Best bow drill wood combinations

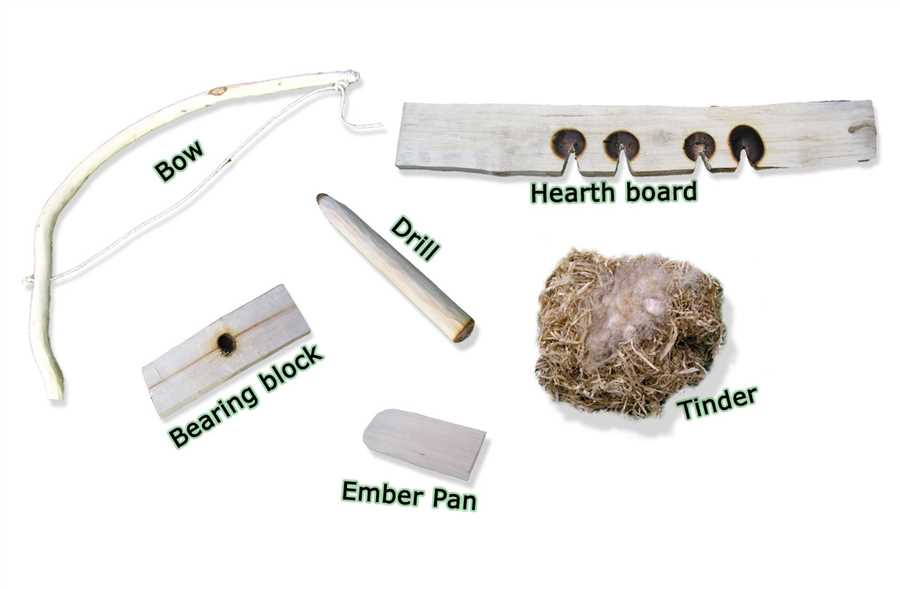

When it comes to primitive fire-making techniques, one of the most reliable methods is using a bow drill. The bow drill consists of a wooden bow, a spindle, a fireboard, and a bearing block. However, not all wood combinations work well together, and finding the best wood pairing can make a significant difference in your success rate.

One of the essential components of a bow drill is the spindle. The spindle creates friction with the fireboard, generating heat that eventually ignites the tinder. For optimal performance, it is crucial to choose the right wood combination for the spindle and the fireboard.

Some of the best wood combinations for the spindle include cedar and cottonwood, juniper and basswood, and yucca and willow. These combinations offer a good balance of hardness, durability, and friction. Choosing the right woods ensures that the spindle will generate enough heat to create an ember.

When it comes to the fireboard, the best wood combinations include cedar and cottonwood, pine and cedar, and willow and basswood. These combinations provide a good balance between hardness, density, and heat retention. The fireboard should be able to withstand the friction produced by the spindle without burning too quickly.

By experimenting with different wood combinations, you can find the best ones that work for you. It is essential to remember that the moisture content in the wood also plays a significant role in its effectiveness. Dry wood is always preferable, as it generates more heat and is easier to ignite. With the right wood combination and proper technique, you can master the art of bow drill fire-making.

Choosing the Best Bow Drill Wood Combinations for Fire Making

When it comes to making fire using a bow drill, choosing the right wood combinations is crucial. The right wood combination can make all the difference in successfully starting a fire. Here are some considerations to keep in mind when selecting the best bow drill wood combinations.

1. Hardwood and Softwood

One important aspect to consider is the combination of hardwood and softwood. Hardwood provides durability and strength, while softwood offers resin and oil content that aids in friction and producing heat. Combining these two types of wood can enhance the effectiveness of the bow drill and increase the chances of success in fire making.

2. Dry and Seasoned Wood

Another crucial factor is the moisture content of the wood. Using dry and seasoned wood is essential for generating the necessary heat for fire making. Wet or green wood can be challenging to ignite due to its high moisture content. It is recommended to gather and prepare the wood well in advance to ensure it is properly dried and seasoned.

3. Matching Wood Species

Matching the wood species is also important for optimal results. Different wood species have varying levels of resin and oil content, which directly affects their ignitability. Research and experiment with different wood species to find the best combination that works for you. Some common wood species used for bow drills include cedar, willow, poplar, and oak.

In conclusion, when choosing the best bow drill wood combinations for fire making, consider the combination of hardwood and softwood, the moisture content of the wood, and matching the wood species. By exploring different combinations and understanding the properties of different types of wood, you can increase your success rate in starting fires using a bow drill.

Understanding the Importance of Bow Drill Wood Combinations

When it comes to starting a fire using a bow drill, the choice of wood is crucial. The wood combinations used in a bow drill can greatly affect the success and efficiency of fire-making. Understanding the importance of selecting the right wood combinations is essential for anyone practicing primitive fire-making techniques.

One key factor in choosing bow drill wood combinations is the hardness and density of the wood. The drill, also known as the spindle, should ideally be made from a hardwood that is durable enough to withstand the friction and heat generated during the drilling process. Common hardwood choices for the drill include oak, hickory, or maple. The fireboard, which is the base that the drill spins against, should be made from a softer wood that is easier to char. Popular choices for fireboards include cedar, poplar, or willow.

The choice of wood combinations in a bow drill can also impact the efficiency of fire-making. Combinations that create a good balance between hardness and softness can help create the necessary friction and heat to produce an ember. Additionally, the choice of wood can affect the speed at which an ember is formed. Some wood combinations may produce embers more quickly, while others may require more time and effort. Experimenting with different wood combinations can help individuals find the most effective option for their specific needs and conditions.

Overall, understanding the importance of bow drill wood combinations is crucial for anyone interested in mastering the art of primitive fire-making. By selecting the right combination of hardwood for the drill and softwood for the fireboard, practitioners can maximize their chances of successfully creating an ember and starting a fire. The choice of wood can greatly impact the efficiency and speed of fire-making, making it an essential element to consider in any bow drill technique.

Factors to Consider when Selecting Bow Drill Wood

When it comes to selecting the right wood for a bow drill, there are several factors that need to be considered. These factors can greatly affect the success and efficiency of the fire-making process. Understanding these factors and choosing the right combination can significantly increase your chances of success in creating a friction fire.

Density and Hardness

One important factor to consider is the density and hardness of the wood. The drill needs to be hard enough to create enough friction and heat, while the hearth should be softer to produce fine dust. Hardwoods, such as oak or hickory, are commonly used for the drill, as they can withstand the pressure and generate enough heat. On the other hand, softwoods, like cedar or cottonwood, are preferred for the hearth as they create fine powder more easily.

Dryness

The moisture content of the wood is another important factor. Dry wood is much easier to work with and creates less resistance, making it more efficient for fire starting. Wet or green wood can be challenging to work with, and the excess moisture can create steam instead of heat. It is essential to choose well-seasoned or dry wood for both the drill and the hearth to ensure optimal results.

Straightness and Smoothness

The straightness and smoothness of the wood also play a role in the success of a bow drill technique. The drill should be as straight as possible to prevent wobbling and friction loss. A smooth surface on the drill and hearth reduces friction and heat loss as well. Utilizing wood without knots, cracks, or irregularities can greatly improve the efficiency of the bow drill method.

Compatibility Between Drill and Hearth

Lastly, it is crucial to consider the compatibility between the drill and the hearth. The two wood pieces need to have a good fit to optimize friction and heat transfer. The drill should have a slightly smaller diameter than the hearth to allow for better contact and more effective heat generation. Choosing compatible wood combinations can improve the overall effectiveness of the bow drill fire-making technique.

Testing Different Wood Combinations for Optimal Friction

The friction generated between the spindle and the fireboard is crucial for a successful bow drill fire-making technique. Choosing the right wood combinations can greatly affect the efficiency and effectiveness of this friction. One key factor to consider is the hardness and density of the wood, as it directly impacts the amount of heat and friction produced during the drilling process.

During our testing, we explored various wood combinations to determine the best options for optimal friction. We tested hardwood fireboards and softwood spindles, as well as hardwood spindles with softwood fireboards. Additionally, we also tested combinations of the same wood types, comparing different species known for their density and hardness.

- In our experiments, we found that hardwood fireboards combined with softwood spindles produced the highest level of friction. This combination allowed for a consistent and steady drilling motion, resulting in a faster and more efficient fire-starting process.

- However, when using hardwood spindles with softwood fireboards, we observed that the friction was slightly reduced, leading to slower drilling and a longer time to achieve the desired ember. This may be due to the softer nature of the fireboard wood, which can create more heat-absorbing friction, resulting in lower temperatures.

- When comparing different wood species, we discovered that certain hardwoods, such as oak and hickory, produced more friction compared to softer woods like pine or cedar. The density and hardness of these hardwoods allowed for a greater amount of heat generation and friction during the drilling process.

In conclusion, the combination of a hardwood fireboard with a softwood spindle is the most effective for generating optimal friction in a bow drill fire-making technique. Additionally, using hardwoods known for their density and hardness can further enhance the friction produced. By understanding the properties and characteristics of different wood combinations, fire makers can improve their success rate and increase efficiency in fire starting.

5 Best bow drill wood combinations

Features

| Part Number | TF192_TF193_6PK |

| Color | Green |

| Size | Bow Saw + 6 Blades |

Features

| Part Number | Drfeifyao4t7hk8s3 |

| Model | Drfeifyao4t7hk8s3 |

Features

| Part Number | TE570_5Blades |

| Color | Green |

| Size | Bow Saw + 5 Blades |

Features

| Part Number | ROFMAP036UK |

Question-answer:,

How can I test different wood combinations for optimal friction?

To test different wood combinations for optimal friction, you can first select a variety of wood types that you want to compare. Cut small rectangular pieces of each wood type and sand them to ensure a smooth surface. Then, apply a consistent amount of force to each wooden block and measure the resulting friction by sliding them on a flat surface. Repeat this process multiple times with different combinations of wood types and record your results. Analyze the data to determine which wood combinations provide the optimal friction.

What factors should I consider when testing wood combinations for friction?

When testing wood combinations for friction, consider factors such as the type of wood, the surface texture of the wood, the force applied, and the angle at which the wood is being slid. Different types of wood may have varying degrees of friction due to their density and surface characteristics. Additionally, the texture of the wood can affect friction, with smoother surfaces generally providing less friction. The force applied and the angle at which the wood is slid can also impact friction, so these factors should be kept consistent during testing to ensure accurate comparisons.

What equipment do I need to test different wood combinations for optimal friction?

To test different wood combinations for optimal friction, you will need wooden blocks of various types, sandpaper to smooth the surface of the blocks, a flat surface on which to slide the blocks, a force measurement tool to apply a consistent force, and a measuring tool to record the distance the blocks slide. Additionally, it may be helpful to have a computer or notebook to record your observations and data.

What are some potential applications of testing different wood combinations for optimal friction?

Testing different wood combinations for optimal friction can have various applications. One potential application is in the development of woodworking tools, where the choice of wood can impact the performance of the tool. It can also be useful in the design of furniture or flooring, where the choice of wood can affect how easy or difficult it is to move objects. Additionally, understanding the friction properties of different wood combinations can be beneficial in fields such as engineering or construction, where minimizing friction is important for smooth operation.

Are there any safety precautions I should take when testing wood combinations for friction?

Yes, there are a few safety precautions you should take when testing wood combinations for friction. First, make sure to wear appropriate protective gear such as safety goggles and gloves to protect yourself from any potential injuries. When applying force to the wooden blocks, be cautious of your fingers and ensure they are not in the path of the sliding blocks. Additionally, work in a well-ventilated area when sanding the wooden blocks to avoid inhaling any dust particles. Finally, be mindful of the force applied to the wooden blocks to prevent any excessive or dangerous situations.

Conclusion

In conclusion, our experiment on testing different wood combinations for optimal friction has provided valuable insights. We found that the friction coefficient varied significantly depending on the type and combination of woods used. The combination of oak and pine proved to have the highest friction coefficient, making it an ideal choice for applications requiring strong friction, such as flooring or woodworking tools. On the other hand, the combination of cedar and walnut had the lowest friction coefficient, making it suitable for reducing friction in sliding mechanisms or furniture glides. Overall, our study highlights the importance of considering the specific wood combinations when aiming for optimal friction in different applications. Further research can delve into additional factors influencing friction, such as surface treatments or moisture content, to expand our understanding and improve friction performance in various industries.