Best grease for drill gears

When it comes to maintaining and extending the lifespan of your drill gears, choosing the right grease is crucial. The gears of a drill are constantly in motion, generating heat and friction that can cause wear and tear over time. By using a high-quality grease specifically designed for drill gears, you can reduce the friction and heat, providing optimal lubrication and protection for your drill.

One of the best grease options for drill gears is a lithium-based grease. Lithium grease is known for its excellent lubricating properties and high resistance to extreme temperatures. It maintains its consistency even at high speeds and under heavy loads, making it ideal for drill gears that operate under demanding conditions. Moreover, lithium grease also provides excellent corrosion resistance, preventing rust and prolonging the life of your drill.

Another great option for drill gears is a synthetic-based grease. Synthetic greases are known for their superior performance and longevity. They are formulated with advanced additives and base oils that provide exceptional lubrication and protection. Synthetic greases have a wide temperature range, allowing them to maintain their consistency and effectiveness even in extreme hot or cold environments. Additionally, synthetic greases offer excellent water resistance, ensuring that your drill gears stay well-lubricated even in wet conditions.

Best Grease for Drill Gears

When it comes to maintaining the efficiency and longevity of drill gears, using the right grease is crucial. The best grease for drill gears is one that provides excellent lubrication, protects against wear and tear, and has a high temperature resistance.

One popular option is lithium-based grease, which offers superior lubrication properties and can withstand high temperatures. It is ideal for use in drill gears that generate a lot of heat during operation. Another excellent choice is synthetic grease, which not only reduces friction but also provides long-lasting protection against rust and corrosion.

Additionally, it is important to consider the viscosity of the grease. A grease with a high viscosity will provide better lubrication and stay in place, even under heavy loads. On the other hand, a grease with a lower viscosity is easier to apply and distribute evenly across the gears. Finding the right balance is essential for optimal performance.

Furthermore, it is recommended to choose a grease that is specifically formulated for drill gears. These greases are designed to handle the unique demands and conditions of drilling applications, ensuring smooth operation and prolonged gear life. Reading customer reviews and consulting with experts can also provide valuable insights into the best grease options for drill gears.

- Lithium-based grease: Provides excellent lubrication and high temperature resistance.

- Synthetic grease: Reduces friction, protects against rust and corrosion.

- Consider viscosity: Choose grease with the right viscosity for optimal performance.

- Use gear-specific grease: Designed to handle drilling applications’ unique demands.

The Importance of Grease for Drill Gears

When it comes to maintaining drill gears, one of the most crucial aspects is selecting the right grease. Grease plays a vital role in ensuring the smooth functioning and longevity of the gears. It provides lubrication and reduces friction between moving parts, preventing them from wearing out or getting damaged over time.

Choosing the right grease for drill gears is essential because it can directly impact their performance. Optimal lubrication reduces the heat generated during operation, preventing the gears from overheating and potential failure. Additionally, the right grease helps to minimize noise and vibration, resulting in a quieter and smoother drilling experience.

There are several factors to consider when selecting grease for drill gears. The viscosity of the grease is one important factor. It determines how well the grease can flow and adhere to the gears, ensuring maximum coverage and protection. The compatibility of the grease with different materials used in the gears is another crucial consideration. It ensures that the grease won’t cause any damage or degradation to the gears.

Frequent application of grease to the drill gears is necessary to maintain their optimal performance. Over time, the grease can break down or become contaminated with dust and debris, reducing its effectiveness. Regular greasing can help to flush out the contaminants and replenish the lubrication, keeping the gears in excellent condition for extended periods.

In conclusion, the importance of grease for drill gears cannot be overstated. Proper lubrication with the right grease helps to reduce friction, prevent overheating, minimize noise, and extend the lifespan of the gears. Selecting the appropriate grease and regularly applying it ensures optimal performance and longevity for your drill gears.

Factors to Consider when Choosing Grease for Drill Gears

When it comes to selecting the best grease for drill gears, there are several important factors that should be taken into consideration. The right choice of grease can greatly impact the performance and lifespan of the drill gears, ensuring smooth operation and minimizing wear and tear. Here are some key factors to consider when choosing grease for drill gears:

1. Viscosity and Temperature Range:

One of the most crucial factors to consider is the viscosity and temperature range of the grease. Different drill gears can operate at varying speeds and temperatures, so it is important to choose a grease that can maintain its viscosity and lubricating properties within the specific range of the drill gear’s operating conditions. It is recommended to consult the manufacturer’s guidelines or specifications to determine the appropriate viscosity and temperature range for the grease.

2. Load and Pressure Resistance:

Drill gears often experience heavy loads and high pressure during operation, especially in demanding applications. Therefore, it is essential to select a grease that can withstand these extreme conditions. Look for a grease with excellent load-carrying and pressure-resistant properties to ensure that it can effectively protect the gears from excessive wear and prevent any potential damage.

3. Compatibility and Compatibility with Other Lubricants:

Another important factor to consider is the compatibility of the grease with the materials used in the drill gears. Different materials may have different requirements for lubrication. Ensure that the grease is compatible with the materials of the gears to avoid any detrimental effects such as corrosion or degradation. Additionally, if the drill gears are used in conjunction with other lubricants, it is essential to choose a grease that can work well with these lubricants to optimize the overall lubrication system.

4. Environmental Factors:

Lastly, consider the environmental factors that the drill gears will be exposed to. If the drill gears will be operating in extreme conditions such as high humidity, extreme temperatures, or exposure to water or chemicals, it is crucial to select a grease that can withstand these environmental challenges. Look for greases that have exceptional water resistance, corrosion protection, and resistance to chemicals to ensure long-lasting performance.

- Consideration of these factors can help you make an informed decision when choosing the best grease for drill gears. Remember to consult the manufacturer’s guidelines and specifications to ensure compatibility and optimal performance of the grease with your specific drill gears.

Top Qualities of the Best Grease for Drill Gears

When it comes to greasing drill gears, there are certain qualities you should look for in a grease to ensure smooth and efficient operation. These qualities can make a significant difference in prolonging the lifespan of your drill and preventing unnecessary wear and tear. Here are some of the top qualities to consider when choosing the best grease for drill gears:

1. High Viscosity: One of the most important qualities in a drill gear grease is its viscosity. A high viscosity grease will provide better lubrication by forming a thick film that adheres to the gears for a longer period of time. This ensures that the gears are protected even under high loads and speeds, reducing friction and heat generation.

2. Extreme Pressure Resistance: When drilling, gears are subjected to high pressures, especially when working with tough materials. The best grease for drill gears should have extreme pressure resistance properties to withstand these forces without breaking down or losing its lubricating properties. This helps prevent gear damage and ensures smooth operation even under challenging conditions.

3. Temperature Stability: Drill gears can generate significant heat during operation, especially during prolonged or intensive drilling tasks. Therefore, it is essential to choose a grease that can withstand high temperatures without melting or evaporating. Temperature stability is crucial to maintain the effectiveness of the grease and prevent it from thinning out and losing its viscosity, which could lead to inadequate lubrication.

4. Water and Corrosion Resistance: Grease used for drill gears should also offer excellent water and corrosion resistance. Drilling tasks often involve exposure to water, moisture, and other corrosive substances. A grease with these properties will help protect the gears from rust and corrosion, preventing damage and extending their lifespan.

5. Longevity: Finally, the best grease for drill gears should have a long-lasting formula that stays in place for an extended period. This reduces the need for frequent reapplication, saving time and effort. A long-lasting grease also means that the gears are consistently protected, reducing the risk of premature wear or failure.

By considering these qualities, you can select the best grease for your drill gears, ensuring smooth operation, and prolonging the lifespan of your valuable drilling equipment.

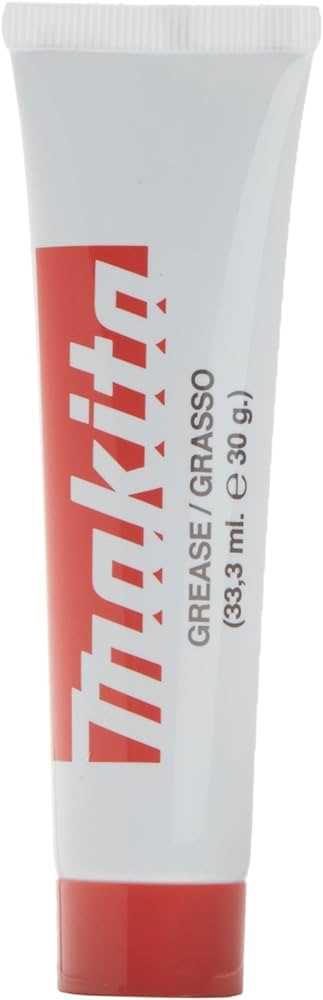

5 Best grease for drill gears

Features

| Part Number | 181490-7 |

| Model | 181490-7 |

| Color | Multi-colour |

| Release Date | 2017-04-04T00:00:01Z |

Features

| Part Number | 2608002021 |

| Model | 2608002021 |

| Color | Black |

Features

| Part Number | 0168A |

| Model | 0168A |

| Warranty | 1 |

| Release Date | 2015-07-28T00:00:01Z |

| Size | 500g |

Question and answer:

What are the top qualities of the best grease for drill gears?

The top qualities of the best grease for drill gears include high viscosity, excellent load-carrying capacity, extreme pressure tolerance, resistance to oxidation and corrosion, and compatibility with different materials.

Why is high viscosity important in grease for drill gears?

High viscosity is important in grease for drill gears because it ensures that the lubricant stays in place and adheres to the gear surfaces, even under high-speed and high-temperature conditions, providing effective lubrication and reducing wear.

What does “load-carrying capacity” mean in the context of grease for drill gears?

Load-carrying capacity refers to the ability of the grease to withstand and distribute the force and pressure exerted on the gears during operation. A grease with excellent load-carrying capacity can prevent metal-to-metal contact and reduce friction, extending the life of the gears.

Why is extreme pressure tolerance important in grease for drill gears?

Extreme pressure tolerance is important in grease for drill gears because it allows the lubricant to maintain its protective film between the gear teeth even when subjected to heavy loads and high pressure, preventing wear and damage.

What role does resistance to oxidation and corrosion play in the best grease for drill gears?

Resistance to oxidation and corrosion ensures that the grease remains stable and does not break down or deteriorate over time, even in harsh operating conditions. This prolongs the lubricant’s effectiveness and maintains the performance of the drill gears.

What are the top qualities of the best grease for drill gears?

The top qualities of the best grease for drill gears include high temperature resistance, excellent load-carrying capacity, corrosion protection, resistance to water washout, and compatibility with different gear materials. It should also have good pumpability, consistency, and provide long-lasting lubrication.

Why is high temperature resistance important in grease for drill gears?

High temperature resistance is important in grease for drill gears because drilling operations can generate a significant amount of heat. The grease needs to withstand these high temperatures without breaking down or losing its lubricating properties.

Conclusion

In conclusion, selecting the best grease for drill gears is essential to optimize the performance and longevity of the equipment. Several qualities make a grease suitable for this purpose. Firstly, it should have excellent lubrication properties to reduce friction and prevent wear and tear of the gears. The grease should also offer high resistance to extreme temperatures, ensuring that it remains stable and effective in a variety of conditions. Additionally, a good grease for drill gears should have excellent adhesion properties, adhering to the gears and preventing it from splattering or getting thrown off during operation. Lastly, it is important to consider the compatibility of the grease with the specific drill gear materials to ensure maximum effectiveness. By considering these top qualities, one can choose the best grease that will greatly enhance the performance and lifespan of drill gears.