews that are specifically designed for metal. These screws are typically made of stainless steel or coated with a corrosion-resistant finish to prevent rusting. They have a sharp point and fine thread to effectively penetrate metal surfaces.

What type of self-drill woodscrews should I use for plastic?

When working with plastic, it is best to use self-drill woodscrews made of stainless steel or those with a corrosion-resistant coating. These screws have a sharp point and fine thread to prevent cracking or splitting of the plastic material during installation.

Conclusion

In conclusion, choosing the best self-drill woodscrews for different materials is essential for ensuring a secure and reliable construction or DIY project. The materials used and the intended purpose of the project should be taken into account when selecting the appropriate woodscrews. High-quality screws with features such as self-drilling capabilities, corrosion resistance, and strength should be prioritized. Whether it’s fixing wood to wood, metal to wood, or even concrete to wood, there are specialized screws available for every application. By carefully considering the specific requirements and using the right woodscrews, builders and DIY enthusiasts can achieve long-lasting and sturdy results.